Patents

Literature

33results about How to "Extrusion resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reusable multifunctional three-dimension sealing and packing material and method for preparing same

ActiveCN101513952ACorrosion resistanceUse light materialEnvelopes/bags making machineryPackage recyclingEngineeringPack material

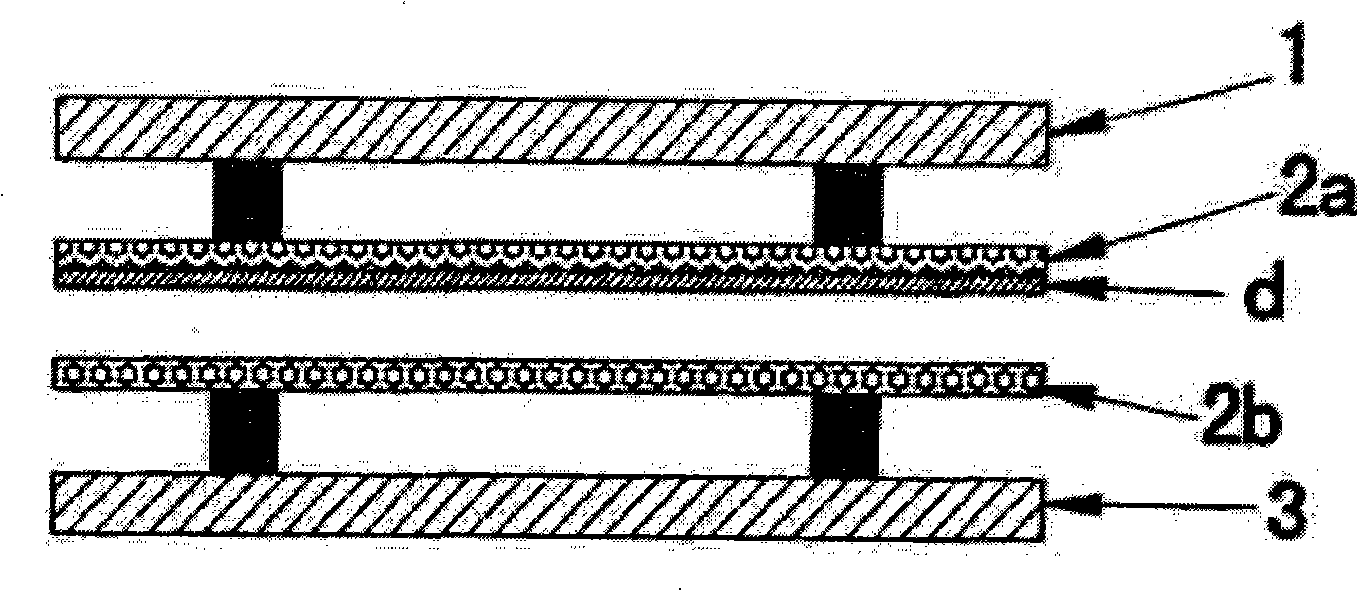

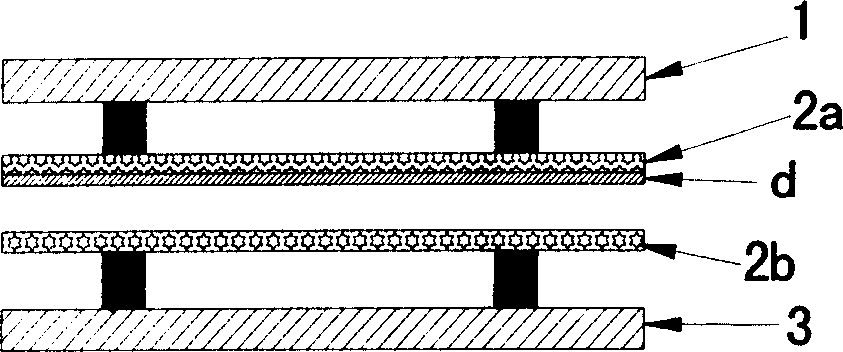

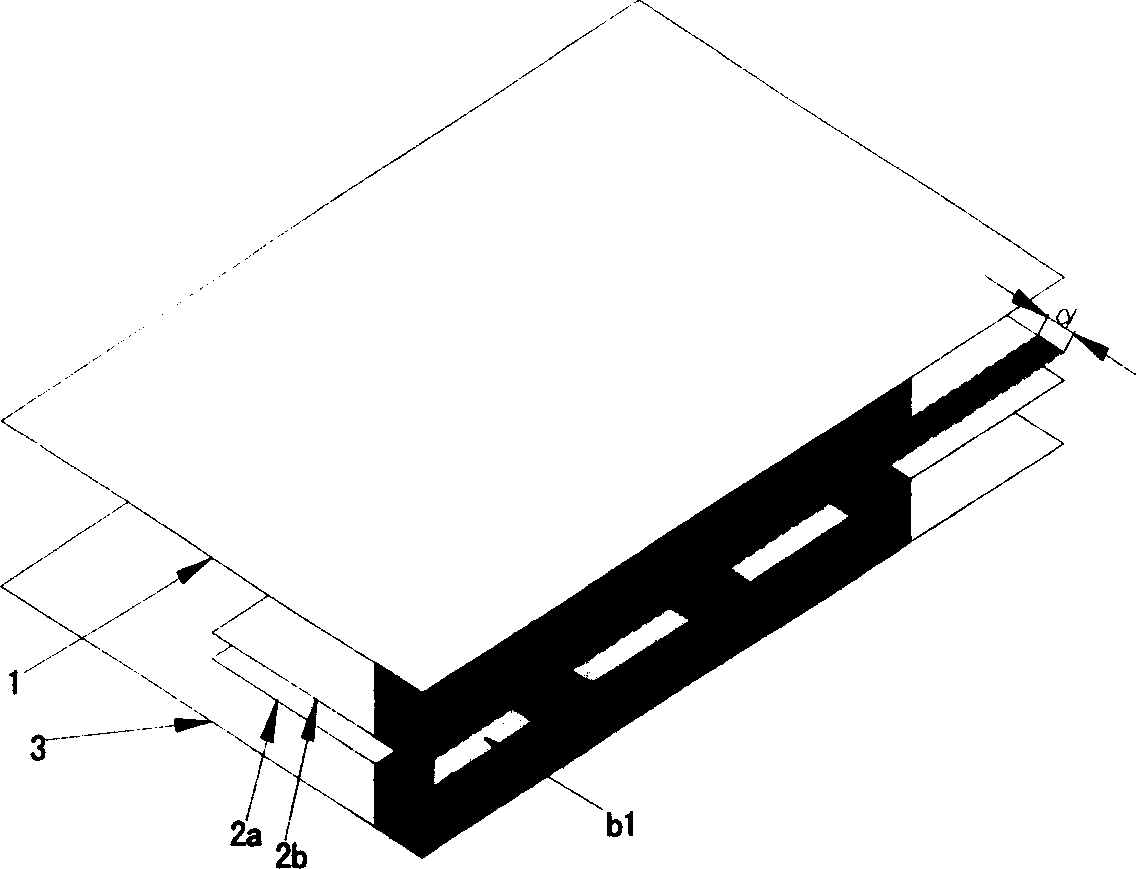

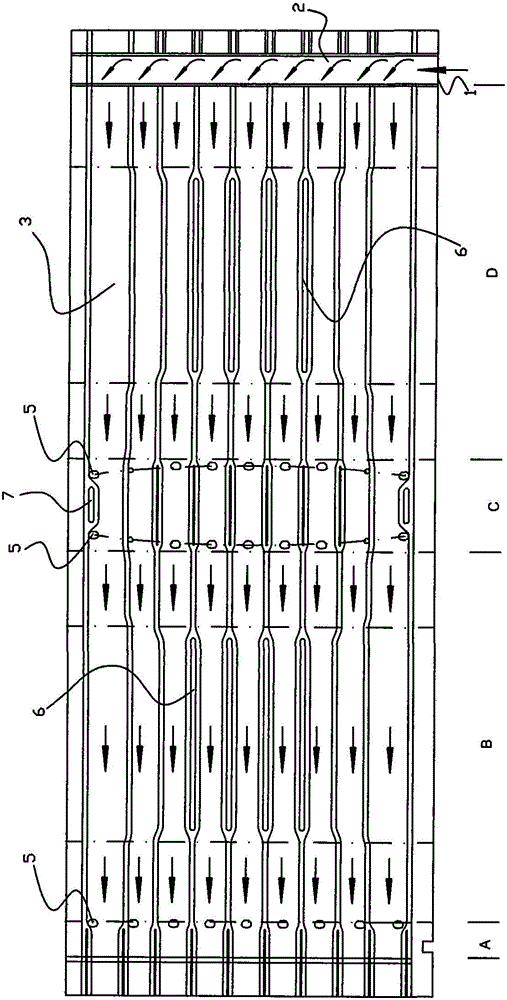

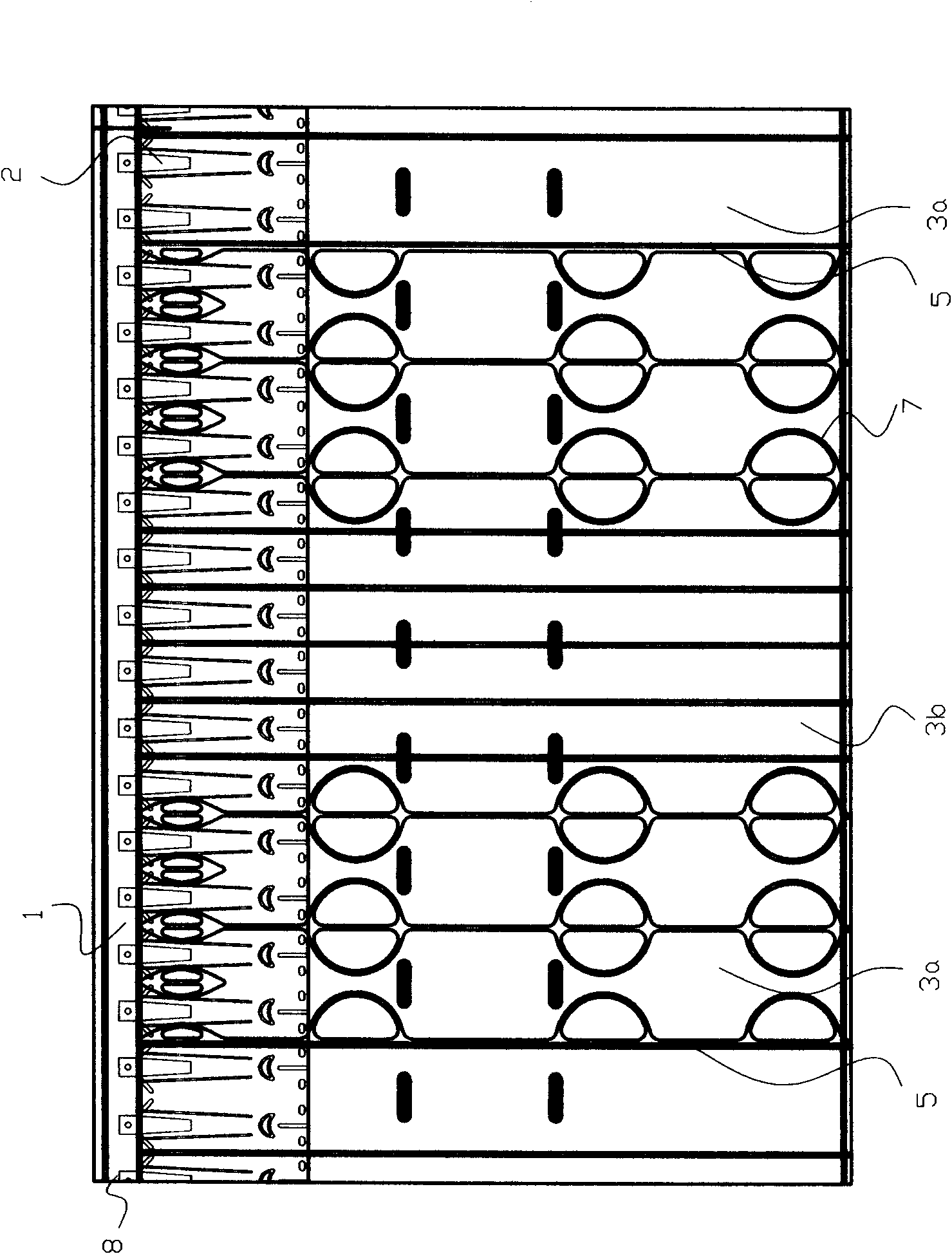

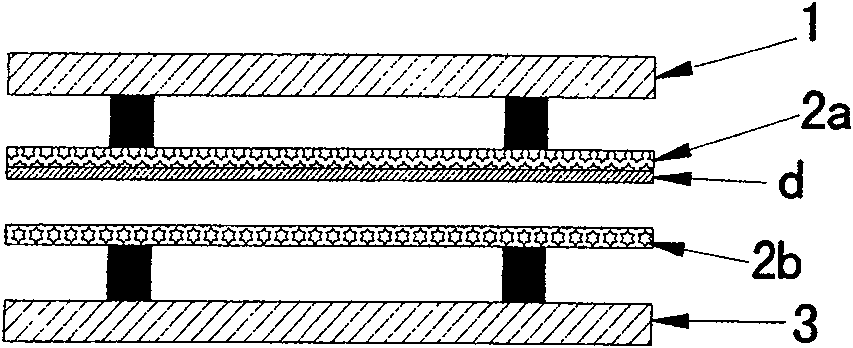

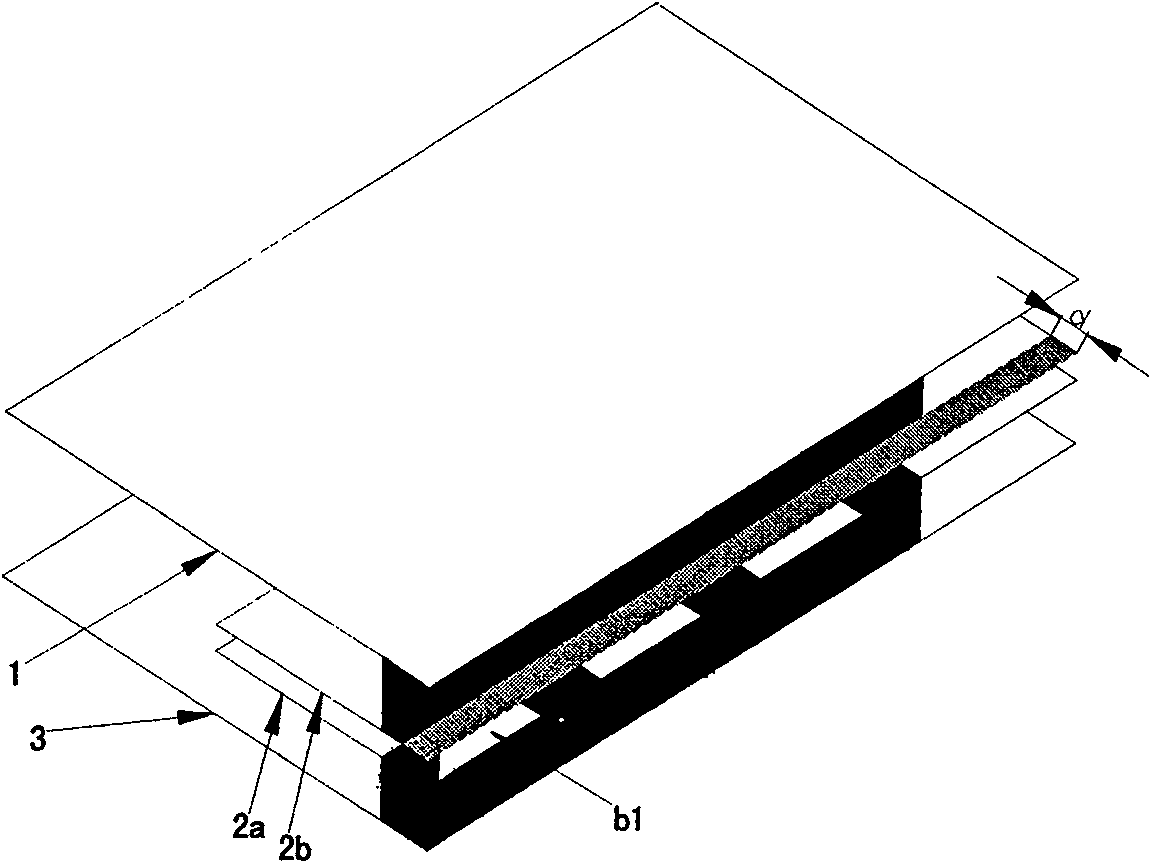

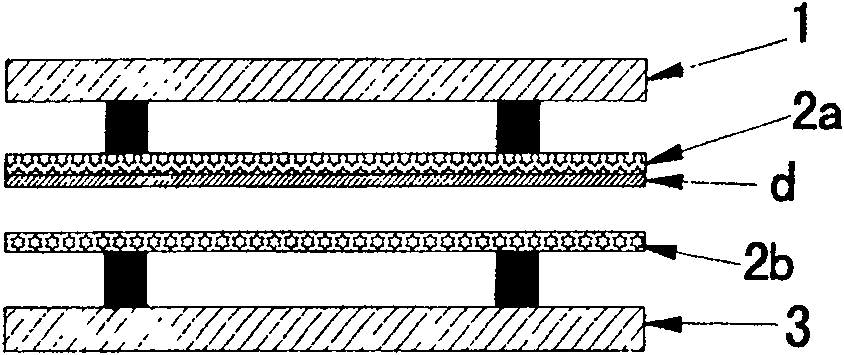

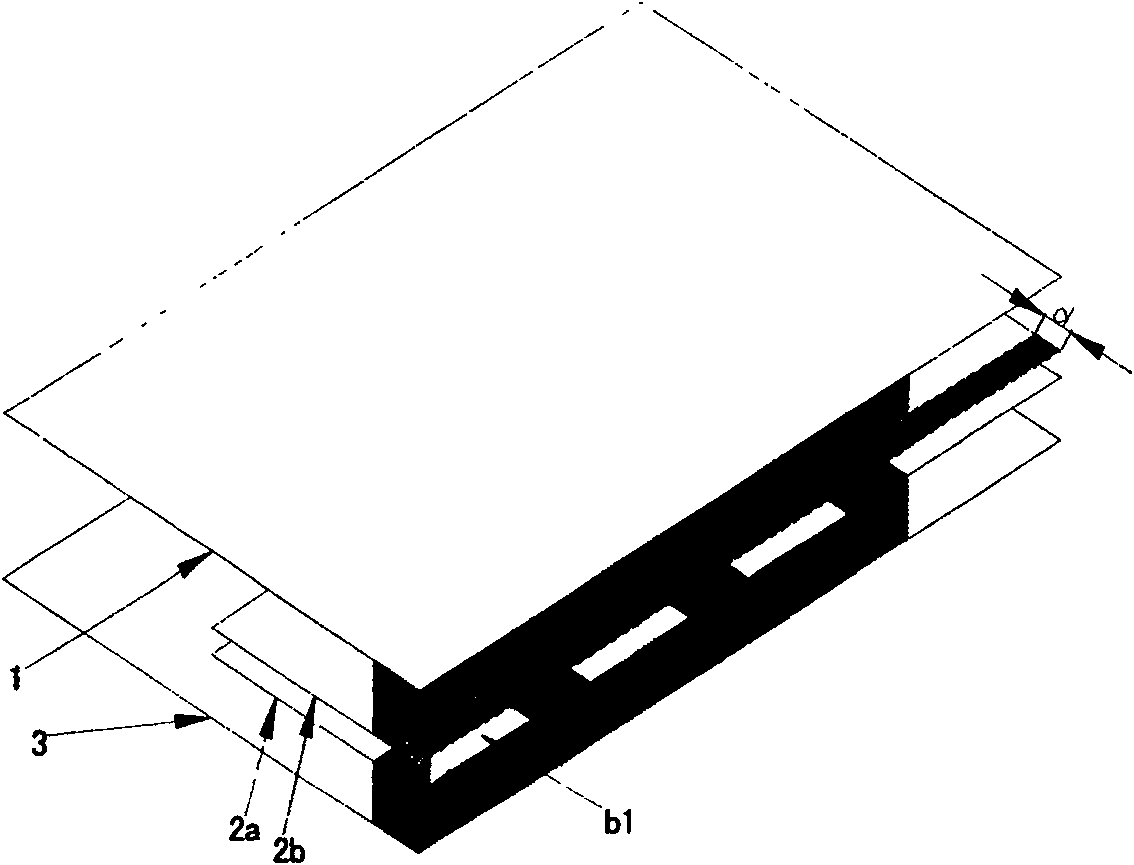

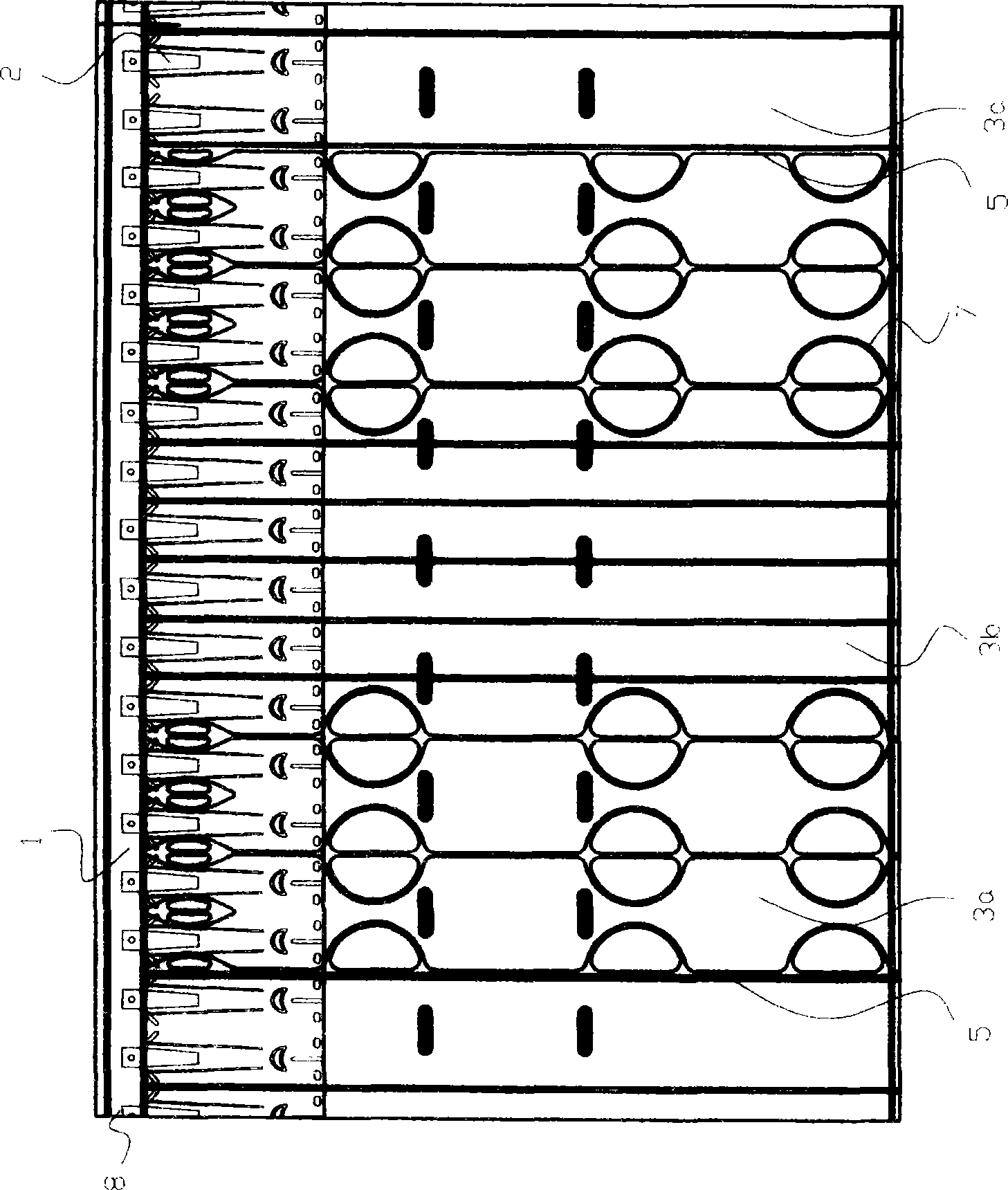

The invention provides an environmentally-friendly three-dimension sealing and packing material which is developed by using the characteristics of different film products, has different functions, can be formed quickly on use sites and has recycling value. The three-dimension packing material is combined with a plurality of layers of functional resin films without any extra supporting device. The films are sealed by heat and folded to form a space capable of storing gas media including the air for a long time, and the air and the films jointly form the functional three-dimension packing material by using a self-adhesive film preventing and air blocking technology. The three-dimension packing material is completely flat before use, is quickly formed in three dimensions by using a gas such as the air when to be used by a user and forms an air bag protective structure around an product to be protected. The three-dimension packing material has excellent