Return plug type air packaging device and manufacturing method thereof

A technology of air packaging and manufacturing methods, applied in the direction of packaging, transportation and packaging, and containers to prevent mechanical damage, etc., can solve problems such as puncture, gas leakage in sealed air chambers, etc., to reduce time, increase impact resistance, and shorten inflation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The back-plug air-packing device of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0040] Primary plastic sealing refers to the process of sealing two layers of thermoplastic film and one-way valve to form a flat bag that can store air. Secondary plastic sealing refers to folding the semi-finished product after primary plastic sealing and sealing it again along the secondary plastic sealing line. The process of forming a three-dimensional bag that can hold objects.

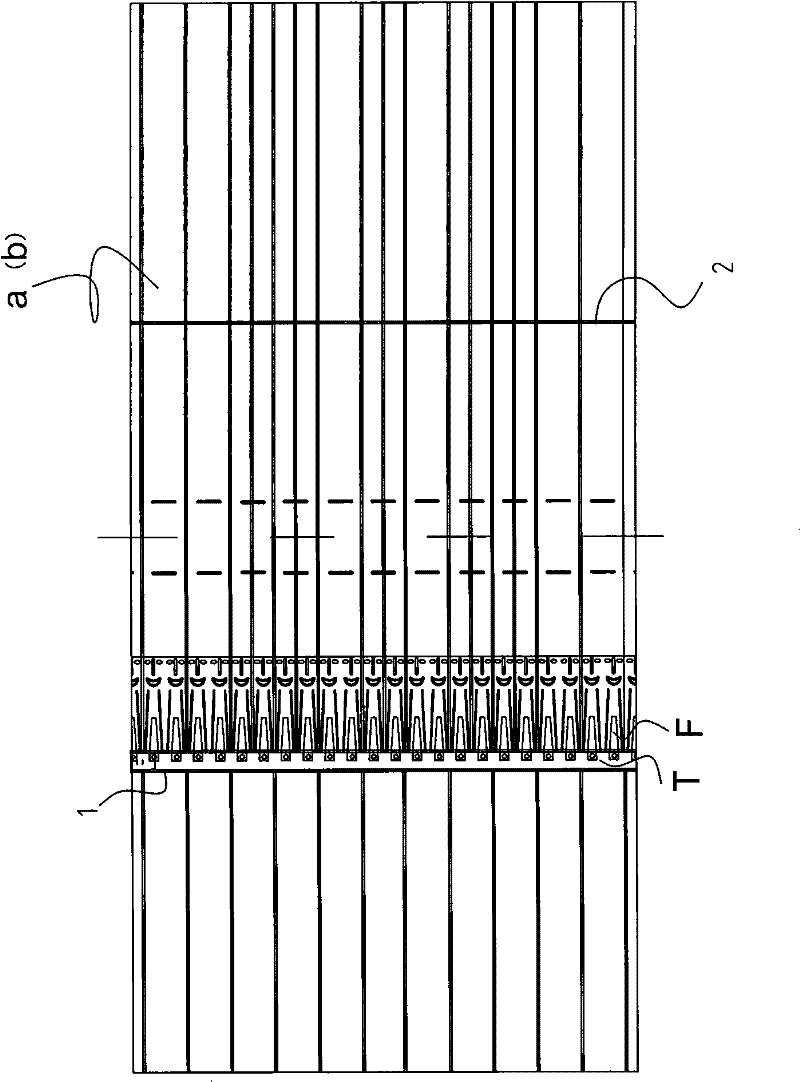

[0041] Such as figure 1 As shown, a schematic diagram of an embodiment before secondary plastic sealing, the whole is formed by two rectangular films a and b of the same size after one plastic sealing, and the one-way valve F and the main channel T formed by two layers of small films are arranged in The middle part of the film a, b, wherein the main channel sealing line 1 and the bottom sealing line 2 will be divided into a non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com