Patents

Literature

245results about How to "Solve lifting problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

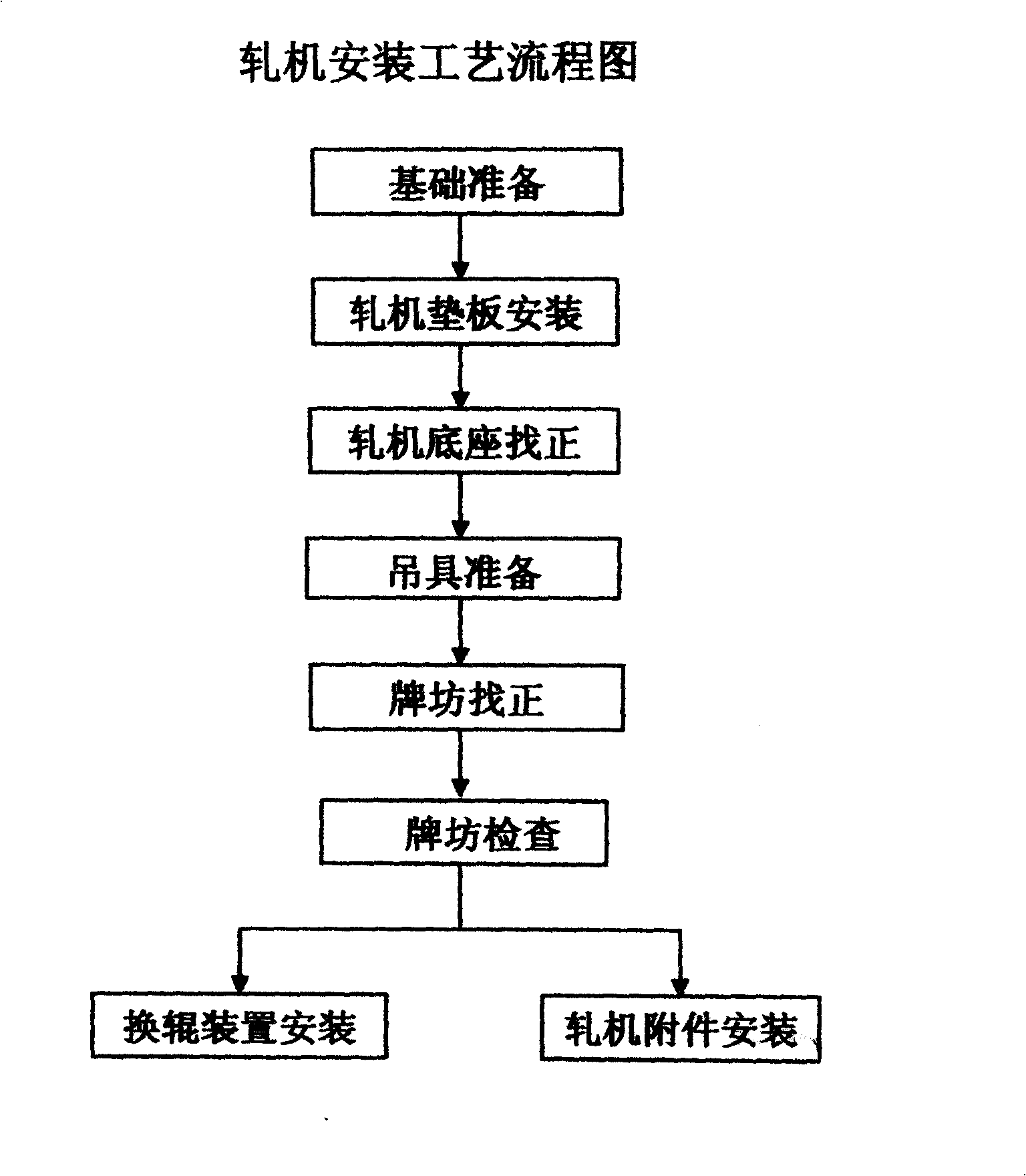

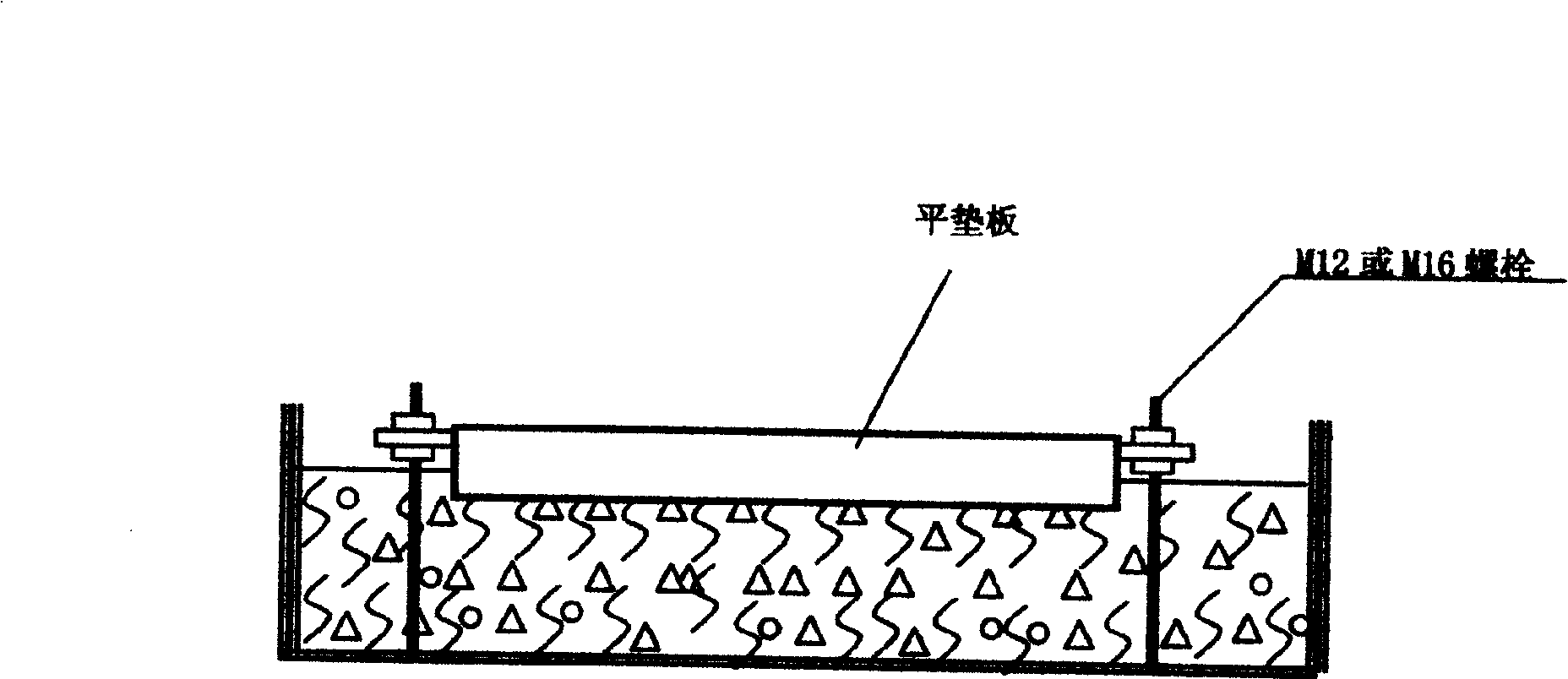

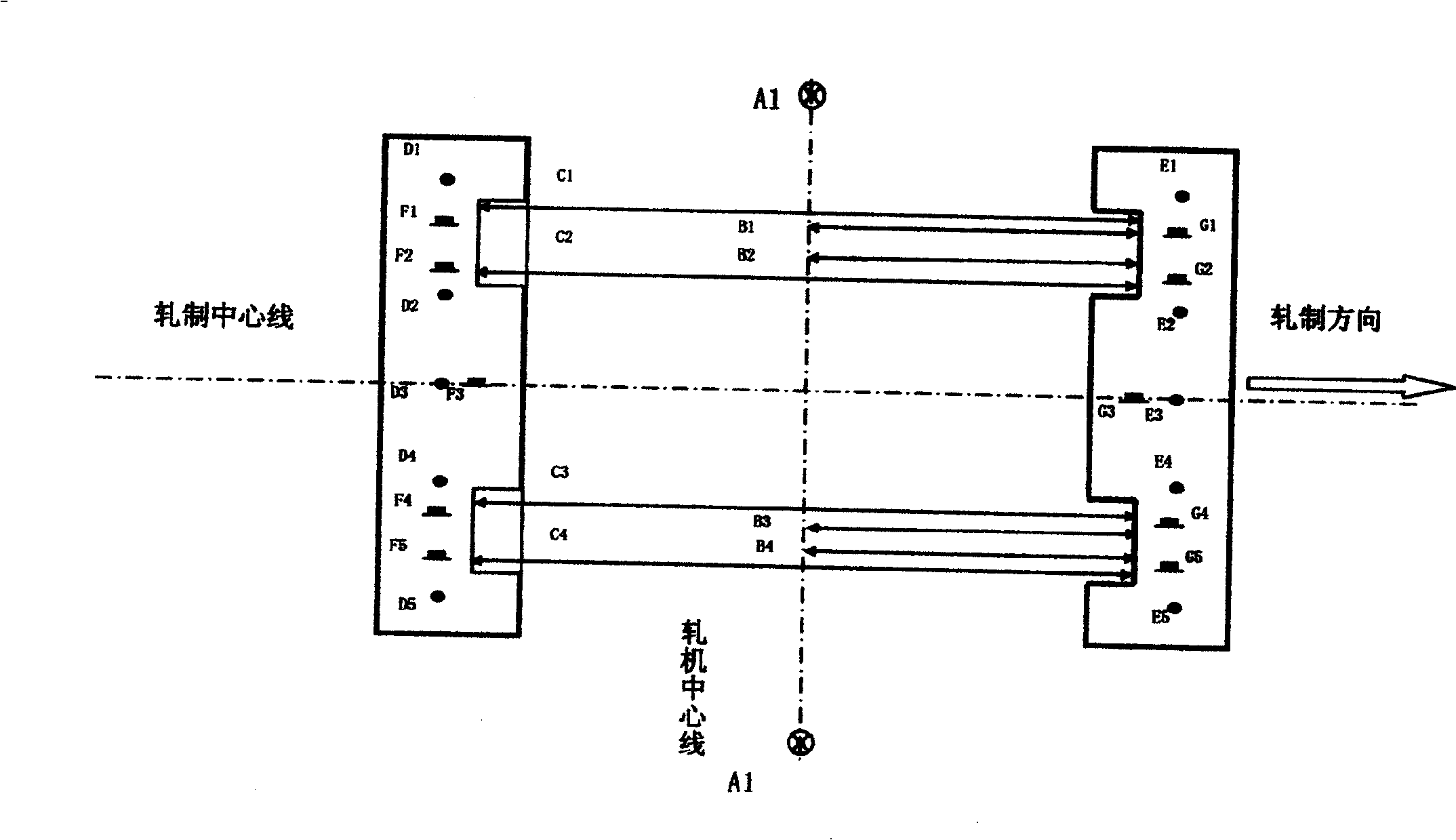

Method for mounting large-sized rolling mills

InactiveCN101275400AReduce loosenessAvoid damageFoundation engineeringBuilding material handlingStrip millMechanical equipment

The invention relates to an installation of metallurgy industry rolling mills, pinch pass mill, burnishing machines and the like large-scale mechanical equipment, especially to an installation method of a large-scale rolling mill, which is characterized in that the installation of a large-scale rolling mill is realized by the process steps of base preparation, rolling mills bearing plate installation, rolling mills motherboard transverse alignment, sling preparation, memorial archway transverse alignment, memorial archway check-up, roll-changer installation and rolling mill accessory installation. The invention satisfies all requirement of different construction sites, effectively resolves hanging difficult problem, saves work efficiency about 6-7 times, ensures installation quality, uses hydraulic bolt stretchers to avoid bolt up force moment from macrolesion bolt, and adopts small fastening force moment to allow rolling mills subbase to become flexible. Work difference bands are used to control the roll changing transmission device central line and the rolling mill central line to ensure installation quality. According to combination of calculation and on-site practicality, the invention not only can be used for rolling mills installation, but also can spread in mechanical equipment installation with common advising signification.

Owner:ANGANG CONSTR CONSORTIUM

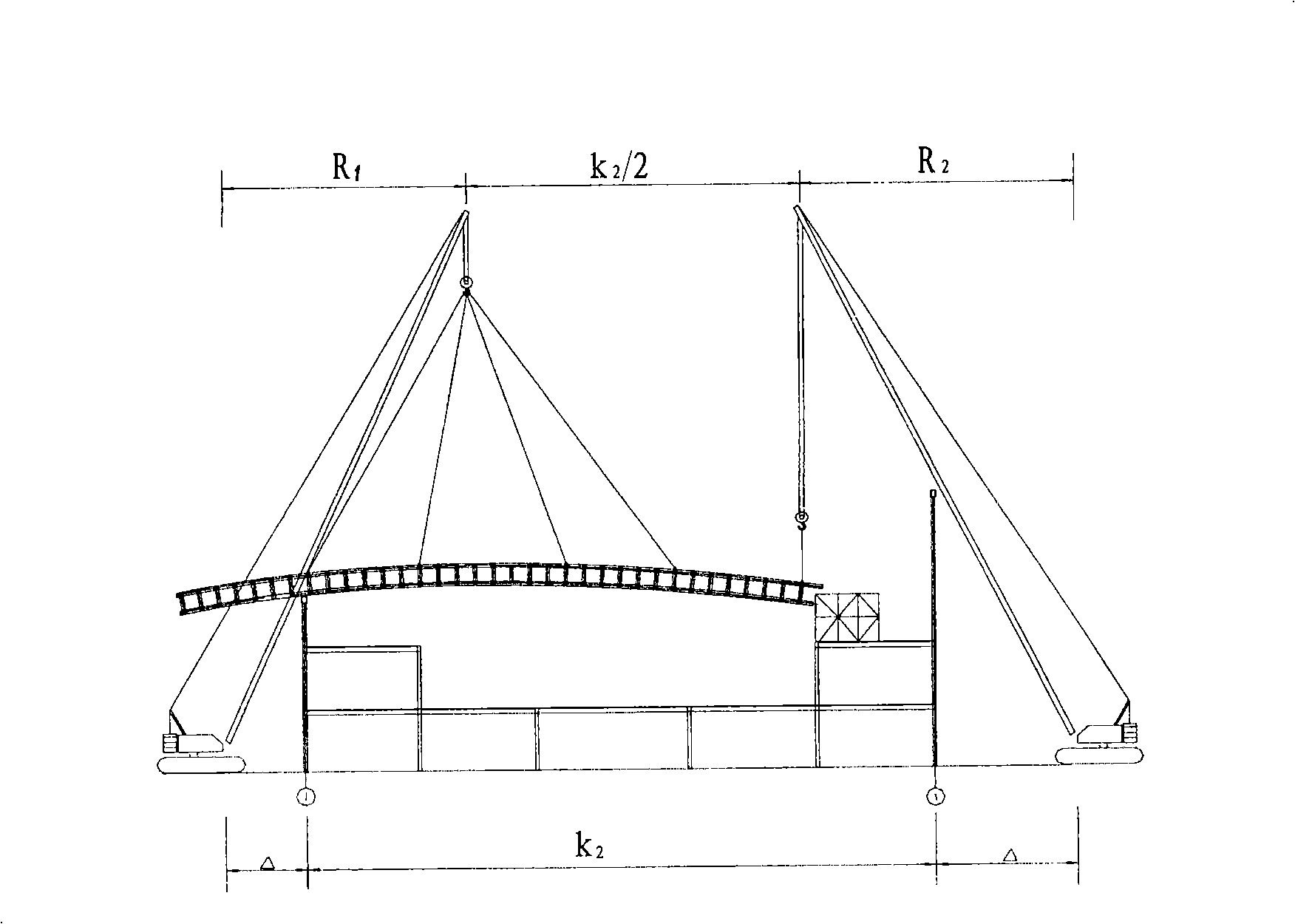

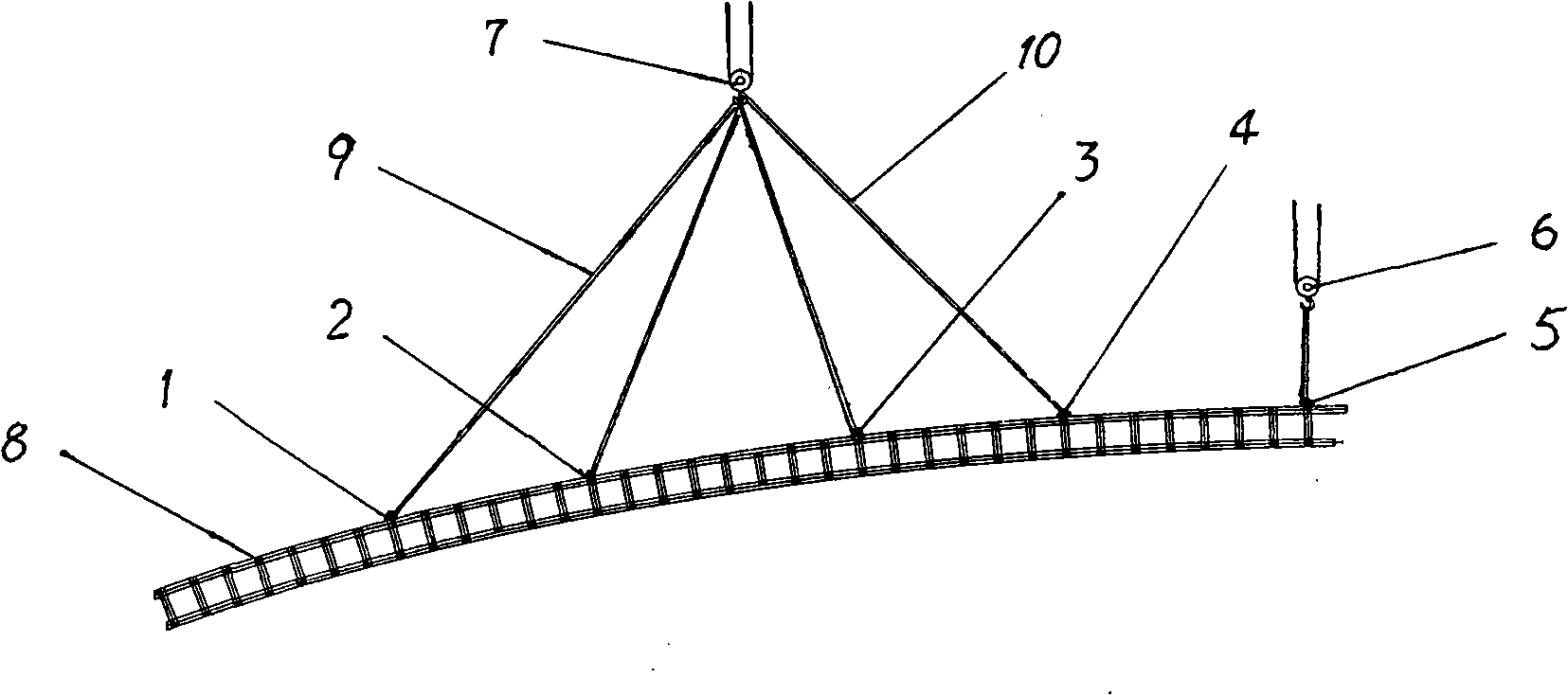

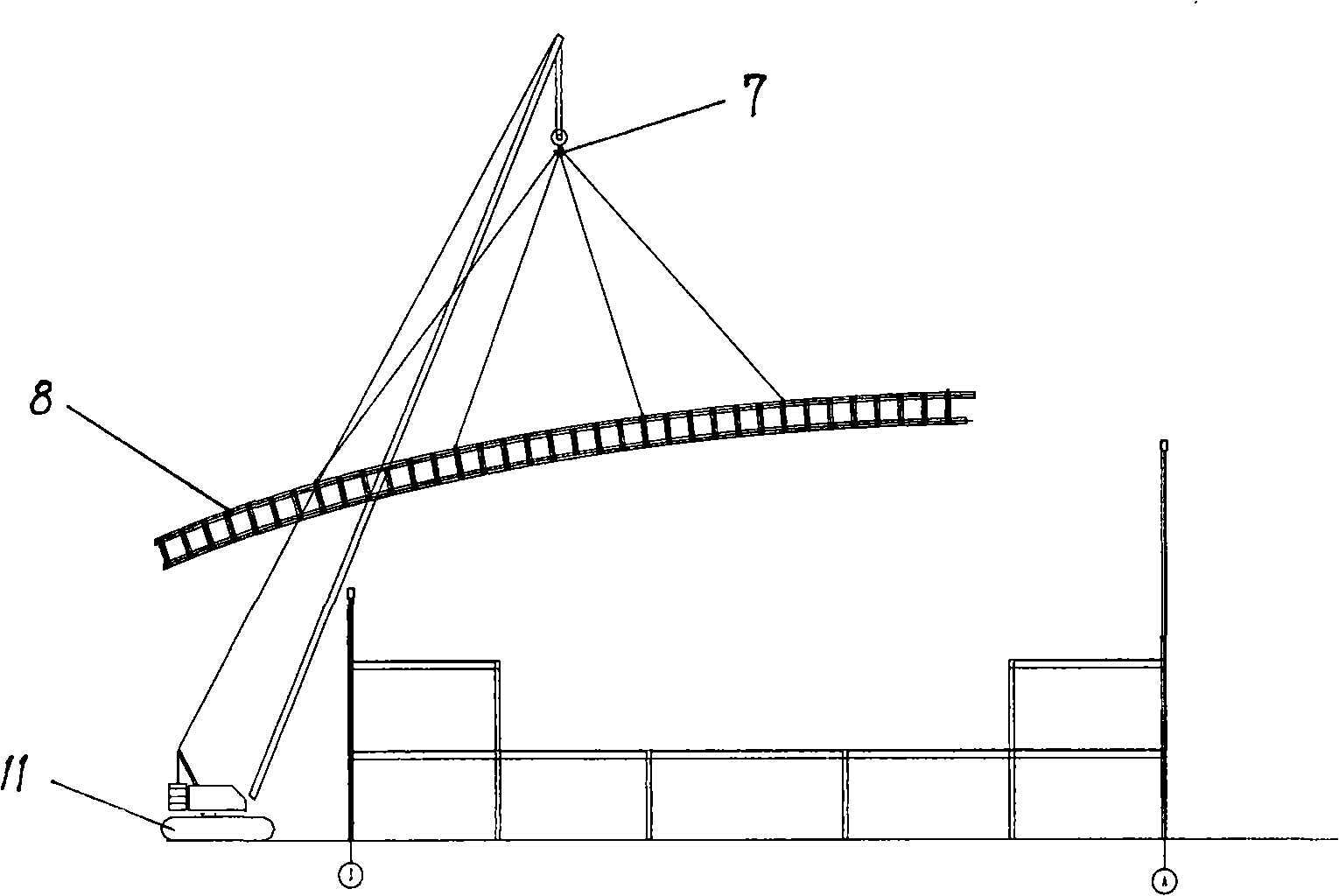

Construction method for hanging wide span arcuated open-web beam

InactiveCN101324146ASolve lifting problemsIncrease spanBuilding material handlingSpandrelStructural component

The invention relates to a large-span arc laced beam hoisting construction method used for constructing an ellipsoid roof. The method comprises the steps that a main crane hoists in a stand-alone way at one side beyond the span and delivers the laced beam to be within the span, one end of the laced beam is hoisted by an assistant crane beyond the span at the other side of a building, and dual-machine lifting and hoisting is formed by hoisting point shifting on the laced beam so as to jointly hoist and position the laced beam. The invention is a brand new dual-machine delivering lifting and hoisting construction method, and solves the hoisting problem of the large-span steel structure laced beam under special conditions that a construction field can not be provided within the span of the building, the dual-machine lifting and hoisting can not be carried out due to the obstruction of the running line of the cranes at the two sides of the building, and a gliding method can not be used for hoisting, etc., and the span of a hoisting structural component can be greatly improved, thus improving construction safety, guaranteeing construction quality and shortening construction period.

