Rapid glass packaging and unpackaging box and packaging method

A packaging box and glass technology, applied in transportation and packaging, packaging of vulnerable items, types of packaging items, etc., can solve problems such as troublesome operators, fragile, broken glass, etc., to shorten packaging time, facilitate storage, and packaging efficiency. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

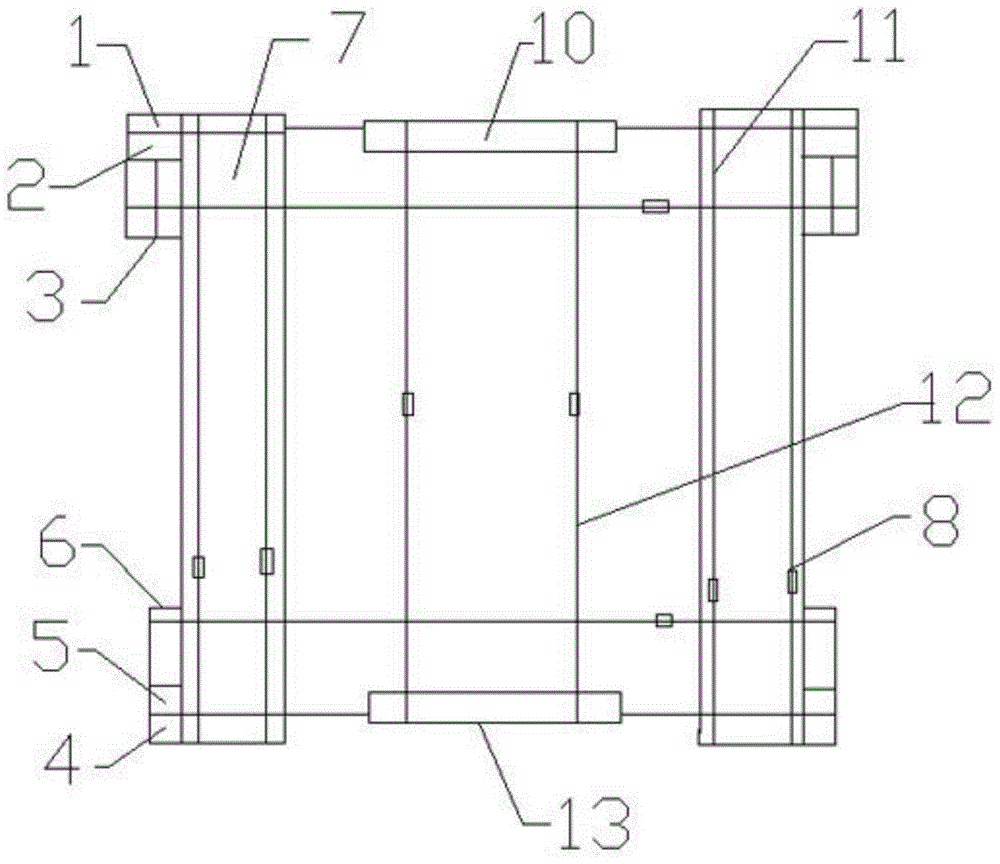

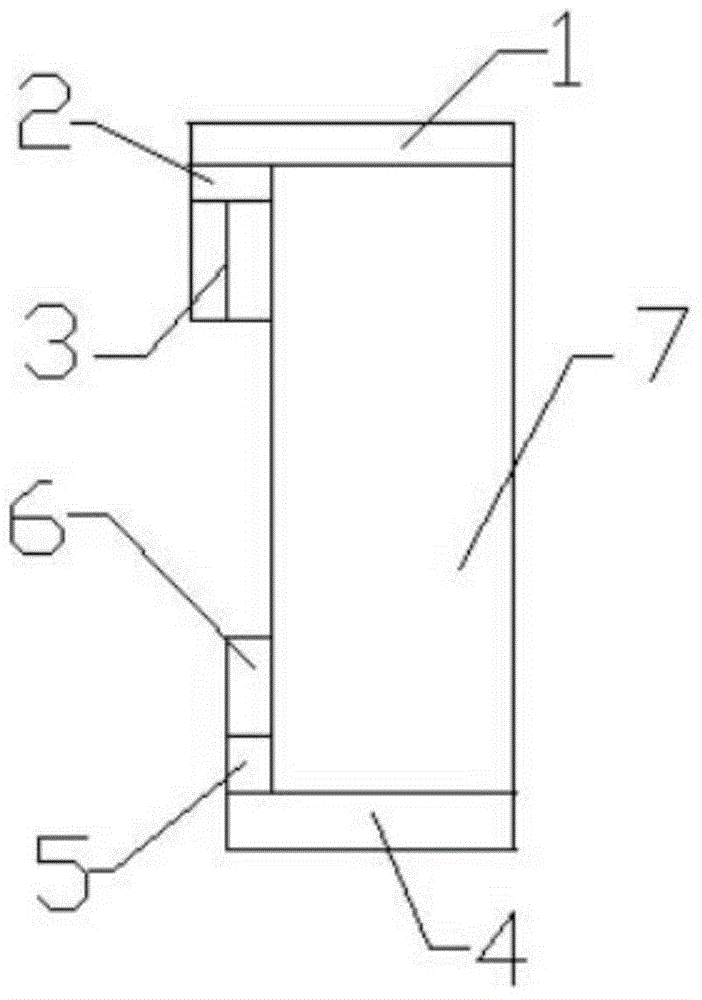

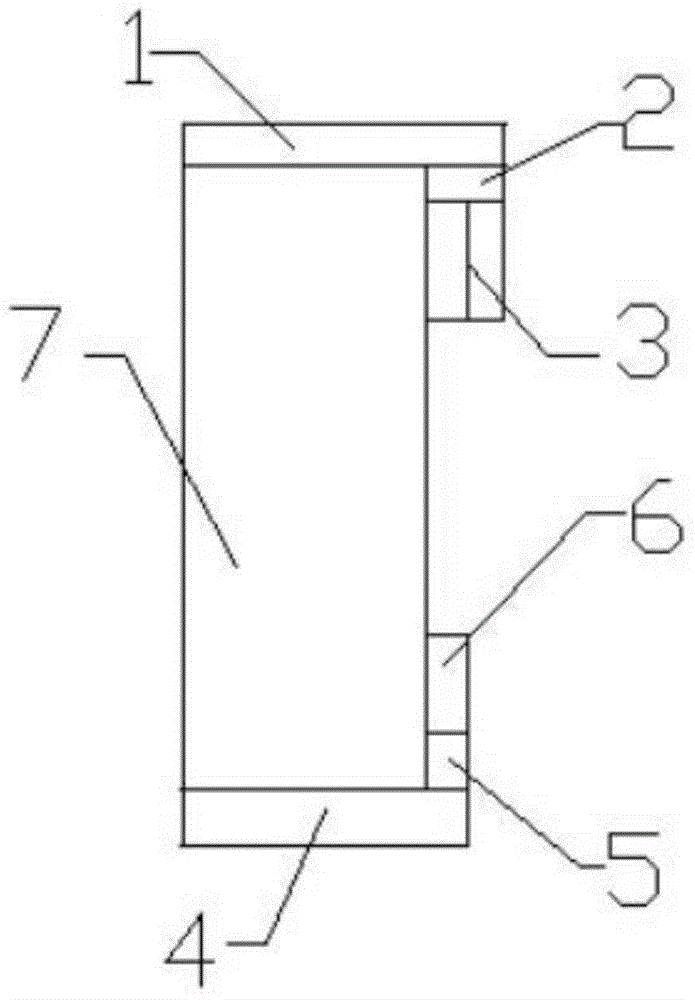

[0033] Such as Figure 1 to Figure 4 A packaging box for quickly packing and dismantling glass as shown, including: a box plug for packaging; the box plug for packaging includes an upper plug and a lower plug; the upper plug includes: an upper pad Plate 1, the upper backing plate 1 is fixed with an upper through plate 2 in the middle of the lower surface, the width of the upper through plate 2 is smaller than that of the upper backing plate 1, and the width difference is twice the thickness of the vertical side plate 7, and the width of the upper through plate 2 is wider than that of the glass to be packaged. The thickness of the upper side plate 3 is 15-20 mm wide, the upper side plate 3 is perpendicular to the upper through plate 2, and the end of the upper side plate 3 is fixed on the lower surface end of the upper through plate 2, and the upper side plate 3 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com