comprehensive protective functions such as extrusion resistance, shock resistance, falling resistance and impact resistance and functions such as light shielding, moisture prevention, electrostatic prevention, conductivity, wear resistance, corrosion resistance, rust resistance, and printability.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

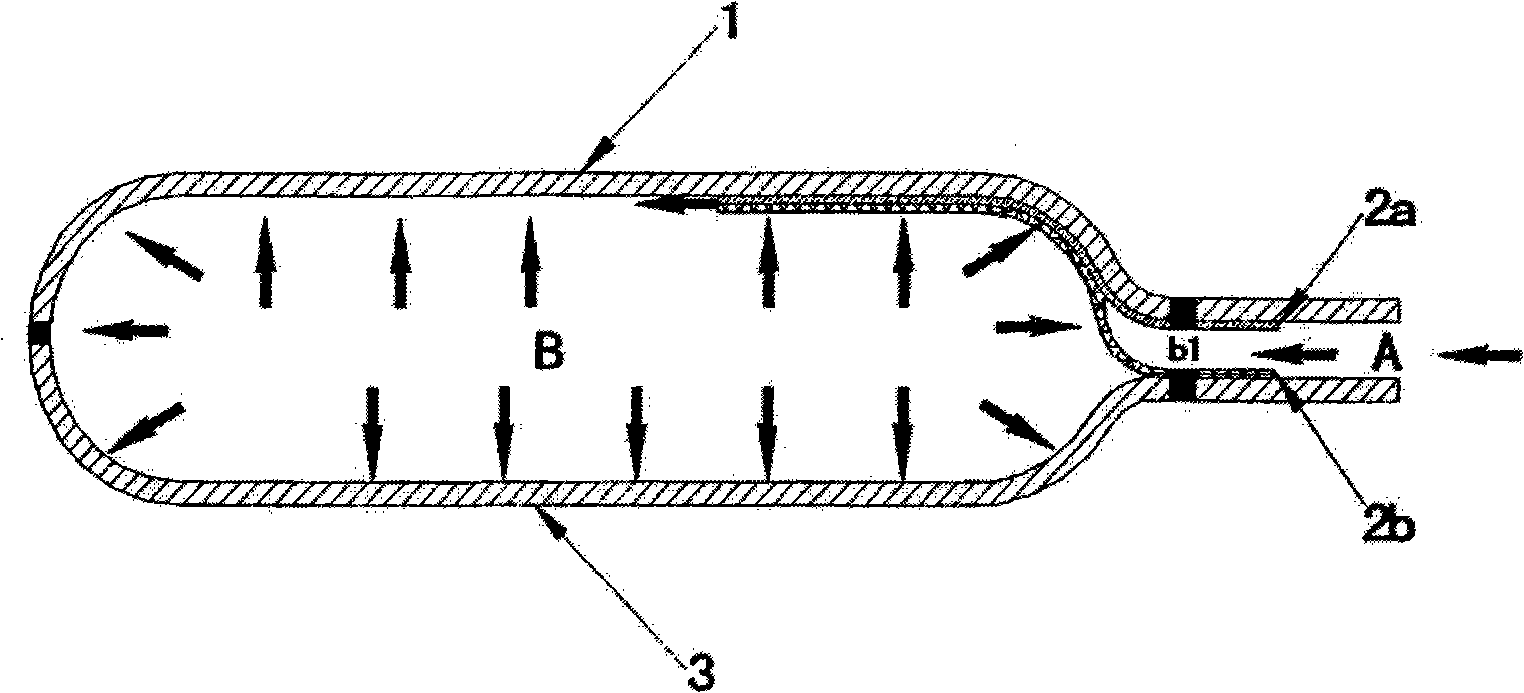

Function type cling-wrap one-way air blockage volumetric packaging material and preparation method thereof

InactiveCN101337609AEasy to useWear-resistantEnvelopes/bags making machineryLaminationImpressionabilityEngineering

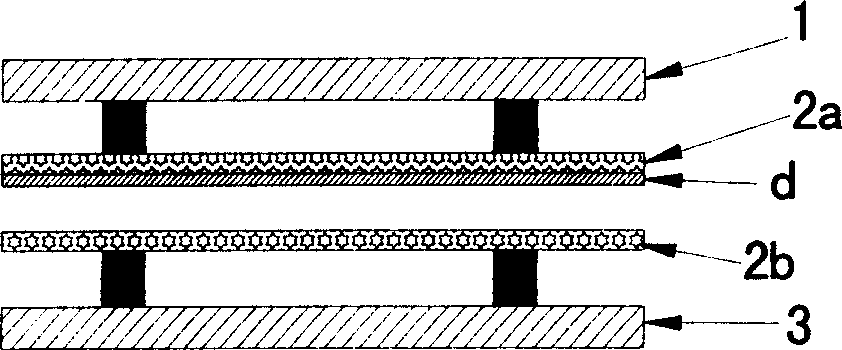

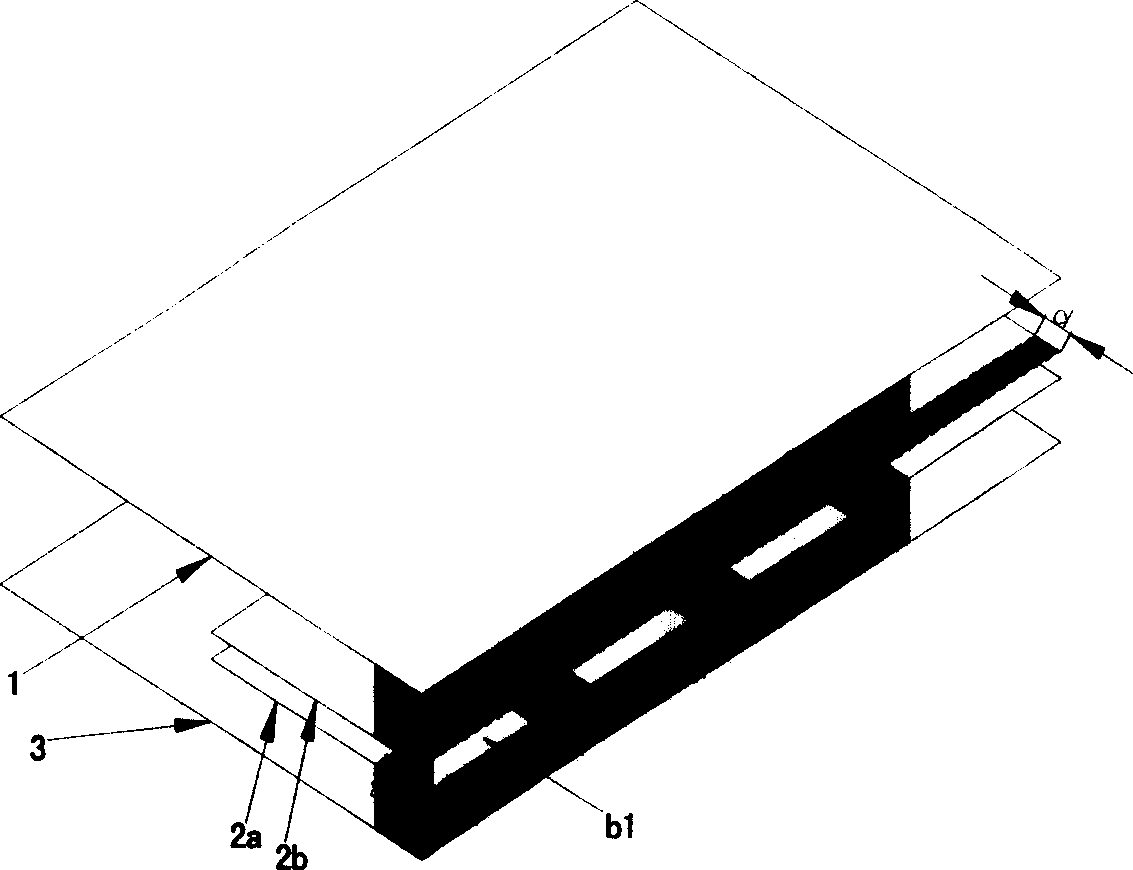

The invention relates to a functional type self-adhesive film one-way air blocking three-dimensional packing material and a preparation method thereof. The three-dimensional packing material is formed by combing a plurality of layers of functional resin thin films, the functional resin thin films form a space used for storing the gaseous medium including air through hot sealing and folding, and the air and the thin films are combined into the functional type self-adhesive film one-way air blocking three-dimensional packing material. Compared with the prior art, the air three-dimensional packing material of the invention has excellent comprehensive protective properties of extrusion resistance, vibration resistance, falling prevention and buffering, and meanwhile, can be embodied with the functions of light prevention, moisture resistance, electrostatic prevention, electric conduction, wear-resistance, corrosion resistance, rust protection and impressionability, etc.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