Owner:HEBEI CONSTR GRP

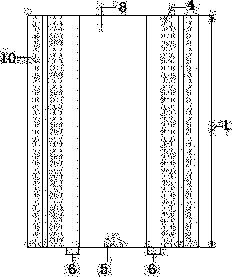

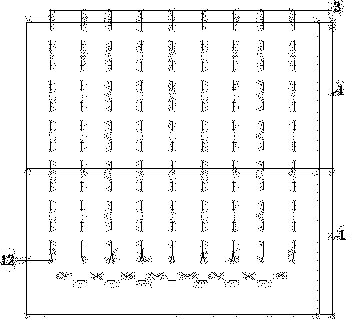

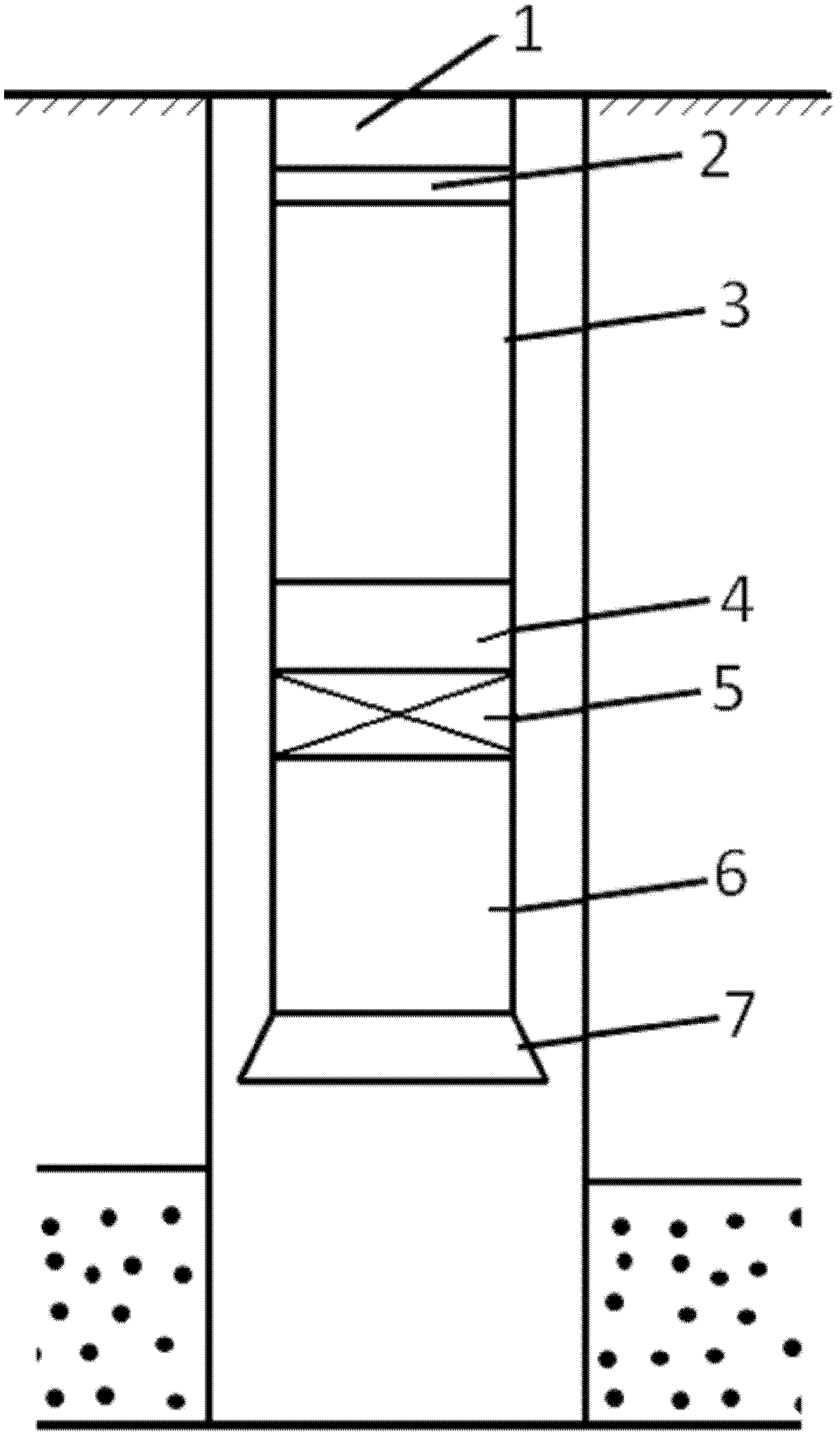

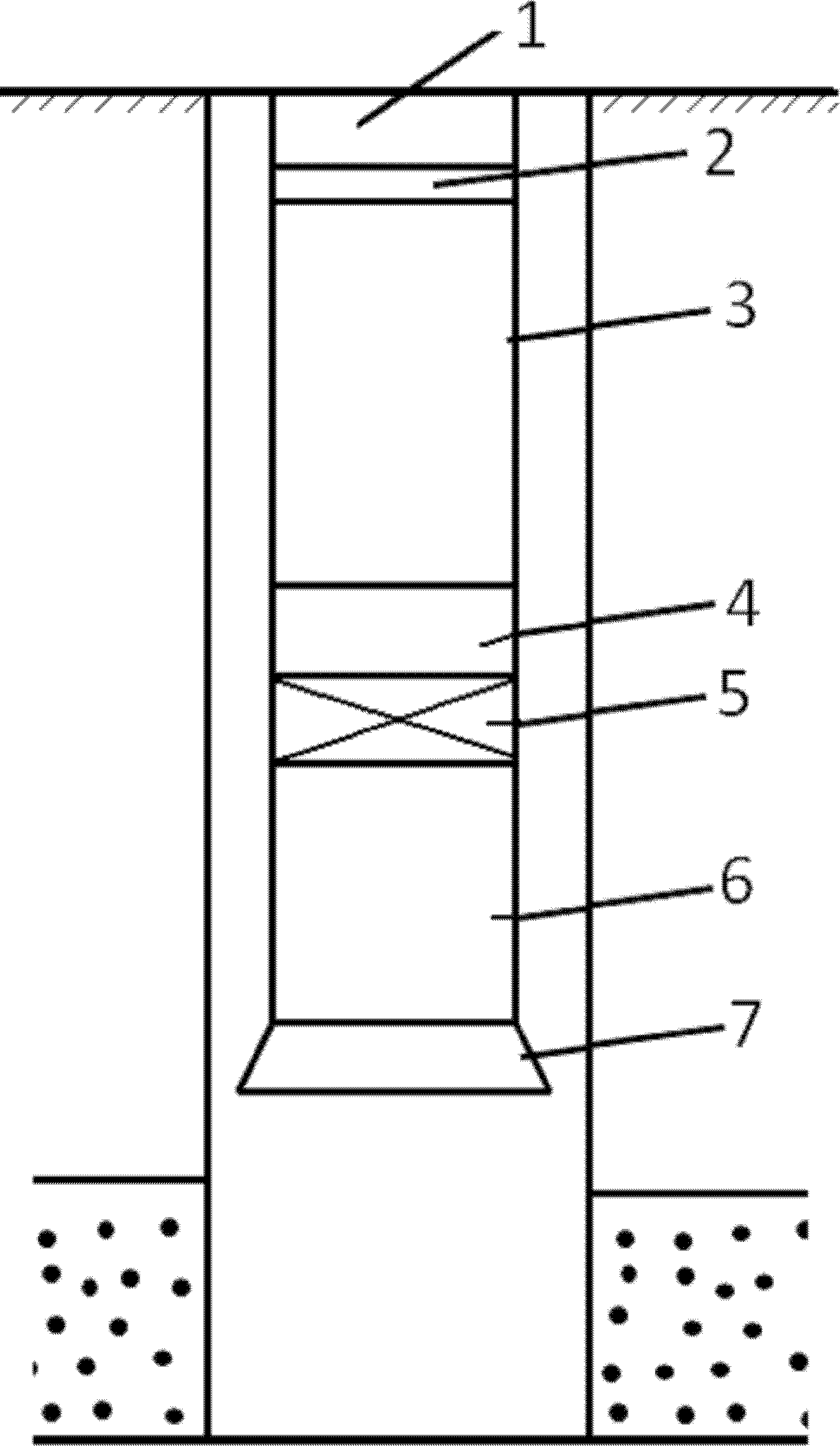

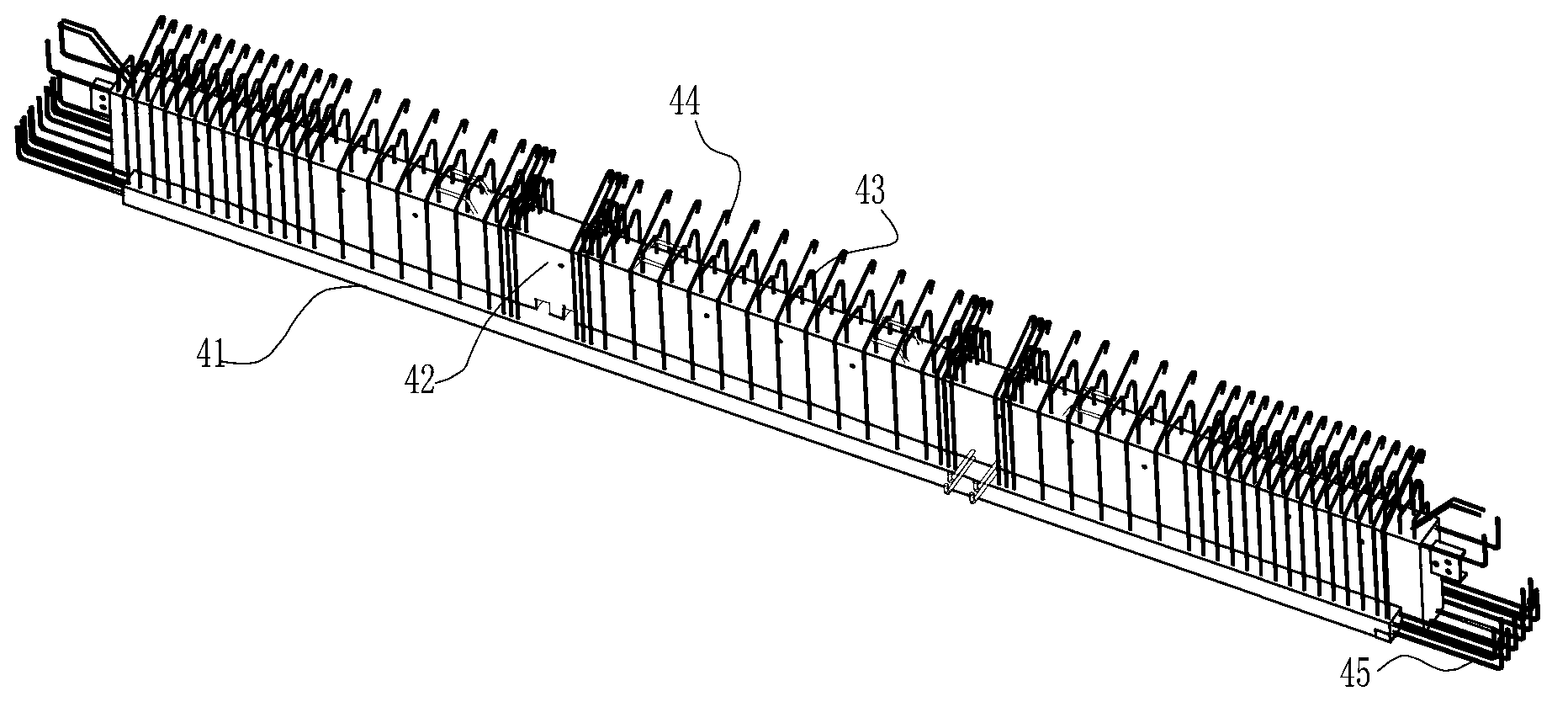

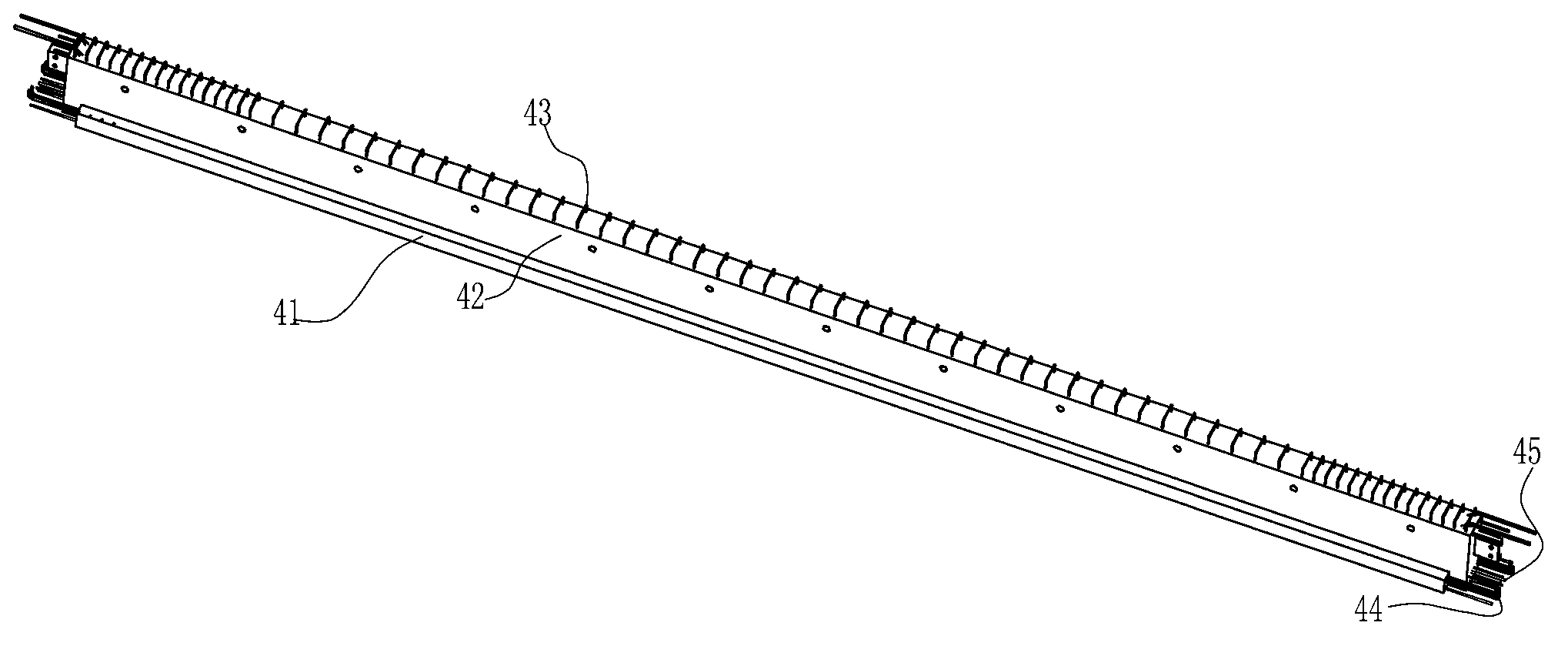

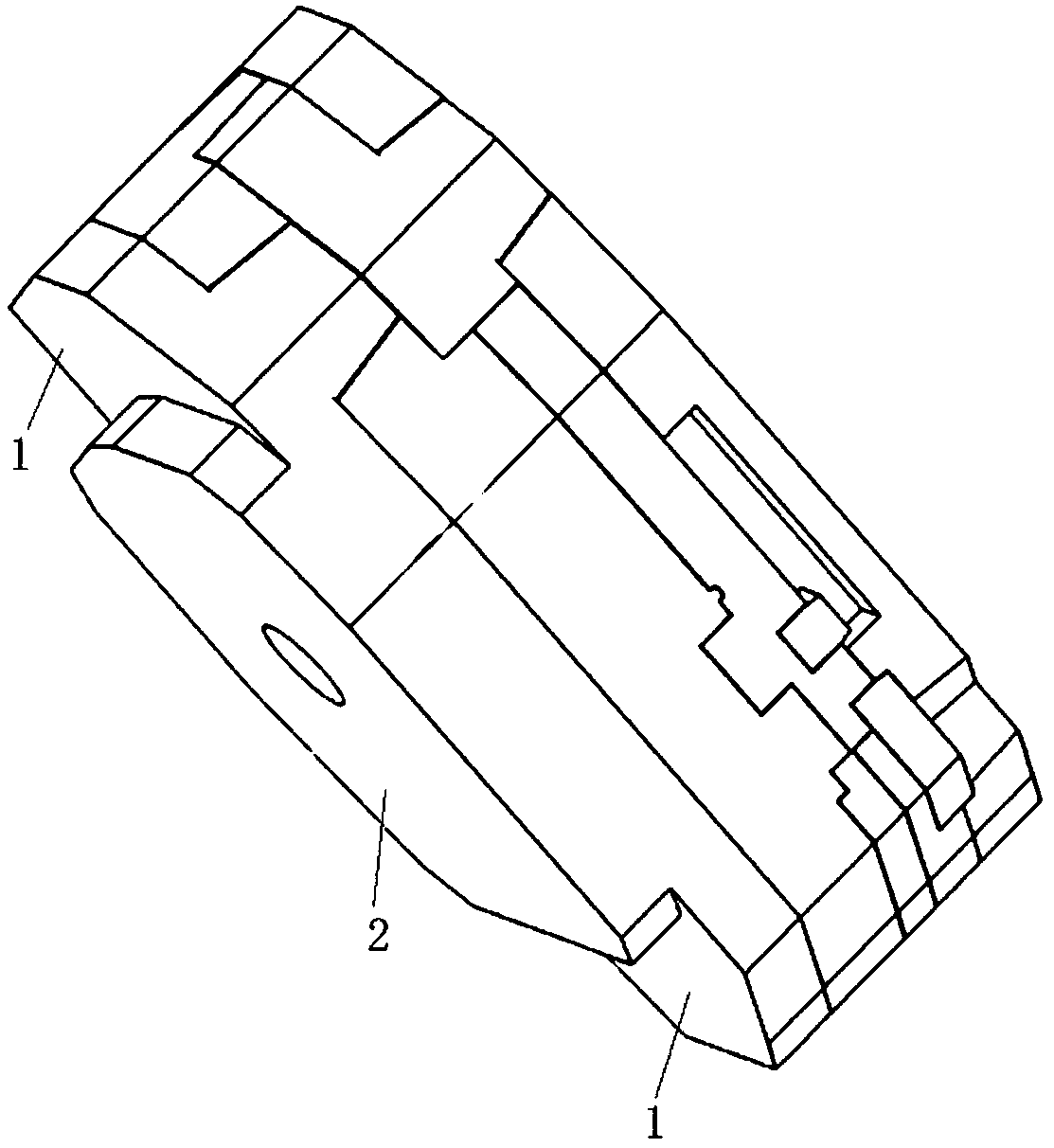

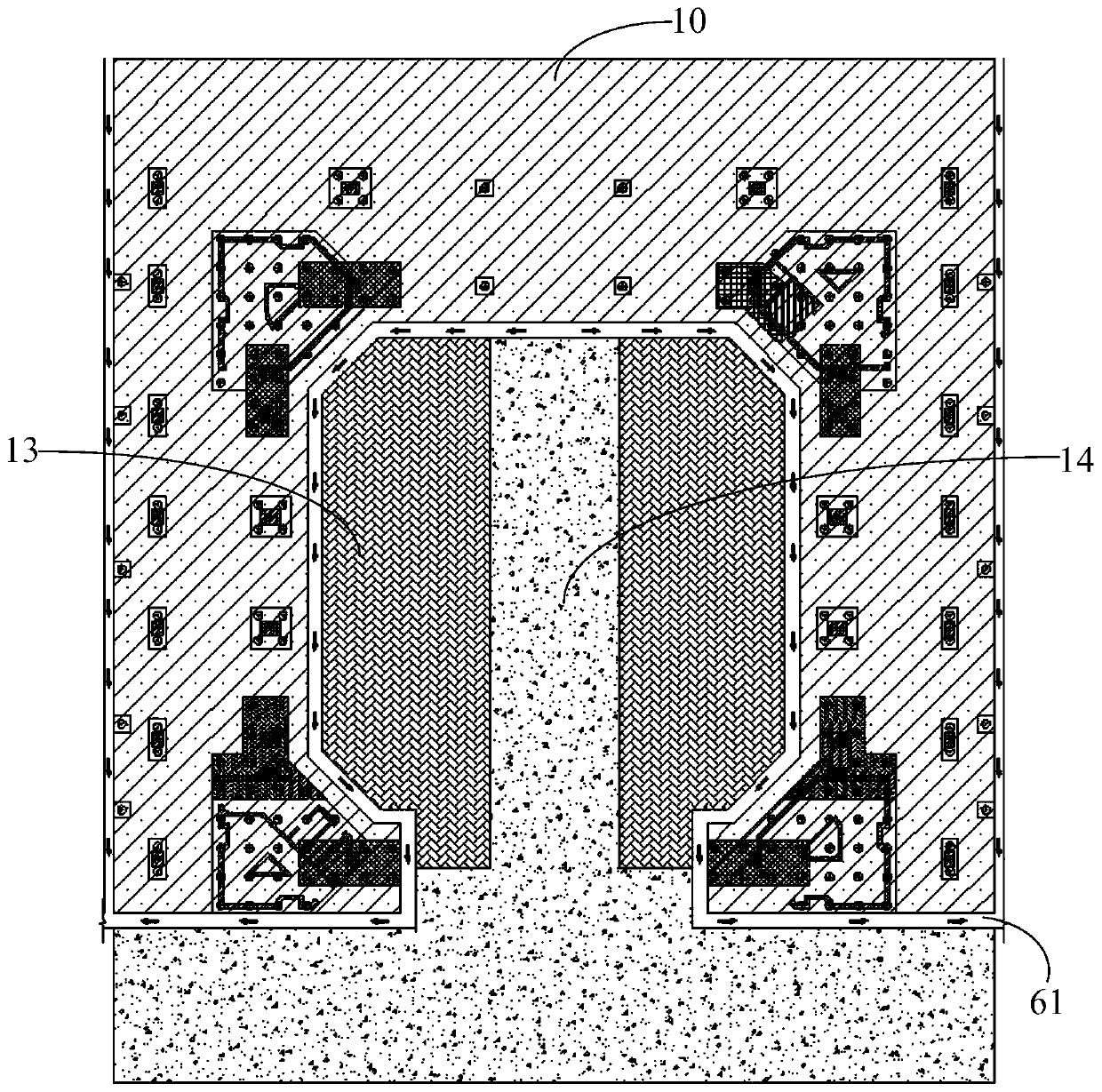

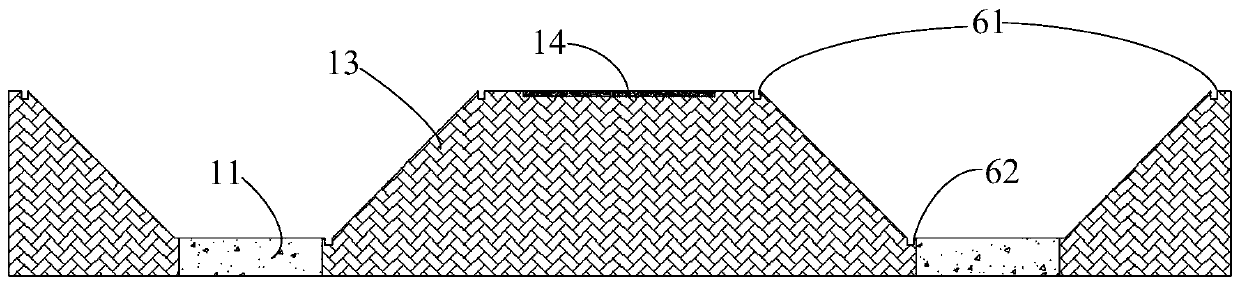

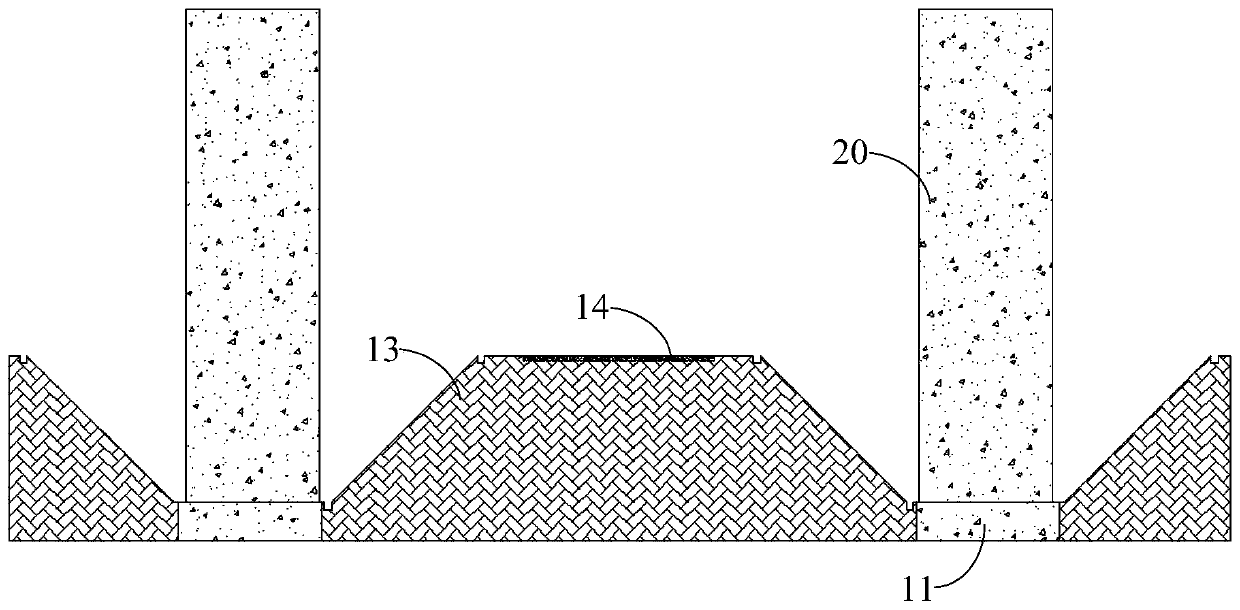

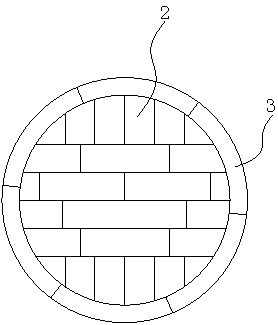

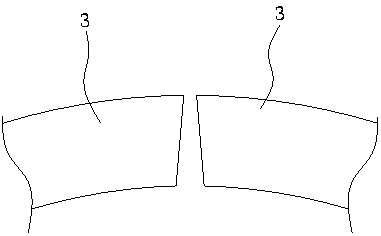

All-wet-joint precast prestressed underground continuous wall and construction method thereof

The invention provides an all-wet-joint precast prestressed underground continuous wall and a construction method of the all-wet-joint precast prestressed underground continuous wall. The continuous wall is formed by sequentially connecting a plurality of wall segments (1). The middle of the section of each wall segment (1) is provided with a cavity (4). Concave groove segments (8) are arranged at the center of the wall segments (1) in the length direction. Semi-conical holes (5) are formed in the upper connection parts and the lower connection parts of the wall segments (1). The semi-conical holes (5) are communicated with the cavities (4) and the concave groove segments (8). Water-proof wet joints are formed by pouring concrete in the semi-conical holes (5). According to the continuous wall, all the wall segments are connected through the wet joints, so that the problem of leakage at the connection parts of the wall segments is solved. By exerting prestressing force between the wall segments, the flexural rigidity, the anti-cracking ability and the lasting quality of the underground continuous wall are improved. Due to the fact that the underground continuous wall is connected with reinforcing mesh pieces, the shear-resistant performance between the wall segments is strengthened. As the wall segments are constructed on the ground, the quality of the continuous wall is easy to guarantee.

Owner:SOUTHEAST UNIV

Method for lifting heavy oil through shaft in heavy oil cold production

ActiveCN102635343AImprove liquiditySolve lifting problemsFluid removalDrilling compositionSoftened waterOil field

The invention discloses a method for lifting heavy oil through a shaft in heavy oil cold production, which is applied to the oil production in oil fields and is especially used for heavy oil cold production. The method comprises the following steps of: preparing a viscosity reducer A; putting a production string in a heavy oil well; putting a production roof-bolt in an oil tube; adjusting the dead space of the production roof-bolt; adding circulating softened water from a water inlet of a tee for two coaxial hollow rods, and starting a ground circulating pump to carry out softened water circulating; after the outlet temperature of the circulating softened water subjected to heating reaches 55-60 DEG C, opening the oil well and starting a pump to carry out production; and adding the viscosity reducer A from a position between the oil tube of the oil well and a casing, and recovering liquid in the well through lifting. The method disclosed by the invention has the effects that: the liquidity of heavy oil in the shaft can be improved, and the problem of shaft lifting can be solved; and in the process of restarting the pump to pump oil after power failure, an internal circulating system of the two coaxial hollow rods is started firstly, and after the output temperature reaches 55-60 DEG C, the oil well is opened to carry out oil production, thereby reducing the load of the oil well in the process of starting, and prolonging the pump inspection time of the oil well.

Owner:PETROCHINA CO LTD

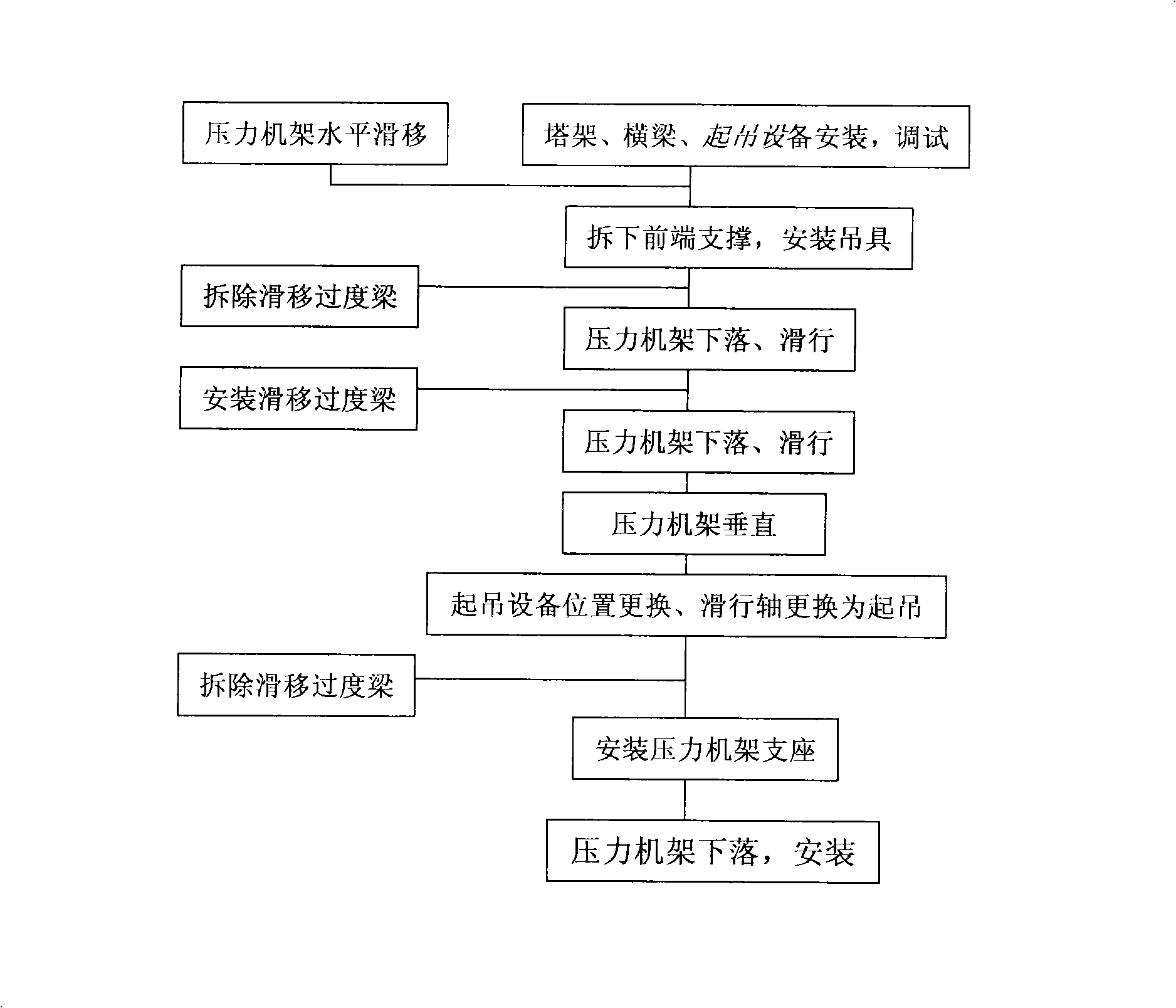

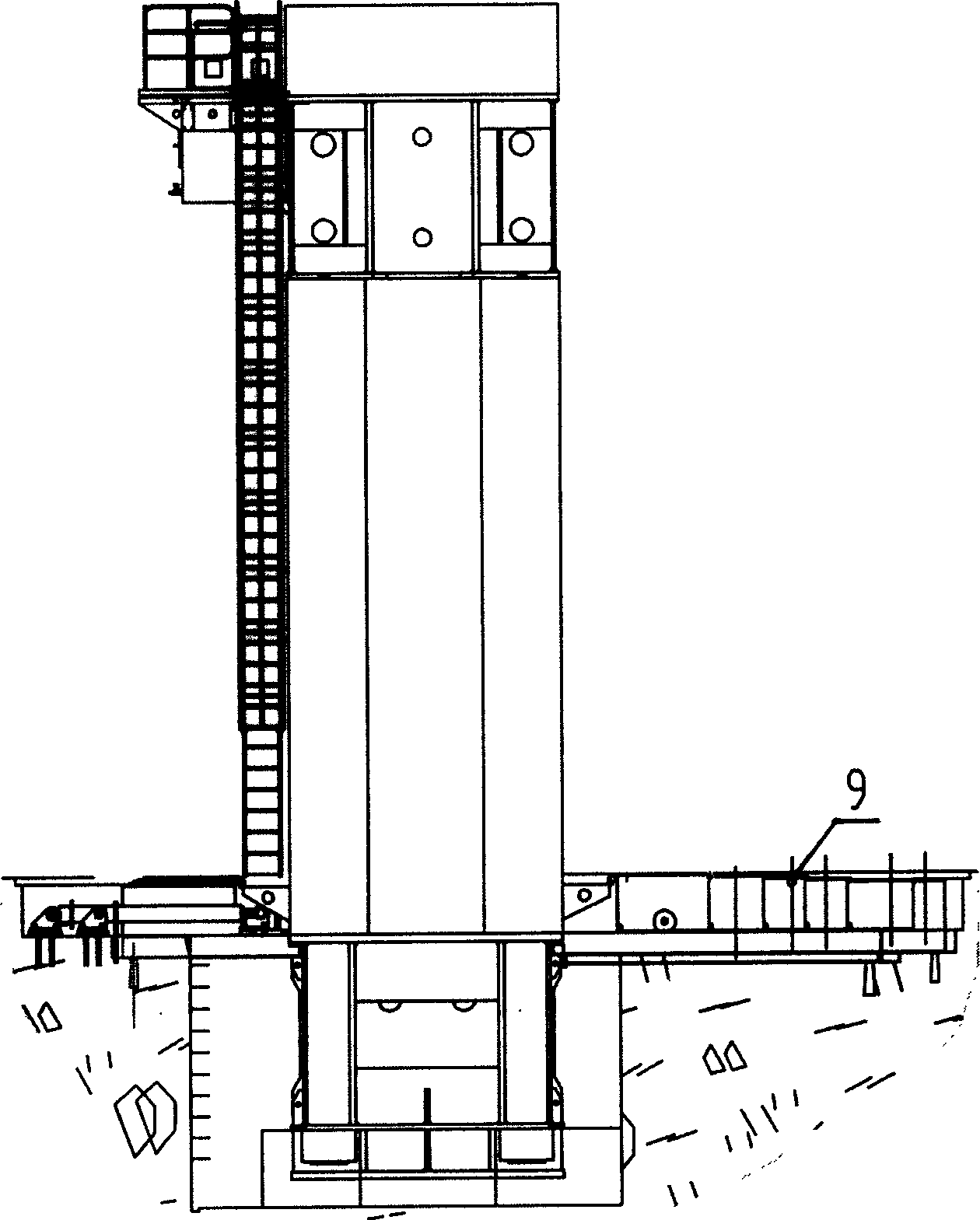

Hoisting method for framework of large tonnage pressing machine

ActiveCN101284628ALower the altitudeSolve lifting problemsTravelling cranesLoad-engaging elementsDevice placementIndustrial engineering

The invention relates to a method for hoisting large scale equipment, in particular to a method for hoisting a large-tonnage pressing machine frame. The method comprises the following steps: derrick beams are arranged on the two side of the installation position of the pressing machine frame, a large scale hoisting device is arranged thereon, a sliding shaft and a falling shaft are arranged respectively in the front and the back of the pressing machine frame, the sliding shaft is arranged at the top of the pressing machine frame in the back, and the falling shaft is arranged at the bottom in the front, the sliding shaft is slid rotationally forwards on a slideway, the falling shaft rotationally falls down, until the pressing machine frame is upright, a hoisting point is changed at the position of the sliding shaft, and the installation is finished after the pressing machine frame falls down for a certain distance. Compared with the prior hoisting method, the method of the invention has the outstanding advantages as follows: the height of the derrick is reduced, so that all the work can be done in the installed workshop; the hoisting equipment in the workshop is fully utilized, so that the hoisting problems of all the hoisting equipment are solved and the hoisting cost of the prior art is saved; the construction period is shortened, and the safety is guaranteed; and the method is suitable for the hoisting installation exercises in narrow spaces or at high altitude, underground, and in other construction situations.

