Biochemical pool MBBR process and denitrification deep-bed filter tank coupled nitrogen and phosphorus removal system and method thereof

A denitrification and phosphorus removal, biochemical tank technology, applied in the field of biochemical tank MBBR process coupled with denitrification deep bed filter denitrification and phosphorus removal system, can solve the problem of not considering the removal of total nitrogen, total phosphorus multiple functions, and the expansion of the use of suspended fillers , secondary treatment of unstable operation and other problems, to achieve the effects of high efficiency and flexible operation, long mud age, and strong anti-shock load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

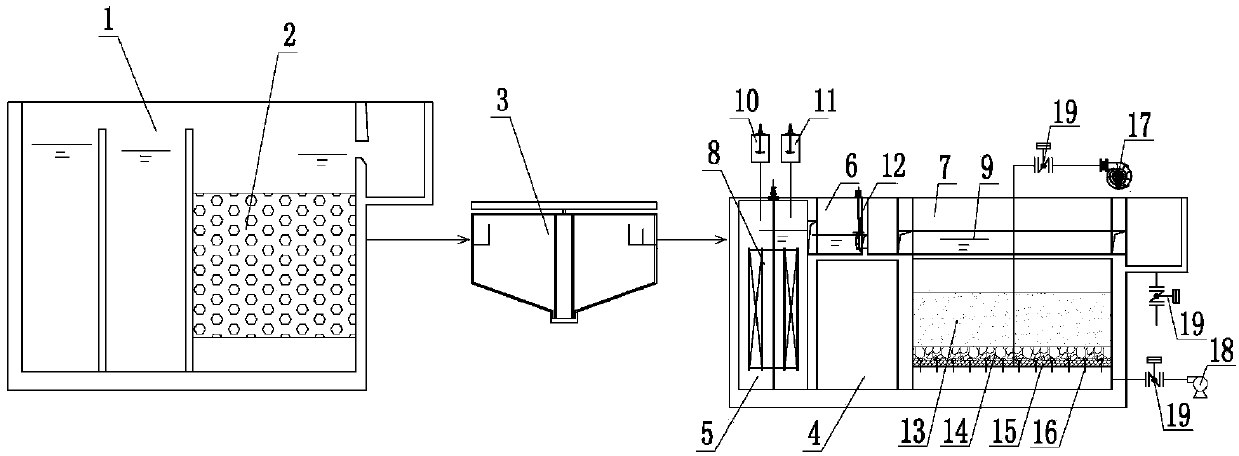

[0036] figure 1 It is a structural schematic diagram of the denitrification and phosphorus removal system coupled with the denitrification deep bed filter of the present invention. Including a biochemical tank 1 and a secondary sedimentation tank 3, the biochemical tank 1 is provided with at least one partition, separated into at least two chambers, a number of suspended fillers 2 are arranged in the chamber near the outlet, and the secondary sedimentation tank 3 is located in the biochemical tank 1 downstream and connected;

[0037] The denitrification deep bed filter 4 is located downstream of the secondary sedimentation tank 3, and it includes: a flocculation tank 5, a stirring mechanism 8 is provided in the flocculation tank 5, and a carbon source dosing mechanism 10 and a flocculant are also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com