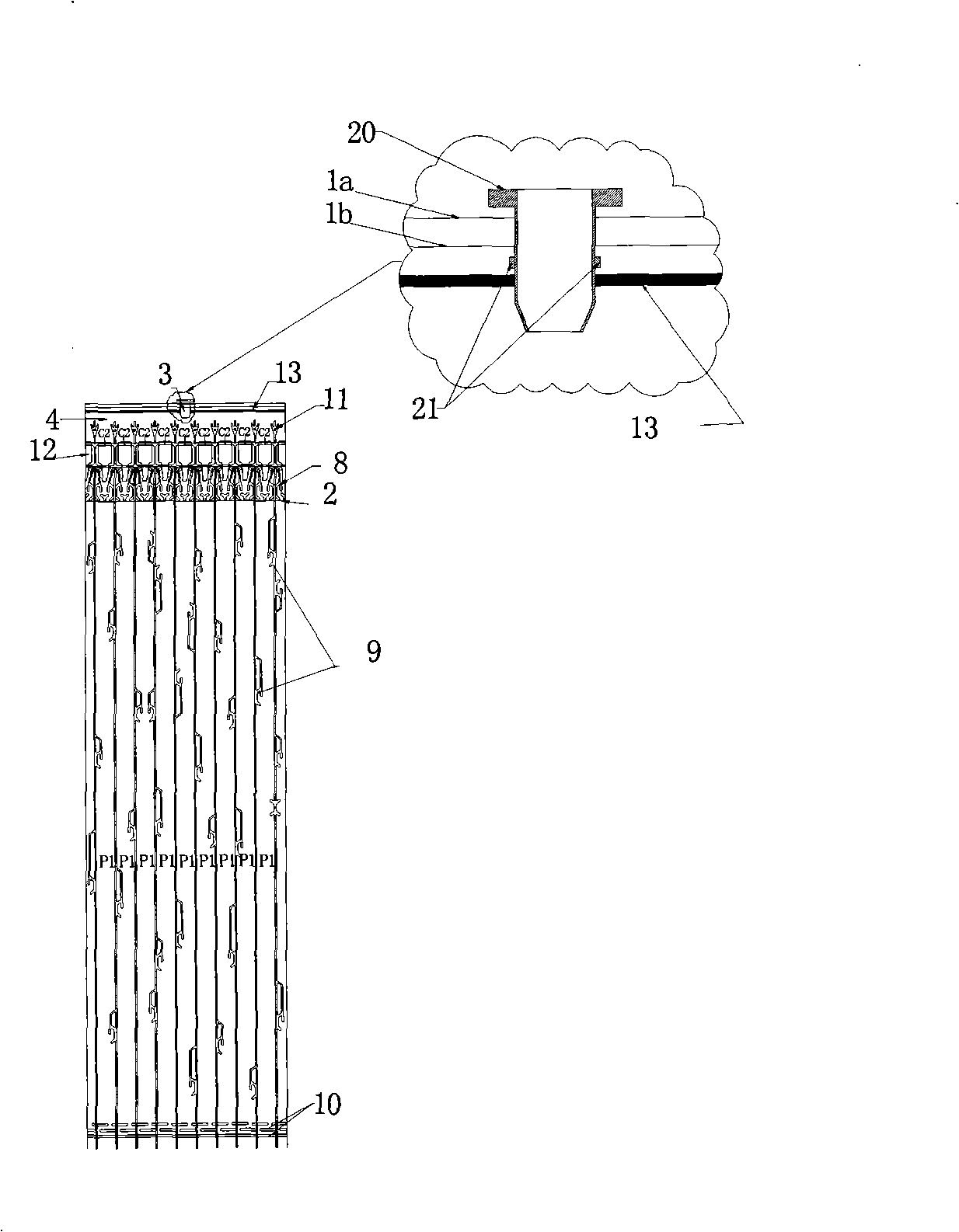

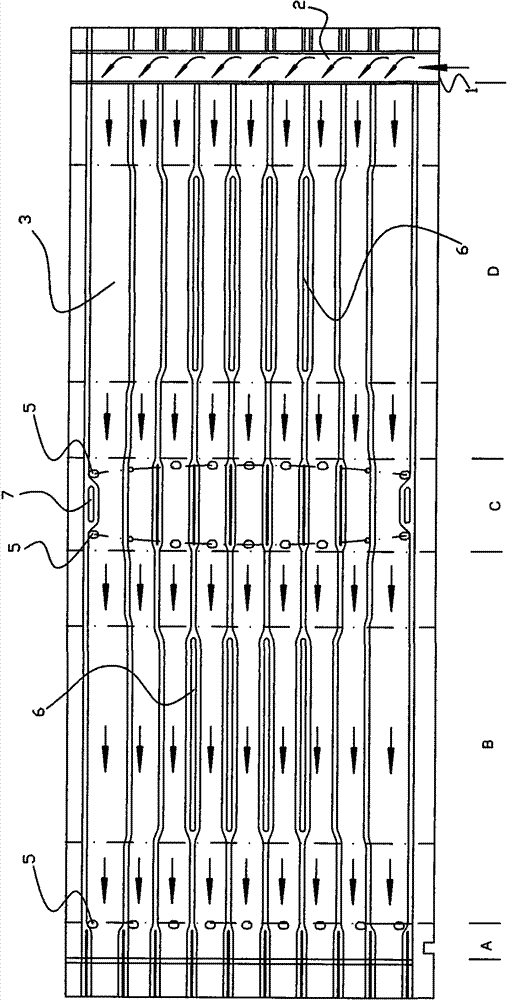

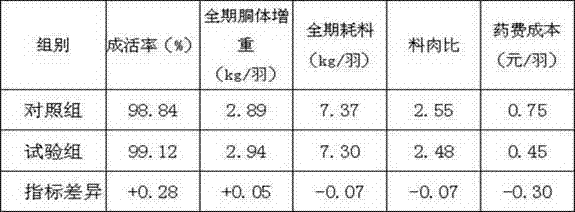

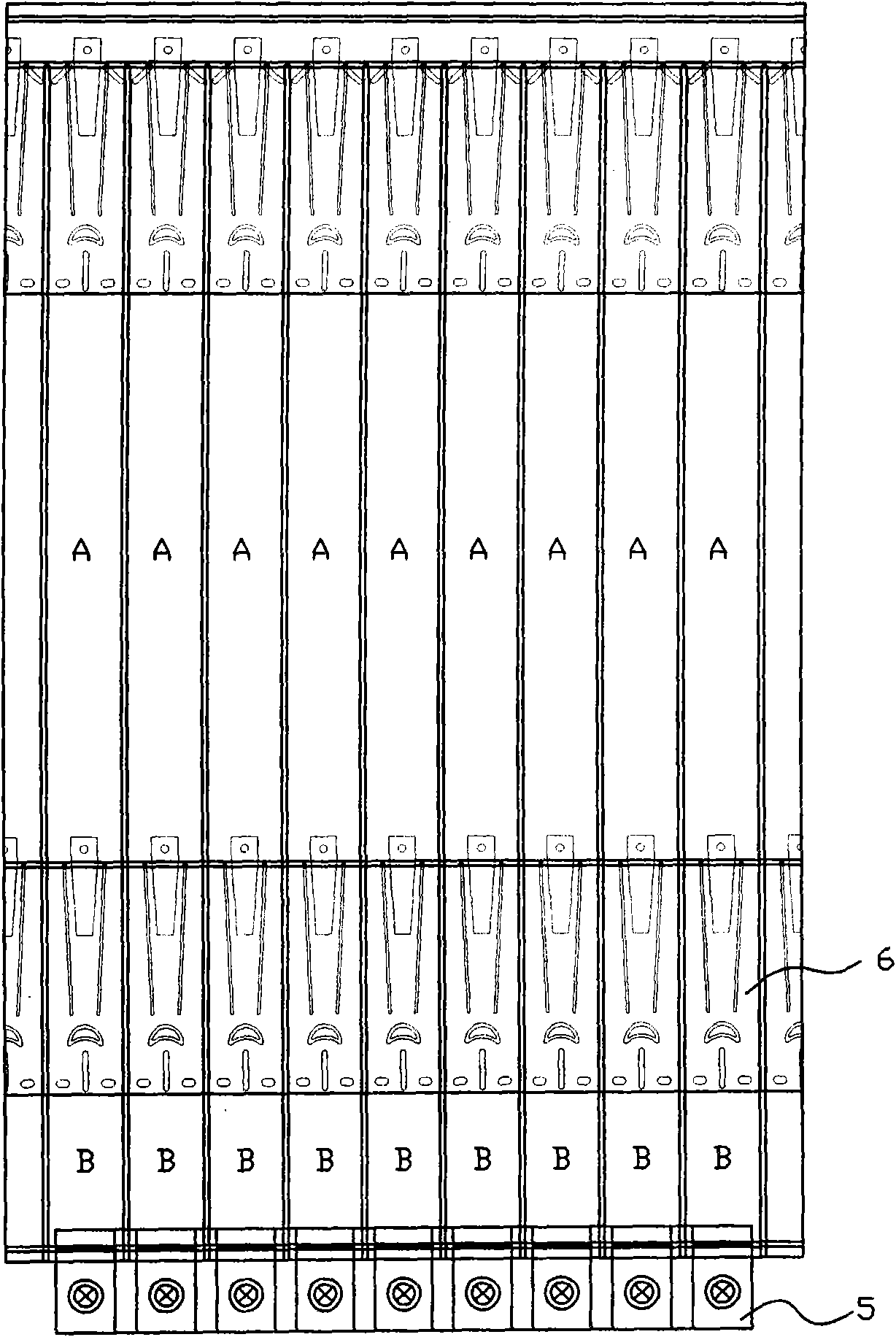

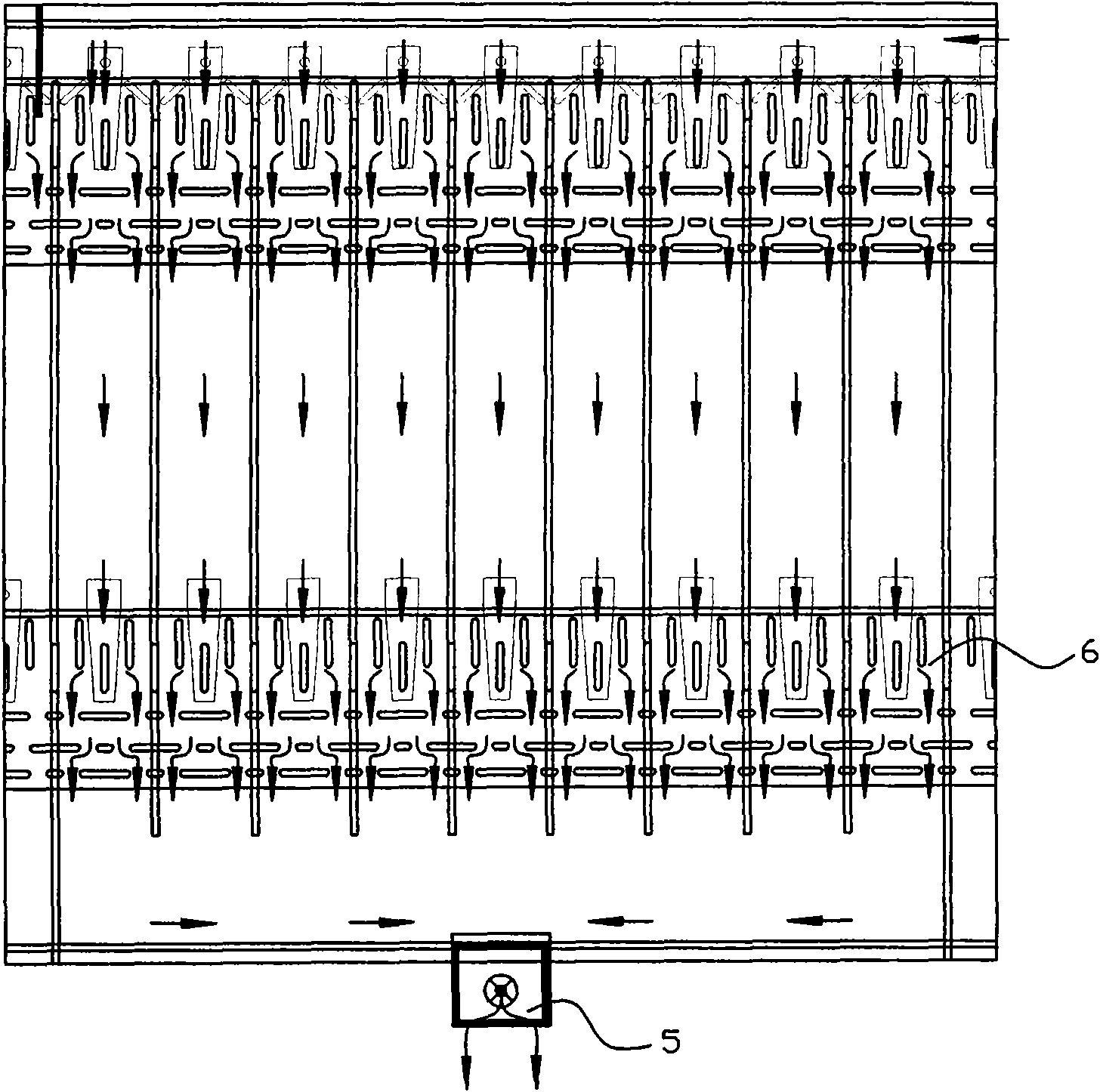

Improved air packaging device

ActiveCN101934892AImprove securitySolve the problem of high cost of long-distance transportationContainers to prevent mechanical damageDamagable goods packagingThin membraneEngineering

