Catalytic conversion process for petroleum hydrocarbons

A catalytic conversion method and technology for petroleum hydrocarbons are applied in the field of catalytic conversion of petroleum hydrocarbons for increasing the production of propylene and BTX, which can solve the problems of unachieved and limited increase, and achieve the effects of fast recovery, increased octane number and less investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

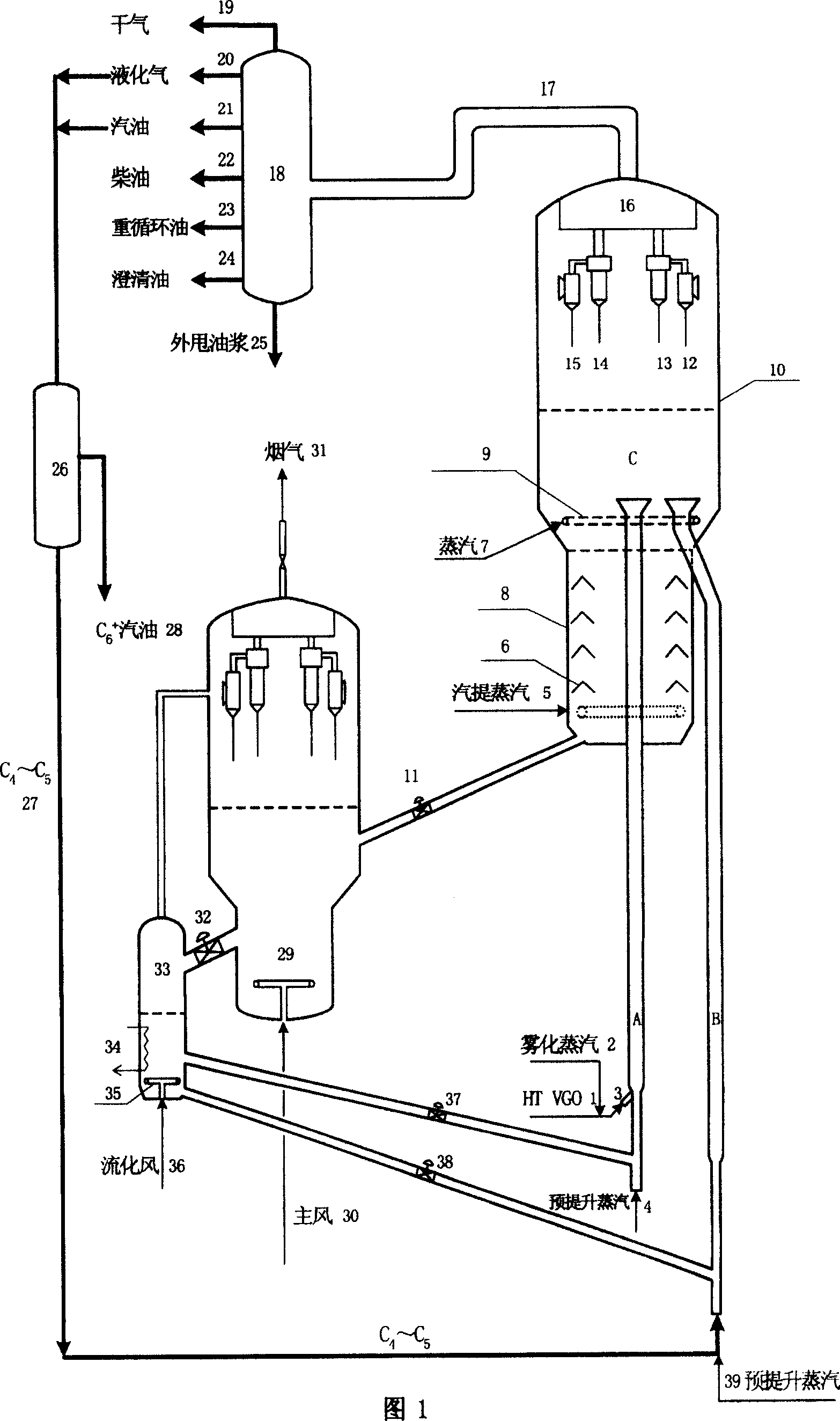

[0046] This example shows that the method provided by the invention can significantly increase the yield of propylene, and at the same time increase the content of BTX in gasoline products.

[0047] The test was carried out on a medium-sized catalytic conversion device modified according to the method of the present invention, and the structure schematic diagram of the reaction and regeneration part is shown in Fig. 1 . The physicochemical properties of the petroleum hydrocarbon raw materials used in the test are shown in raw material a in Table 1. The catalyst used was industrially produced by the Catalyst Factory of Qilu Petrochemical Branch of China Petroleum and Chemical Corporation, and the brand name was RMP. See feedstock A in Table 3 for the weight composition of the C4 fraction used. The main operating conditions and product conditions are shown in Table 4.

[0048] The test procedure is as follows: the raw material a in Table 1 is preheated and injected into the re...

Embodiment 2

[0051] This example illustrates: adopting the method provided by the invention can significantly increase the yield of propylene, and at the same time increase the content of BTX in gasoline products.

[0052] The test was carried out on a medium-sized catalytic conversion device modified according to the method of the present invention, and the structure schematic diagram of the reaction and regeneration part is shown in Fig. 1 . The physical and chemical properties of the petroleum hydrocarbon raw materials used in the test are shown in Table 1, raw material b. The catalyst used is the same as in Example 1. See feedstock B in Table 3 for the weight composition of the C5 fraction used. The main operating conditions and product conditions are shown in Table 5.

[0053] The test procedure is as follows: the raw material b in Table 1 is injected into the riser reaction zone A after preheating, contacts and reacts with the regenerant in it, and the resulting reaction oil gas an...

Embodiment 3

[0056] This example illustrates: adopting the method provided by the invention can significantly increase the yield of propylene, and at the same time increase the content of BTX in gasoline products.

[0057] The test was carried out on a medium-sized catalytic conversion device modified according to the method of the present invention, and the structure schematic diagram of the reaction and regeneration part is shown in Fig. 1 . The physical and chemical properties of the petroleum hydrocarbon raw materials used in the test are shown in Table 1, raw material b. The catalyst used is the same as in Example 1. See feedstock C in Table 3 for the weight composition of the C4-C5 cuts used. The main operating conditions and product conditions are shown in Table 6.

[0058] The test procedure is as follows: the raw material b in Table 1 is injected into the riser reaction zone A after preheating, contacts and reacts with the regenerant in it, and the resulting reaction oil gas and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com