Owner:CHINA 22MCC GROUP CORP

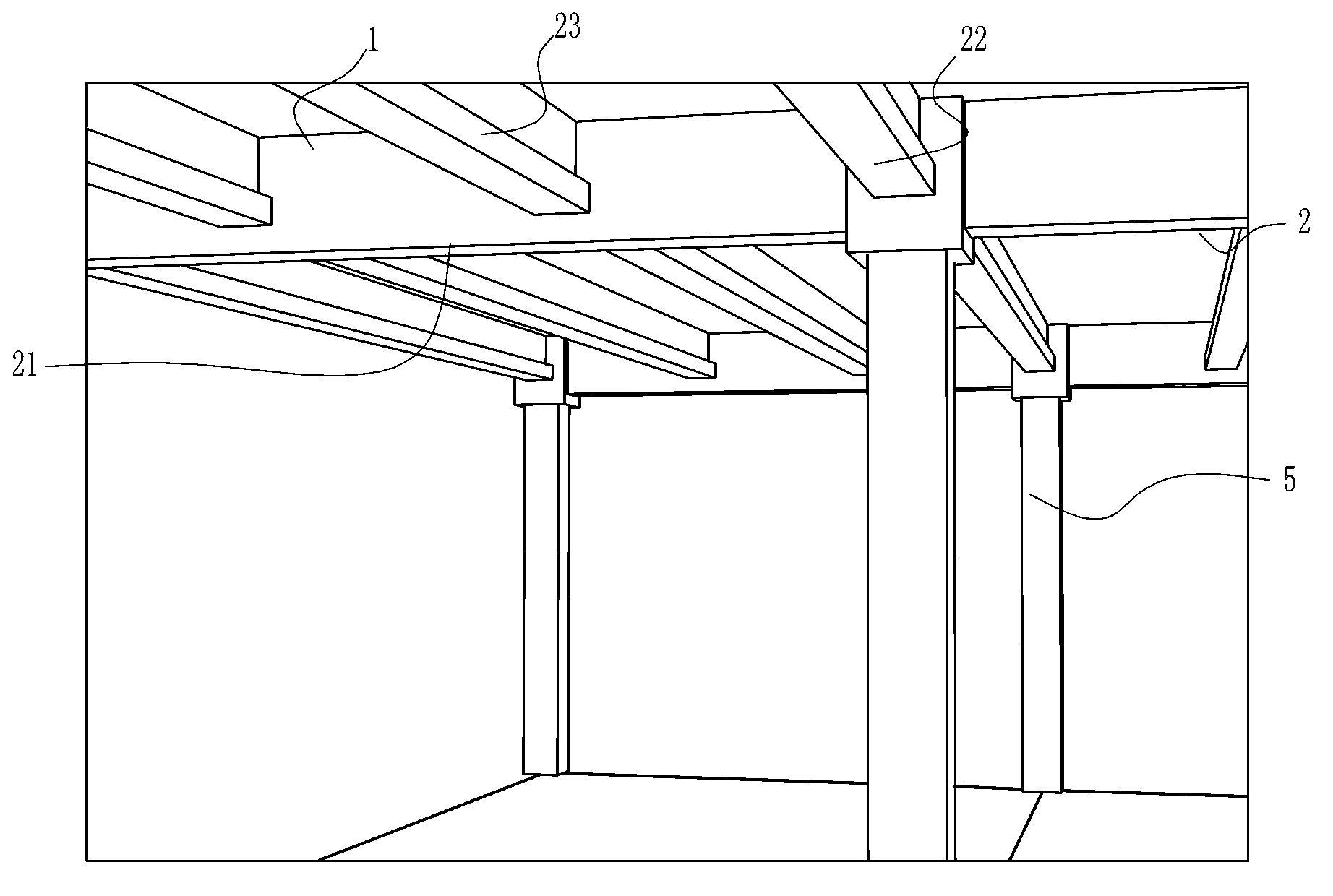

Large span prefabricated monolithic casting structure and construction method

ActiveCN103046645AImprove shear resistanceSmall floor spanBuilding material handlingShaped beamFloor slab

Disclosed is a large span prefabricated monolithic casting structure. The large span prefabricated monolithic casting structure comprises a floorslab, a superposed beam and a column, the superposed beam and the column are used for supporting the floorslab, the superposed beam is divided into a short frame main beam, a long frame beam and an auxiliary beam, the auxiliary beam is connected with the main beam, the superposed beam comprises a prestress prefabricated beam and a cast-in-situ portion, the prestress prefabricated beam comprises a beam body and a pre-stressed steel strand which is buried in the beam body and serves as a main rib, two ends of the short frame main beam and the long frame beam are connected with the column, cross sections of prefabricated beam portions of the long frame beam and the auxiliary beam are invertedly T-shaped, the superposed beam after monolithic casting is an I-shaped beam connected with the floorslab, and the auxiliary beam and the long frame beam utilize the inverted T-shaped prestress prefabricated beams with small intervals. The large span prefabricated monolithic casting structure has the advantages that the span, the thickness and the self weight of the floorslab are small, heights of the beams are reduced, reinforcing bars are reduced, and the short main beam which uses a superposed rectangular beam is good in shear resistance and convenient to connect with the auxiliary beam.

Owner:宁波优造建筑科技有限公司

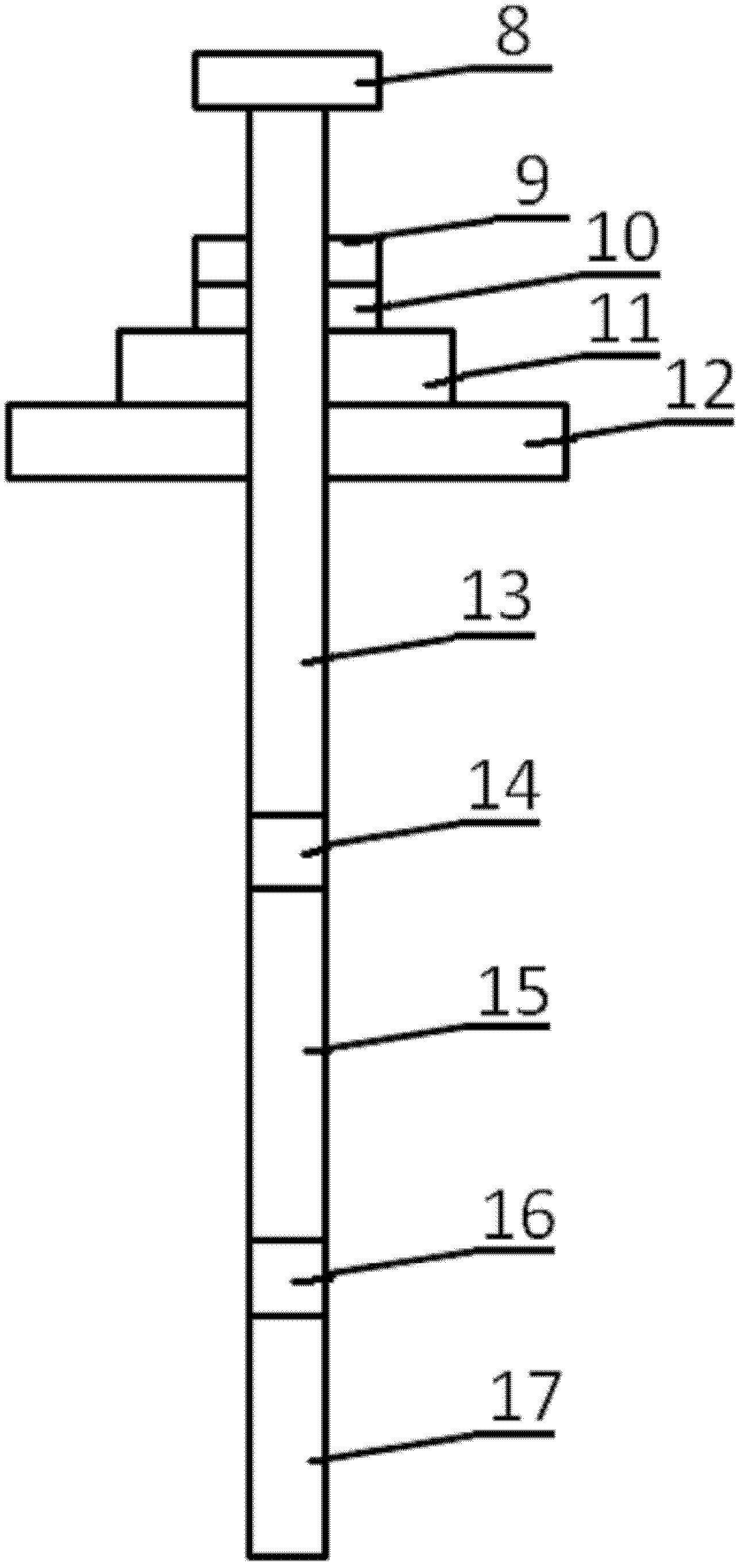

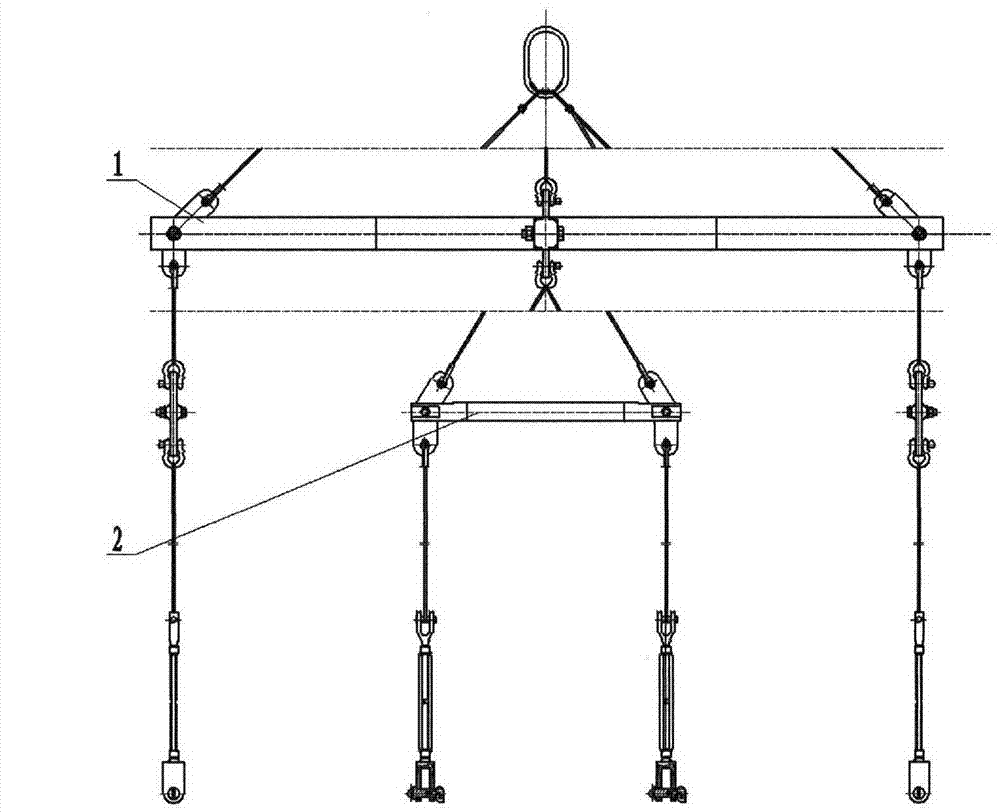

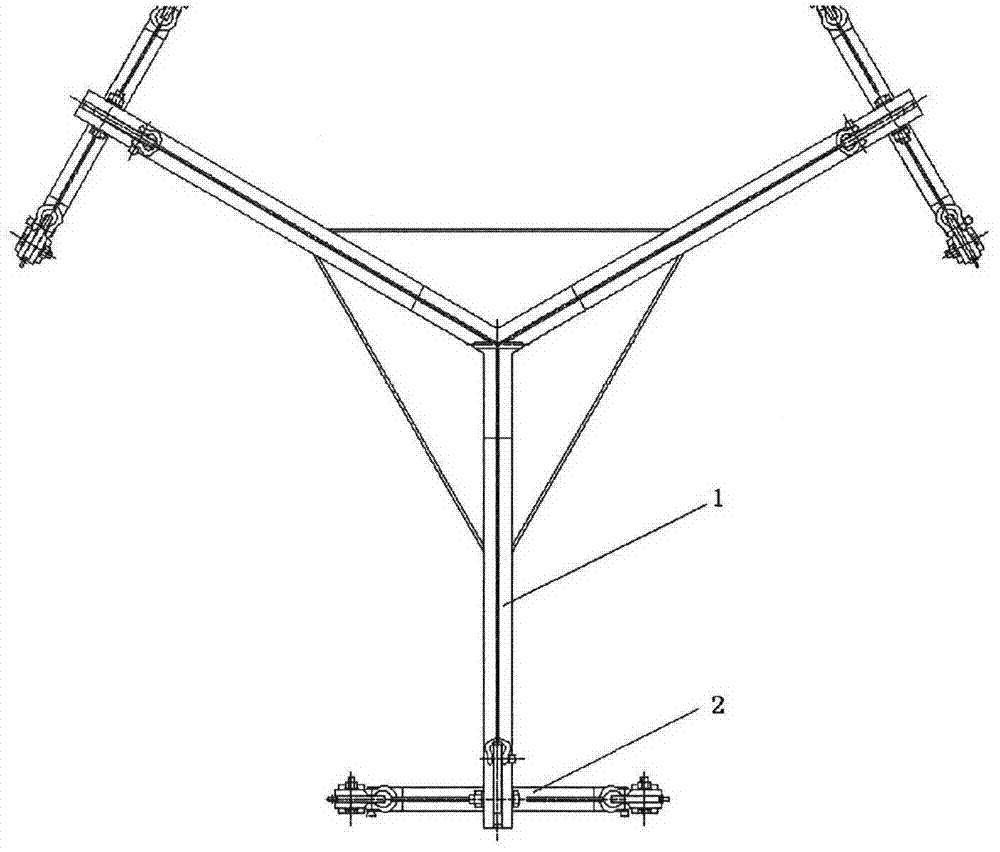

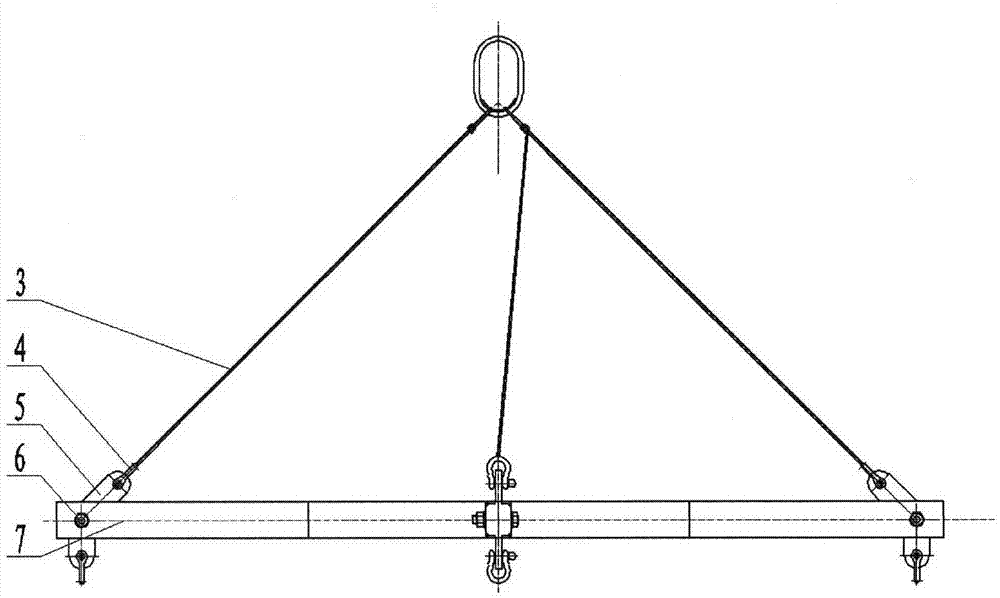

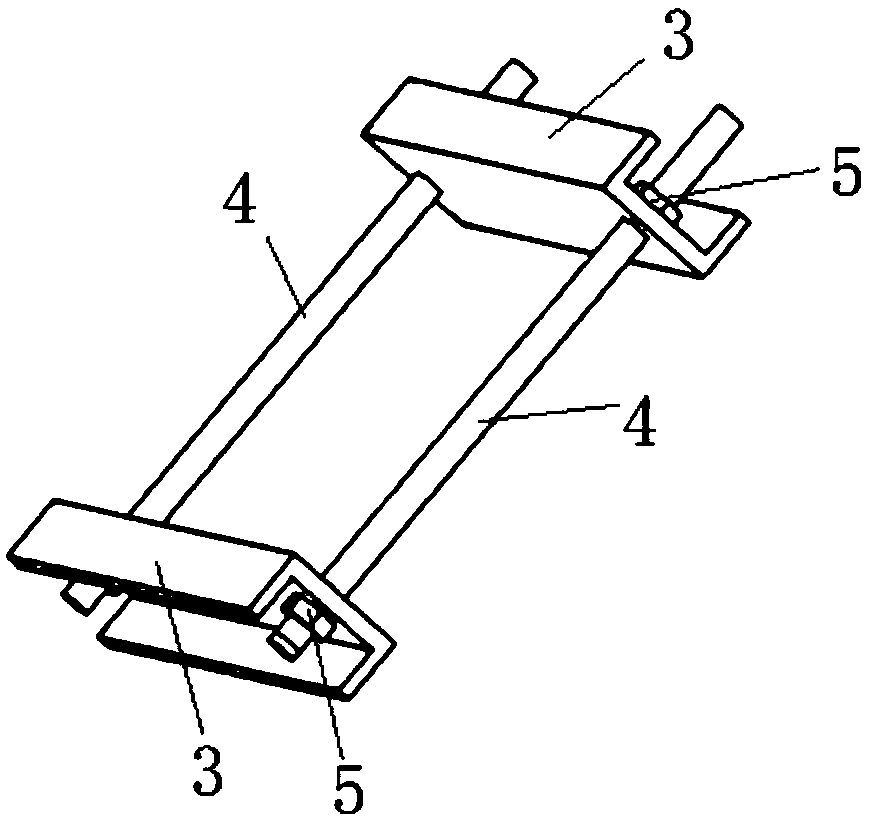

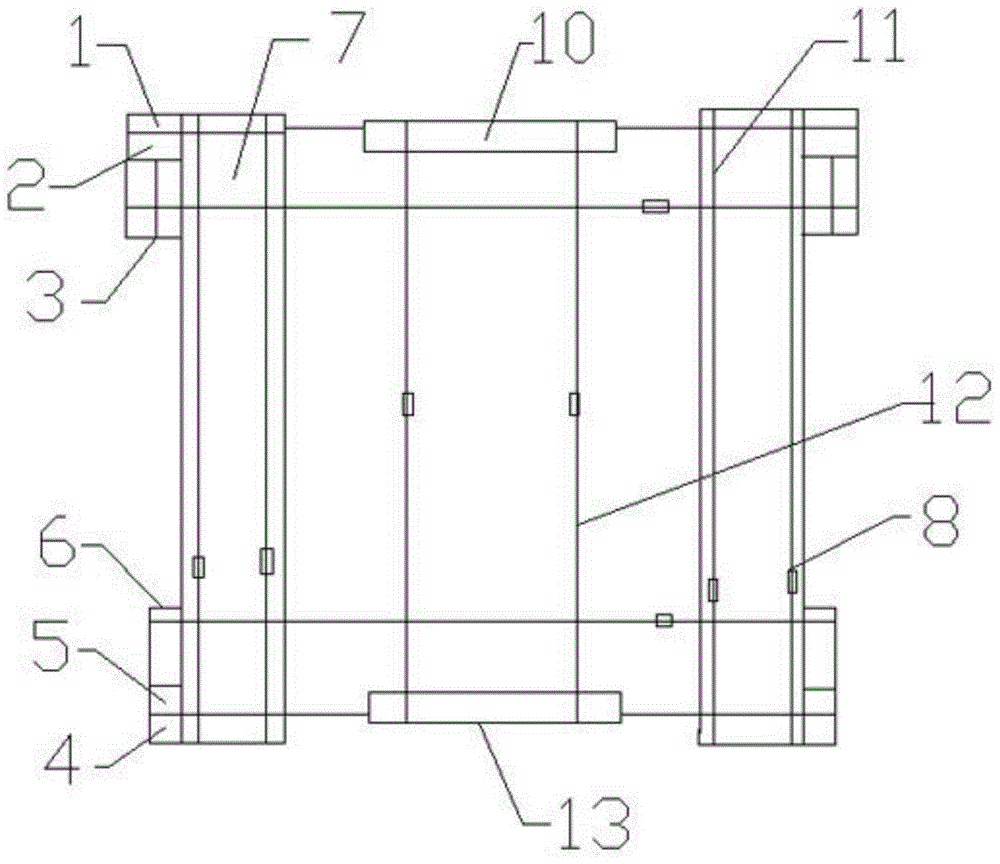

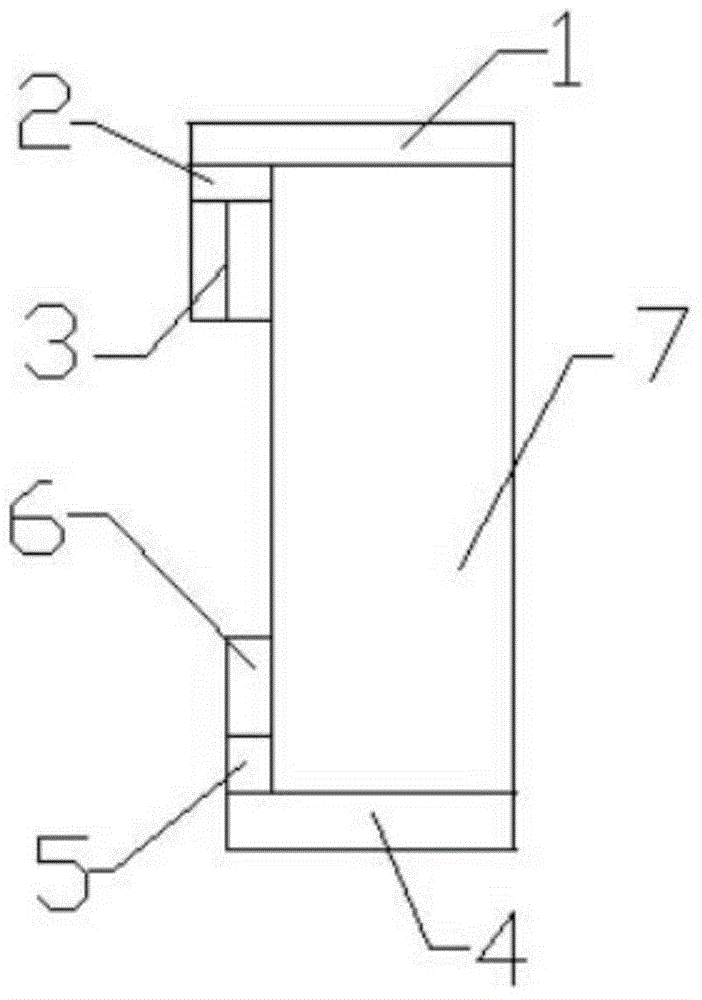

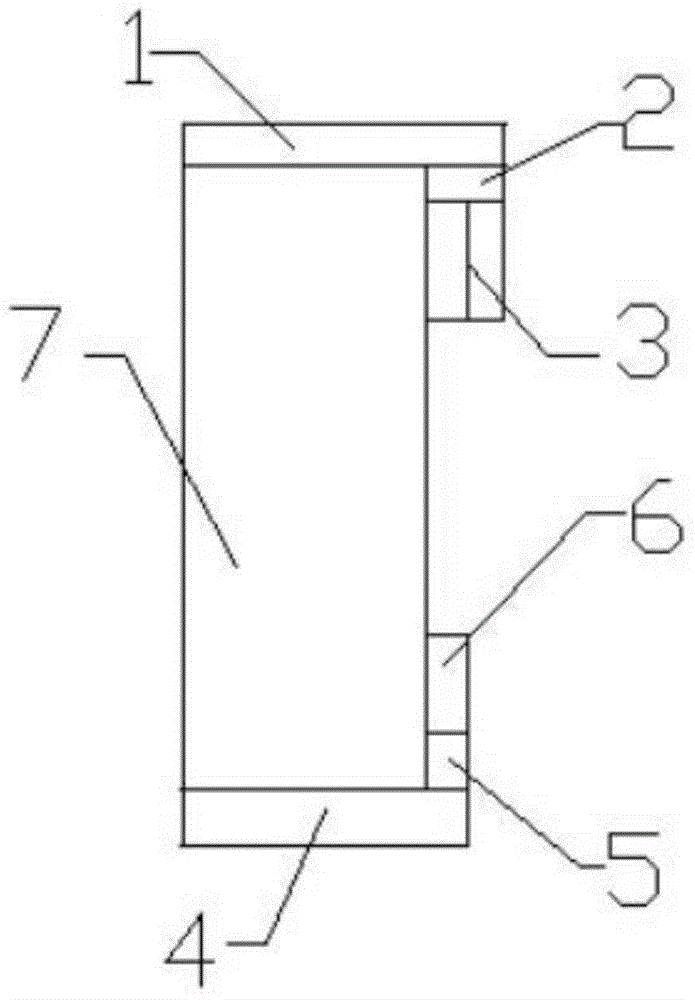

Multi-function combination lifting device for minisatellite

The invention discloses a multi-function combination lifting device for a minisatellite, comprising a triangular special-shaped lifting unit (1) at the upper portion and three straight beam lifting units (2) at the lower portion, wherein the triangular special-shaped lifting unit (1) comprises a three-leg combination lifting belt (3), a shackle (4), a large connection block (5), a pin roll (6) and a triangular beam (7); the straight beam lifting unit comprises a lifting belt (8), a small shackle (14), a small connection block (9), a beam (10), a small lifting belt (11), six turn buckles (12) and six quick-release stop pins (13); and the triangular special-shaped lifting unit (1) is connected with each straight beam lifting unit through the shackle (4). According to the invention, by combining the triangular special-shaped lifting unit with the three straight beam lifting units, the problem of lifting a minisatellite with six lifting points and six prisms is solved; simultaneously, the triangular special-shaped lifting unit has a stable triangular structure, thus the adaptive ability is strong, and uniform stress distribution of the six lifting points can be realized without adjusting the level of the minisatellite.