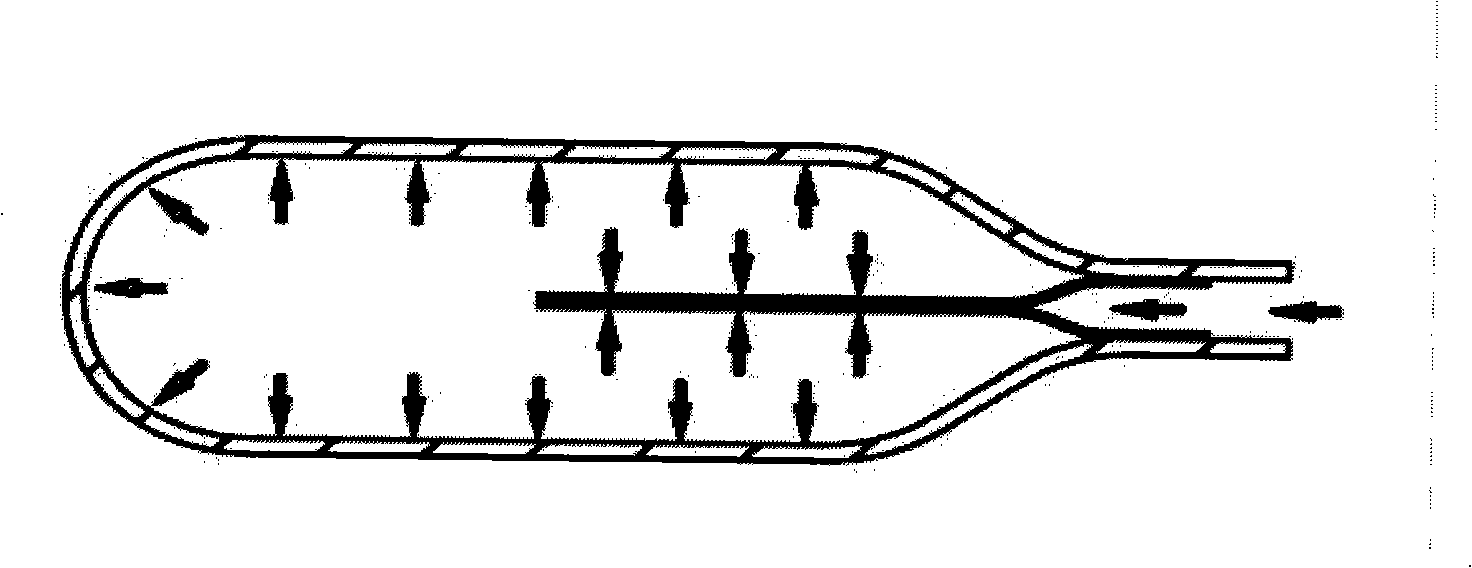

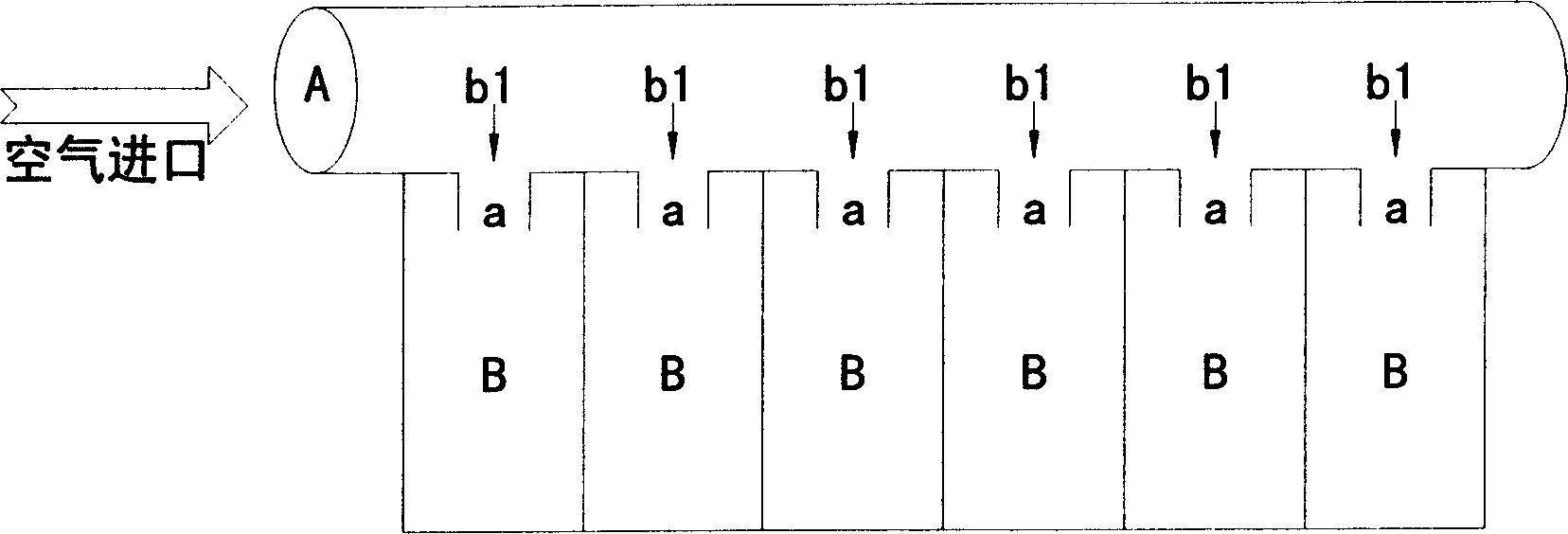

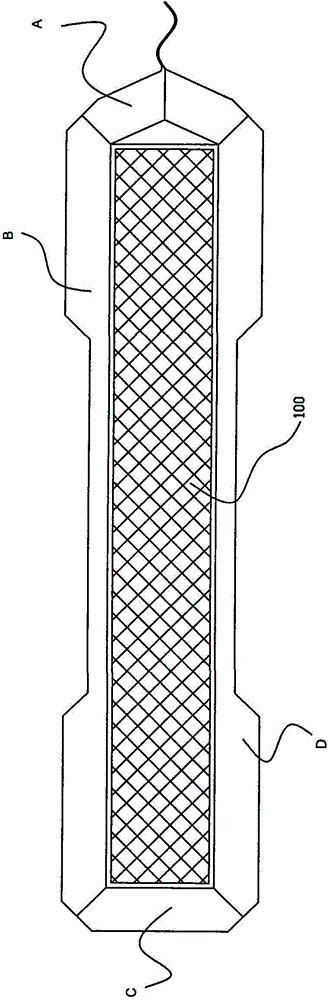

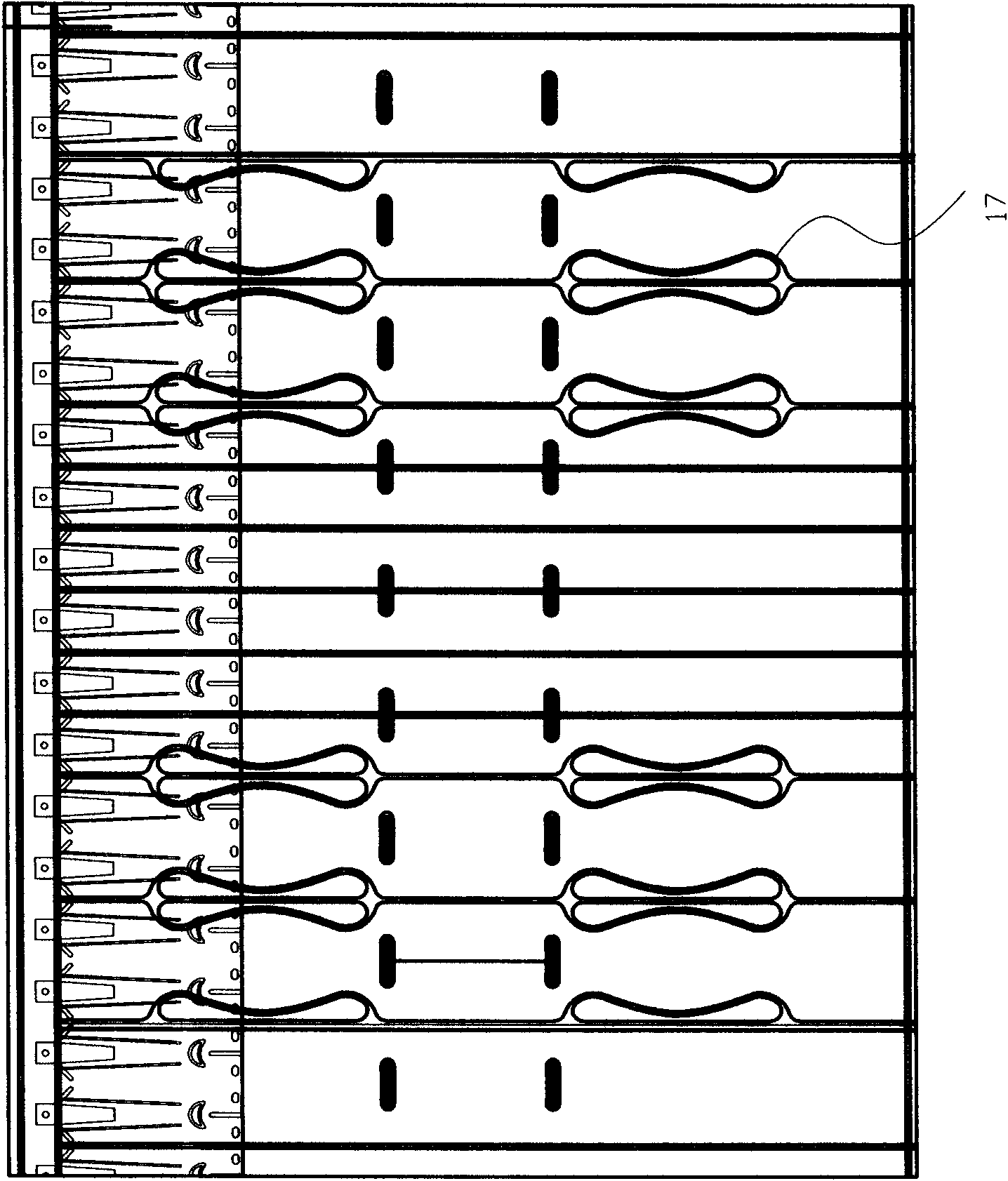

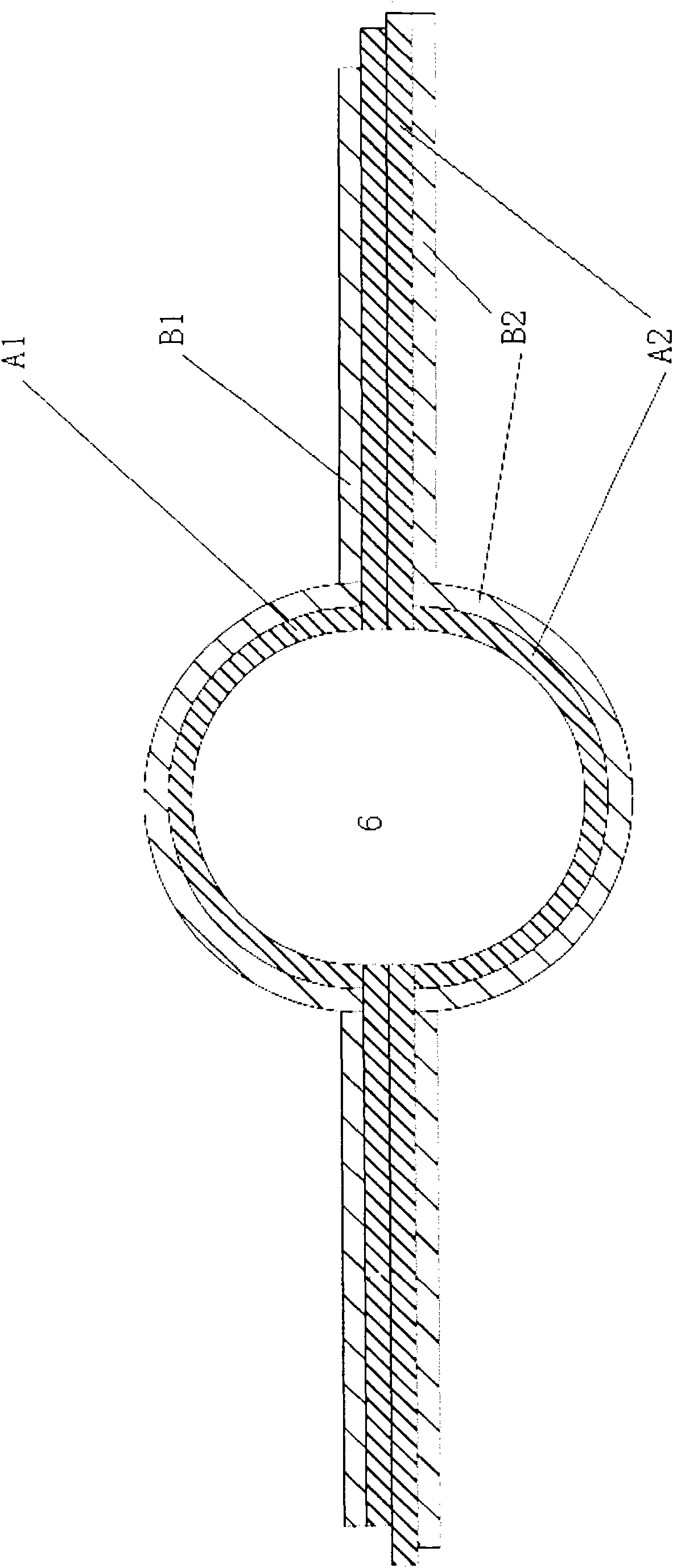

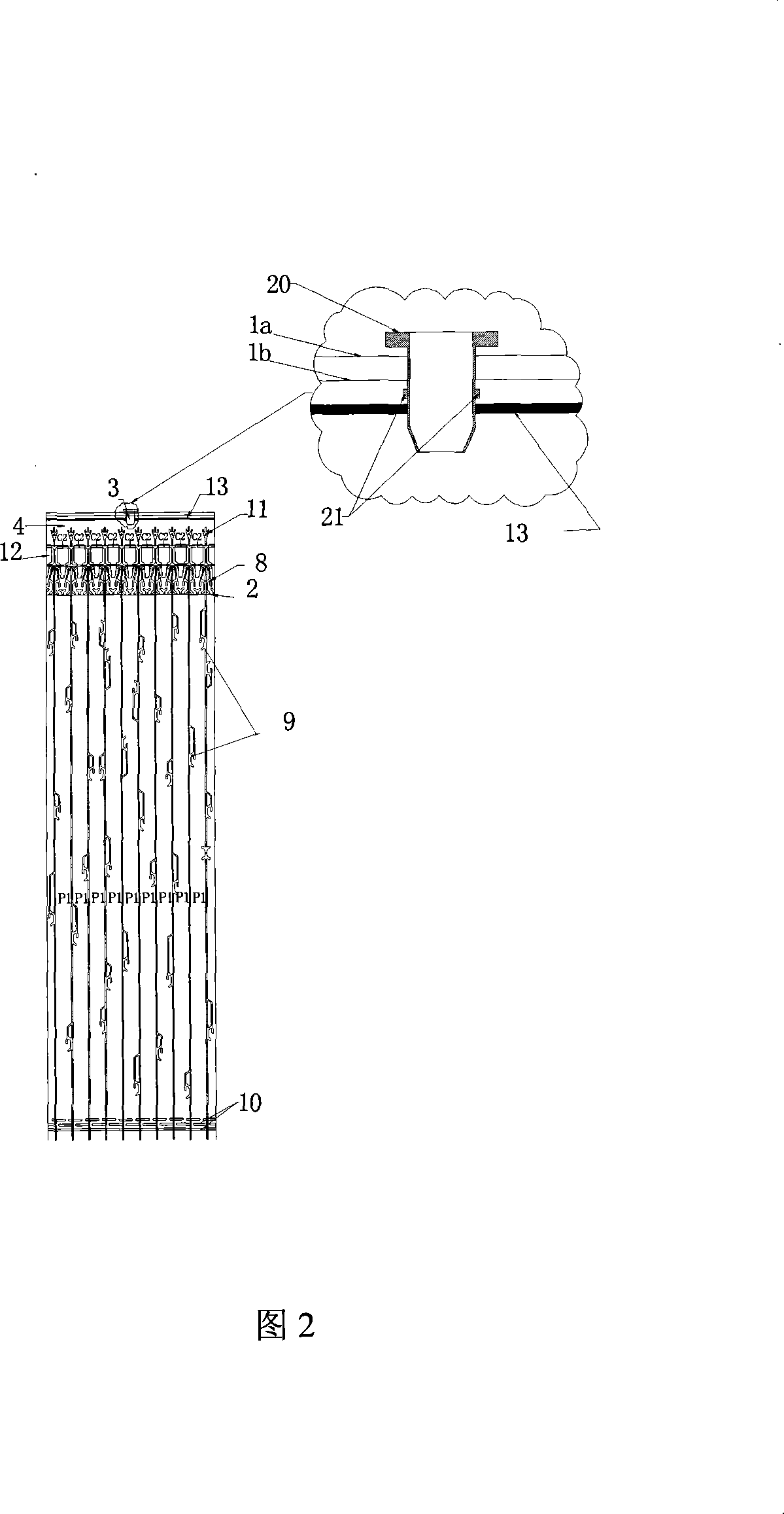

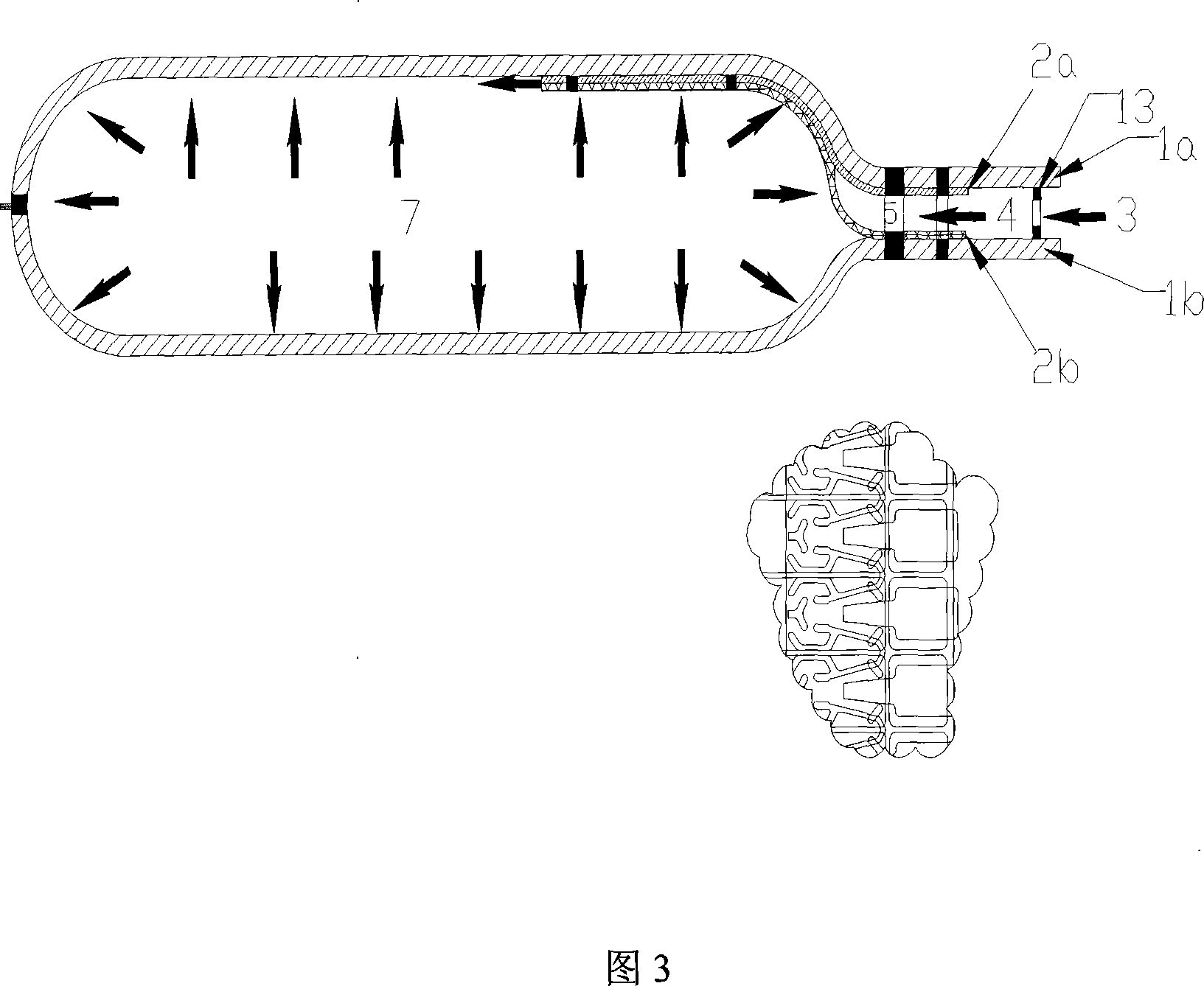

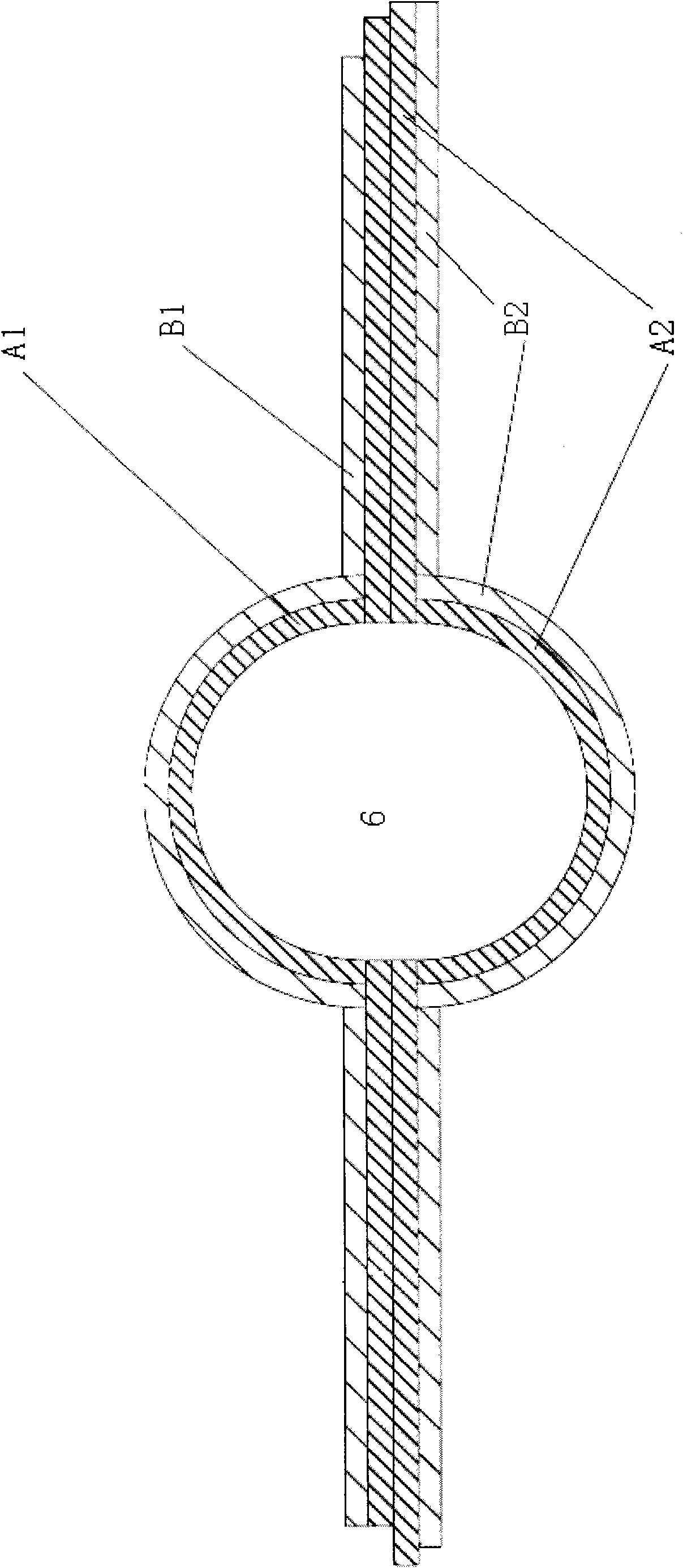

The invention relates to an improved air packaging device. Two layers of thermoplastic films are subjected to secondary thermoplastic packaging to form a stereoscopic packaging body which can be sealed. The improved air packaging device comprises a plurality of independent seal air chambers and a main passage, wherein the main passage is provided with an air inlet; and each seal air chamber is communicated with the main passage by a check valve formed by two layers of films. The improved air packaging device is characterized in that the check valve and the main passage for inflating the check valve are formed by carrying out thermoplastic packaging on the two layers of films and one layer of thermoplastic film of the packaging body into a whole and can be arranged in any position of the seal air chambers. Meanwhile, because the two layers of check valve films are only fixed on any layer of thermoplastic film, and the check valve films are adhered to the thermoplastic film after inflated and do not bear any tension, the tearing risk does not exist, and the safety of the packaging device is greatly improved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Hybrid intestinal micro-ecologic preparation and preparation method thereof

InactiveCN105475988AImprove the immunityIncrease mass concentrationFood ingredient functionsBacillus licheniformisIsomaltooligosaccharide

