Hoisting device for assembling fan blades of large-size wind driven generator

A technology for wind power generators and hoisting devices, which is applied to cranes, transportation and packaging, and load hanging components, etc. It can solve problems such as long construction period, high risk, and difficult construction, and achieve the effect of solving hoisting problems and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

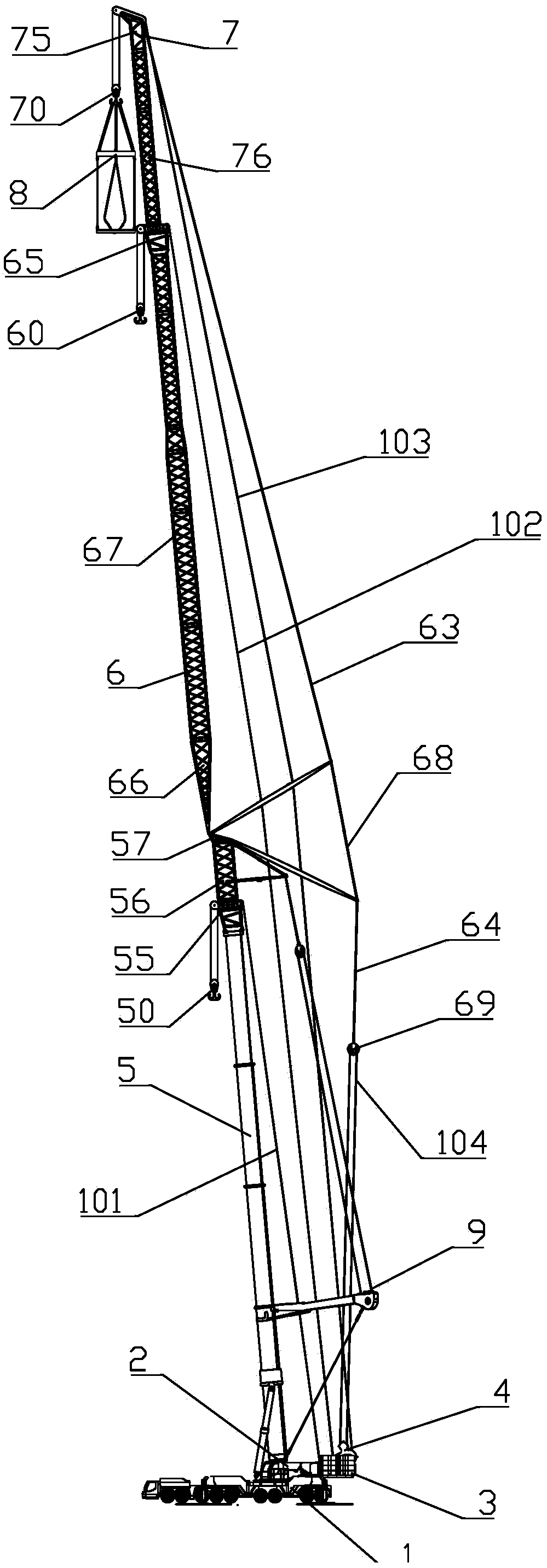

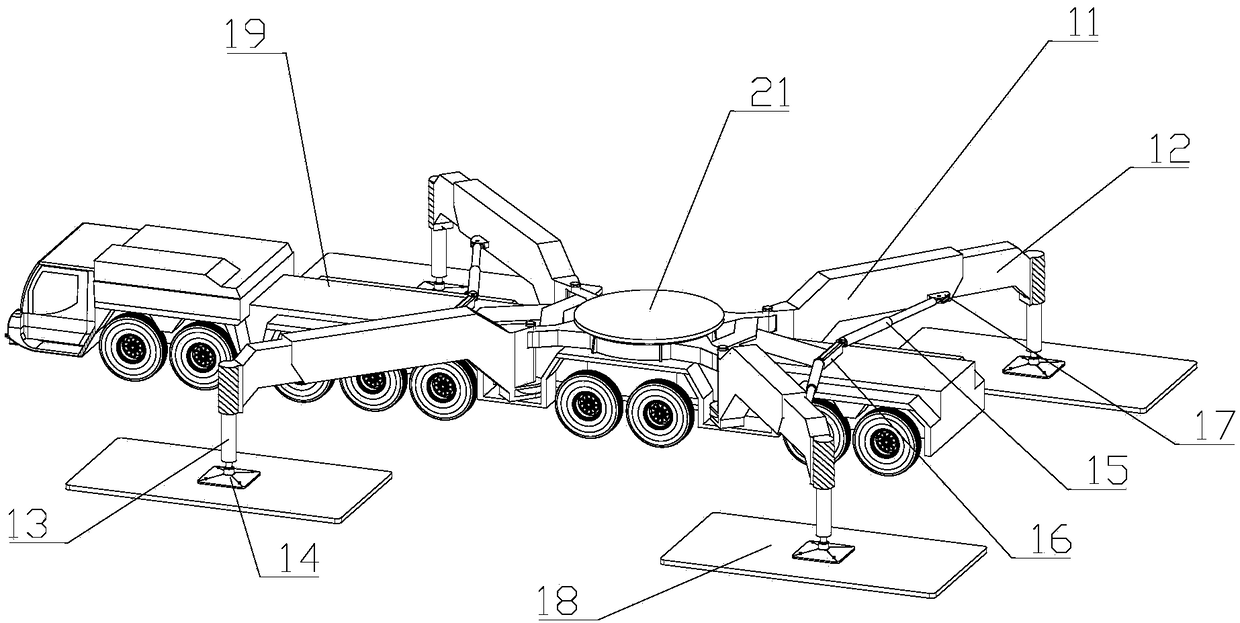

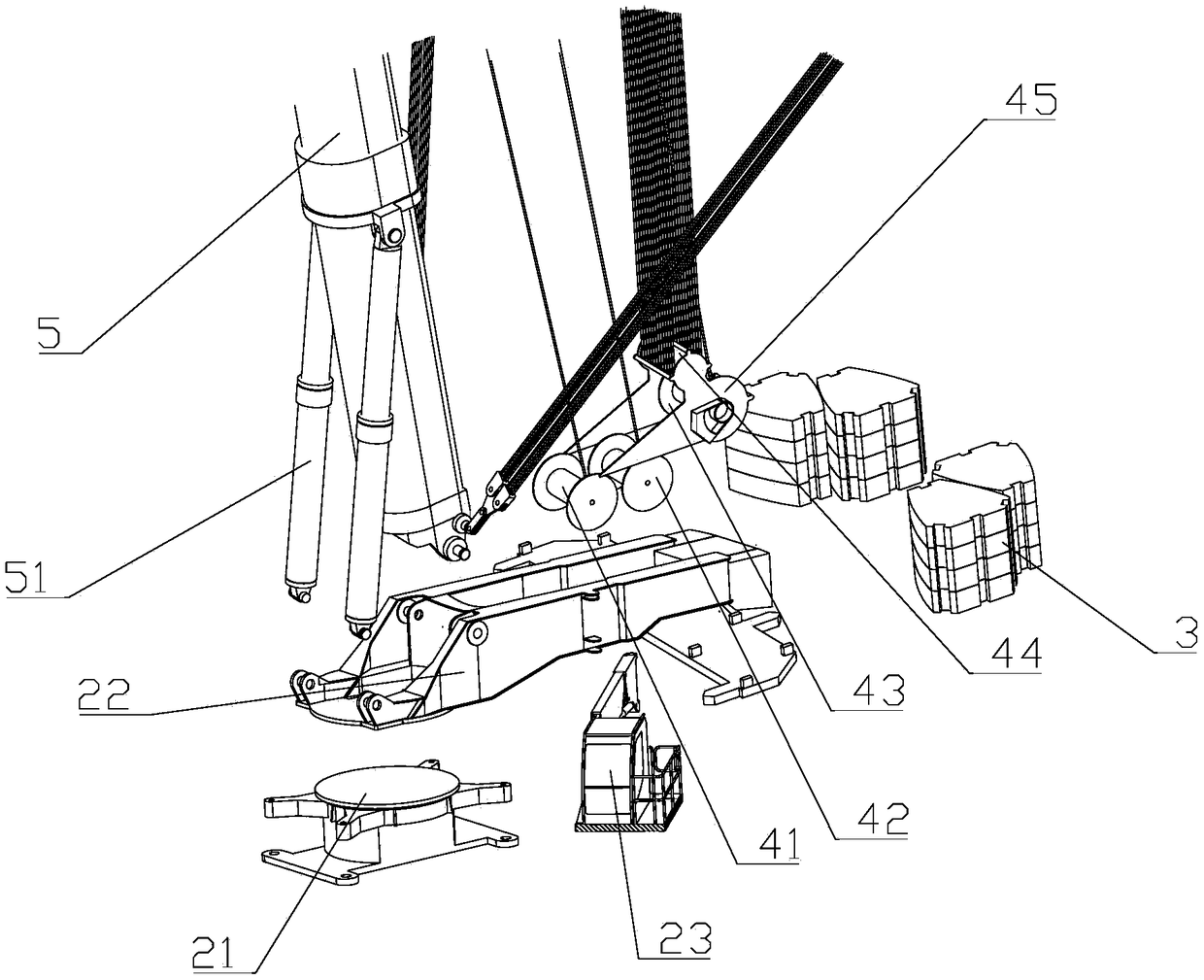

[0032] Such as figure 1 Shown is a hoisting device for the installation of large-scale wind power generators, the hoisting device includes a chassis 1, a slewing mechanism 2, a balance counterweight 3, a main boom 5, a hoisting mechanism 4, a luffing boom 6, a The second hook 60, the third hook 70, the fan blade carrier 8 and the stable support device 9. The chassis 1 is fixedly connected and arranged on the heavy truck, the slewing mechanism 2 is arranged on the chassis 1, the bottom of the main boom 5 is hingedly arranged at the front end of the slewing mechanism 2, and the balance counterweight 3 is fixedly arranged At the rear end of the slewing mechanism 2. The main boom 5 is composed of four telescopic sleeves, the first sleeve 51 is arranged on the outermost side, the fourth sleeve 54 is arranged on the innermost side, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com