Owner:AEROSPACE DONGFANGHONG SATELLITE

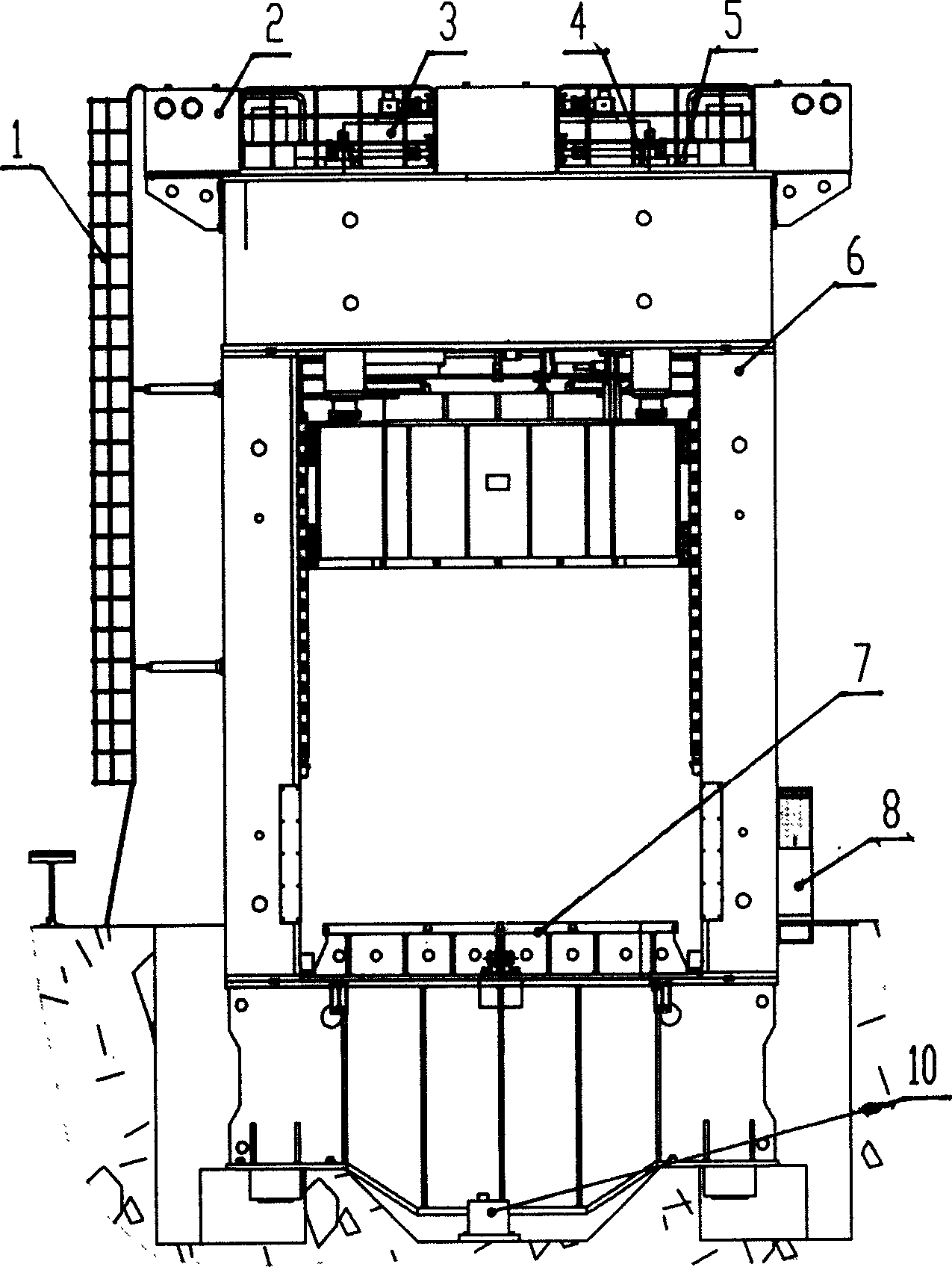

Large-scale double-action hydraulic drawing machine for heavy plate

The large double-acting thick plate drawing hydraulic press as one kind of hydraulic machinery consists of mainly body, platform, driving system, main cylinder, outer block edge pressing back stroke cylinder, inside block back stroke cylinder, movable bench and electric system. The movable bench consists of movable right and left benches fixed together. There are on ground oil cylinder fixing frame, connecting shaft on the frame and hinged with the ears integrally with the oil cylinder, and driving oil cylinder with piston rod connected to oil cylinder fixing frame. The main cylinder is one with double liquid filling valves, and there is block fall preventer installed onto the upper cross beam. The present invention has smooth running of the movable bench, high efficiency and other advantages.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Anti-gravity casting moulding method for 3D printing sand mould

ActiveCN109175307AEasy to carryInhibit sheddingAdditive manufacturing apparatusAnti-gravitySelf locking

The invention discloses an anti-gravity casting moulding method for a 3D printing sand mould. The anti-gravity casting moulding method comprises the following the steps of: designing a casting systemaccording to the characteristic of a casting; parting the casting of the designed casting system by adopting a three-dimensional map-making software, and arranging a water-glass sand mould and a self-locking workpiece placing platform at the bottom end of a pouring cup; adding support according to the parting results, adopting pre-coated sand to print sand moulding blocks added with the support, and a core, and roasting different sand moulding blocks after printing is completed; and adopting a wooden mould and water-glass sand to manufacture a pouring gate, assembling the sand mould and the water-glass sand pouring gate, jointing a self-locking tool, adopting an anti-gravity low-pressure way to cast the sand mould, thereby obtaining the casting. The anti-gravity casting moulding method solves the sand mould box-lifting problem as a result of great anti-gravity casting mould-filling pressure, enables the 3D printed sand mould to be free of phenomena such as cracks, delamination and evenbreakage, enables the dimension tolerance of the casting to reach HB6103 CT6 level, enables weight and volume deviation of the casting to be lower than or equal to 5%, and enables production cost ofthe casting to be greatly reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

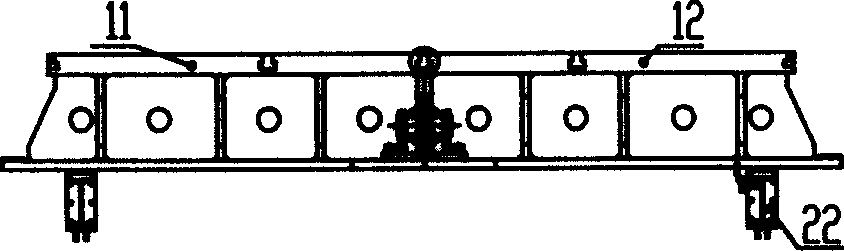

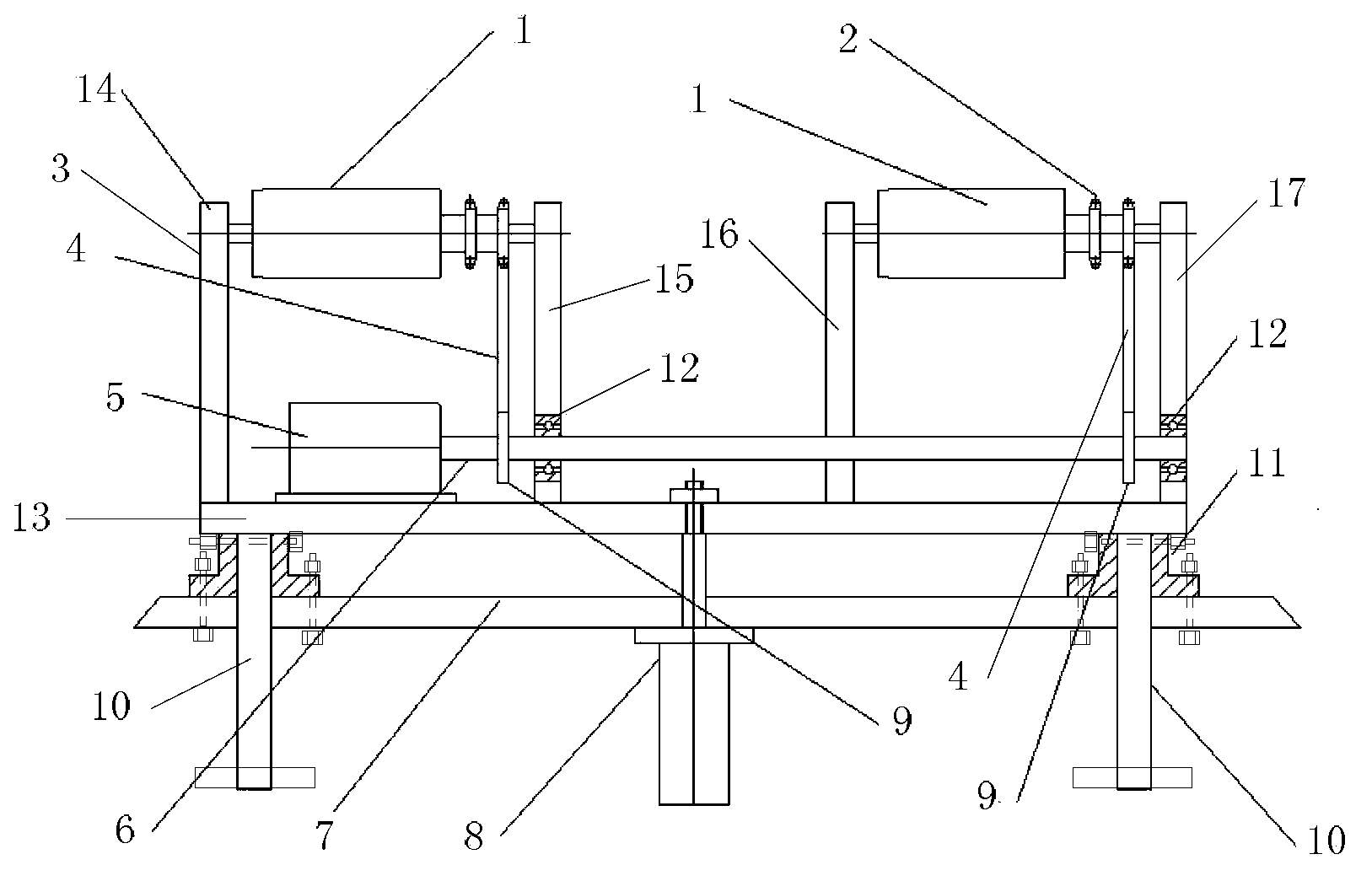

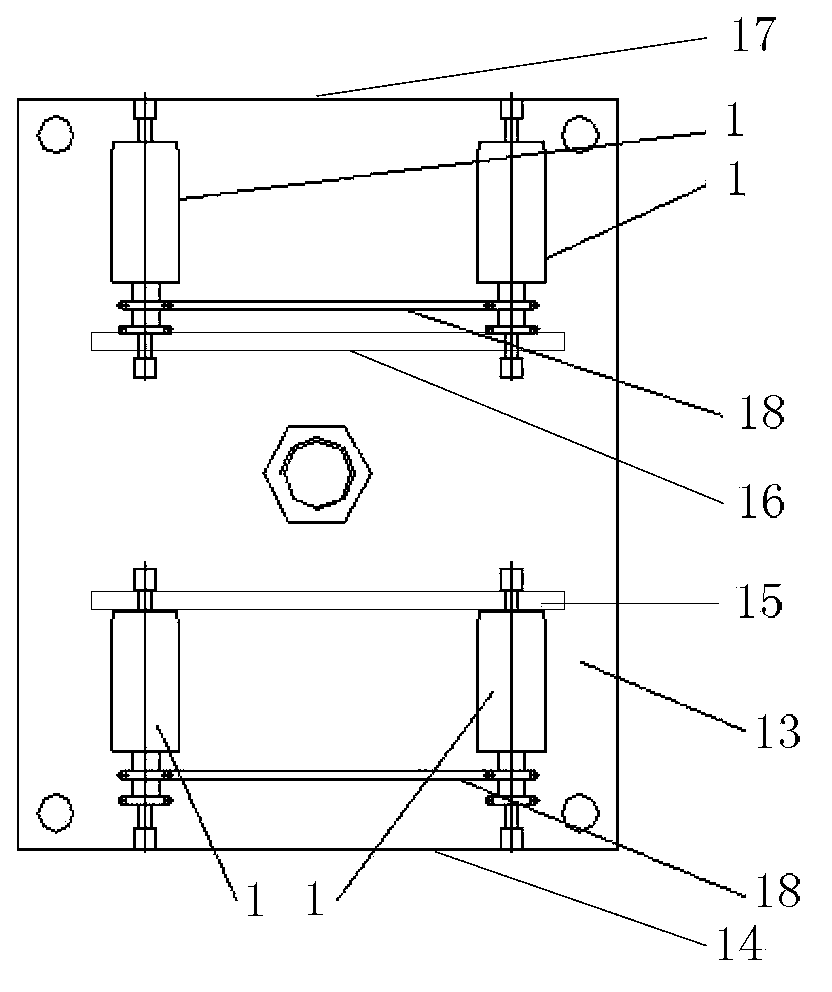

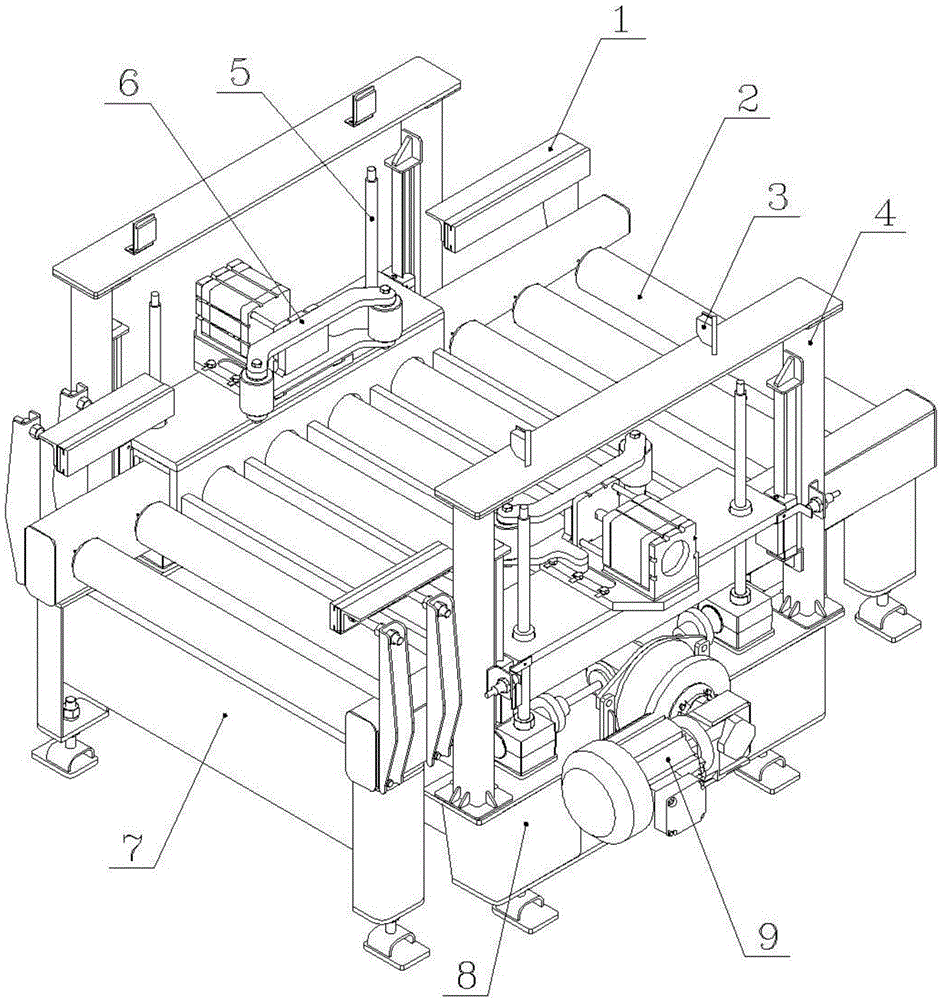

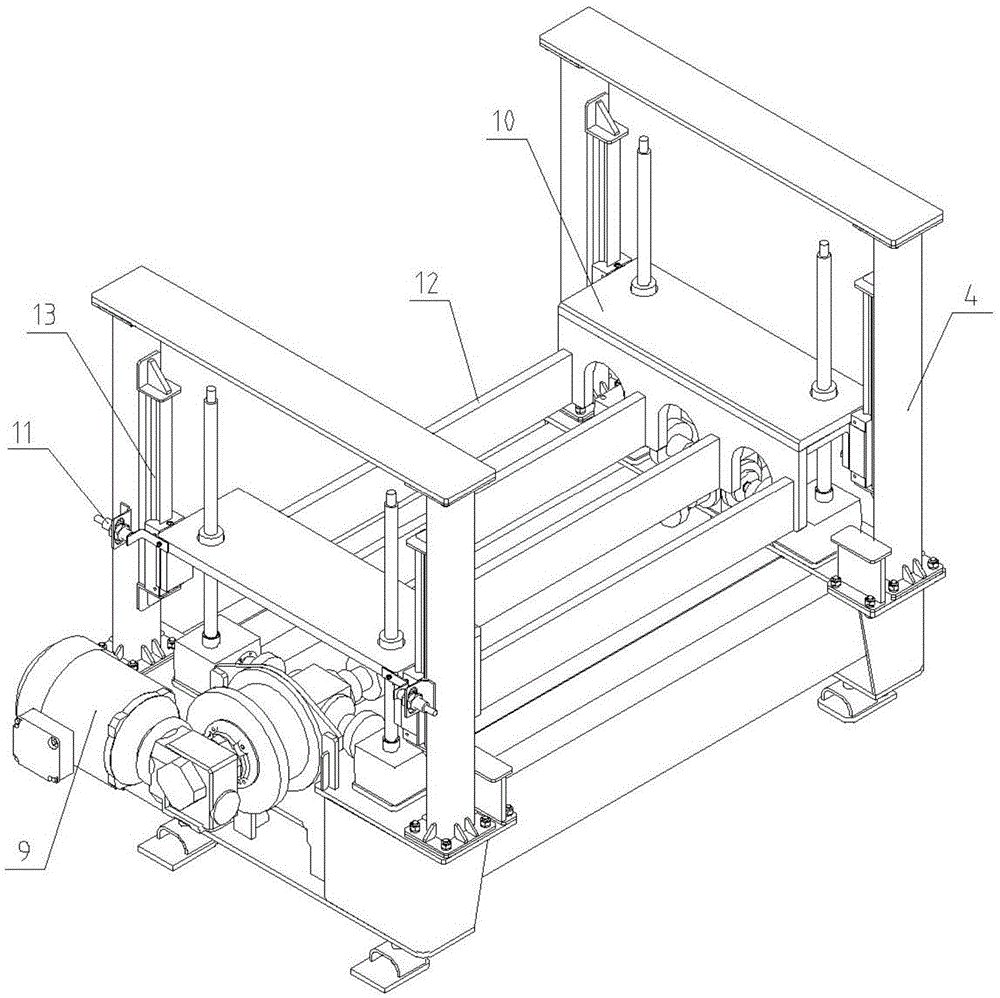

Lifting mechanism of lifting transverse moving device of large-area thin substrate

InactiveCN103832813ASimple structural designReasonable structural designConveyor partsDrive shaftEngineering

The invention discloses a lifting mechanism of a lifting transverse moving device of a large-area thin substrate. The lifting mechanism comprises a lifting machine frame, a roller conveying mechanism and a cylinder structure, wherein the lifting machine frame is composed of a lifting platform, a first support, a second support, a third support and a fourth support, the center of the lifting platform is provided with a through hole, the first support, the second support, the third support and the fourth support are arranged on the lifting platform and fixedly connected with the lifting platform, the four corners of the lower end of the lifting machine frame are provided with guide columns, and the guide columns are fixedly connected with a fixing machine frame through corners; the roller conveying mechanism comprises a small roller, a small motor installed on the lifting platform and a main transmission shaft connected with an output shaft of the small motor; the cylinder structure comprises a cylinder, and a piston rod of the cylinder is fixed to the lifting platform through a through hole in the fixing machine frame. The lifting mechanism is simple and reasonable in structural design, can effectively solve the lifting problem of the lifting transverse moving device of the large-area thin substrate and has wide application prospects.

Owner:XIAN DAYU PHOTOELECTRIC TECH

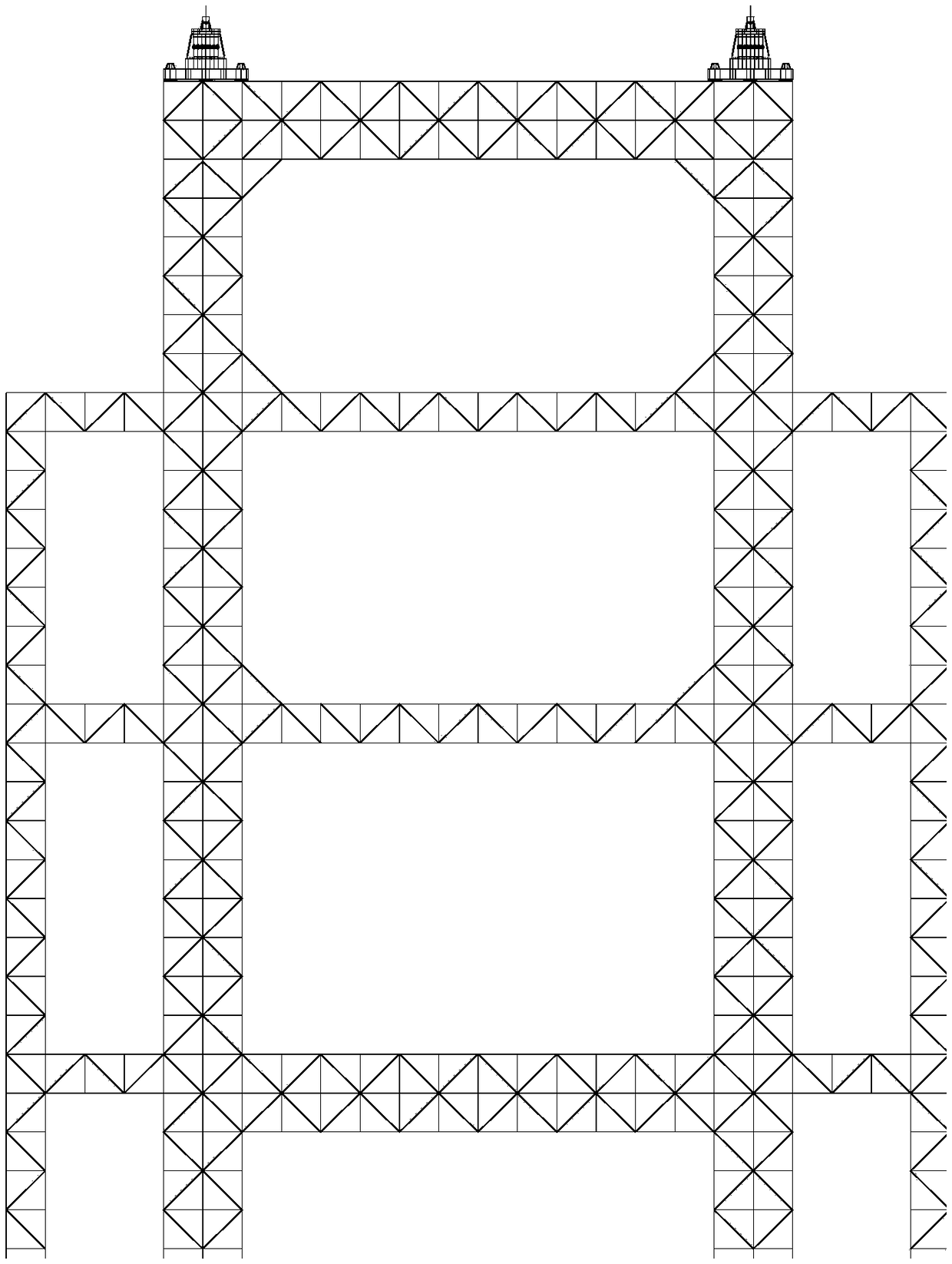

Construction method for suspended building structure

ActiveCN110616809AEnsure safetySatisfy the principle of forceFoundation engineeringGirdersStress conditionsVertical load

The invention discloses a construction method for a suspended building structure. The method comprises the following steps that S1, a peripheral core tube bearing platform foundation region is excavated, a peripheral core tube bearing platform foundation is constructed at the foundation region, and a vertical load-bearing structure is installed on the core tube bearing platform foundation; S2, a support jig is erected at a position, outside the core tube bearing platform foundation, of the foundation region; S3, a roof truss is installed above the support jig and the vertical load-bearing structure, and the support jig is removed after the roof truss is installed; and S4, a floor steel structure is installed below the roof truss from top to bottom in a layer-by-layer mode. According to themethod, construction is carried out by obeying the structure stress sequence, actual deformation and stress conditions of the suspended structure are convenient to obtain, the structure safety in theconstruction process is ensured, the construction flow and a hoisting process are optimized, a construction site is fully utilized, the construction cost is reduced, the construction efficiency is improved, moreover, the construction quality is ensured, and the method can be widely applied to construction of the suspended structure.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

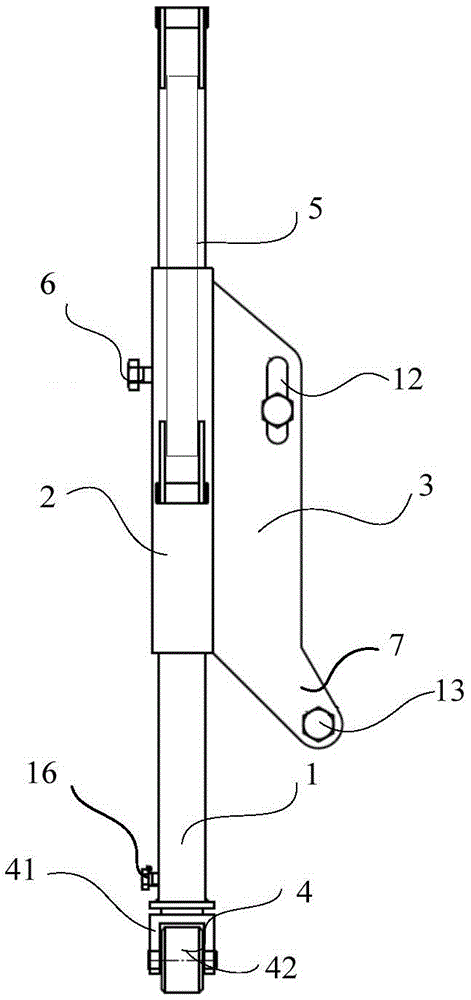

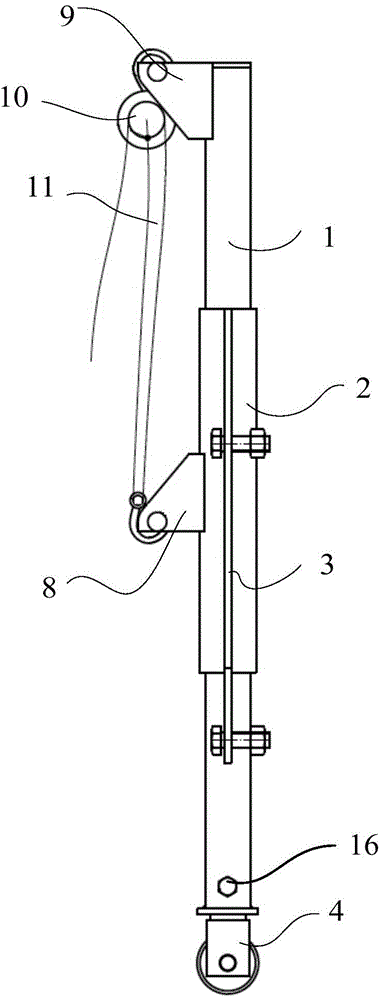

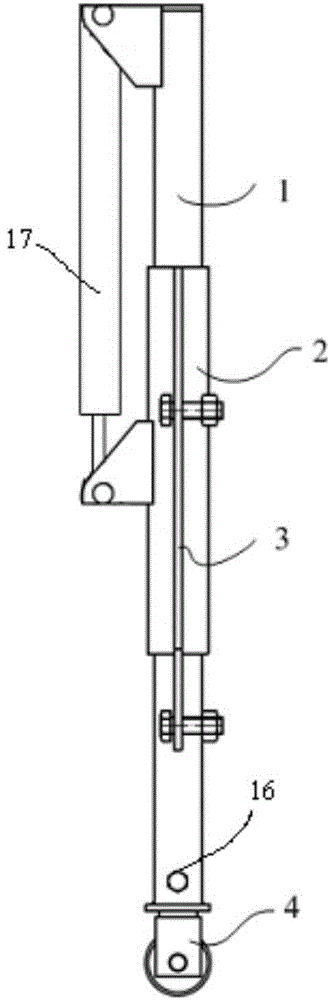

Mechanical equipment lifting frame and lifting method

The invention provides a mechanical equipment lifting frame and a lifting method. The mechanical equipment lifting frame comprises a stand column; a slide sleeve sleeves the stand column; the slide sleeve is fixedly provided with a connecting piece for connecting with mechanical equipment to be lifted; a roller device is arranged at the bottom end of the stand column; a driving device for driving the slide sleeve to axially move relative to the stand column is arranged between the slide sleeve and the stand column; and the slide sleeve is provided with a locking device for locking the slide sleeve. The mechanical equipment lifting frame, provided by the invention, is smaller in size, can adapt to narrow factory building space, is simple and flexible in operation, and can conveniently and quickly shift and lift the mechanical equipment.