The invention provides a hybrid intestinal micro-ecologic preparation and a preparation method thereof. The preparation method comprises the following steps: carrying out third-stage fermentation culture on probiotics butyric acid bacteria, lactobacillus acidophilus, Bacillus coagulans and Bacillus licheniformis, adding a freeze drying protection gent, freeze-drying the obtained culture product, carrying out microcapsule embedding, freeze-drying the embedded product, and mixing the embedded product with isomaltooligosacharide, fructooligosaccharide and vitamins to obtain the micro-ecologic preparation. Butyric acid bacteria and other probiotics can be directly supplemented to the human body intestinal tract, so all the probiotics are propagated and intergrow in the intestinal tract and have synergism, and the intestine controlling, cancer preventing, immunity improving, digestion helping and harmful bacterium and corrupted group growth breeding inhibiting effects of the composite bacterium preparation are effectively performed, thereby the beneficial physiologic effects of the probiotics on human bodies are greatly improved; and the preparation method can effectively guarantee the quantity of live bacteria of the probiotics, the activity of the probiotics and the preservation time of the probiotics.

Owner:HENAN JINBAIHE BIOTECH CO LTD

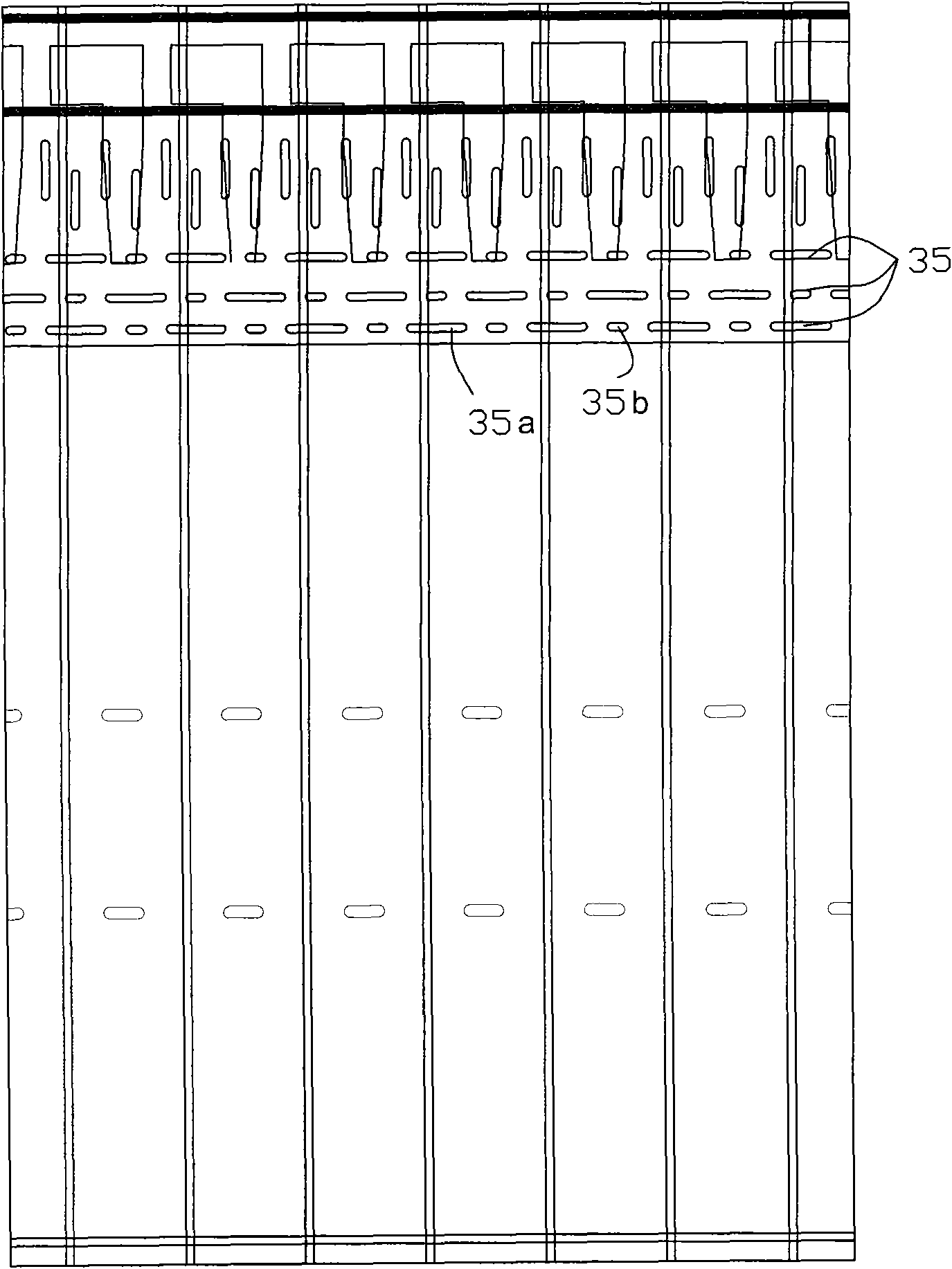

Air-isolated and self-adhering packing material and its preparation

An air-isolated 3D packing material with high resistance to squeeze, vibration and impact and excellent buffering effect is prepared from two thicker films and two narrower films through local heat sealing several times and folding several times to form multiple chambers containing air.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

