Coal thrower chain boiler for reducing NOx emission through flue gas recirculation

A flue gas recirculation, chain boiler technology, applied in combustion equipment, lighting and heating equipment, etc., can solve the problem of lack of practical application examples of industrial boilers, and achieve the effect of short transformation period and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

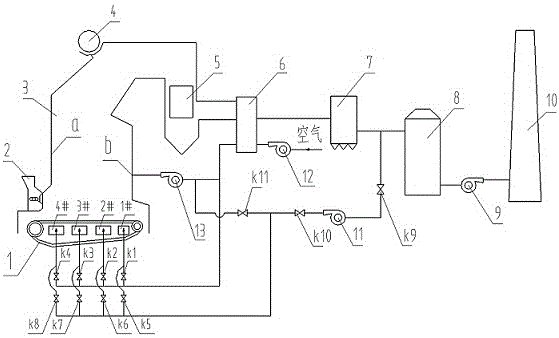

[0021] Such as figure 1 As shown, the coal thrower chain boiler using flue gas recirculation to reduce NOx emissions includes chain grate 1, coal thrower 2, furnace 3, drum 4, economizer 5, air preheater 6, and dust collector 7 , desulfurization tower 8, induced draft fan 9, chimney 10, flue gas recirculation fan 11, primary fan 12 and secondary fan 13; the lower area of the chain grate 1 has multiple primary air chambers (1# ~ 4# are primary air chambers 1~4); the tail flue of the furnace 3 is arranged in sequence with an economizer 5, an air preheater 6, a dust collector 7, a desulfurization tower 8, an induced draft fan 9 and a chimney 10; the primary fan 12 After the air is inhaled, it is preheated by the air preheater 6 to form primary air, which is sent into each primary air chamber (1#, 2#, 3#, 4#); The preheated air is extracted to form seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com