Owner:PETROCHINA CO LTD

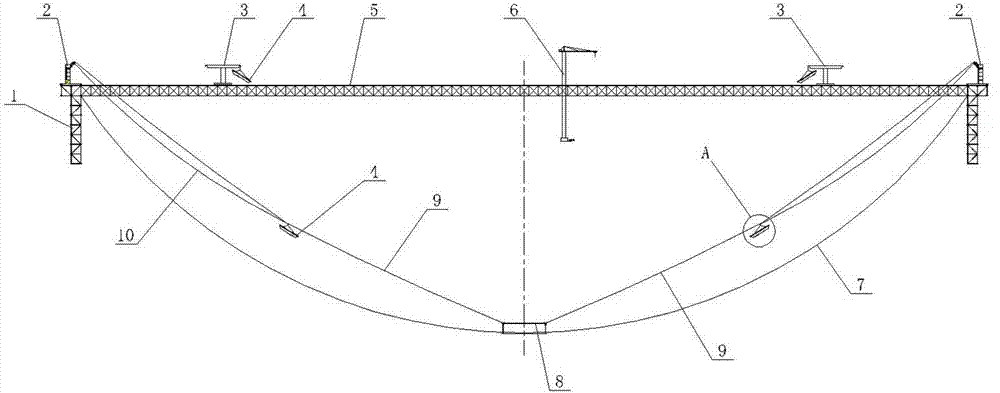

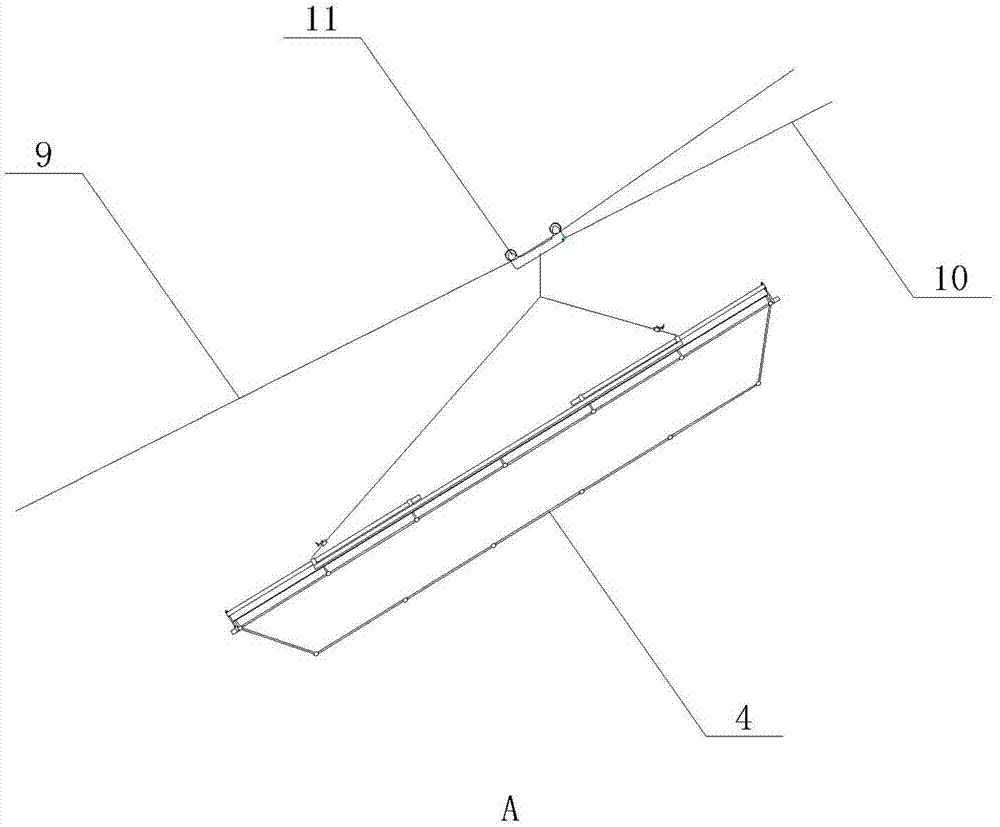

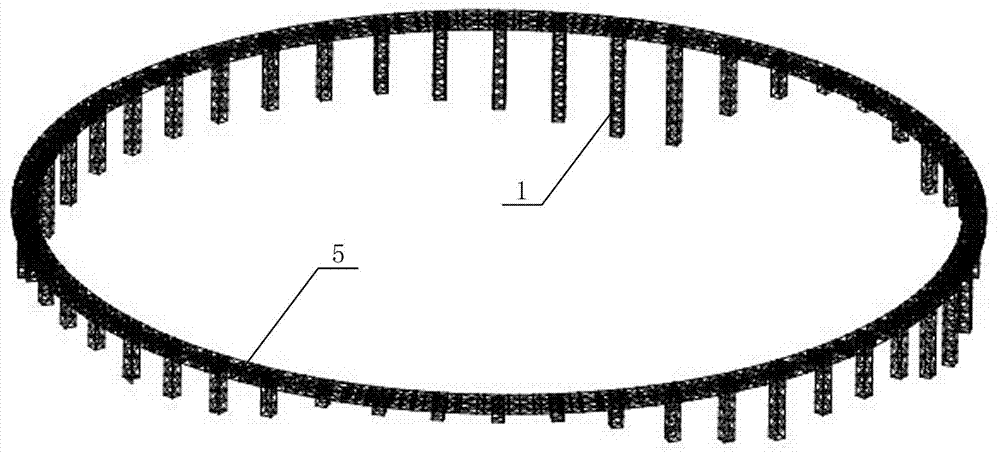

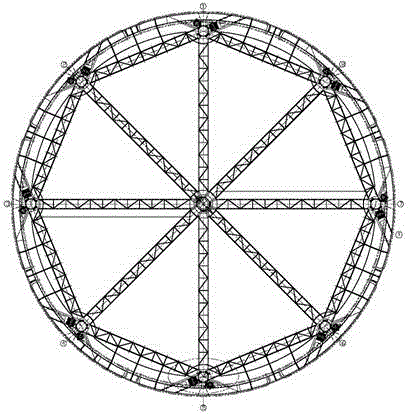

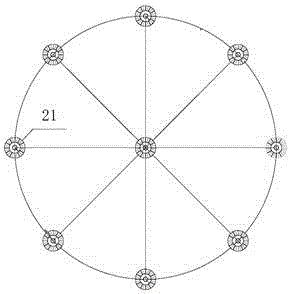

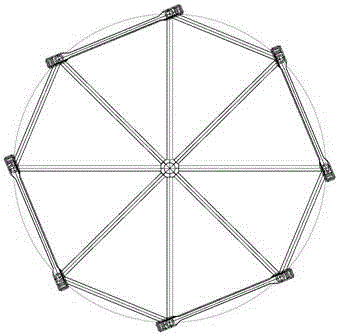

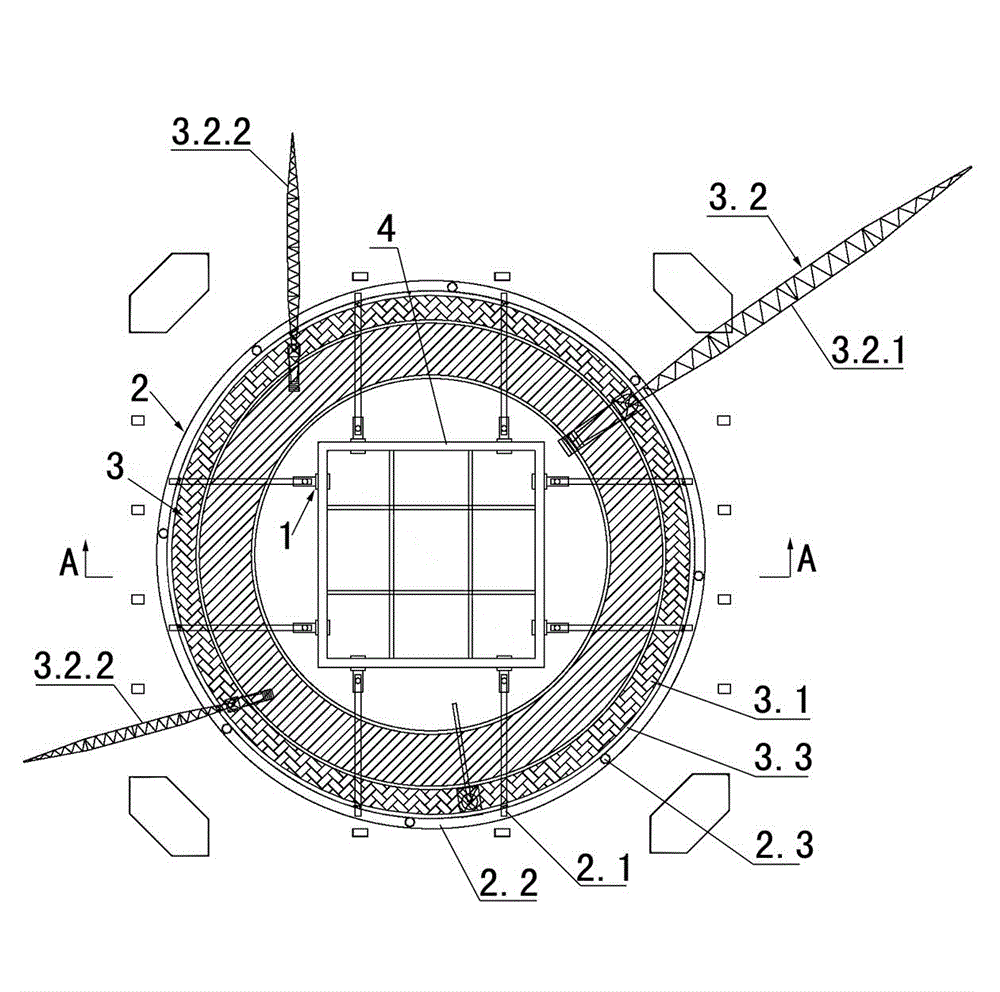

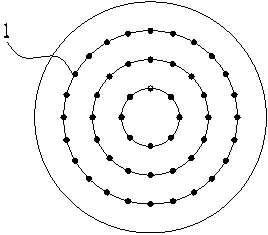

Hoisting device and method for FAST (five-hundred-meter aperture spherical radio telescope) reflection surface unit

InactiveCN104261255ALarge lifting volumeSolve lifting problemsLoad-engaging elementsRadio telescopeCable net

The invention discloses a device for hoisting a FAST (five-hundred-meter aperture spherical radio telescope) reflection surface unit. The device comprises a rail locomotive and an operation locomotive which operate on a ring beam, wherein a center ring beam is arranged at the center position of a radio telescope; a bearing rope is connected between the rail locomotive and the center ring beam; a bearing tackle capable of sliding along the bearing rope is arranged on the bearing rope; the operation locomotive transfers the reflection surface unit to the rail locomotive and suspends the reflection surface unit on the bearing tackle; a traction rope connected with the bearing tackle is arranged on the rail locomotive; under the traction of the traction rope, the reflection surface unit is hoisted and transported to a position above a corresponding mounting position of a main cable net; a winding mechanism for unloading the reflection surface unit to the corresponding mounting position of the main cable net is arranged on the bearing tackle; the connection end of the bearing rope to the center ring beam can slide along the center ring beam; the work is repeated, so that the hoisting transportation on all the mounting positions on the main cable net is realized.

Owner:NAT ASTRONOMICAL OBSERVATORIES CHINESE ACAD OF SCI

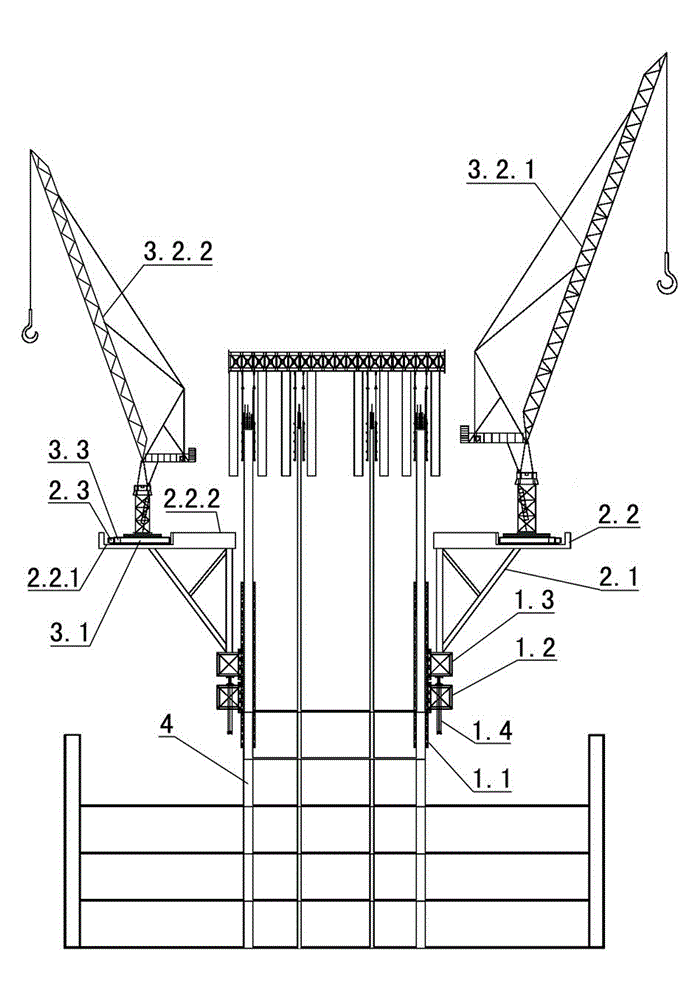

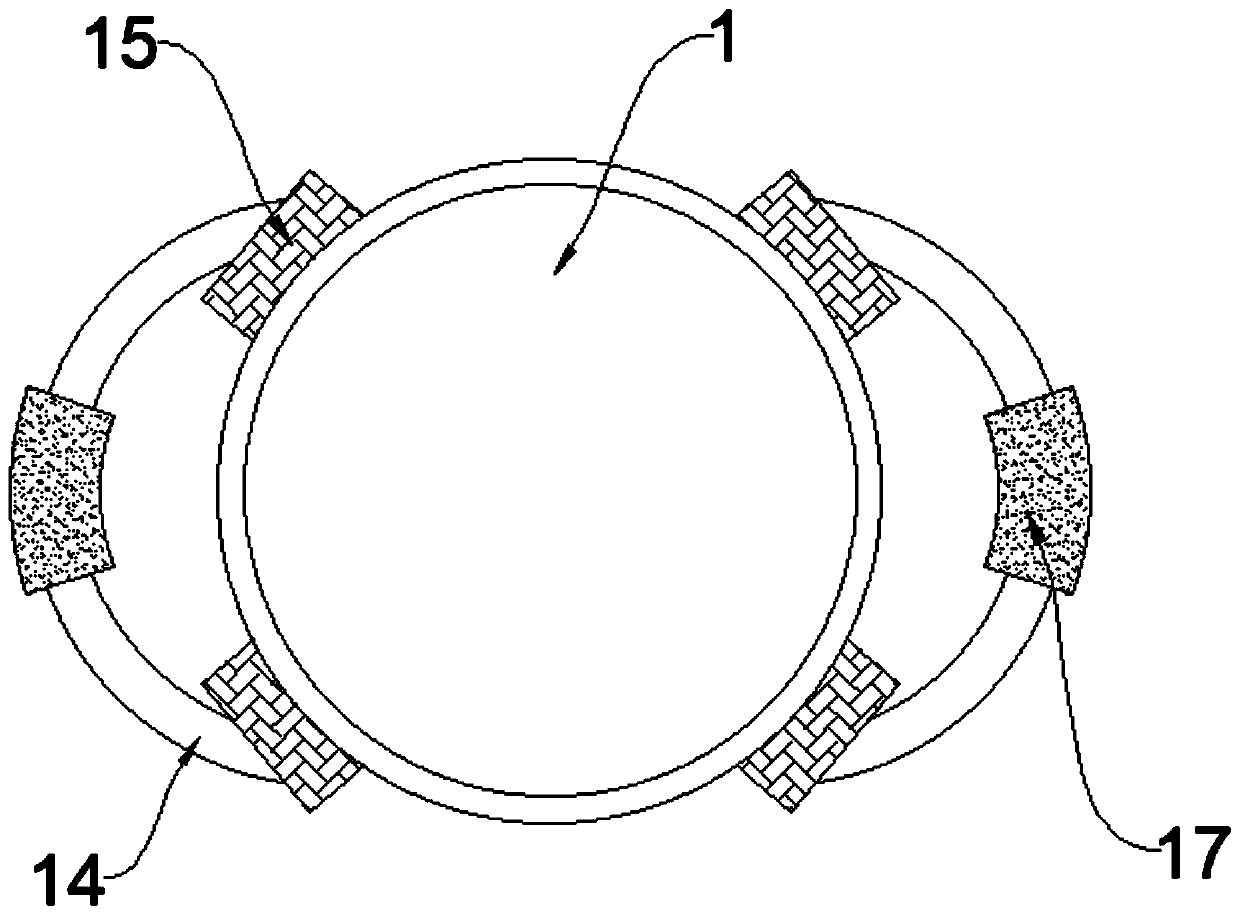

Method for 1/4 land territory preassembling and overwater dispersion of large cylinder main grids of cellular steel sheet piles

ActiveCN104060592AShorten the timeReduce on-site workloadArtificial islandsUnderwater structuresSheet pileBuilding construction

The invention discloses a method for 1 / 4 land territory preassembling and overwater dispersion of large cylinder main grids of cellular steel sheet piles. According to the method, for the large cylinder main grids of the cellular steel sheet piles with the diameters of 31.194m, a special crane ship is anchored on the inner side of an island wall, four 1 / 4 circular steel sheet pile assembling sheets are hoisted on the single side, a rotating mechanism is arranged on a supporting tool, the steel sheet pile assembling sheets on the outer side of the island wall respectively rotate to be in place, and thus integral-type assembling of the steel sheet piles of a grid body is completed. After the assembling of the steel sheet piles of the grid body is completed, vibration sink is carried out gradually in a layering mode by adopting a vibration hammer to the design elevation. The technology can complete the construction of causeways of grid steel sheet piles in the land territory formation process quickly with lower construction cost under the conditions of site operation that all directions are restricted.

Owner:CCCC THIRD HARBOR ENG +2

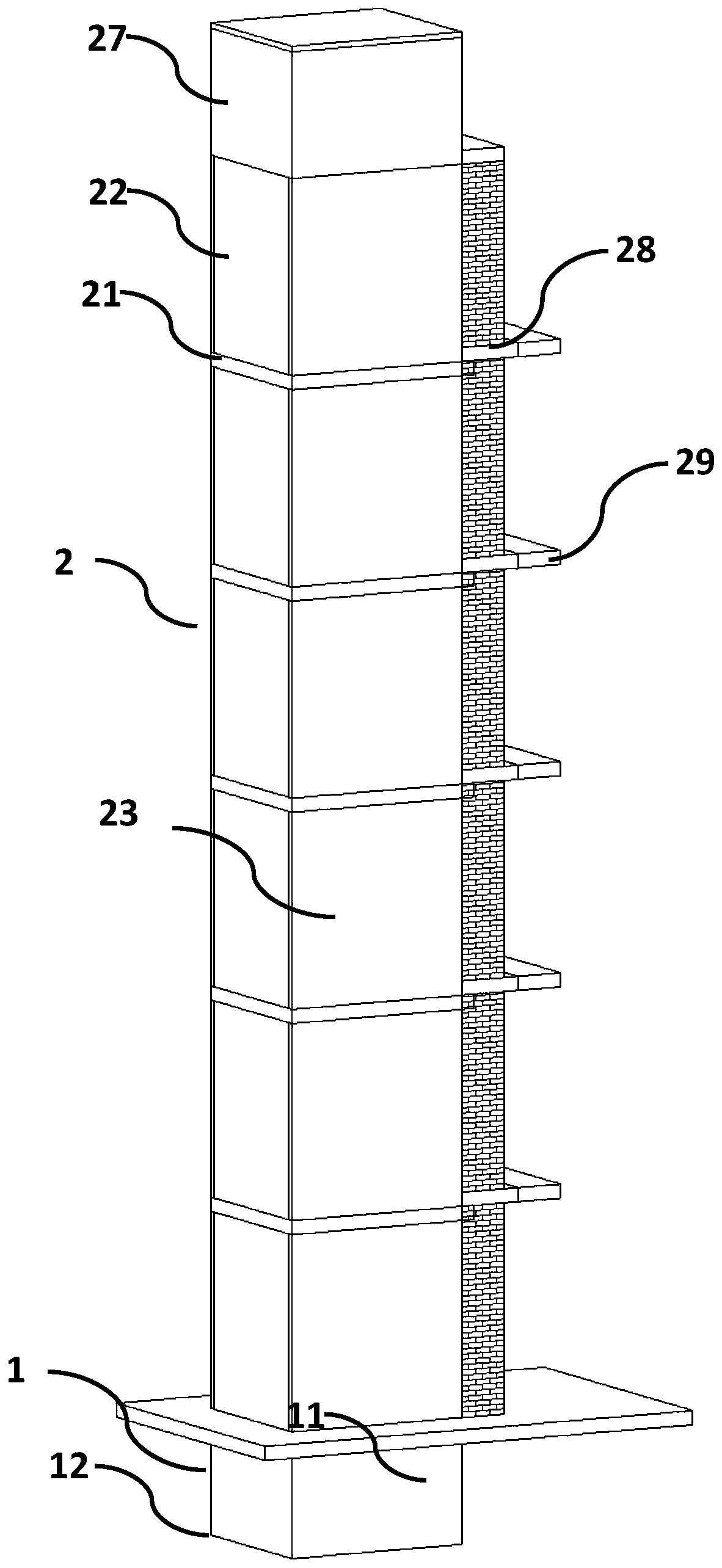

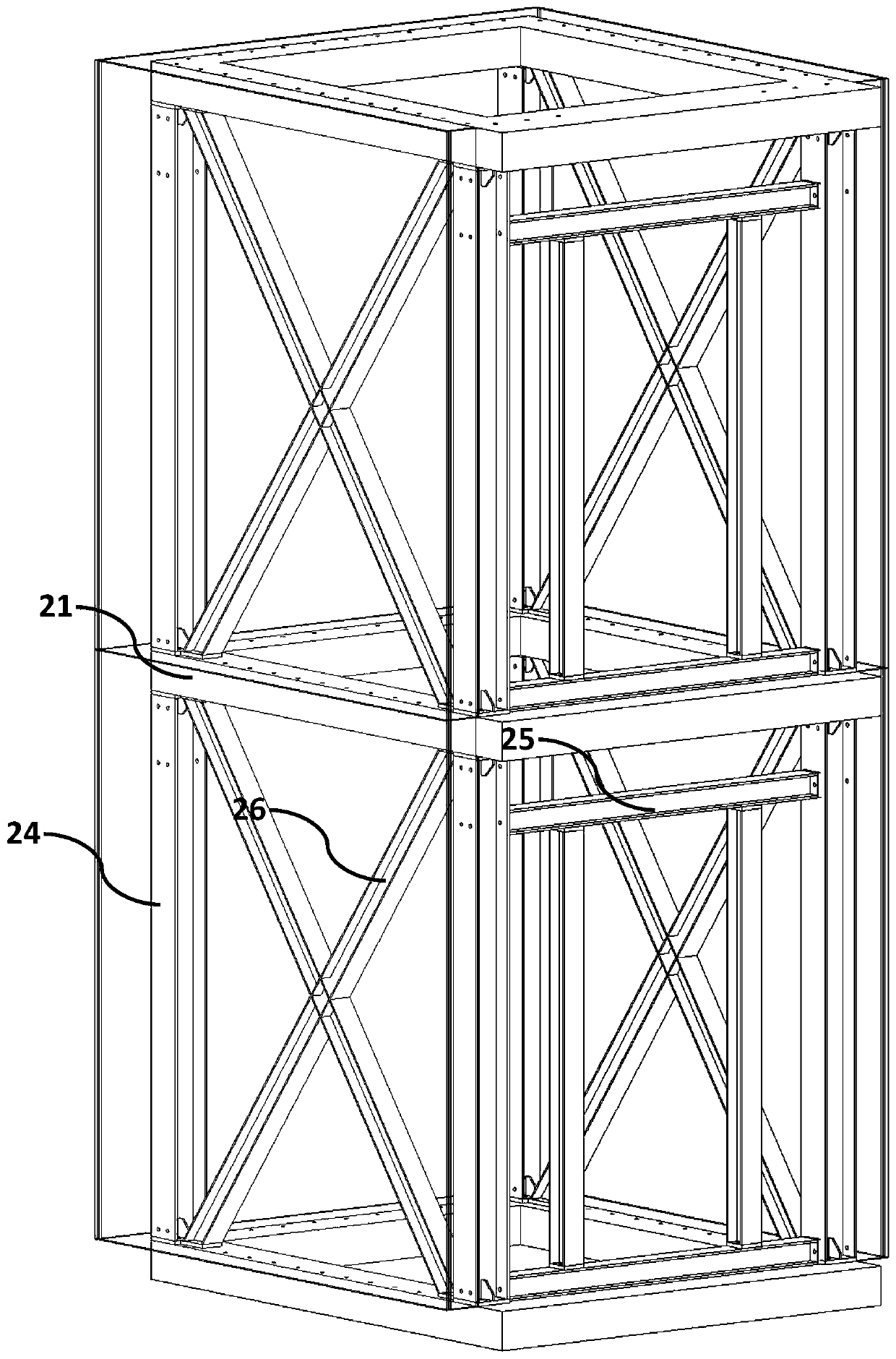

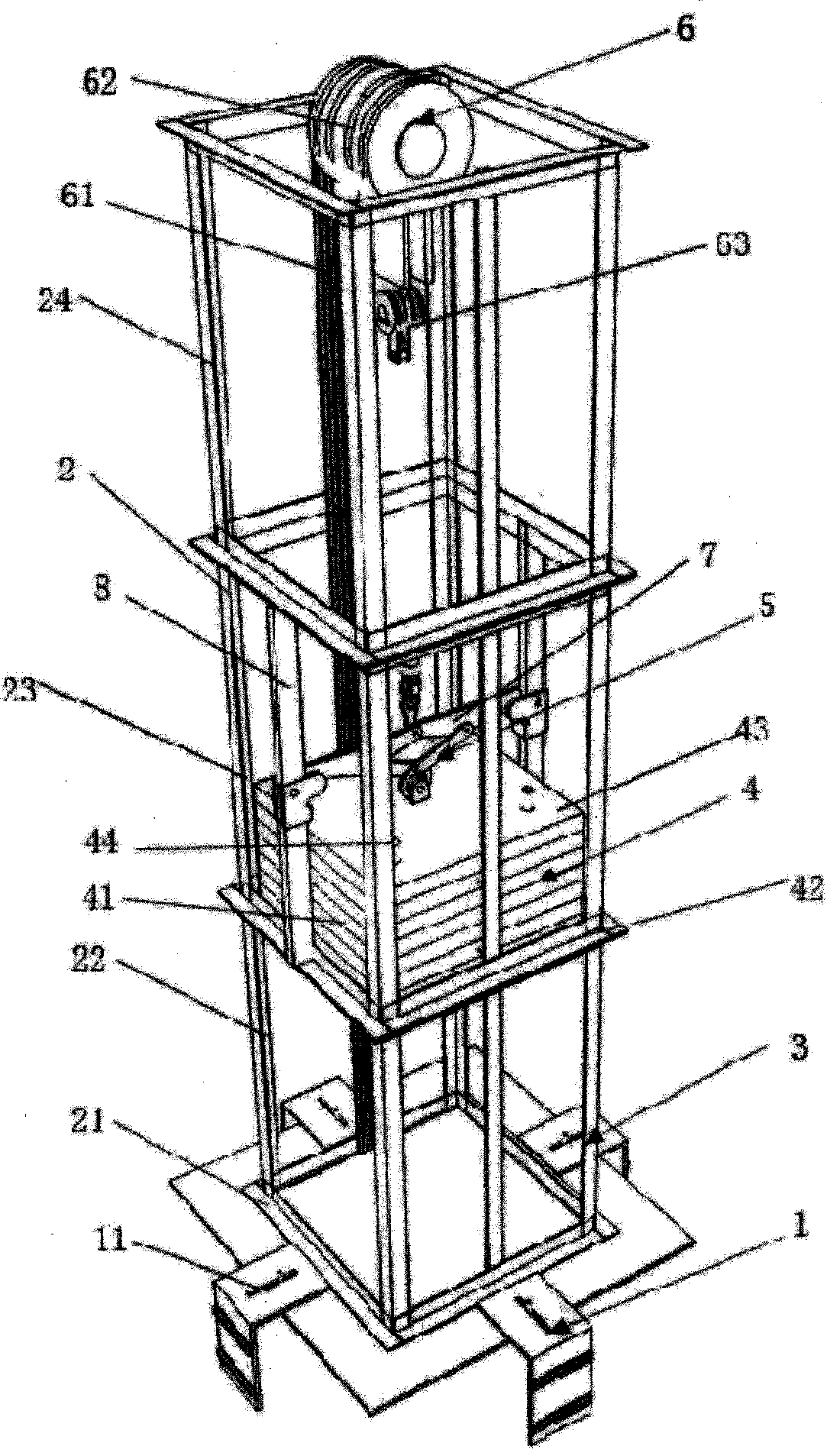

Fully-assembled well of existing building loading elevator and mounting method thereof

PendingCN110182671AReduce construction costsEliminate emissionsBuilding repairsBuilding liftsReinforced concreteRebar

The invention discloses a fully-assembled well of an existing building loading elevator and a mounting method thereof, and the fully-assembled well is divided into an underground structure and an overground structure. The underground structure is of a prefabricated reinforced concrete structure, and is a cover-free box type structure; the overground structure assembly standard component is dividedinto two types of a prefabricated reinforced concrete standard component and a steel standard component; the prefabricated reinforced concrete standard component is composed of an annular ring beam,a rectangular plate and an L-shaped plate, wherein the assembling of the reinforced concrete member is mechanically connected with bolt connecting bolts; the steel standard component is composed of three standard components of a beam, a column and a connecting piece which are assembled and connected through bolts; the steel component is connected with the prefabricated reinforced concrete throughpre-buried nuts, the overground structure is connected with the underground structure through mechanical connecting pieces; the prefabricated concrete wallboard is embedded with connecting pieces forinstalling outer decorative plates. According to the fully-assembled well of existing building loading elevator and the mounting method, the construction cost is saved, and the working efficiency is improved.