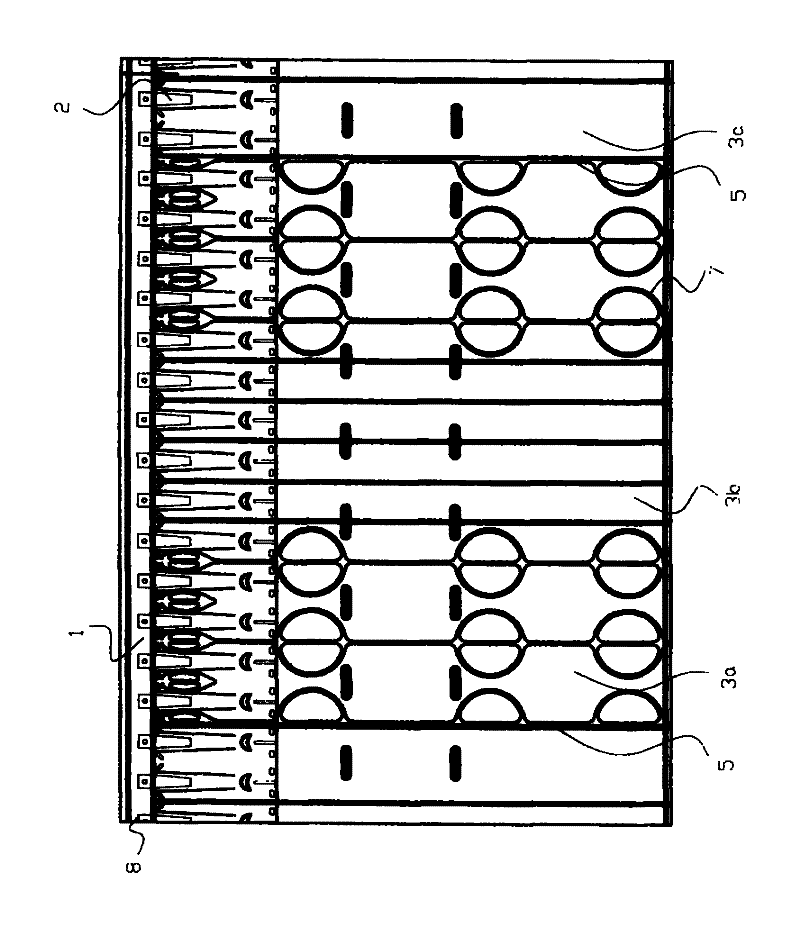

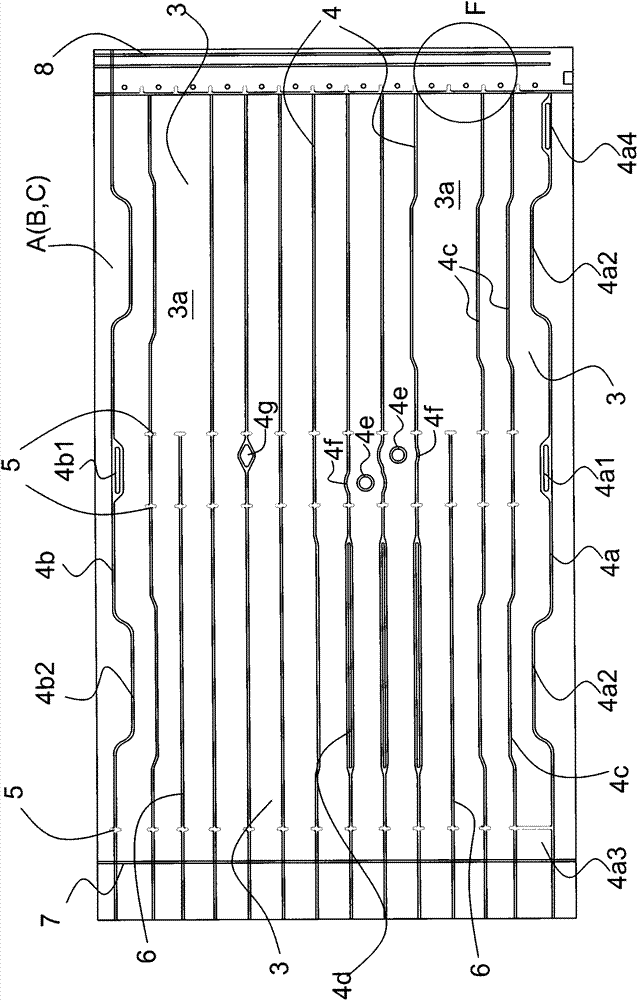

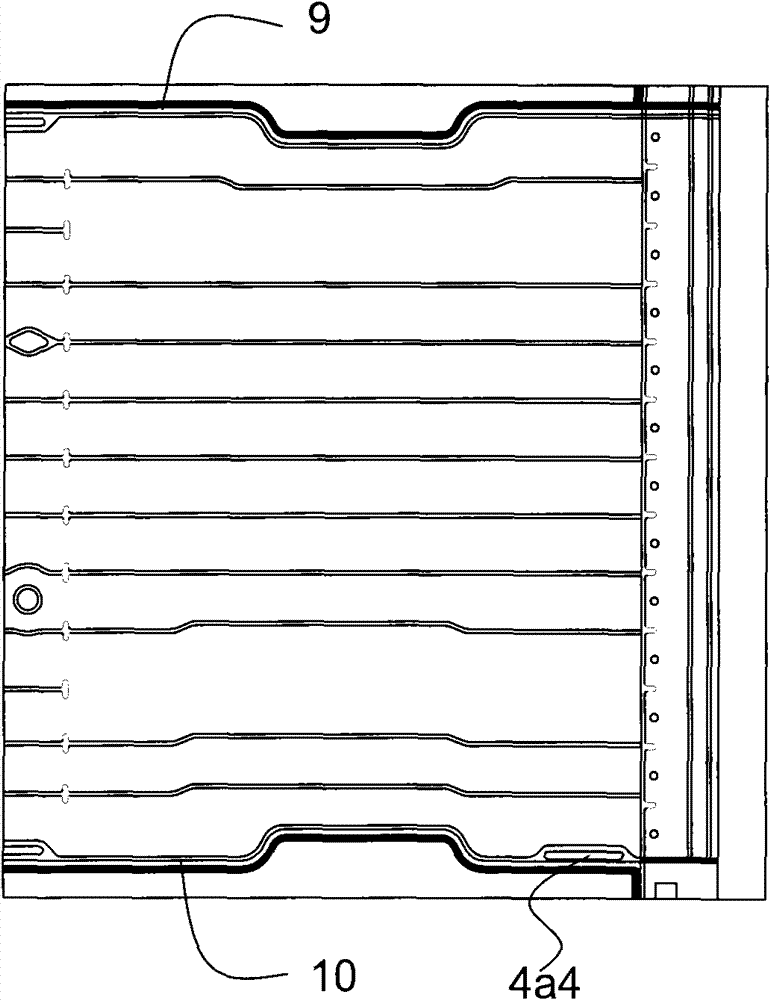

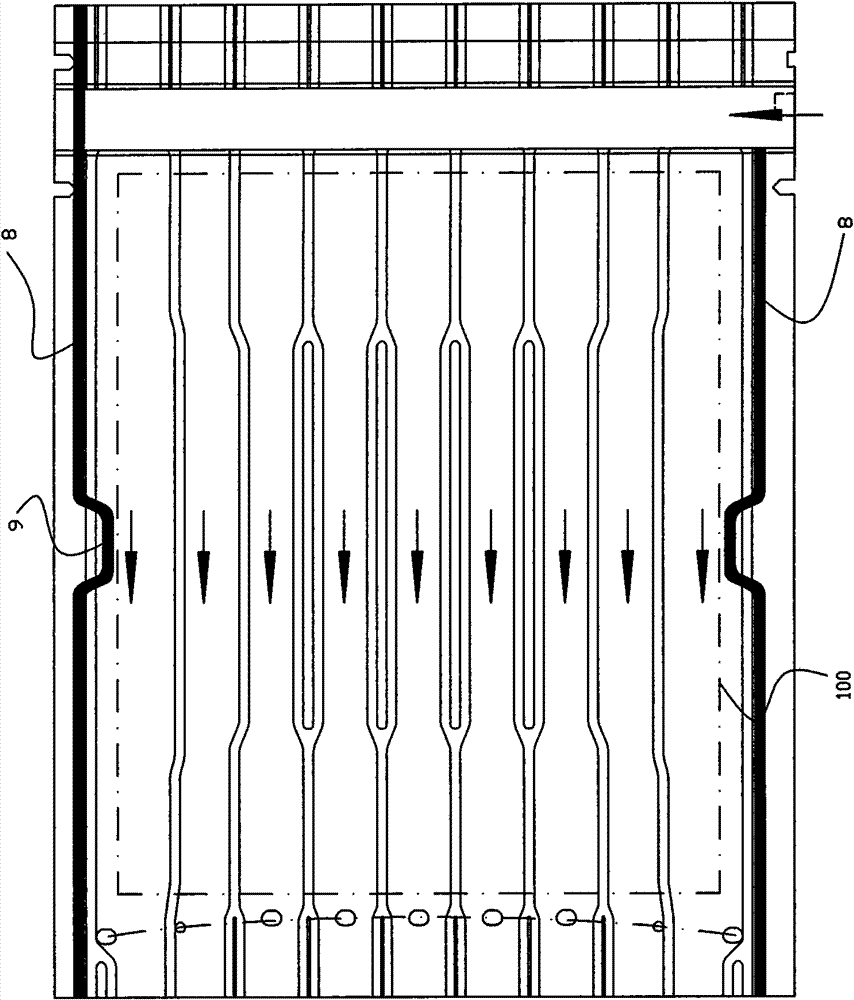

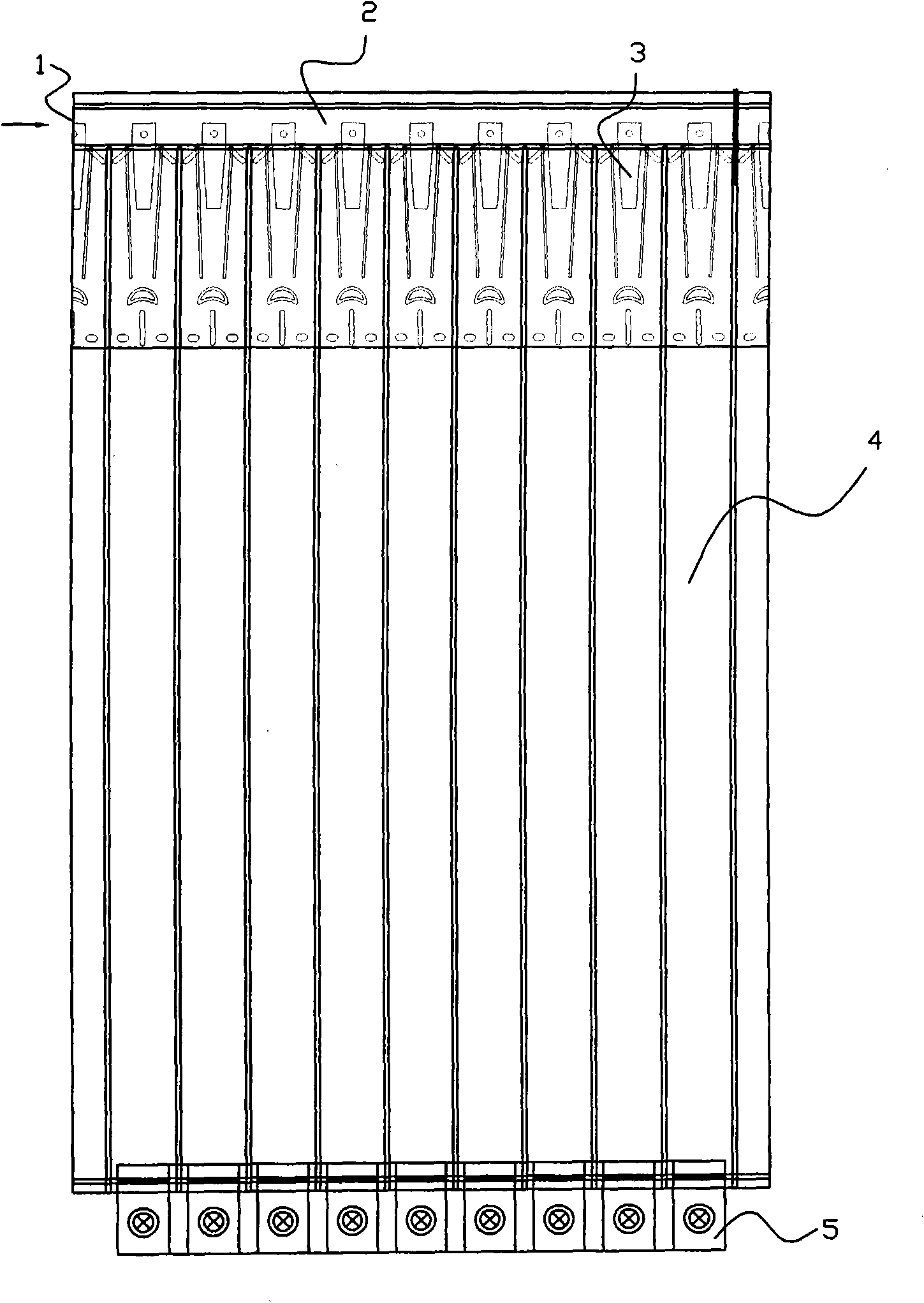

Air packing device having multilevel buffers

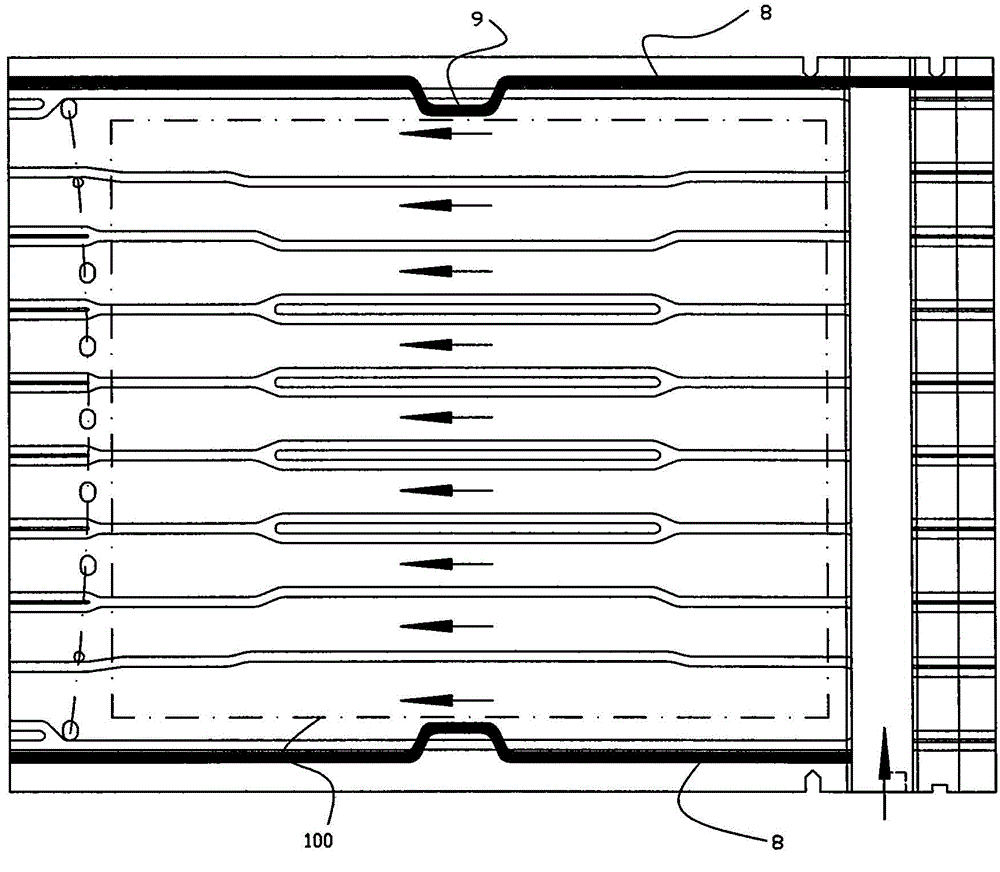

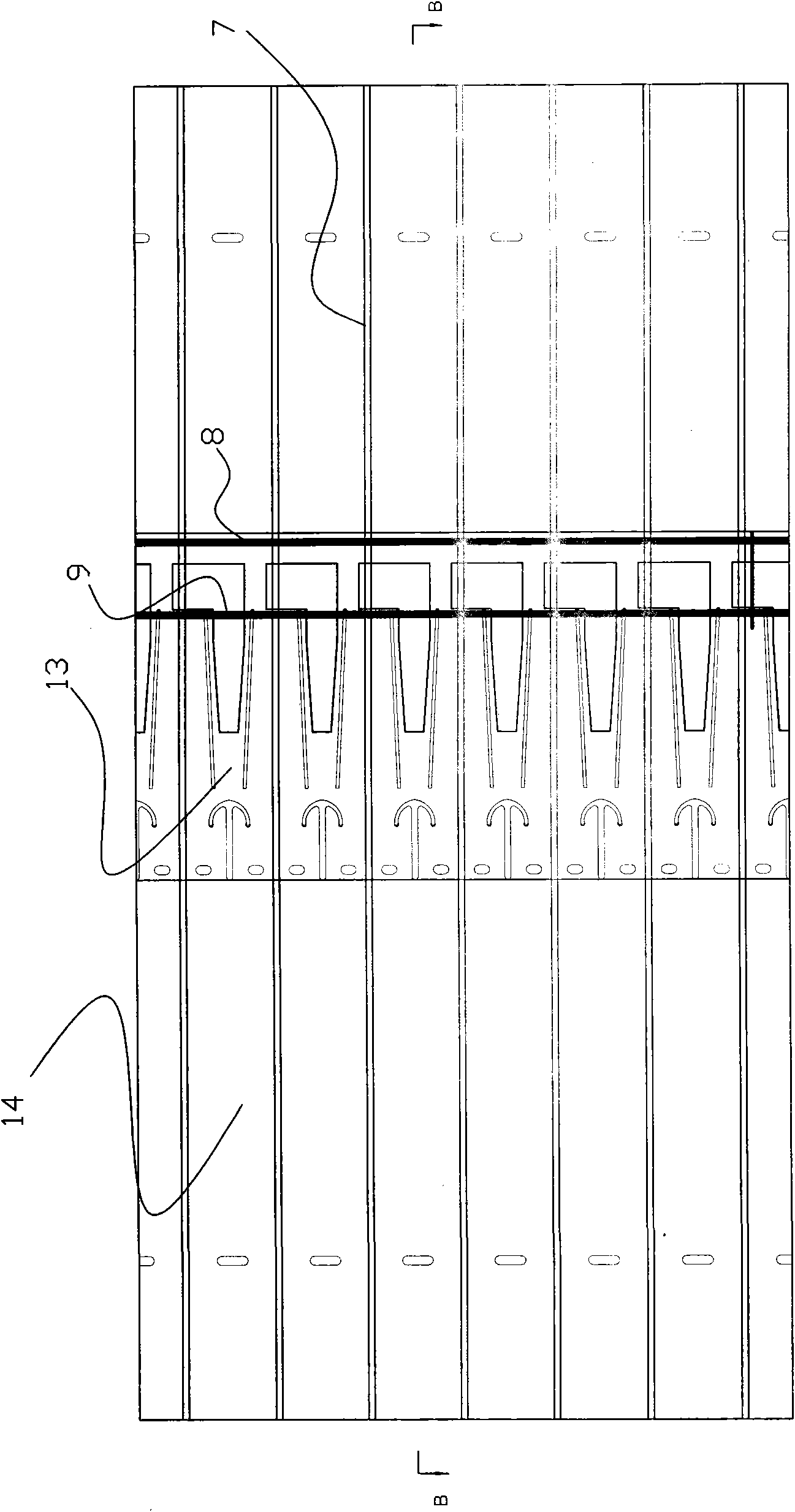

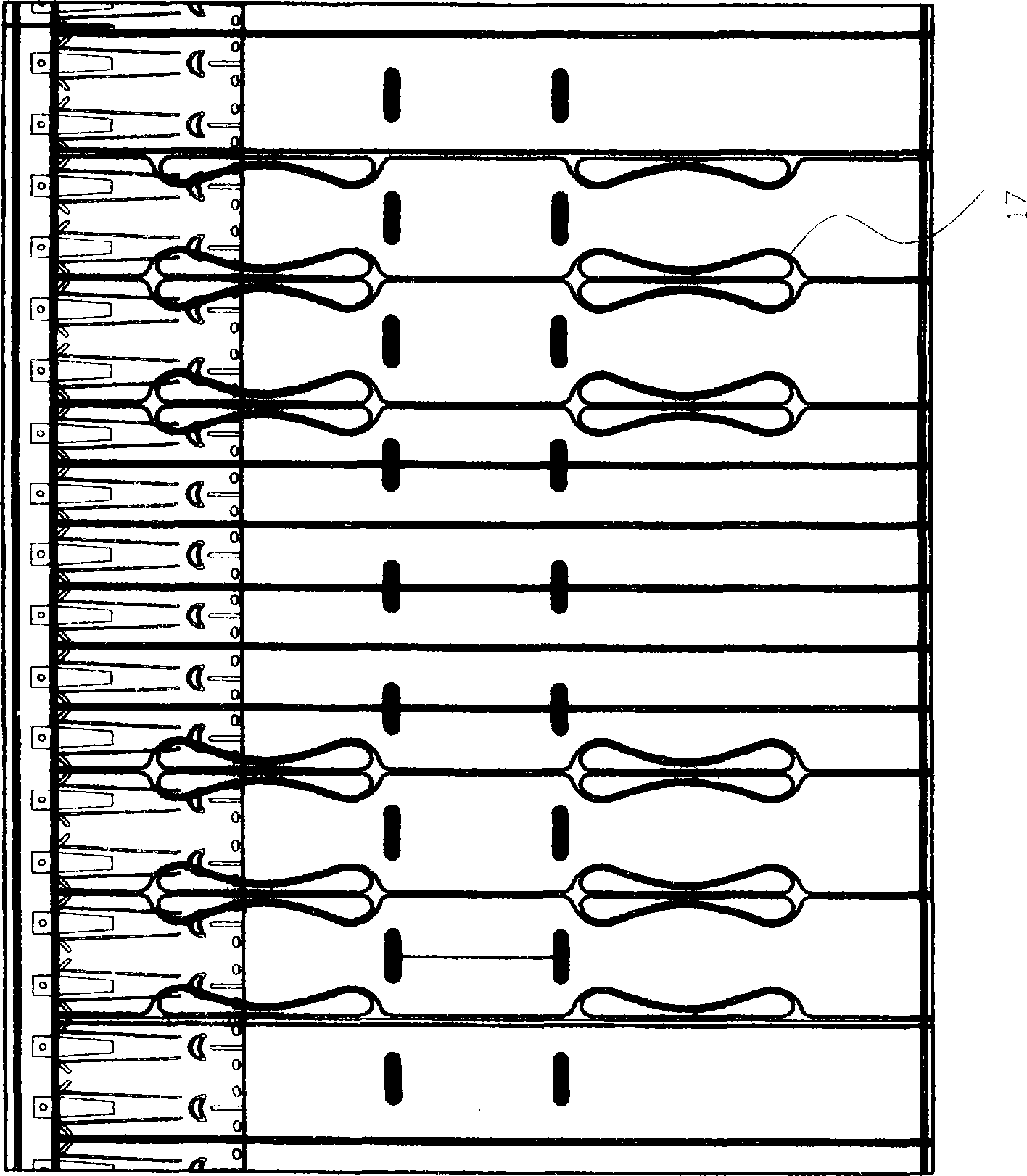

ActiveCN104925378AReduce impactReduce falling speedContainers to prevent mechanical damageMain channelMain bearing

