Marine cabinet cabin entry tool

A cabinet and cabin entry technology, which is applied to lifting devices, ships, etc., can solve the problems of workers’ reluctance to use, difficult operation, and high labor costs, and achieve the effects of shortening the cabin entry cycle, ensuring construction quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

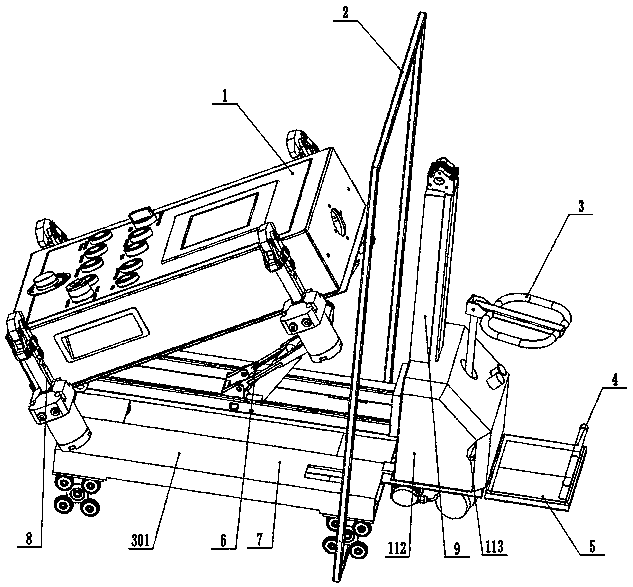

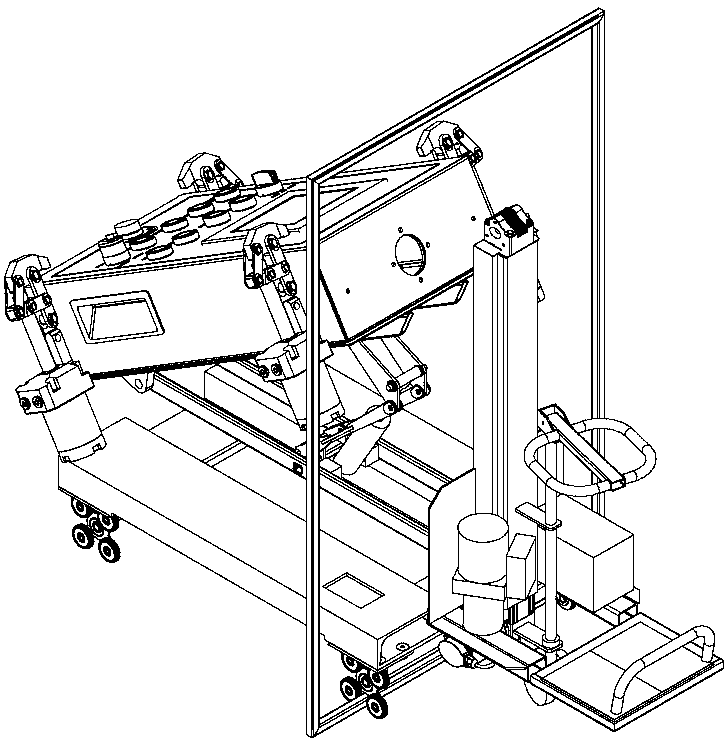

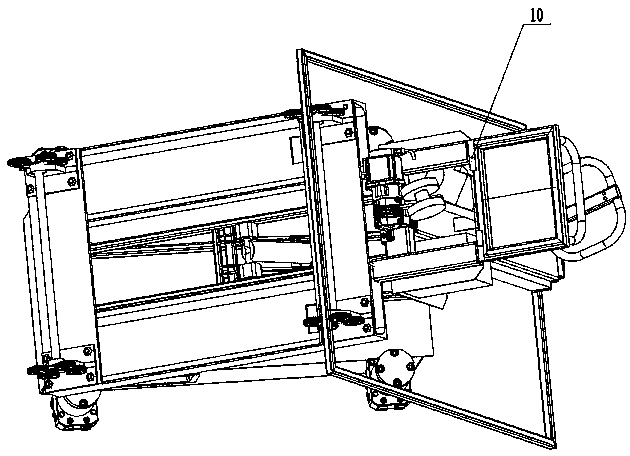

[0033]Embodiment: As shown in the figure, a marine cabinet entry tool includes a tall cabinet 1, a hatch door 2, a guard rail 4, a pedal 5, a hinge 10, a low cabinet 11, and a console 3, a lift Lifting device 6, flat car 7, fixing device 8, lifting mechanism 9, the high cabinet 1 and the low cabinet 11 respectively represent cabinets of different heights, the hatch 2 represents the hatch 2, and the cabinet is placed on the lifting device 6 On the upper plane of the lifting device 6, it can be placed obliquely with the lifting of the lifting device 6 to reduce the overall height. The fixing device 8 is fixedly installed on the side of the lifting device 6 to provide fixed protection for the high cabinet 1 and the low cabinet 11. Function, the console 3 is the control part of the whole tooling, fixedly installed on the front part of the flat car 7, can operate the trolley to move forward, backward, turn and complete the lifting action, the guardrail 4 and the foot pedal 5 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com