Holding tool shared quick changing support of the vehicle final assembly conveying system

A conveying system and support replacement technology, which is applied in the direction of conveyors, mechanical conveyors, motor vehicles, etc., can solve the problems of long renovation period and high cost, and achieve the effect of convenient and reliable operation, fast switching, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

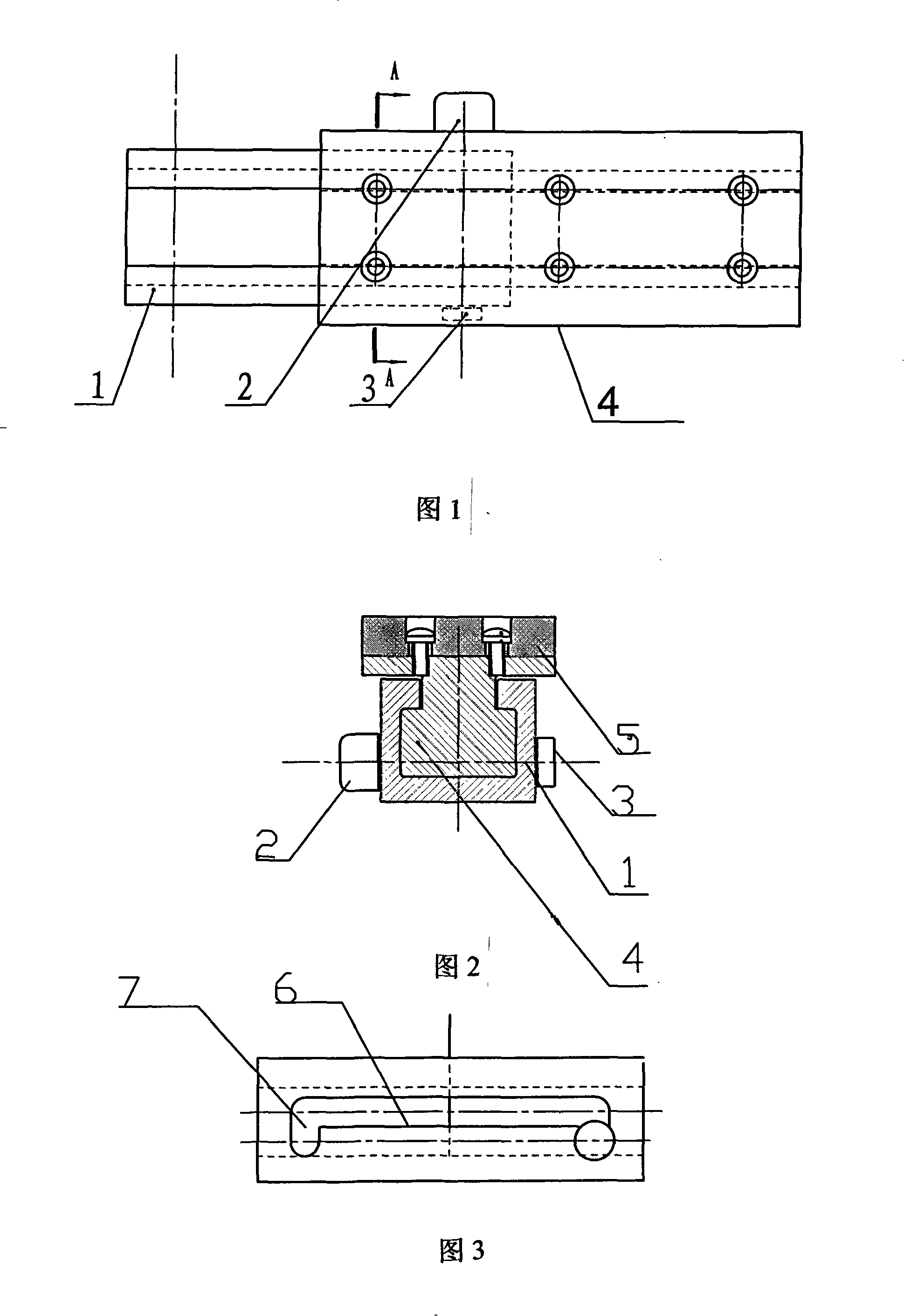

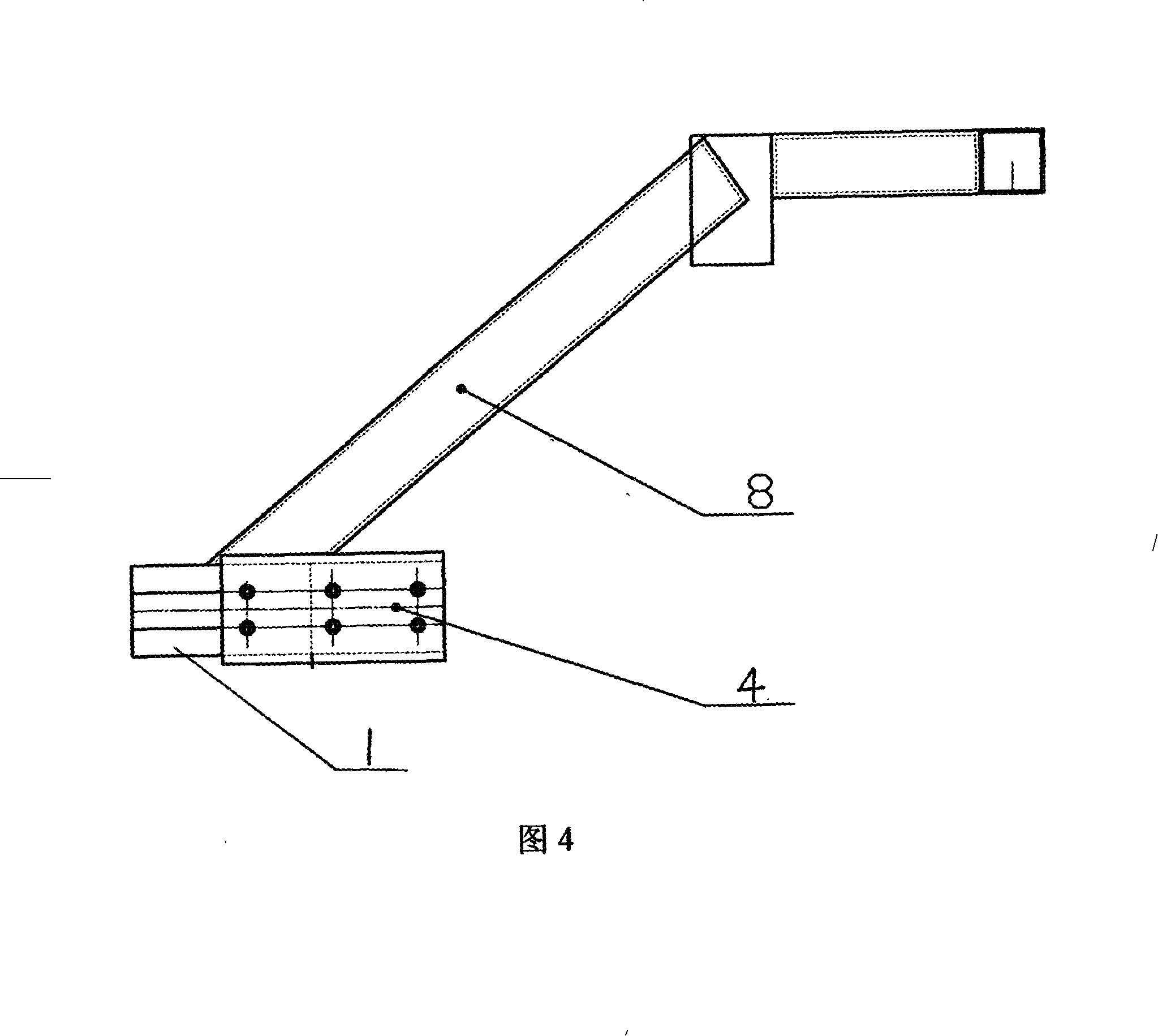

[0012] Referring to Fig. 1 and Fig. 2, the device is mainly composed of a slider 1, a slider 4, a screw 3, a handle 2, a liner 5 and the like. Among them, there is a dovetail chute in the middle of the slider 1, and the slider 4 is I-shaped, and the lower part is installed in the dovetail chute, and there is a space for up and down displacement in the dovetail chute, reducing the structural size and avoiding the Influence on the assembly of parts such as mufflers, fuel tanks, etc. The material of sliding seat 1 and sliding block 4 is Q235 steel, which is easy to process and good in assembly. The surface of the slider 4 is installed with a polyurethane liner 5 by screws.

[0013] Referring to Fig. 3, a long notch 6 consistent with the direction of the dovetail chute is opened on the two side walls of the sliding seat 1, and two limit grooves 7 are connected downward at both ends of the long notch 6. When installing, the screw rod 3 traverses through one of the limiting groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com