The invention discloses a multi-buffer air packing device. In the device, two layers of thermoplastic films are subjected to two times of thermal plastic sealing to form a three-dimensional packing body capable of sealing the air, the packing body comprises a plurality of independent sealed air chambers and a main channel with an air inlet, each sealed air chamber is communicated with the main channel through a one-way valve formed by two layers of films, the sealing chambers have turning points, the packing body is divided into a main bearing face and a lateral bearing face by a turning point line formed by the turning points, the diameter of the middle part of the sealed air chamber of the main bearing face formed after inflation is smaller than the diameters of the sealed air chambers on two sides. In the air packing device of the invention, higher air chambers, when a packed object falling onto the ground is impacted, contact the ground first and then the lower air chambers in the middle contact the ground to produce a secondary buffering effect, so the impact of the packed object is relieved considerably and the impact performance of the packing device is improved. Compared with packing devices of the same volume, the multi-buffer air packing device has much higher impact performance.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

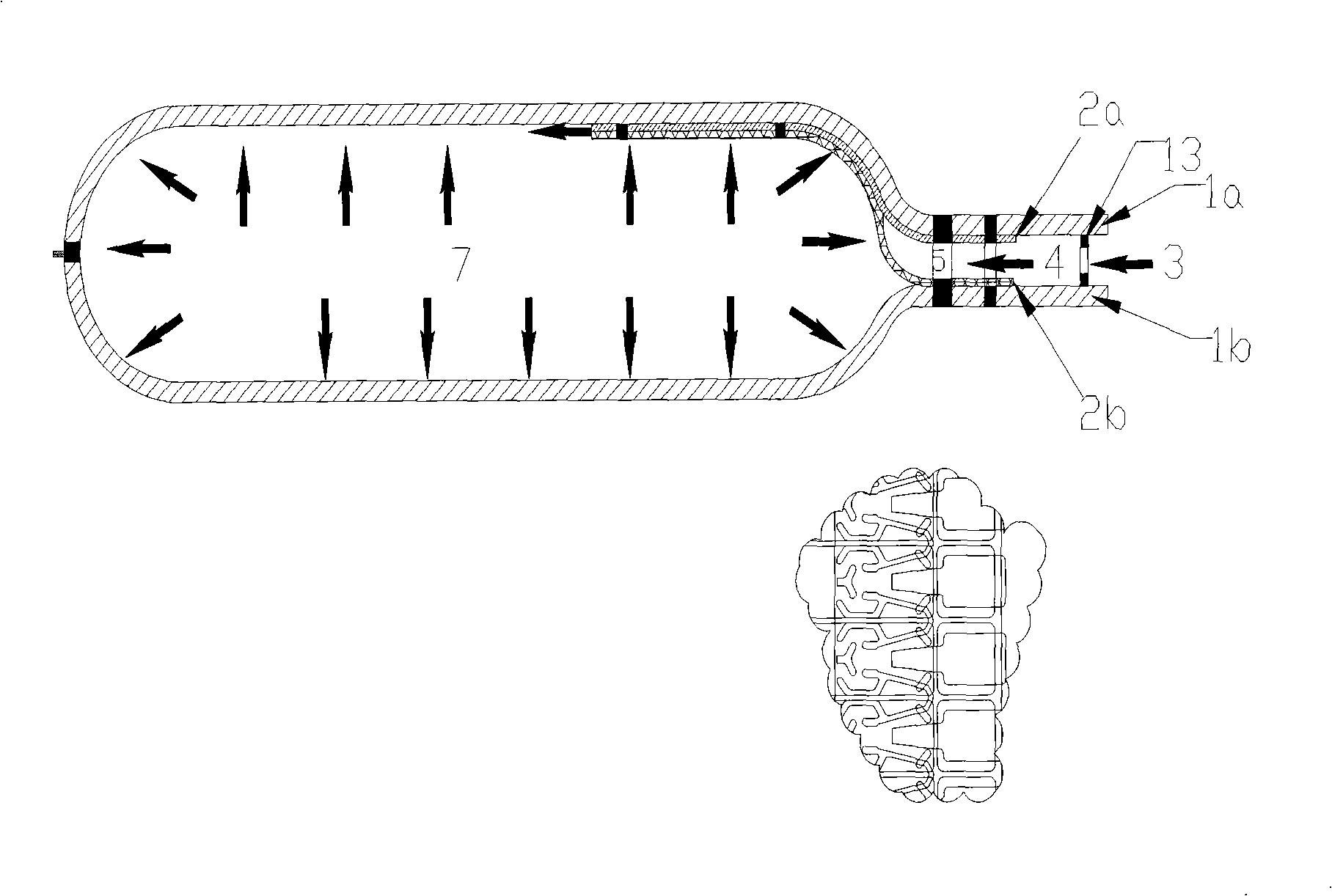

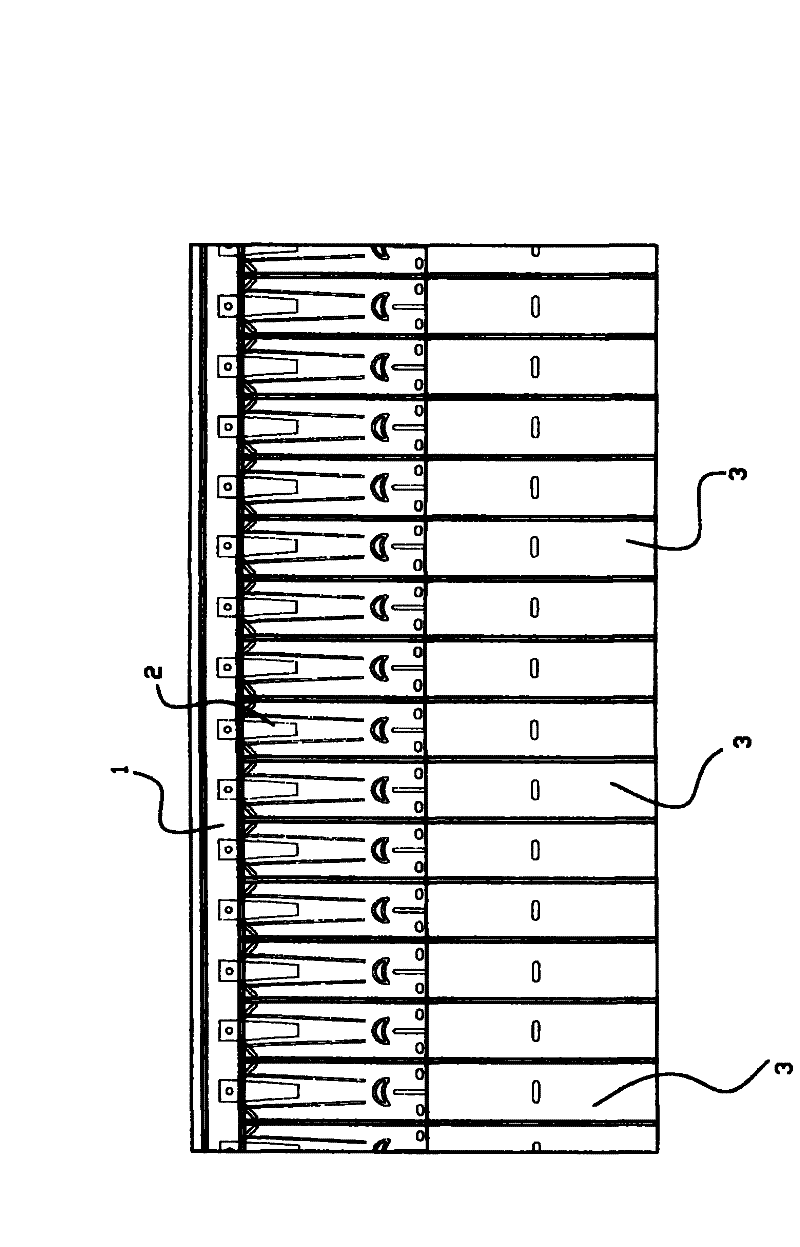

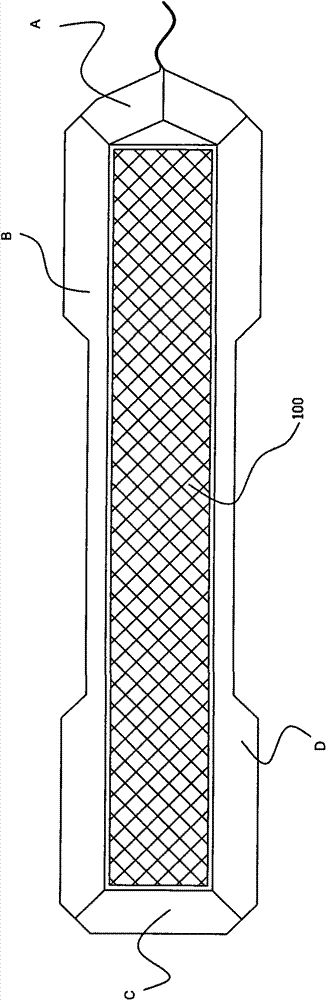

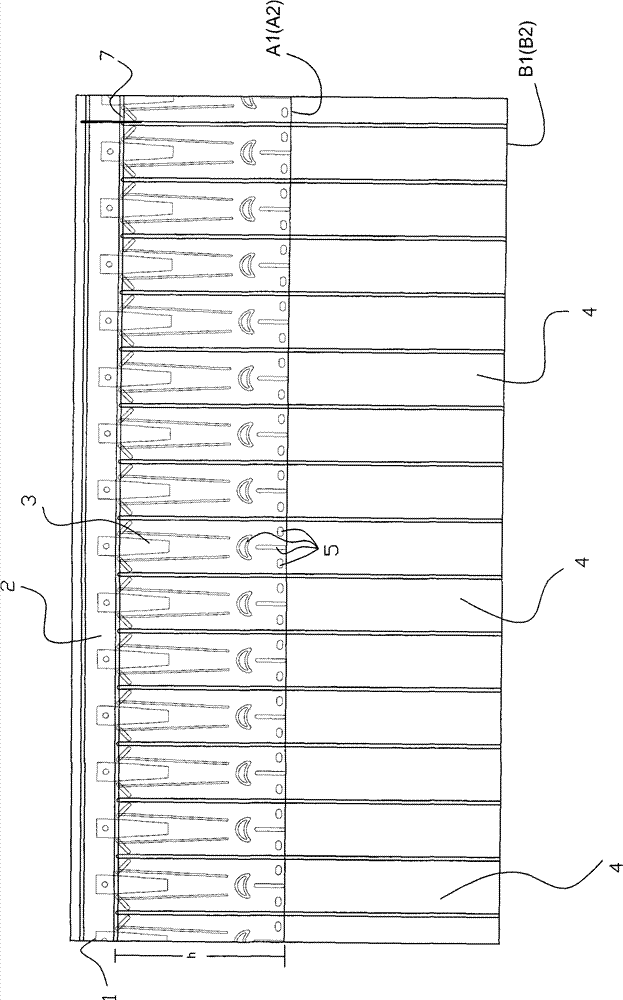

Air packing device

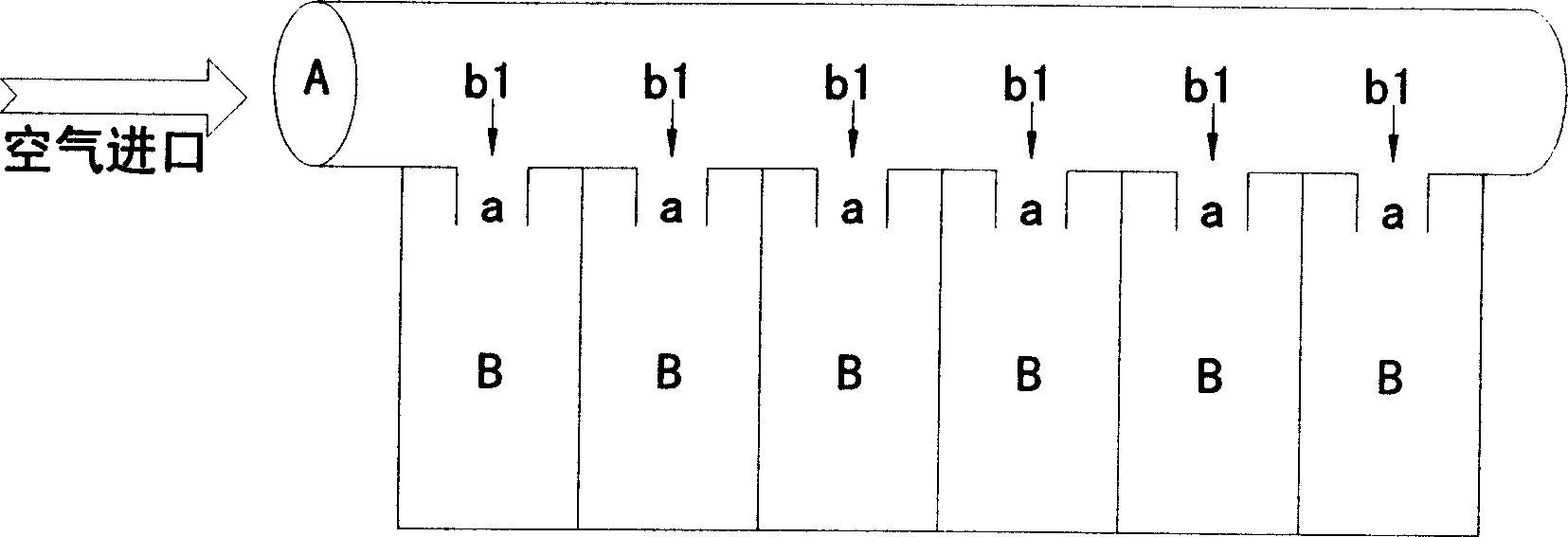

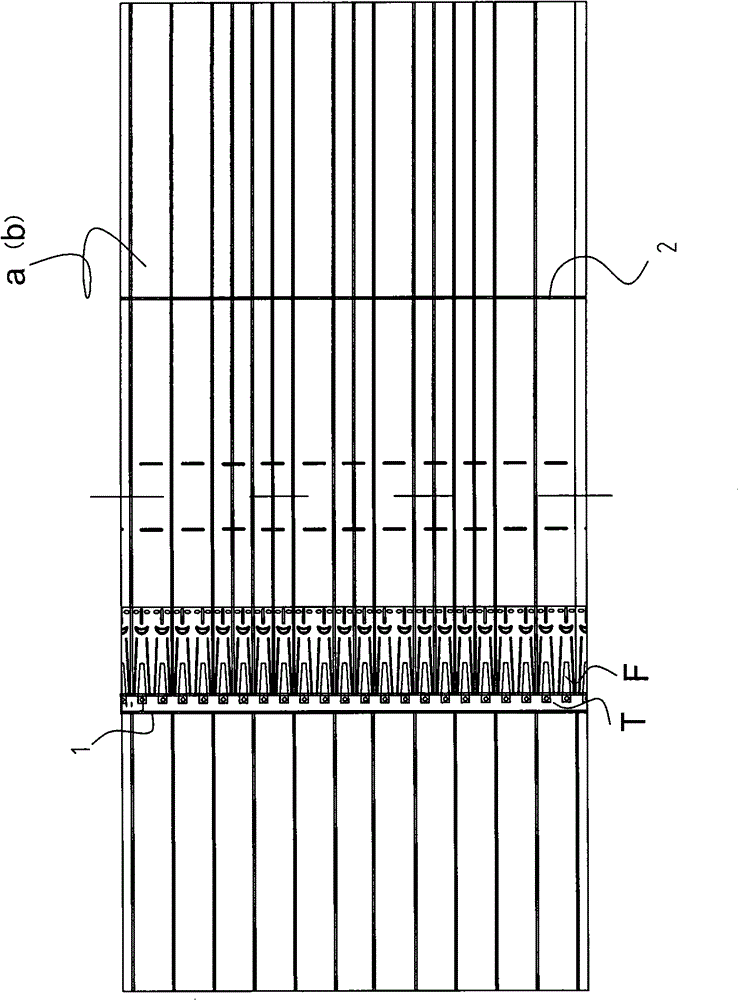

InactiveCN101549775ASolve the problem of high cost of long-distance transportationExtrusion resistantContainers to prevent mechanical damageDamagable goods packagingMain channelEngineering