Owner:王琪

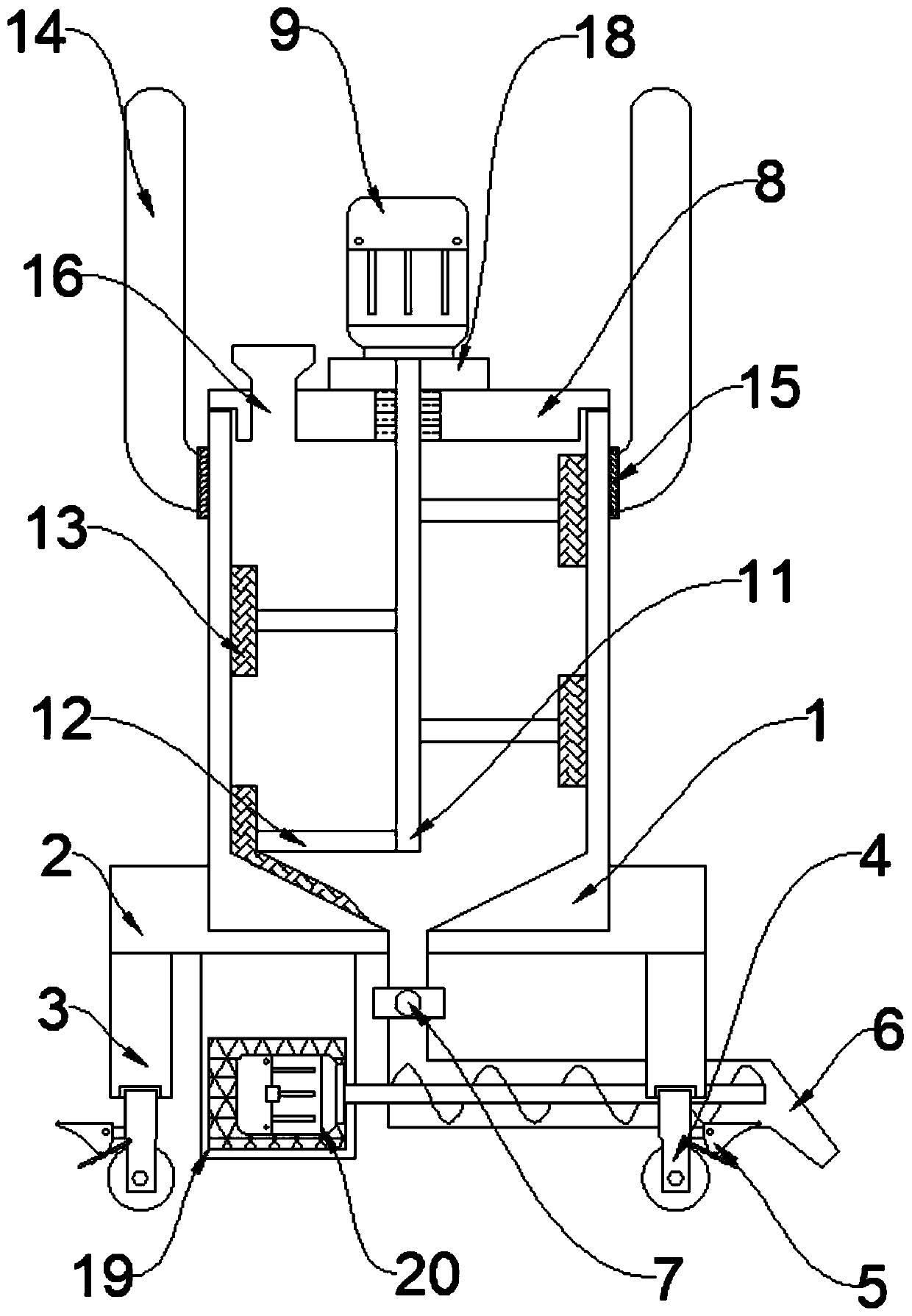

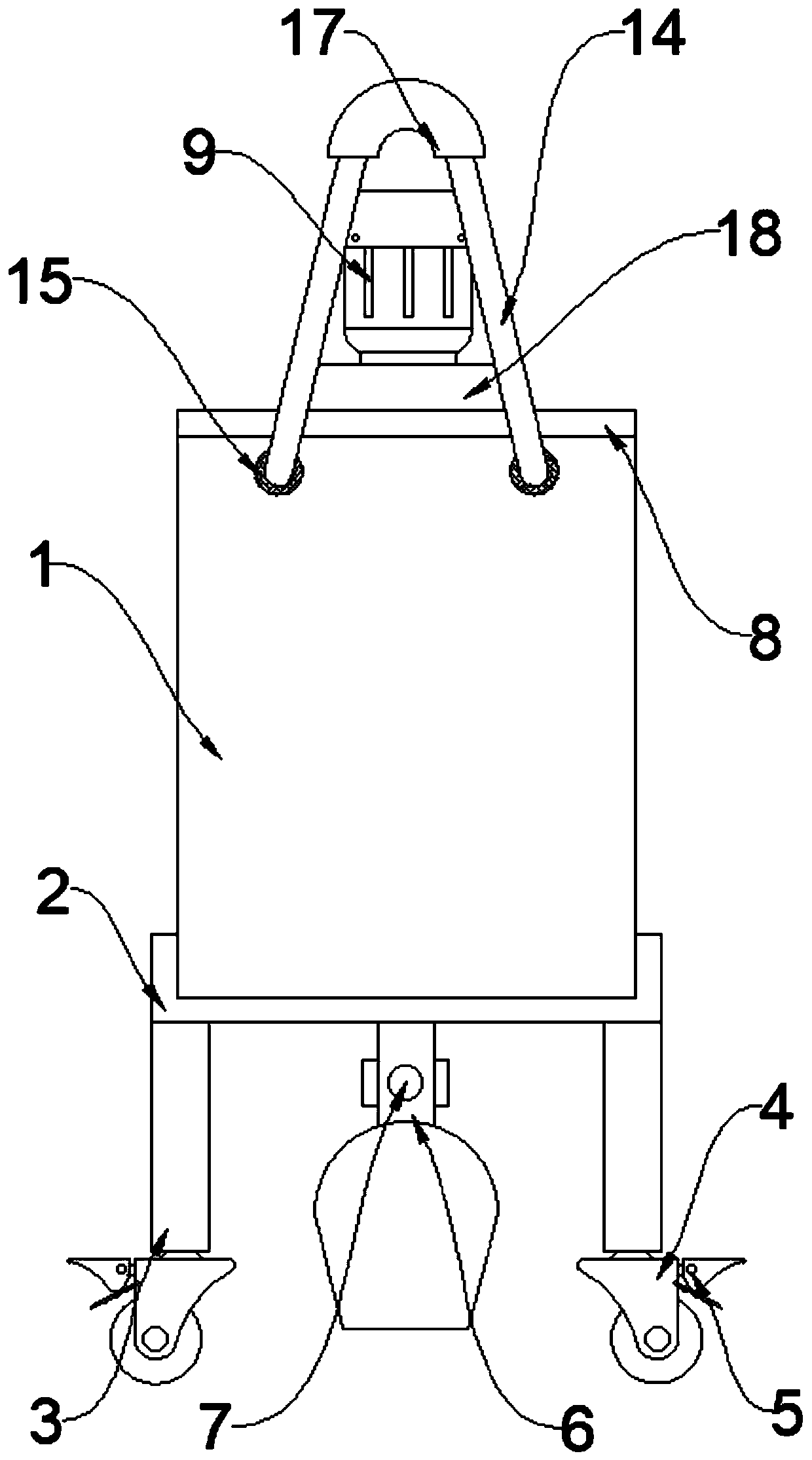

Jacking device

The invention relates to lifting equipment and provides a jacking device used for solving the lifting problem of a waste barrel in the cement solidification line. The jacking device comprises a base and a bracket. The two sides of the base are each provided with two stand columns. Each stand column is provided with a vertical guide rail. The base is further provided with a motor. Lead screws are arranged on the two sides of the base and can achieve linkage under the drive of the motor. The bracket is arranged above the base. The bottom of the bracket is composed of a set of parallel joists. Under the drive of the lead screws, the bracket can move up and down in the vertical direction along the guide rails arranged on the stand columns. The two sides of the bracket are further provided with a waste barrel clamping device and a photoelectric detection device. According to the jacking device, precision positioning and stable jacking of the waste barrel can be achieved, the waste barrel can be precisely matched with a feeding device after being jacked, the jacking device and a waste barrel conveying roll gang have the good suitability, and the lifting problem of the waste barrel in the cement solidification line is solved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

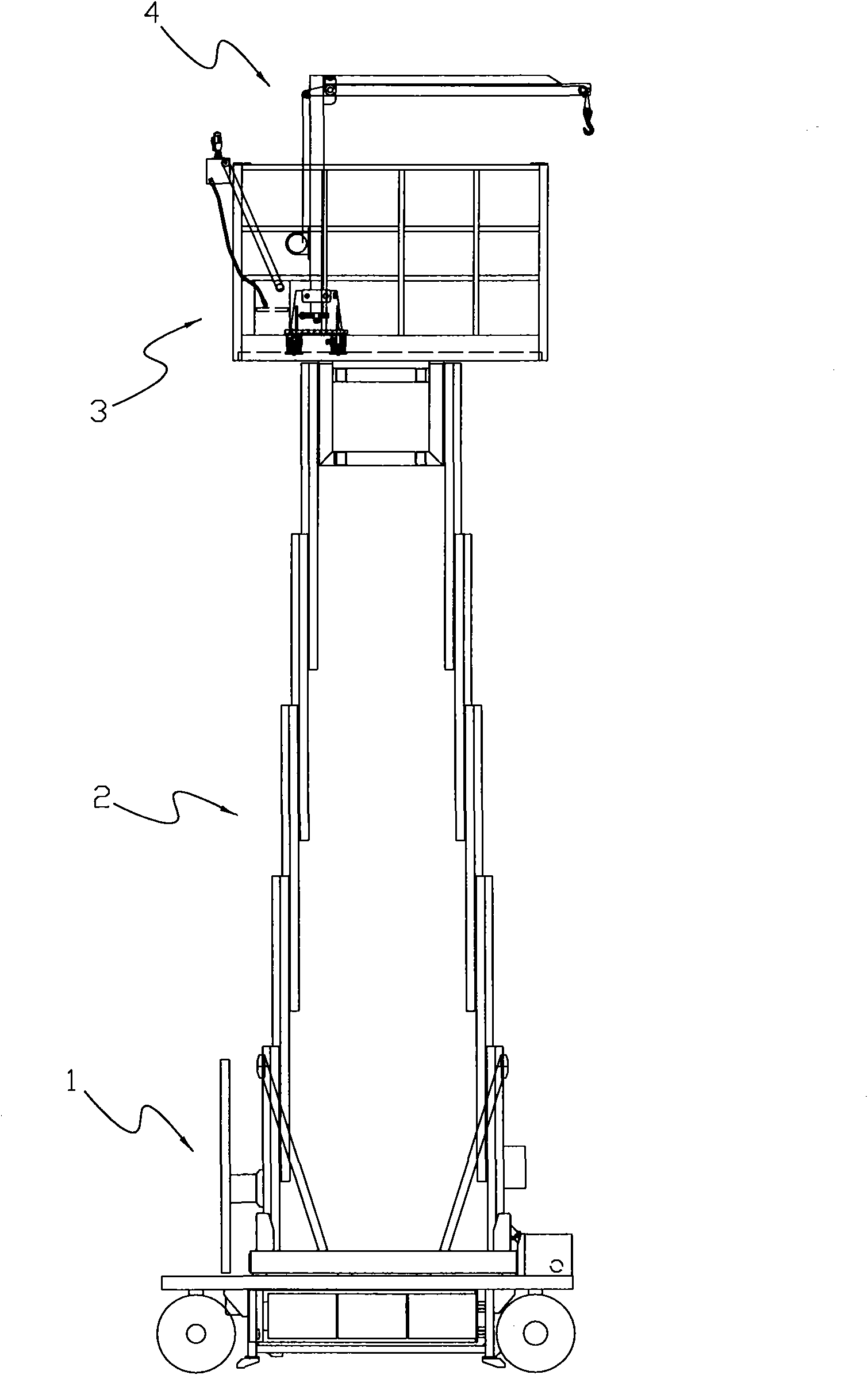

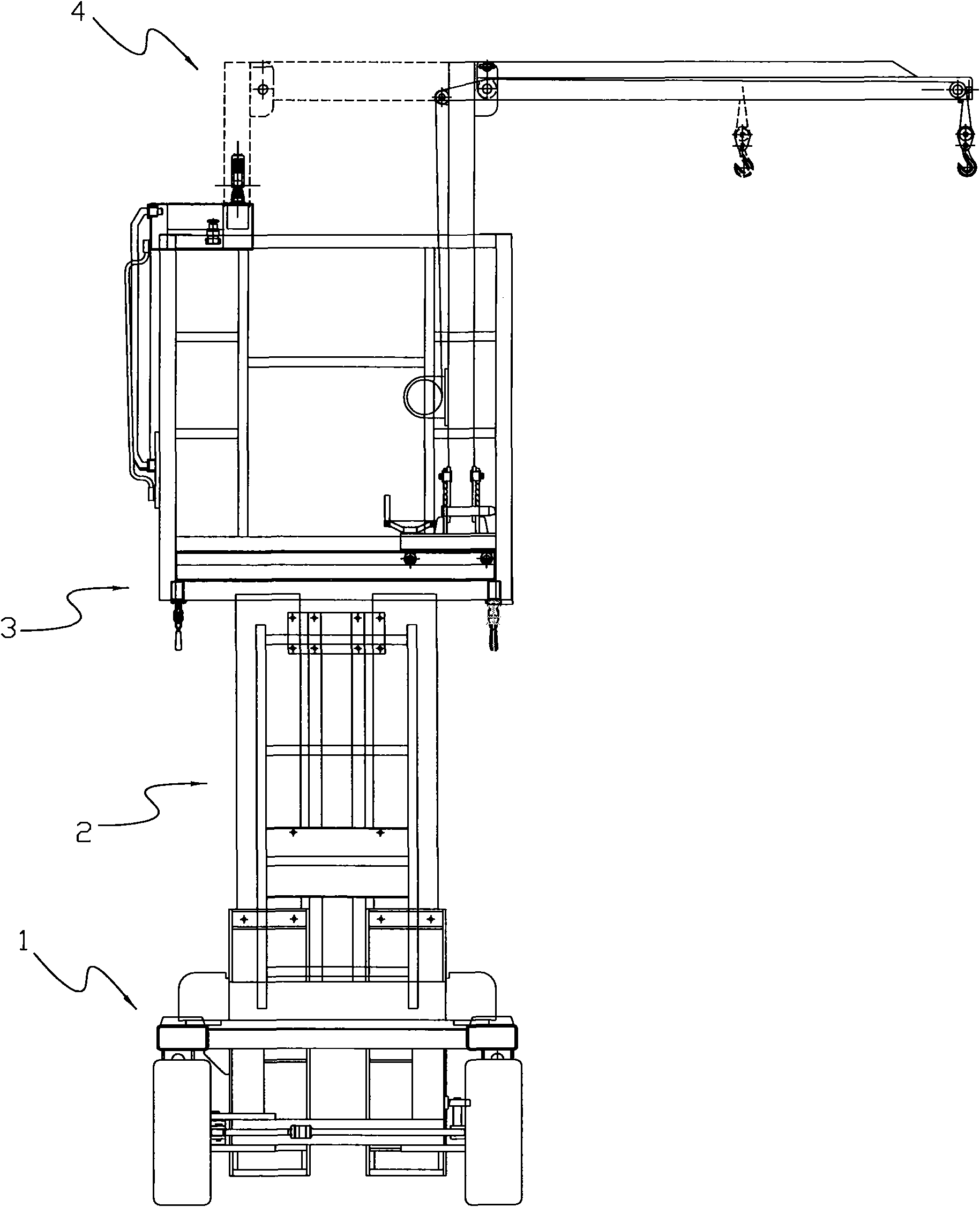

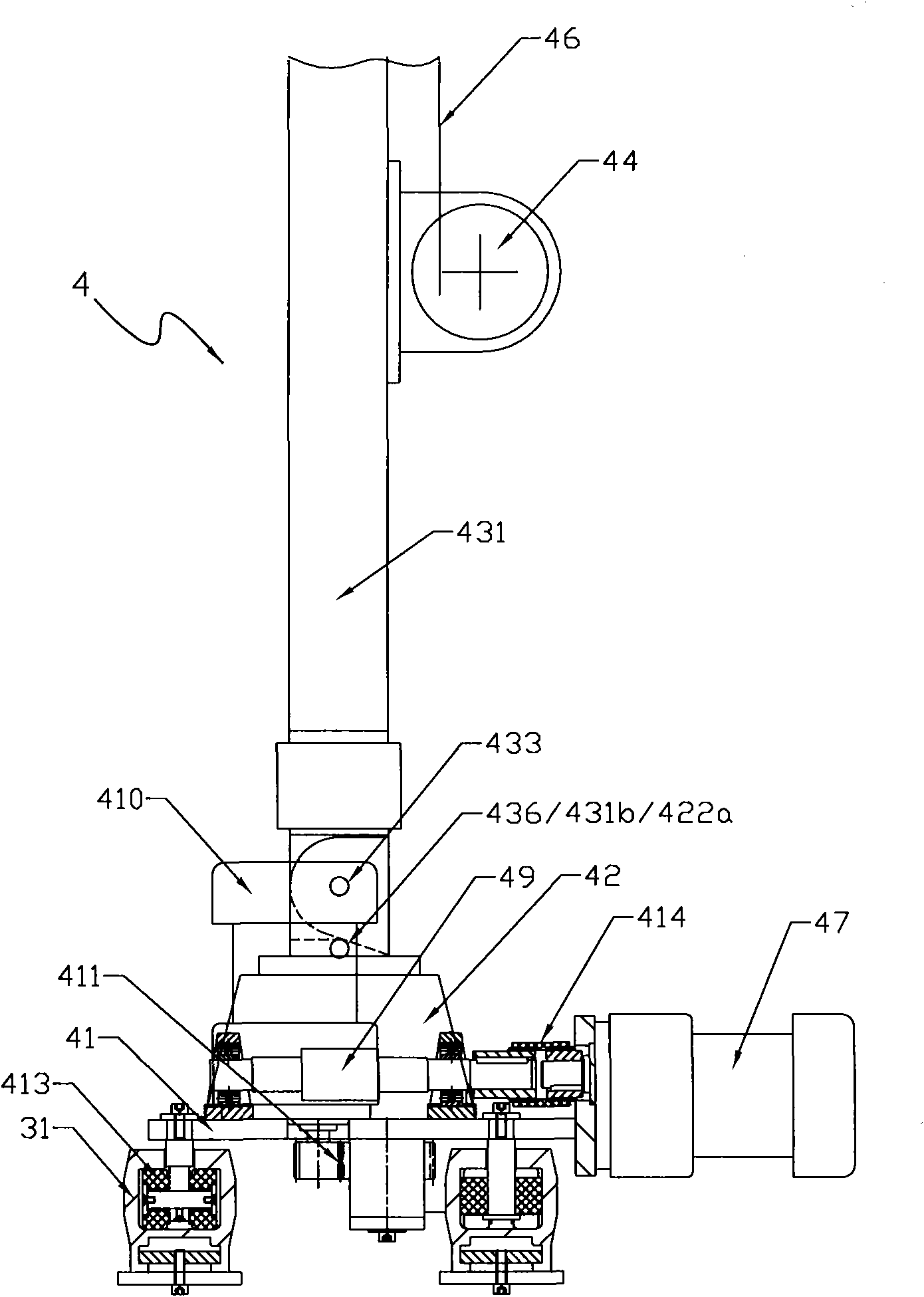

Lifting working platform with lifting device

ActiveCN101537998AImprove convenienceImprove efficiencyLifting devicesCranesSpecial occasionIndustrial engineering

The invention relates to a lifting working platform with a lifting device, which belongs to an aloft work device. A lifting working platform in the prior art has the defect of inconvenient article lifting. The lifting working platform with the lifting device is characterized in that: the lifting device arranged on the working platform comprises a base, a rotary support, a foldable jib, an electric block, a hook and a drag rope; the working platform is provided with a track on which the base is arranged; the rotary support is connected with the base and is provided with a rotating shaft; one end of the foldable jib is connected with the rotating shaft; the drag rope is arranged along the foldable jib; and one end of the drag rope is wound around the electric block, while the other end is led to the other end of the foldable jib and connects the hook with the drag rope. The lifting working platform with the lifting device can transport aloft operation staff to an assigned altitude position and can simultaneously lift the article through the lifting device, thereby enlarging the application of the product, solving the problem of small workpiece lifting for special aloft work, and effectively improving the operating convenience and efficiency.

Owner:HANGZHOU SAIQI MACHINERY CO LTD

Rotating multi-crane integrated operation platform with integral automatic lifting function

A rotating multi-crane integrated operation platform with an integrated automatic lifting function comprises a wall-climbing automatic lifting system arranged on a core tube shear wall, an annular bracket surrounding the periphery of the core tube shear wall and connected on the wall-climbing automatic lifting system, and an annular rotating platform surrounding the periphery of the core tube shear wall and supported on the annular bracket, wherein the annular bracket includes a support truss group, an annular support platform and a driving system; the annular rotating platform includes an annular base, cranes, and a driven system; and the cranes include a large boom-type tower crane and at least one small-medium crane. The operation platform provided by the invention optimizes the crane configuration in construction of super high-rise buildings, reduces the number of the large boom-type tower crane, and reduces the cost of vertical transportation equipment.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

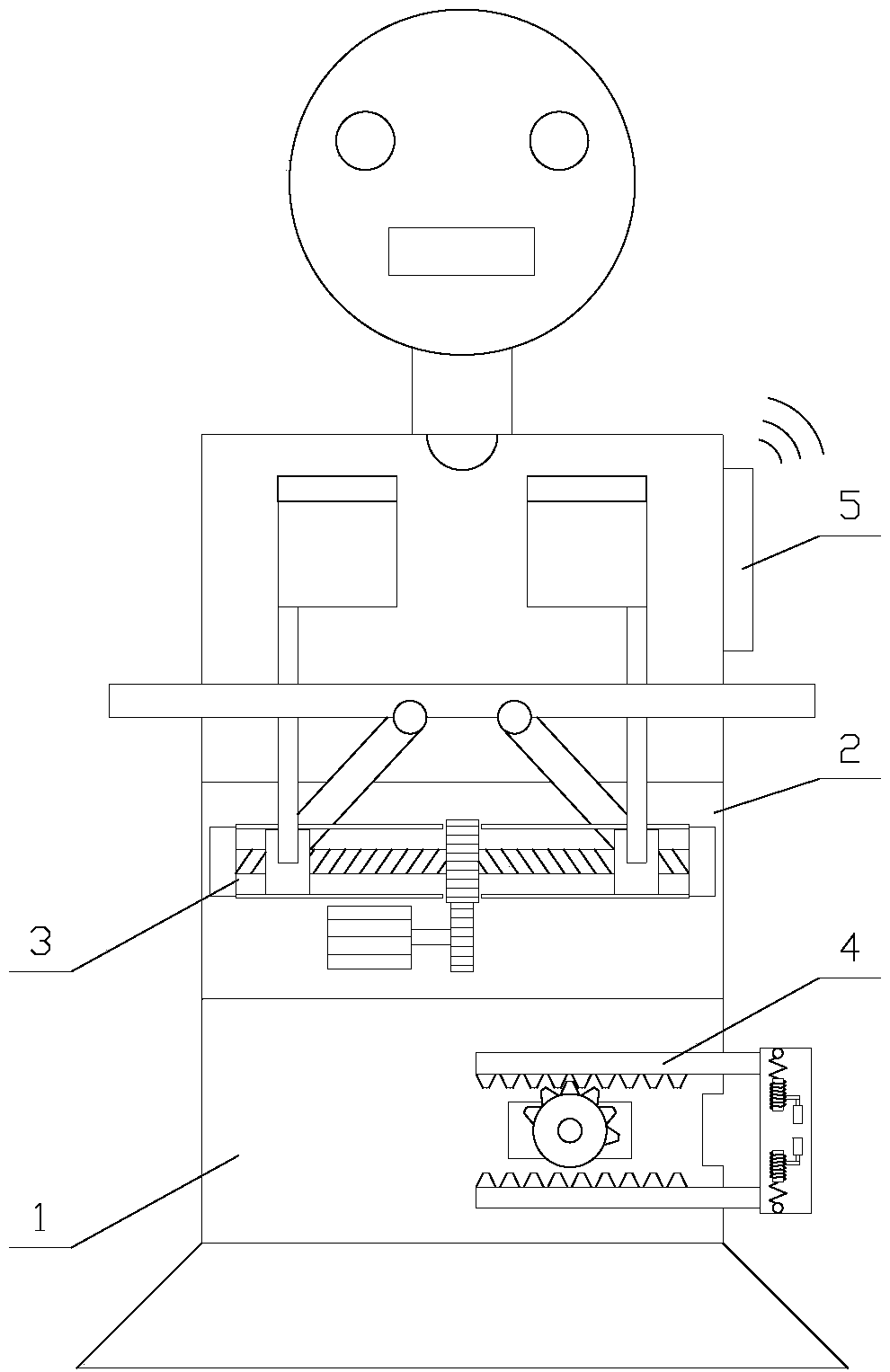

Food delivery robot with high safety factor based on Internet of Things

ActiveCN107618041ASave power costPrevent mosquito bitesTable equipmentsManipulatorFire hazardInternet of Things

The invention relates to a food delivery robot with a high safety factor based on Internet of Things. The food delivery robot comprises a main body, a shell, a food delivery mechanism, a charging mechanism and a central control mechanism. The food delivery mechanism comprises a lifting component and a protection component, and the charging mechanism comprises a reciprocating component and a fastening component. In the food delivery robot with the high safety factor based on the Internet of Things, support plates are lifted through the food delivery mechanism, so that food is prevented from being stolen by children; through a confined space formed, heat preservation and refreshment can be kept, and through the charging mechanism, a charging plug can be fastened during charging, so that theplug is prevented from loosening in the charging process, resulting in poor contact; upon completion of charging, the charging plug can be disconnected, and the condition that the service life of batteries is affected since the robot is charged all the time and is in the charging state for a long time is avoided, and the possibility that fire hazards occur is reduced; and through these mechanisms,the practicability and reliability of the robot are improved.

Owner:广东新又好集团有限公司

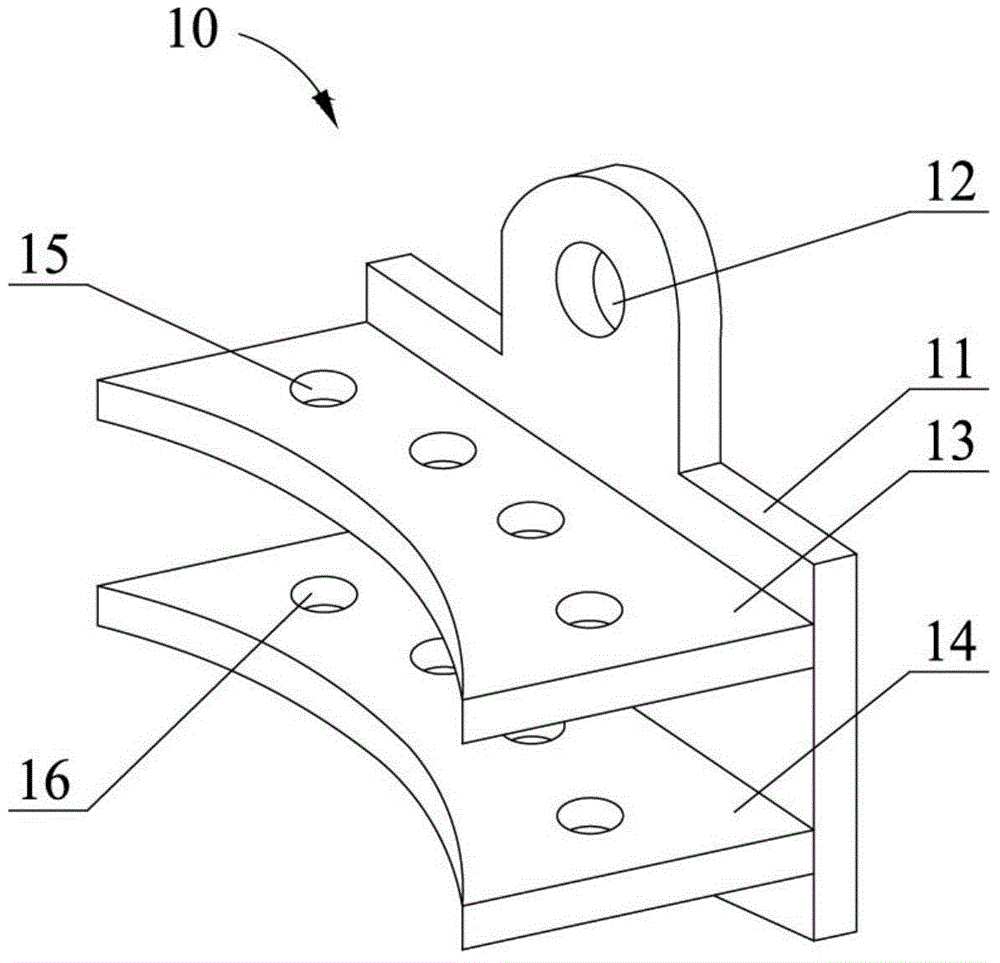

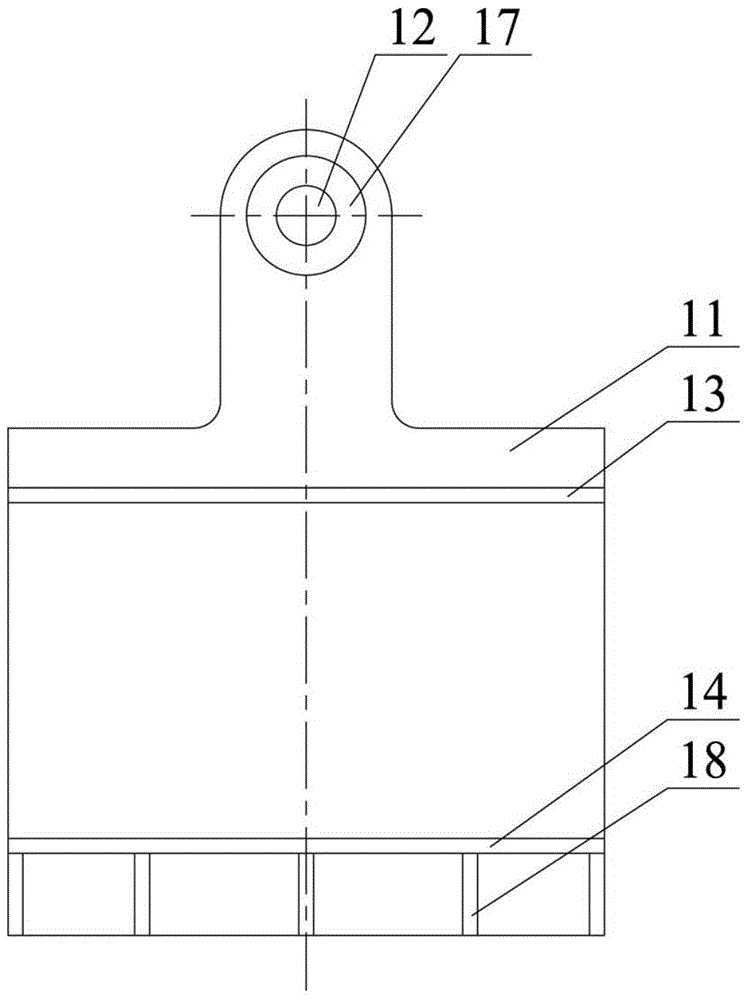

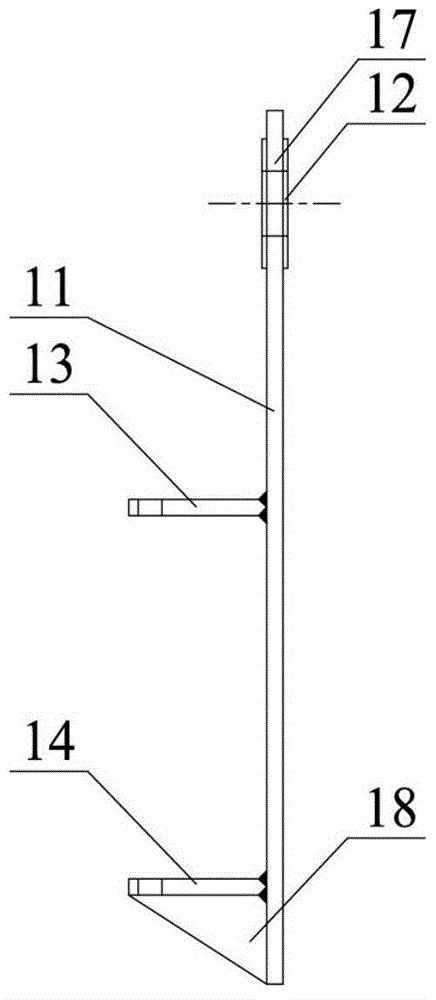

Lifting lug and using method thereof

InactiveCN104444758AWon't breakSolve lifting problemsLoad-engaging elementsIndustrial engineeringFlange

The invention discloses a lifting lug and a using method thereof, relating to the technical field of lifting cranes, and aiming at solving the problems that an existing fixed type lifting lug is welded together with an equipment body fixedly, and cannot be detached, so that the equipment manufacturing cost is increased, and the technology is relatively complex. The lifting lug comprises a lifting lug plate, two clamping plates and at least one pair of bolt holes, wherein one end of the lifting lug plate is provided with a lifting hole; the two clamping plates are arranged in parallel and are respectively fixedly connected with the lifting lug plate; a cover flange of chemical engineering equipment can be embedded between the two clamping plates; the two clamping plates are provided with at least one pair of corresponding bolt holes, and axes of the bolt holes of the two clamping plates are coincided with a bolt hole in the cover flange, so that the lifting lug and the cover flange can be connected together in a bolt mode.

Owner:SHANGHAI INSTALLATION ENG GRP

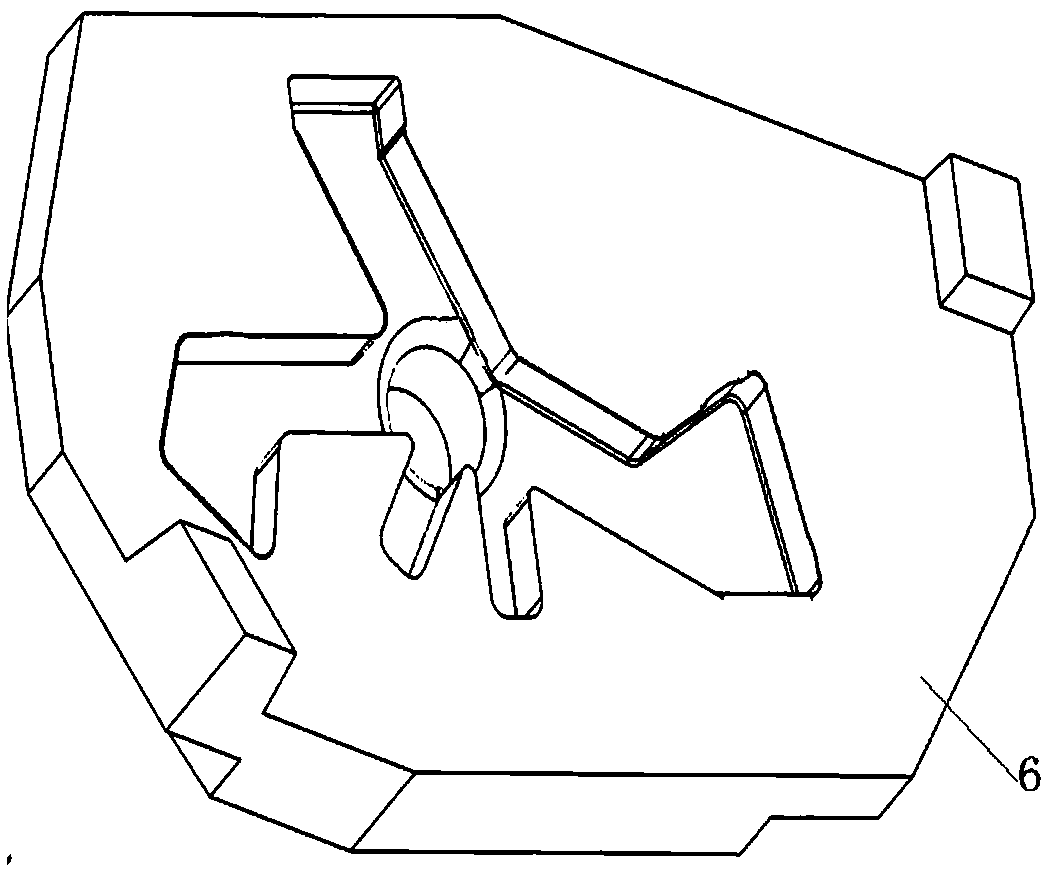

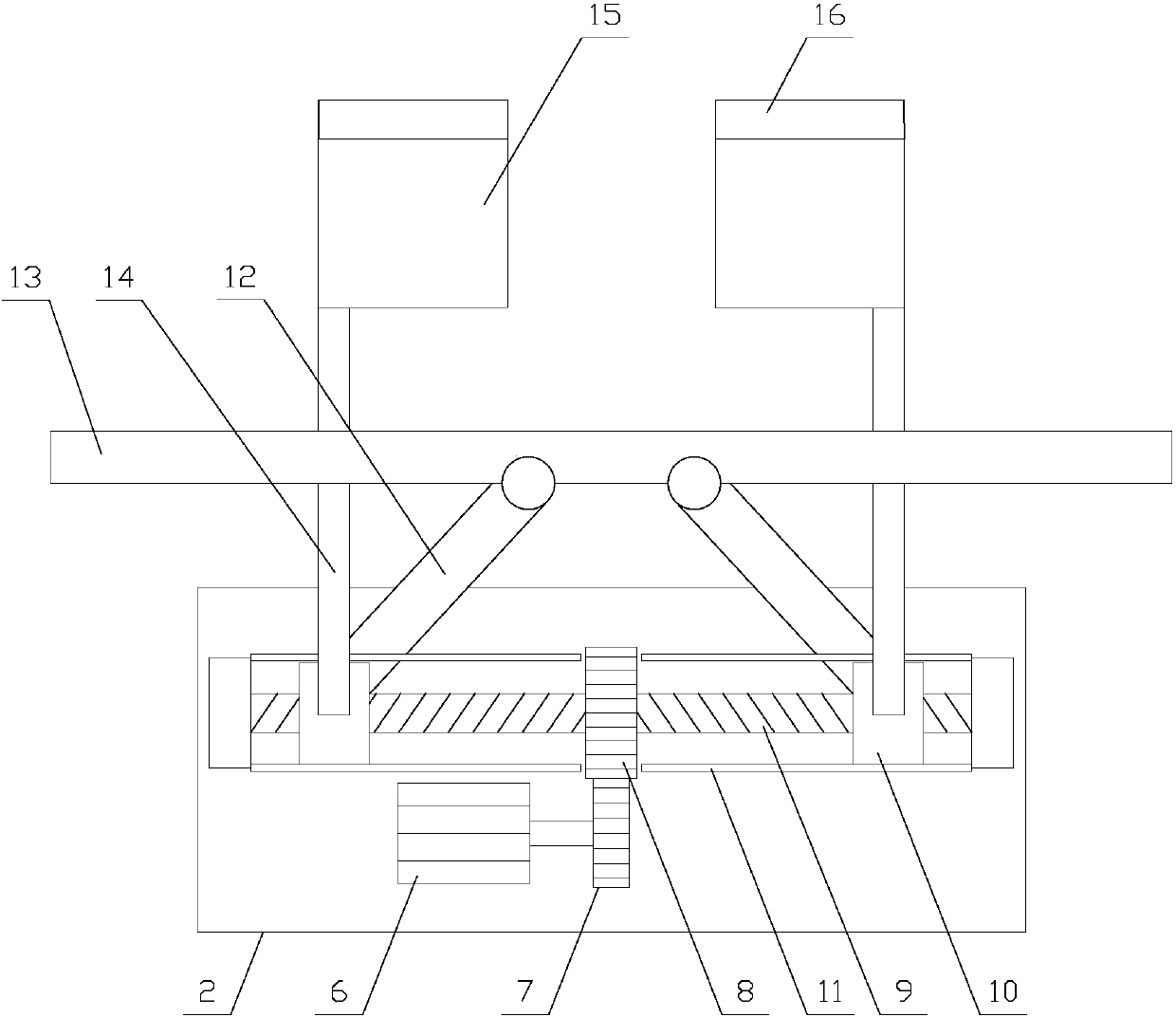

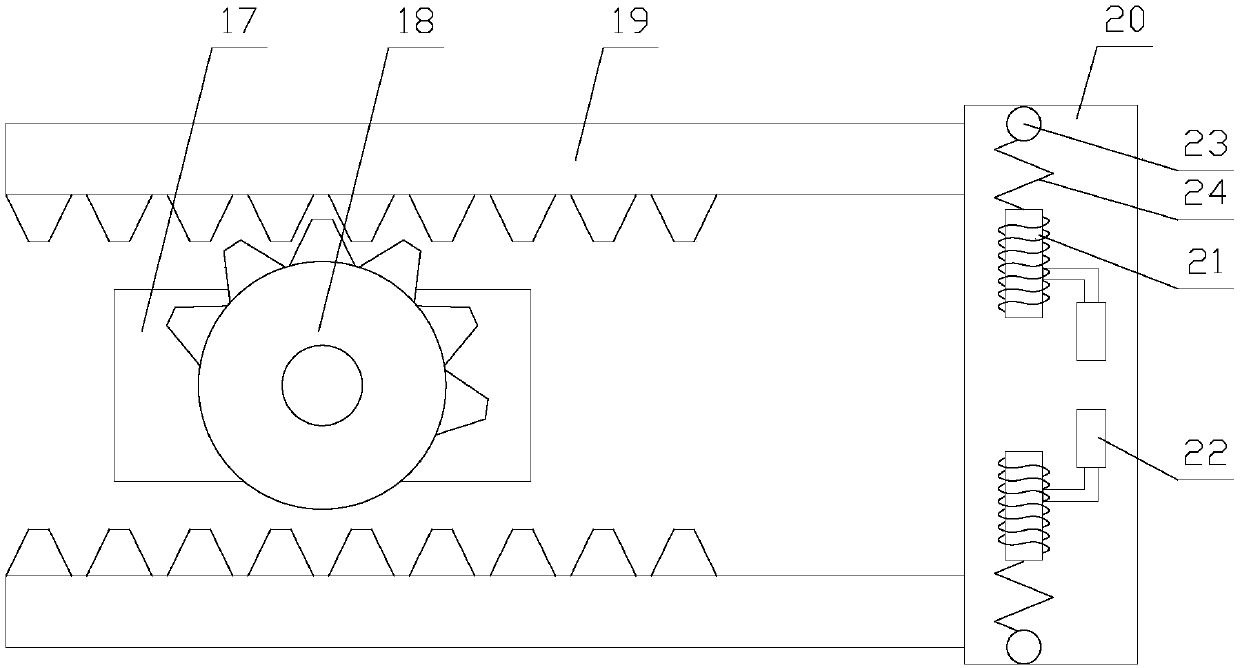

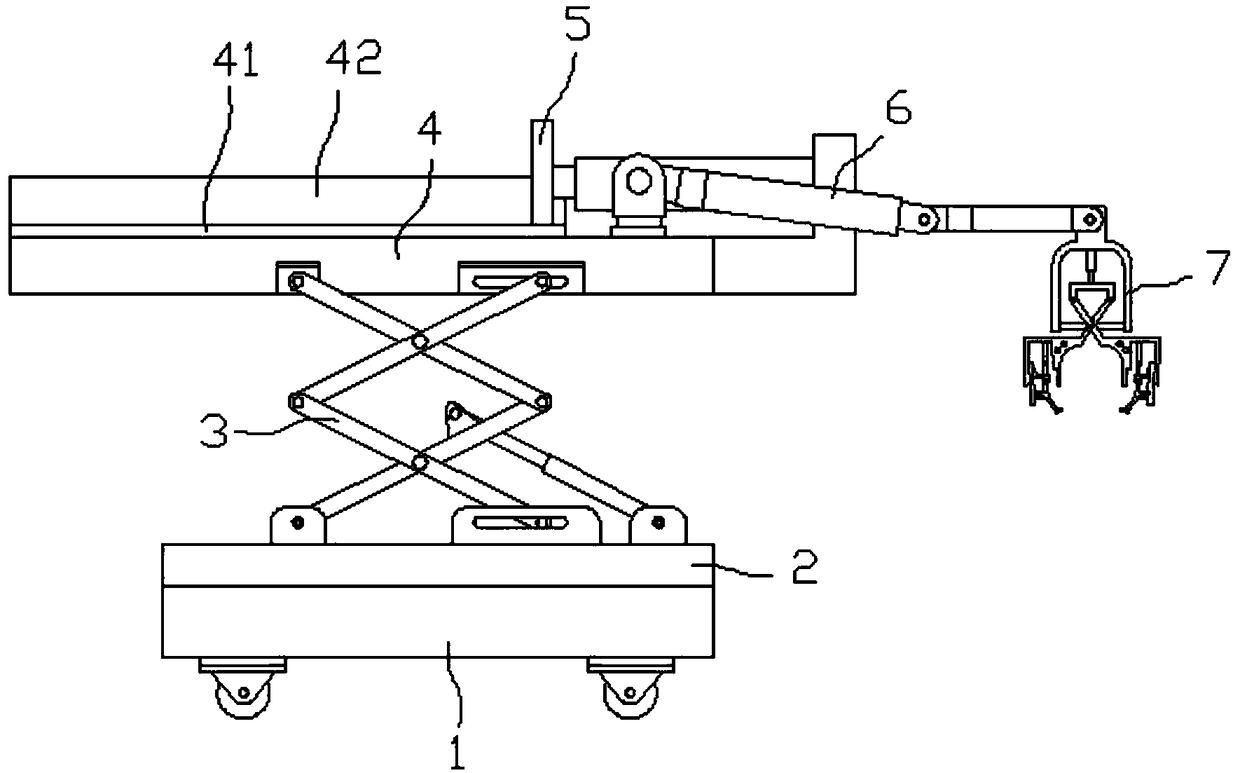

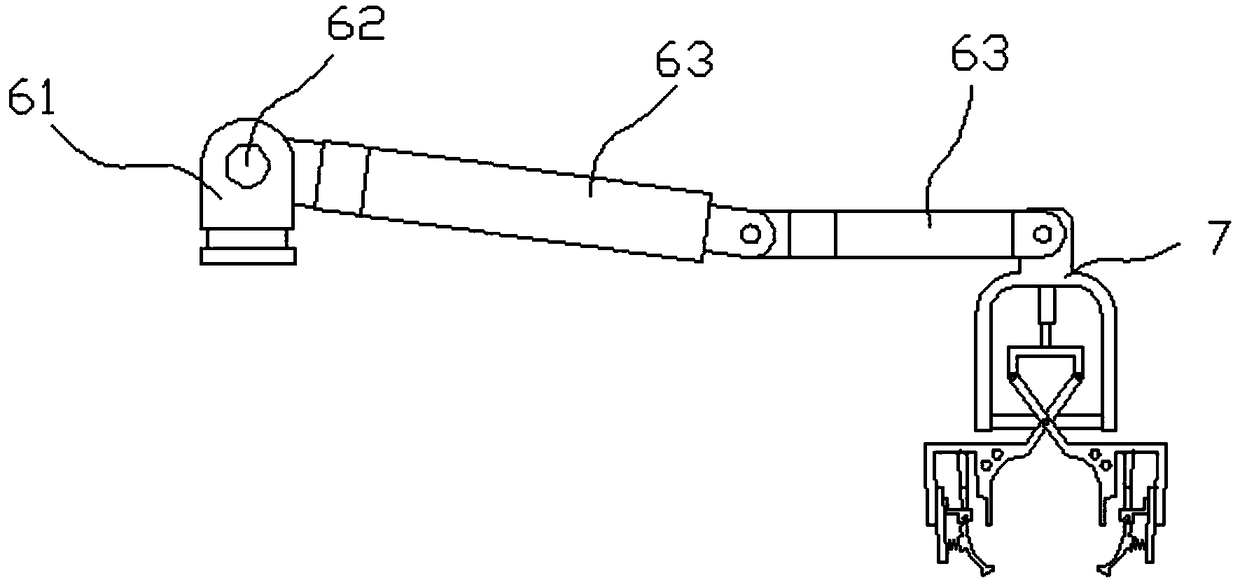

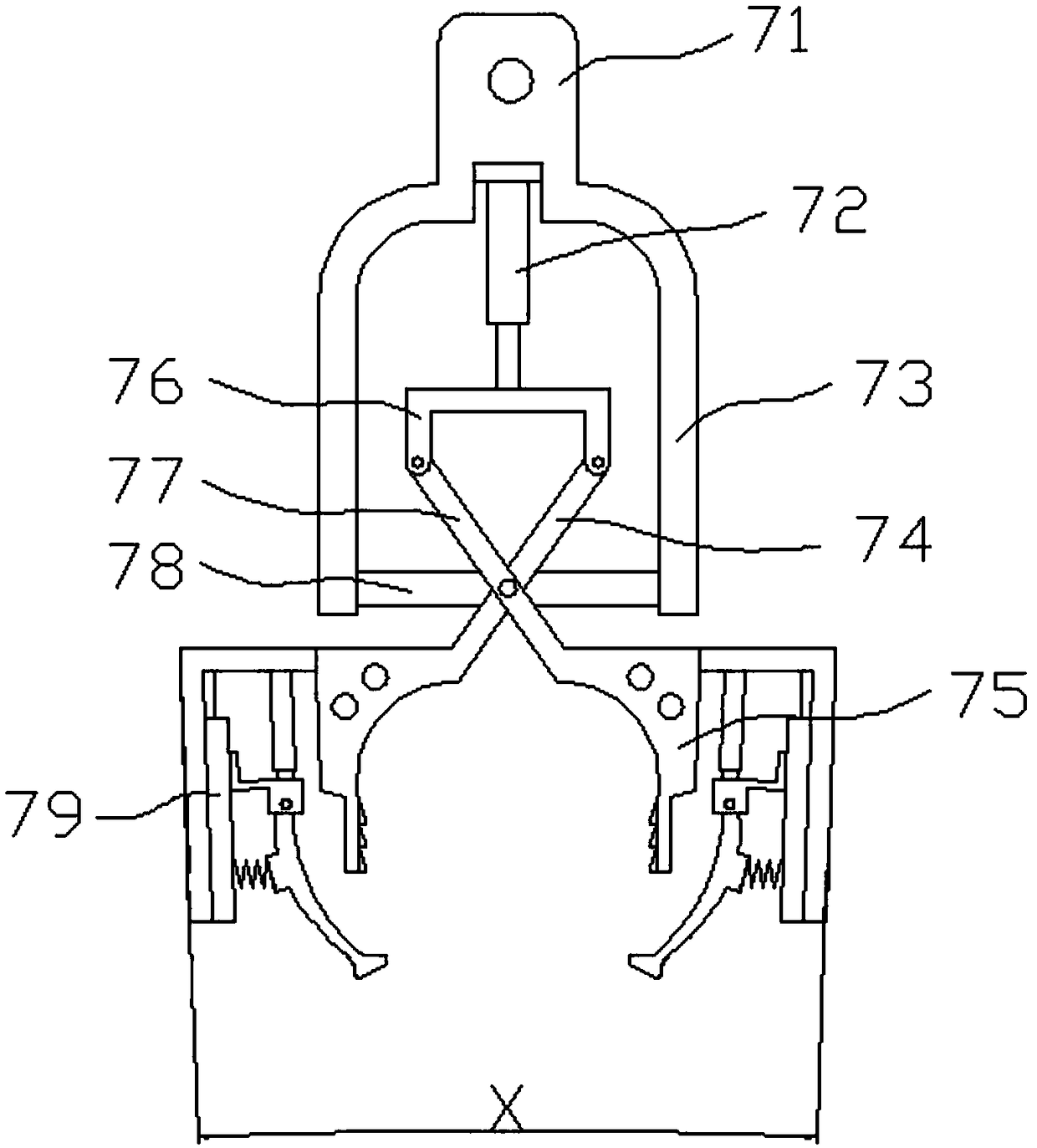

Die transfer robot used in casting process

InactiveCN108907161AImprove securityAchieve crawlingMould handling equipmentsHydraulic cylinderRotary stage

The invention relates to a die transfer robot used in the casting process. The die transfer robot comprises a transfer vehicle body, a rotary table, a lifting mechanism and a loading platform. The upper end of the loading platform is provided with a material pushing mechanism and a mechanical arm, and an anti-dropping mechanical claw is mounted at the tail end of the mechanical arm. The anti-dropping mechanical claw includes a first clamping connecting arm, a second clamping connecting arm and a seat body. The lower end of the seat body is provided with a first U-shaped bracket, and a horizontal plate is disposed in the first U-shaped bracket. The first clamping connecting arm and the second clamping connecting arm are cross and hinged to the middle portion of the horizontal plate. The first clamping connecting arm and the second clamping connecting arm are hinged to a second U-shaped bracket, and the middle portion of the second U-shaped bracket is connected with the extending-out endof a first hydraulic cylinder located at the middle lower end of the seat body. The lower ends of both the first clamping connecting arm and the second clamping connecting arm are provided with clamping blocks, and the outer sides of the clamping blocks are provided with supporting arm mechanisms. The die transfer robot is high in safety performance, the capture, transfer and push and placement of a die can be achieved, and the technical problem of inconvenience in lifting and transfer of an existing casting die is solved.

Owner:湖南紫荆新材料科技有限公司 +4

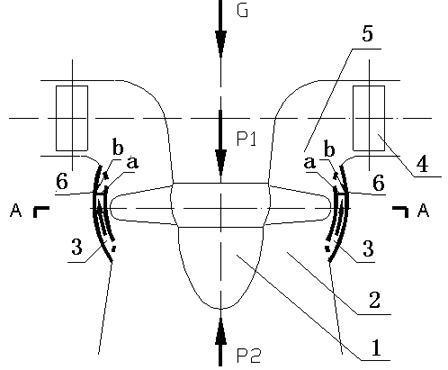

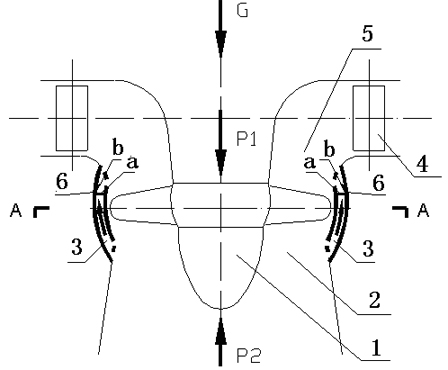

Method and device for preventing machine lifting of water-turbine generator set

InactiveCN101813048ADoes not affect normal operationPerformance is not affectedHydro energy generationMachines/enginesHydraulic machineryEngineering

The invention belongs to hydraulic machinery engineering, in particular to a method and a device for preventing machine lifting of a water-turbine generator set. The method comprises the following steps that: a check valve type flap door M is arranged in a flat pressure passage from a rotating wheel outlet to a rotating wheel inlet of a water turbine; when the generator set is in a normal electricity generation state, P1 is greater than P2, the check valve type flap door M is closed, and water in the passage can not flow downward; when the generator set is about to generate the machine lifting, P2 is greater than P1, the flap door M is opened, the water in the passage flows upward, P2 is reduced, and P1 is increased, so the stress of the water turbine meets a formula that the difference value of P2 and P1 is smaller than or equal to the weight G of the rotating part of the water-turbine generator set, in the formula, P1 is downward axial water thrust, P2 is upward axial water thrust, and G is the weight of the rotating part of the water-turbine generator set. The flat pressure passage can be realized through two or more than two passages which are uniformly distributed along the outer circumference of a rotating wheel chamber. The invention provides the method and the device, which have the advantages of simple structure, safety, reliability and capability of preventing the machine lifting of the water-turbine generator set.

Owner:王文超

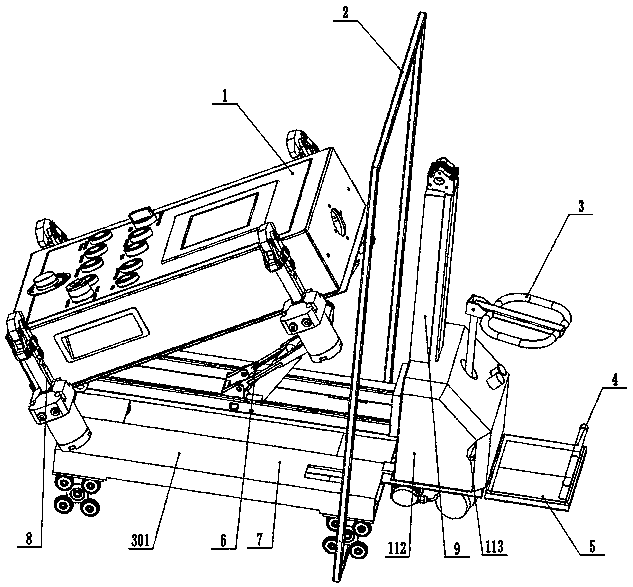

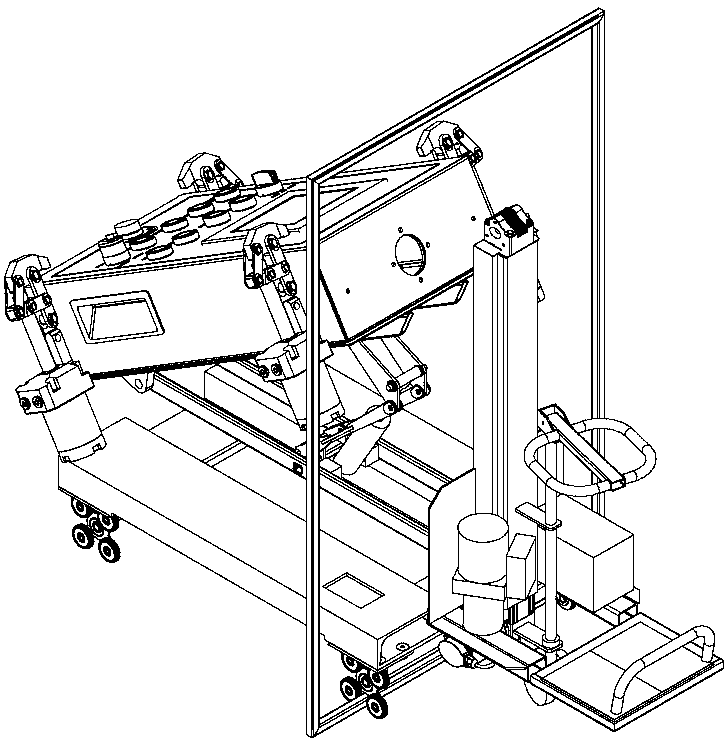

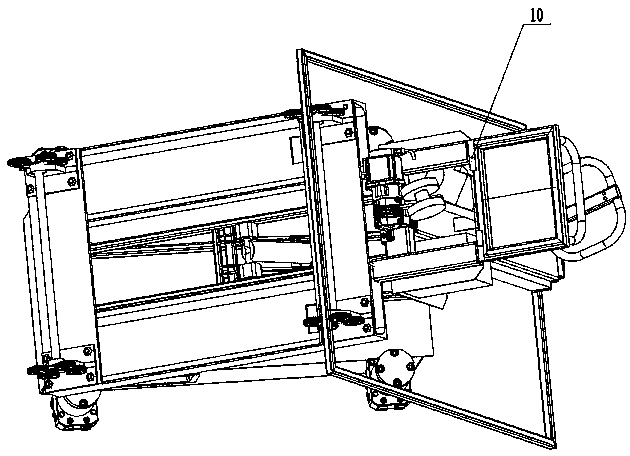

Marine cabinet cabin entry tool

ActiveCN111114714ACompact structureHigh degree of automationWaterborne vesselsLifting devicesStructural engineeringMarine equipment

The invention provides a marine cabinet cabin entry tool. The marine cabinet cabin entry tool comprises a high cabinet, a cabin door, a protective guard, a pedal, a hinge, a short cabinet, a console,a lifting device, a flatcar, a fixing device and a lifting mechanism. The flatcar is a bearing part of the whole tool, four sets of wheels are installed at the bottom of the flatcar, the small wheelsrotate to walk forwards and backwards, the large wheel set rotates to smoothly cross a threshold of the cabin door, and the cabinet enters the cabin. The console is arranged in front of the flatcar, apower part and the lifting mechanism are integrated on the console, the lifting mechanism and the lifting device are connected into a whole and driven by a transmission belt to ascend and descend, and the lifting device enables the cabinet fixedly placed on the lifting device to be placed at different angles through action of an oil cylinder so as to smoothly pass through the cabin door. The problems that in the prior art, a marine equipment cabinet cabin entry mechanism is complex, the cabinet angle is not easy to adjust, the cabin entry efficiency is low, the risk is large, and the cost ishigh are solved.

Owner:东台永胜盈华游艇有限公司

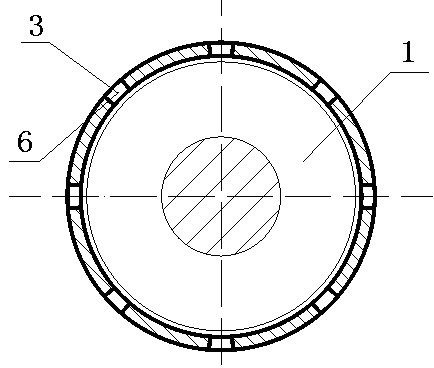

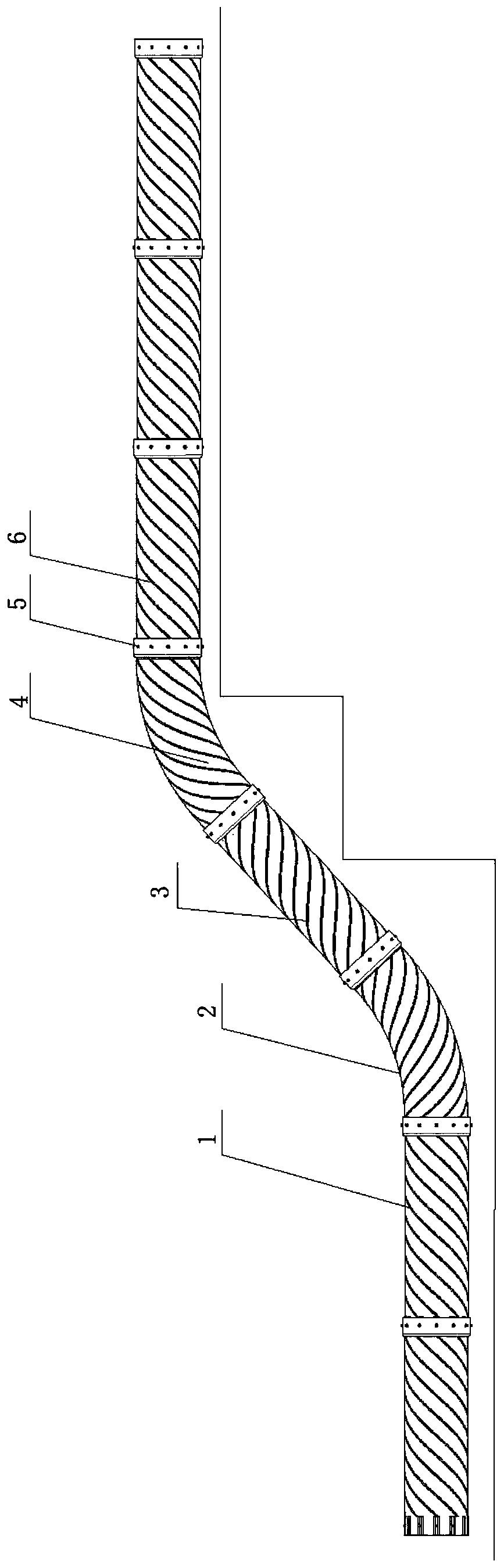

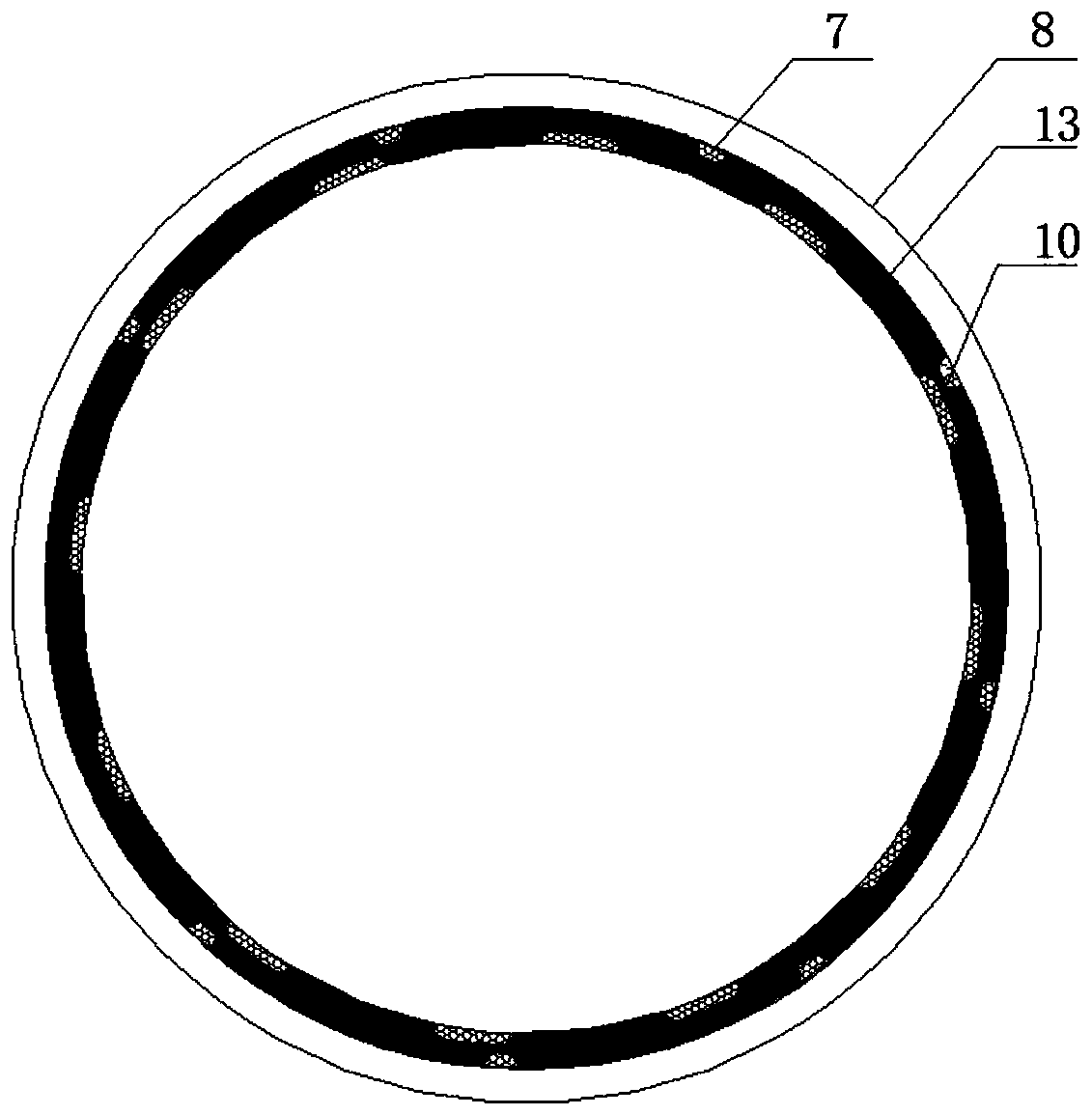

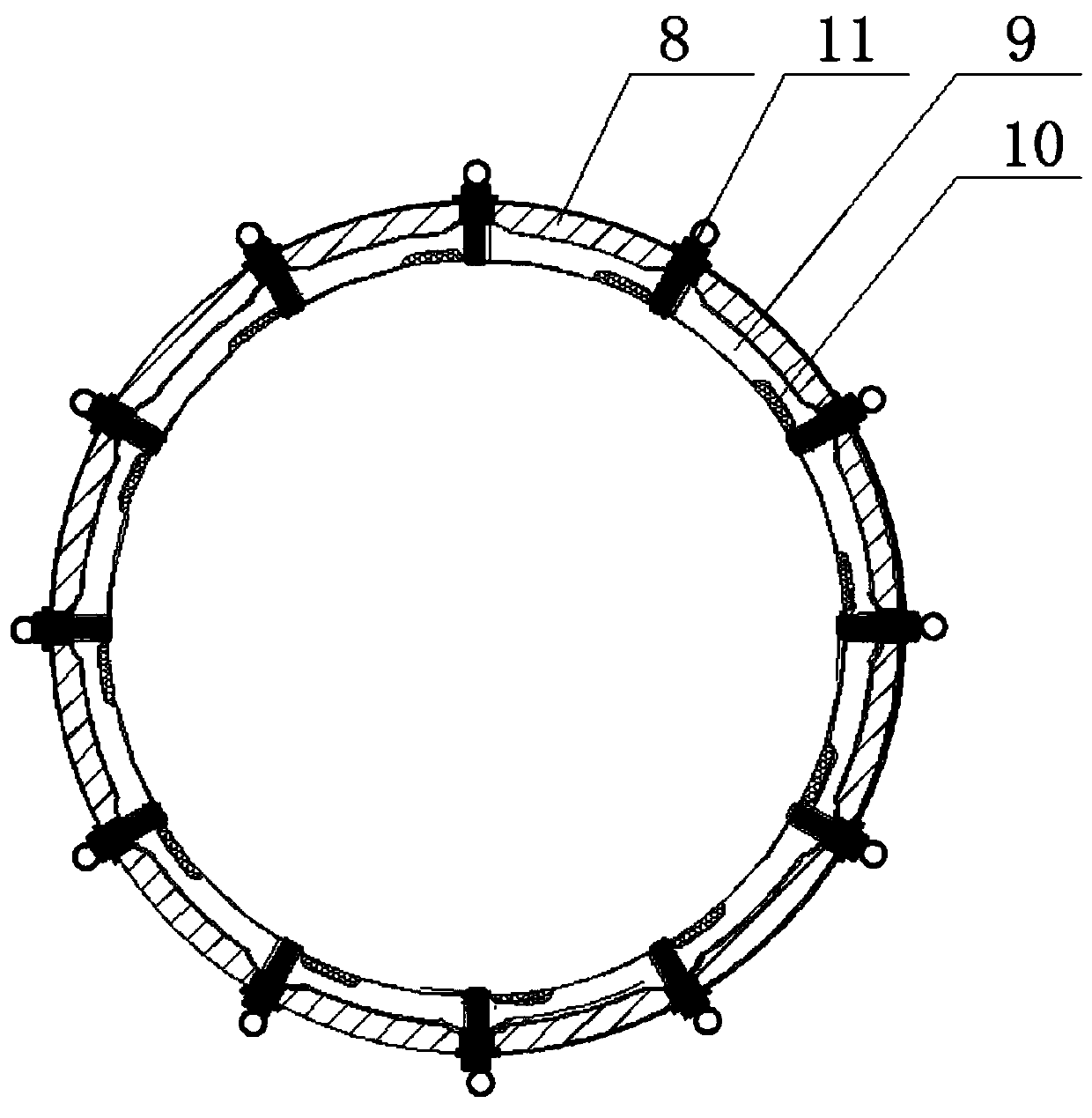

High-strength escape pipeline convenient to lift

PendingCN110513143AFirmly connectedGuaranteed escape speedSafety equipmentsHigh intensityScrew thread

The invention relates to a high-strength escape pipeline convenient to lift. The high-strength escape pipeline convenient to lift comprises a plurality of pipe bodies connected with one another end toend, one ends of the pipe bodies extend to form bearing head sections, and the other ends of the pipe bodies extend to form inserting head sections. Nine threaded grooves are integrally and uniformlyformed in the outer surface of each pipe body at intervals in the circumferential direction, and twelve vertical grooves are uniformly formed in the inner surface of each pipe body at intervals in the circumferential direction. Pipe wall sections of the pipe bodies are of a honeycomb structure. The threaded grooves and the vertical grooves are filled with styrofoam. A plurality of positioning inserting-grooves are integrally and uniformly formed in the inner surface of each bearing head section at intervals in the circumferential direction, and positioning inserting-blocks with the number same as the positioning inserting-grooves of the bearing head sections and matched with the positioning inserting-grooves of the bearing head sections are integrally and uniformly arranged on the outersurface of each bearing head section at intervals in the circumferential direction, nuts are arranged on the middle parts of the positioning inserting-grooves and the positioning inserting-blocks in an embedded mode, and the every two adjacent pipe bodies are connected through bearing-inserting of the bearing head sections and the inserting head sections and nut fixing by bolts. The high-strengthescape pipeline convenient to lift is light in weight, good in compression resistance, resistant in corrosion, convenient to lift and good in bearing and fastening performance.

Owner:TIANJIN RUNMU TECH CO LTD

Device special for high strain test of foundation pile

ActiveCN105369837ASolve manual knockdownSolve the problems caused by pulling offFoundation testingTest qualityEngineering

The invention discloses a device special for a high strain test of a foundation pile. The device comprises a pile head fixing device and a guide frame which is vertically arranged on the pile head fixing device. A guide drop hammer rolling device, a combined hammer head, an automatic tripping device and an electric lifting device are sequentially arranged in the guide frame. The electric lifting device is arranged at the top end of the guide frame. The automatic tripping device is connected between the guide drop hammer rolling device and the electric lifting device. Through the automatic tripping device, the problems caused by manual knock-off or pull-off are well solved. For example, since large torque exists during knock-off or pull-off, decentration of a drop hammer is caused, test signals of a free hammer are poor, and accordingly test quality is affected.

Owner:常州华厦建设工程质量检测有限公司 +1

Multi-point integral lifting construction method for short mast of large-capacity round storage tank

ActiveCN108678388AReduce erectionReduce working at heightsBuilding material handlingBulk storage containerLarge capacityMulti point

The invention relates to the technical field of storage tank construction, the purpose of which is to provide an efficient and stable multi-point integral lifting construction method for a short mastof a large-capacity round storage tank. The technical scheme adopted in the multi-point integral lifting construction method for the short mast of the large-capacity round storage tank is: A, base acceptance; B, prefabrication for a bottom board; C, prefabrication for a wall board; D, prefabrication for an arch-shaped board; E, storage tank assembly; F, water filling test and foundation settlementobservation. With all construction links adopting low-level operation, the multi-point integral lifting construction method for the short mast of the large-capacity round storage tank has the advantages of achieving reduction in aerial work and scaffolding building.

Owner:THE 14TH METALLURGICAL CONSTR GRP YUNNAN INSTALLATION ENG CO LTD

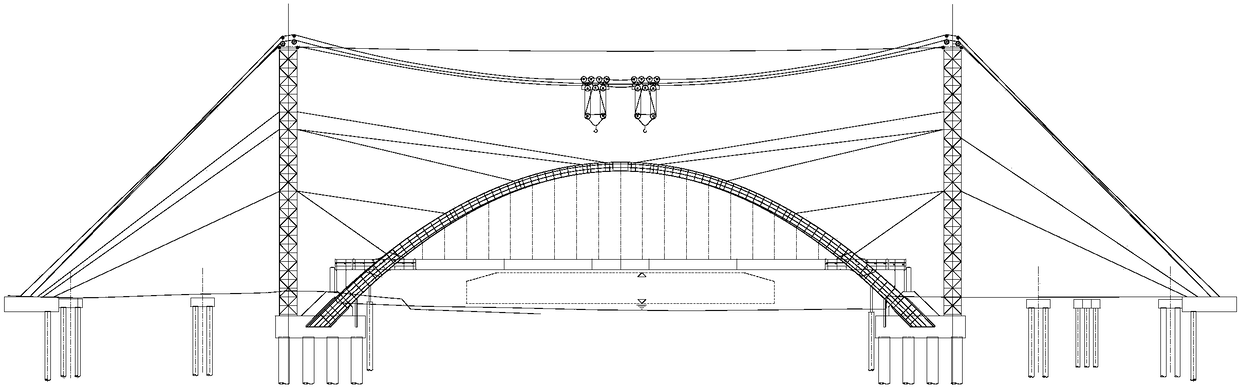

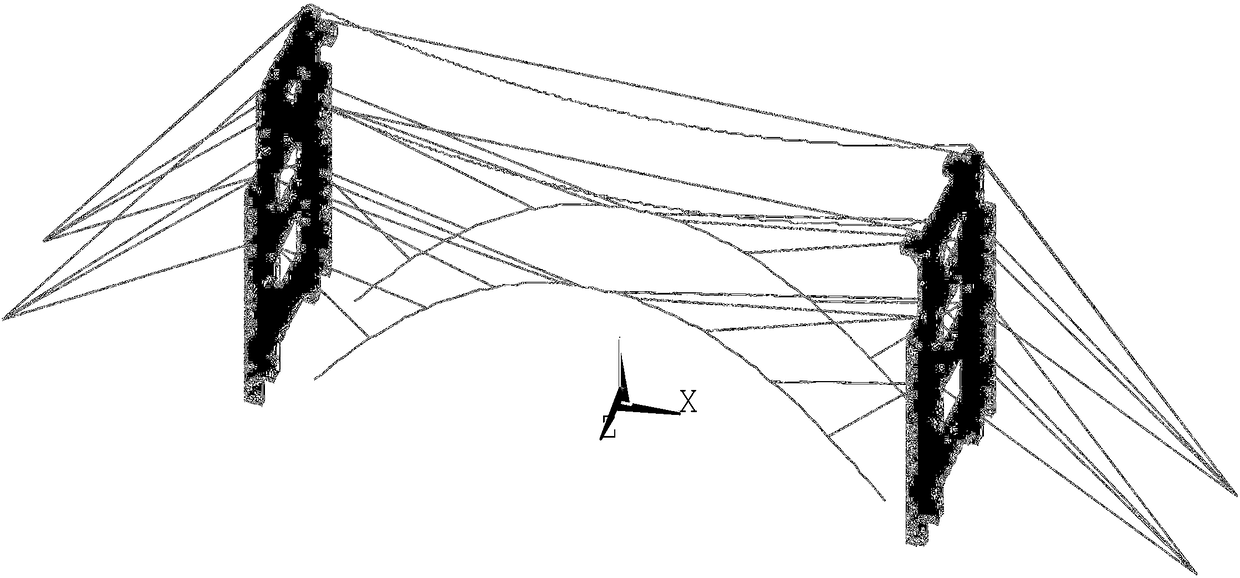

Analysis method for whole process of cable hoisting

ActiveCN108153972ASolve lifting problemsDesign optimisation/simulationBridge erection/assemblyCatenaryAnalysis models

The invention discloses an analysis method for the whole process of cable hoisting. The method includes the steps that a cable hoisting analysis model without a main cable and a cable saddle is established according to a construction drawing; an initial catenary equation of the main cable under the action of gravity is obtained by a flexible iteration method, then the part of the main cable in theconstruction possibly contacting with the cable saddle is selected and simulated with a flexible shell unit, the other part of the main cable is simulated with a bar unit, the cable saddle is simulated with a rigid shell unit to construct a cable saddle-main cable simplified model; in the cable saddle-main cable simplified model, a target unit of which the direction faces outward is established on a cable saddle shell, a contact unit of which the direction faces inward is established on a main cable shell unit, and accordingly a frictional contact pair model with the cable saddle as the target unit and the main cable as the contact unit is established; and a whole model of the cable hoisting whole process analysis is established. According to the analysis method, mechanical states of eachcomponent of cable-arch-rope-tower in the construction process can be more accurately simulated, and a more reliable basis for structural design, structural safety and linear control of arch rib installation is provided.

Owner:TENGDA CONSTR GROUP CORP

Hoist bucket for concrete transporting

InactiveCN110902546APrevent slidingSolve the problem of working intensity and reducing the efficiency of bucket transporting concreteDischarging apparatusHollow article cleaningReduction driveArchitectural engineering

The invention discloses a hoist bucket for concrete transporting, and relates to the technical field of concrete hoist bucket transporting. The hoist bucket for concrete transporting aims to solve theproblems that when the hoist bucket is lifted to a designated position, the hoist bucket needs to be toppled over by manpower to pour out concrete in the hoist bucket, then the concrete is carried bya constructor through a carrying tool to be used, the working intensity of the constructor is enlarged, and the transporting using efficiency is lowered. A base is arranged below a bucket body, supporting columns are arranged below the base, universal wheels are arranged below the four supporting columns correspondingly, a bucket cover is arranged above the bucket body, a speed reducer is arranged above the bucket cover, a first servo motor is arranged above the speed reducer, an injecting pipe is arranged on one side of the first servo motor, a rotary shaft is arranged below the output end of the first servo motor, a bearing is arranged on the contact position of the rotary shaft and the bucket cover, stirring rods are arranged on the two sides of the rotary shaft correspondingly, and mooring rope lifting lugs are arranged on the two sides of the bucket body correspondingly.

Owner:邓婧

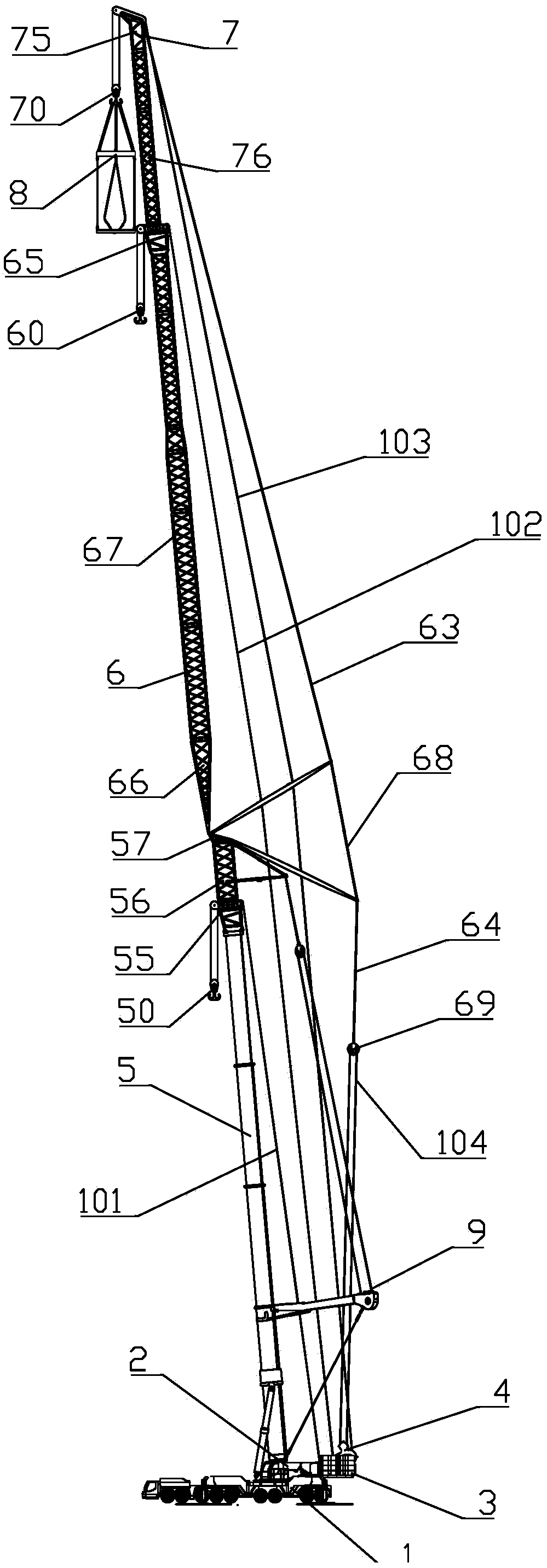

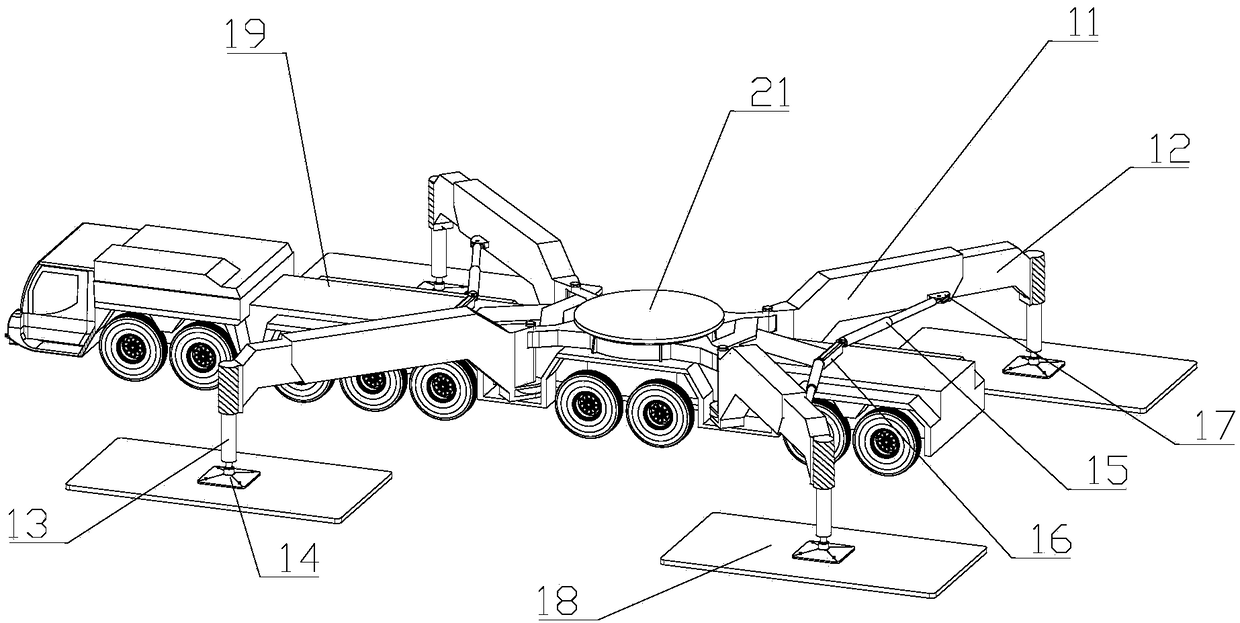

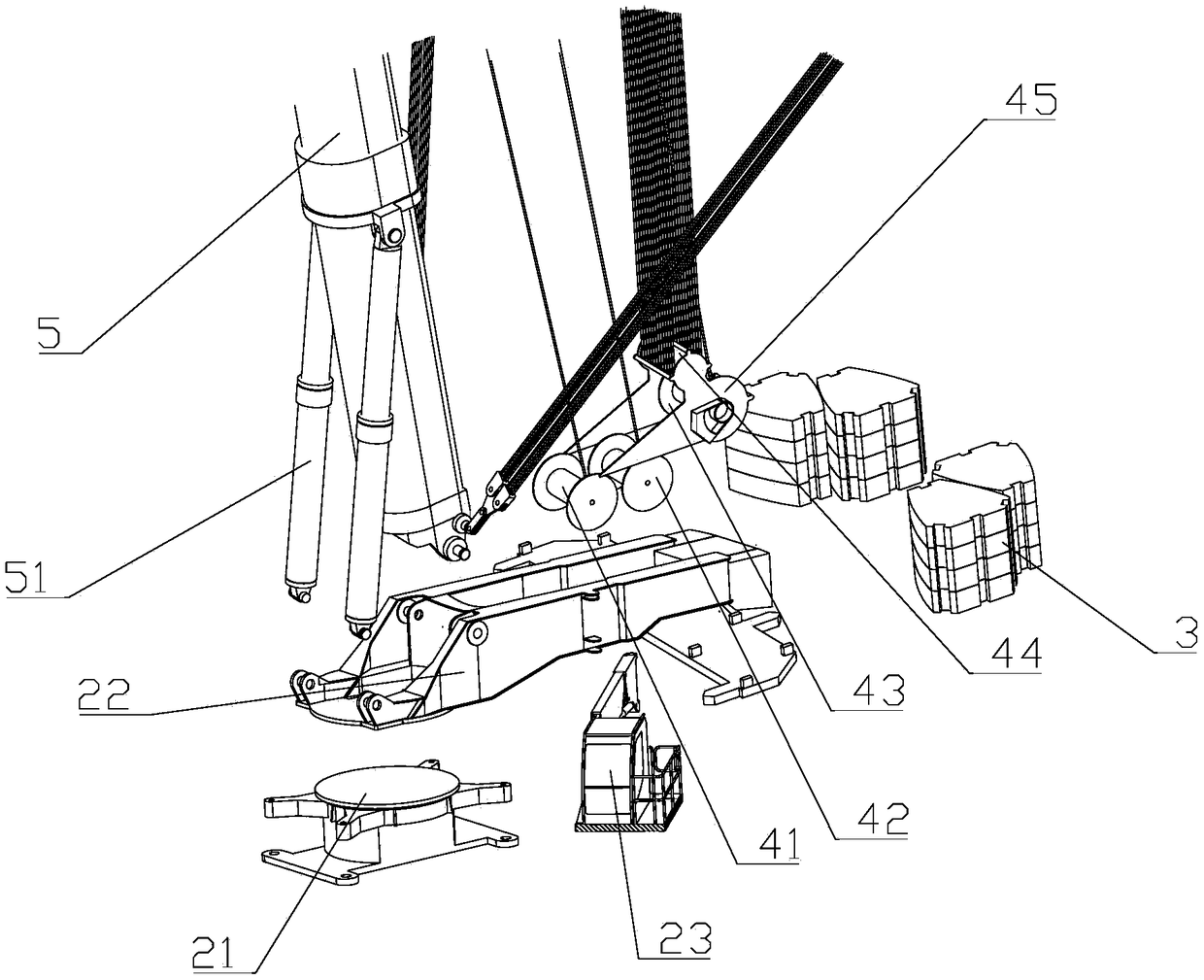

Hoisting device for assembling fan blades of large-size wind driven generator

The invention relates to a hoisting device for assembling fan blades of a large-size wind driven generator. According to the hoisting device for assembling the fan blades of the large-size wind drivengenerator, the hoisting device comprises a base plate, a rotation mechanism, a balance counterweight device, a winching mechanism, a main cargo boom and an amplitude-changing hoisting arm, wherein the amplitude-changing hoisting arm is arranged above the main cargo boom; a third lifting hook mounting seat is fixedly arranged at the top of the amplitude-changing hoisting arm; a third lifting hookis arranged on the third lifting hook mounting seat; the third lifting hook is connected with a third loading winding barrel on the winching mechanism through a third steel cable; a fan blade loadingdevice is connected with the third lifting hook; the fan blade loading device comprises a first belt type hoisting rope, a first bolt, a second bolt, a third bolt, a fourth bolt, a fifth bolt, a firstlifting lug, a second lifting lug, a third lifting lug, a chain plate, a second belt type hoisting rope, a suspension rod, a fan blade supporting plate and a T-shaped frame. The fan blade loading device adopted by the device has the characteristic of good stability and the hoisting difficulty of the fan blades of the large-size wind driven generator is solved.

Owner:滁州捷新建筑科技有限公司

Rapid glass packaging and unpackaging box and packaging method

ActiveCN104944001ASave packing timeImprove packaging efficiencyContainers to prevent mechanical damageDamagable goods packagingSteel beltEngineering

The invention relates to a packaging box and a packaging method, in particular to a glass packaging box and a packaging method. The packaging method specifically comprises the steps that 1, plugs for glass packaging buckle boxes are manufactured according to the thickness of glass to be packaged; 2, the glass packaging buckle boxes are manufactured; 3, two steel belts are packaged to outer box bodies of the glass packaging buckle boxes through a steel belt die; 4, groove boxes shorter than the glass to be packaged are manufactured; 5, the glass to be packaged is packaged on a packaging workbench; 6, the suspended packaged glass is directly hoisted to a storage area to be contained into a cabinet. The glass packaging box and the packaging method have the advantages that the upper and lower groove boxes are manufactured, so that the problem that naked packaged glass cannot be directly placed into the lower groove box by a hoisting belt for years is solved, and the packaging time is greatly shortened; the left and right buckle boxes are utilized for load bearing, so that glass hoisting and prepackaging are achieved; the formed outer package is neat, attractive, elegant, solid and convenient to store, convey and use.

Owner:大连埃玛玻璃配套服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com