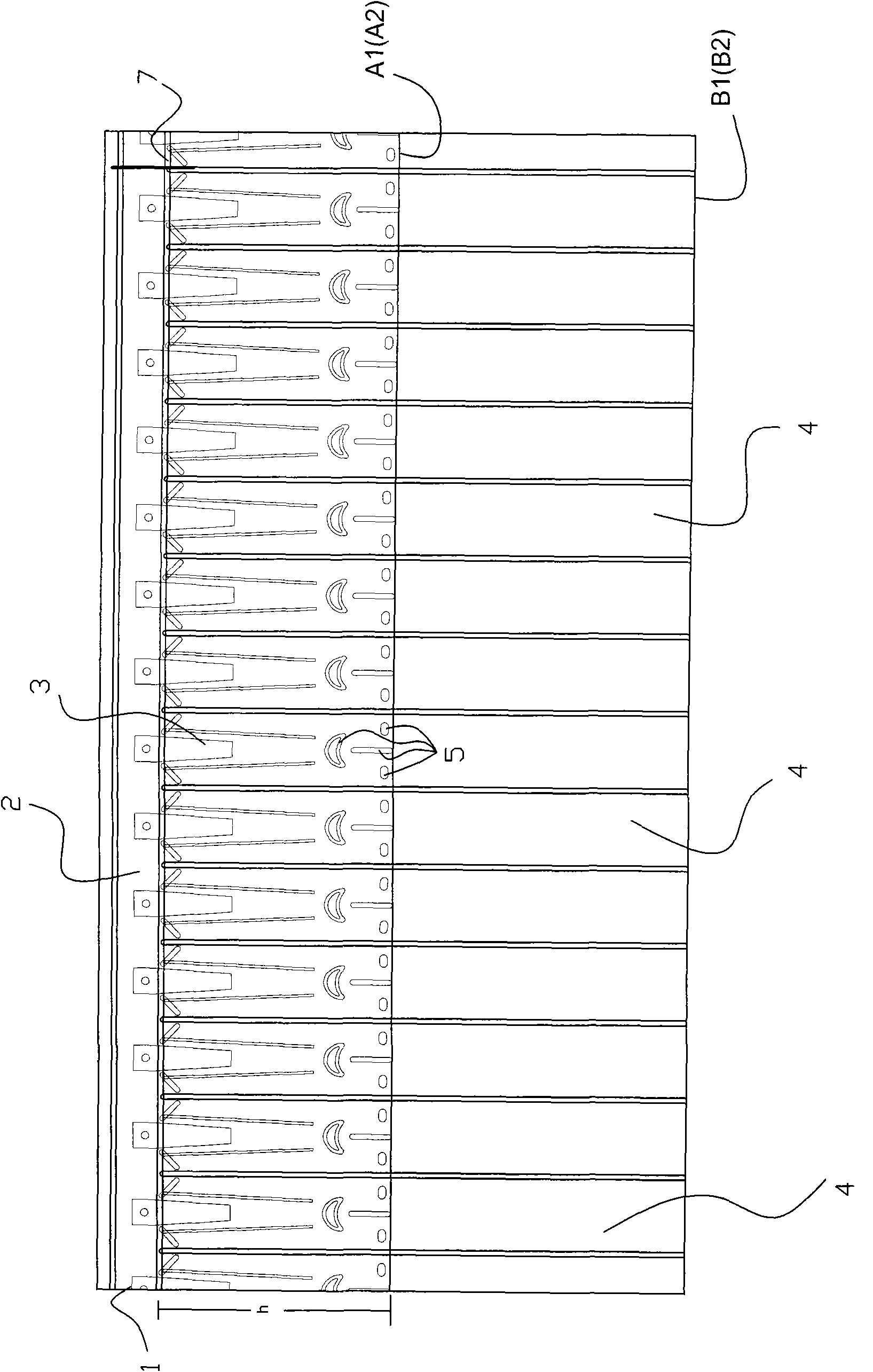

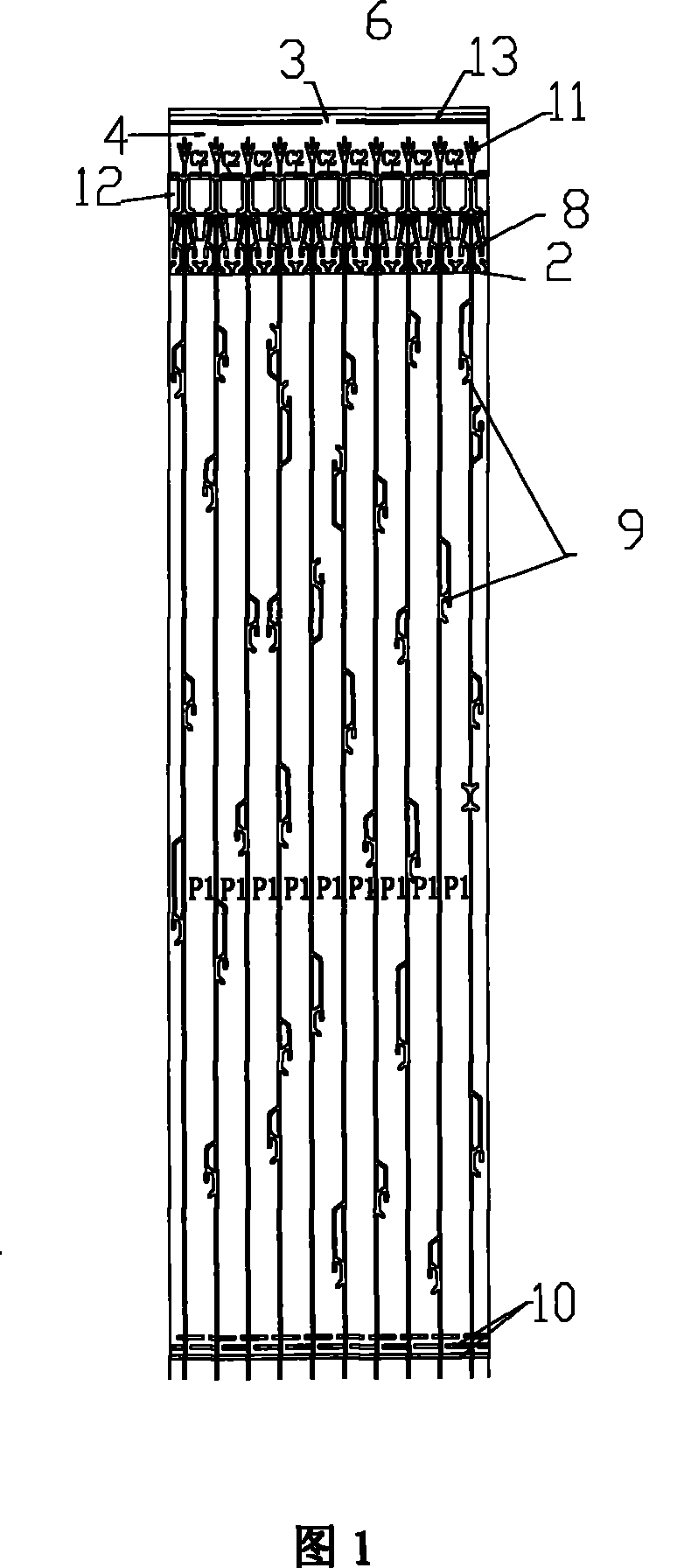

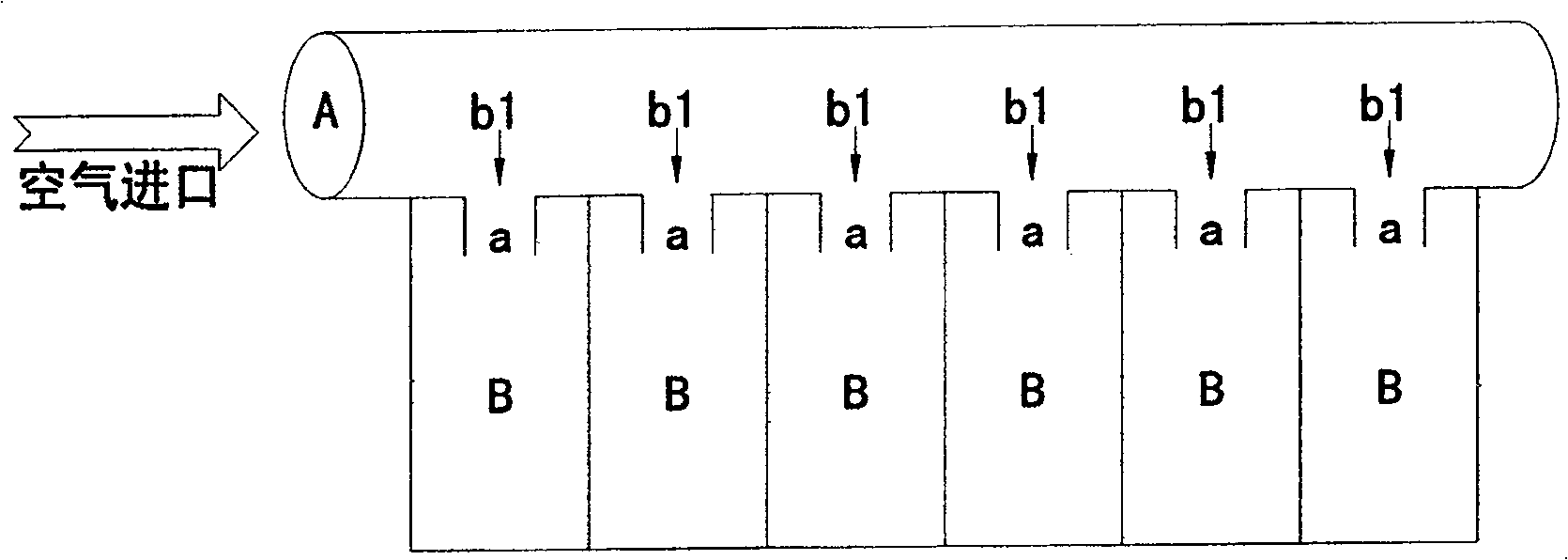

The invention relates to an air packing device. Two layers of thermoplastic films form a space which can store air through thermoplastic process in two steps, and the space comprises a plurality of independent airproof air chambers and a main channel, wherein the main channel is provided with an air inlet, and each airproof air chamber is communicated with the main channel by a check valve formed by two layers of films. The air packing device is characterized in that the main diameters of the airproof air chambers are different. The invention can greatly reduce the transportation space and the transportation cost by a method of direct forming at the using site of a user, thereby solving the problem of overhigh cost due to the long-distance transportation of packing material. The air packing device is additionally provided with the buffering at the major parts and is effectively reduced in the volume by reducing air columns at a plurality of parts that do not need more protections, thereby reducing the transportation cost.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Air package device with transverse air valve and use method thereof

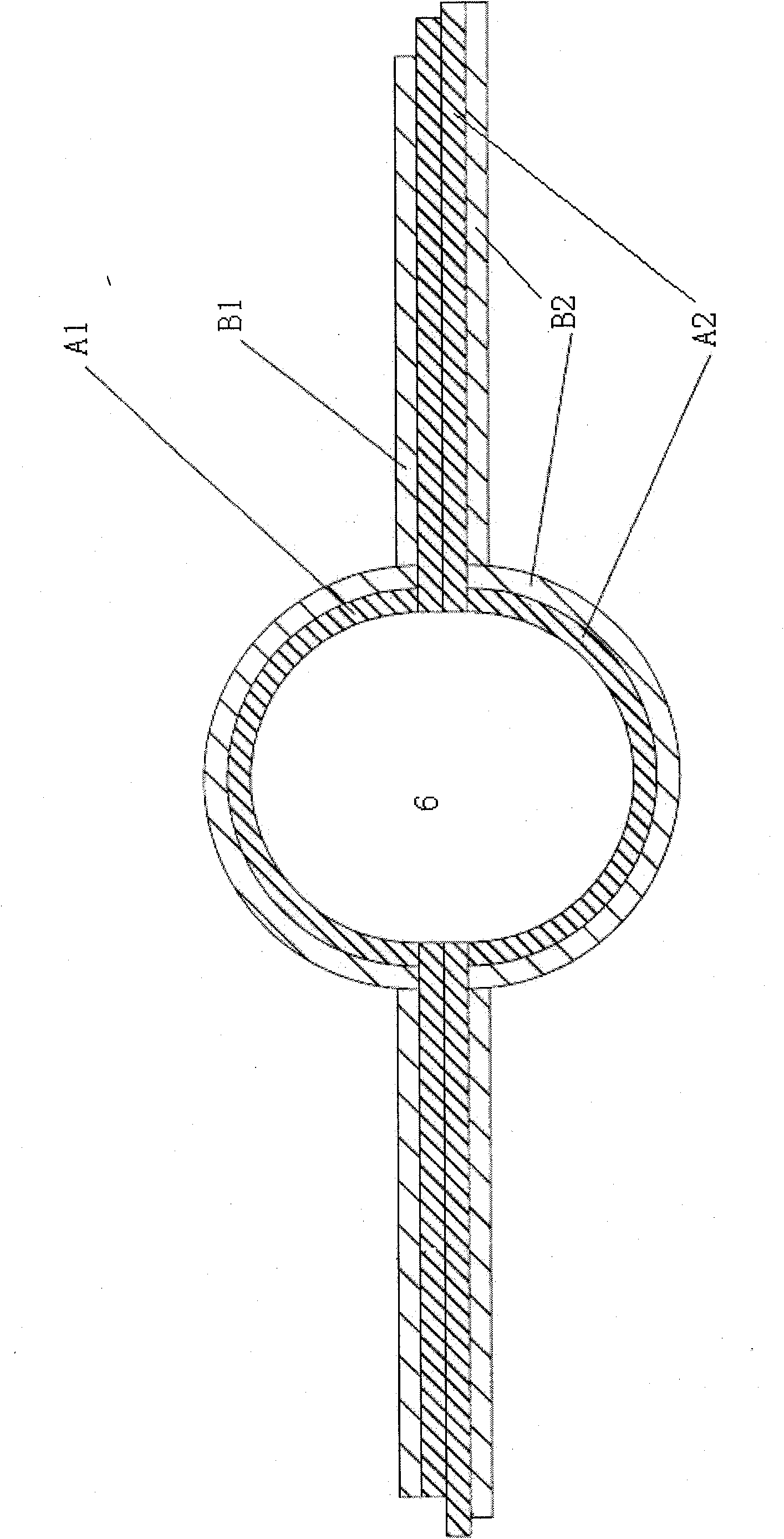

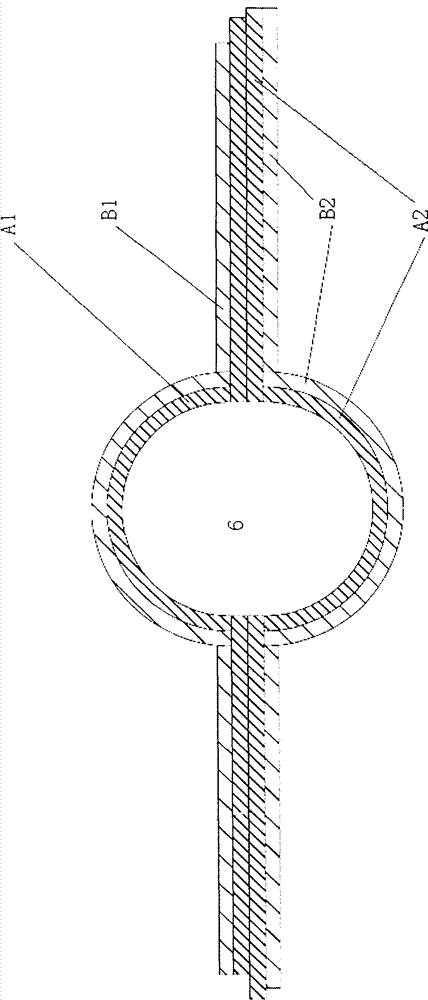

ActiveCN101992893AReduce manufacturing costImprove securityContainers to prevent mechanical damageDamagable goods packagingThermoplasticThin membrane

The invention relates to an air package device with a transverse air valve. A three-dimensional package body capable of sealing air is formed by two layers of thermoplastic films through secondary thermoplastic sealing, and the air package device comprises a plurality of independent sealing air chambers and a main passage, wherein the main passage is provided with an air inlet, each sealing air chamber is communicated with the main passage through a one-way valve air inlet at an air inlet sealing line part of the one-way valve formed by the two layers of one-way valve films, a plurality of outlet pre-setting points are arranged at the outlet of the one-way valve, the pre-setting points of the outlet of the one-way valve are discontinuous straight lines, and broken points in the middle of the straight lines provide air outlet passages for each one-way valve. The air package device of the invention can reduce the height of the one-way valve films because of the adoption of the transverse air valve in one aspect, and greatly save the cost of the one-way valve films. In addition, the universality of the transverse air value is high, and unlike the traditional one-way valve which needs to correspondingly use one mold according to the diameter of the air chambers, the package devices of air chambers in various widths can use one set of one-way valve mold, thus the cost of the mold is reduced.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Air packaging device and production method for same

ActiveCN102556503AIncrease production speedEasy to arrange productionContainers to prevent mechanical damageDamagable goods packagingProduct gasEngineering

Disclosed is an air packaging device. A space capable of storing air is formed by two thermoplastic films by means of two-time thermoplastic packaging. The air packaging device comprises a plurality of independent hermetic air chambers and a main passage, the main passage is provided with an air inlet, each hermetic air chamber is communicated with the main passage through a one-way valve consisting of two films, and two or more than two one-way valves are mounted in parts of air chambers or all the air chambers. Buffers are added on main portions of the air packaging device, and the size of air columns is decreased on the portions which do not need too much protection, so that the size of the air packaging device can be effectively decreased, and transport cost is reduced. By means of direct forming at a use site of a user, transport space and cost can be greatly reduced, so that the problem of excessively high cost during long-distance transport of packaging materials is solved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

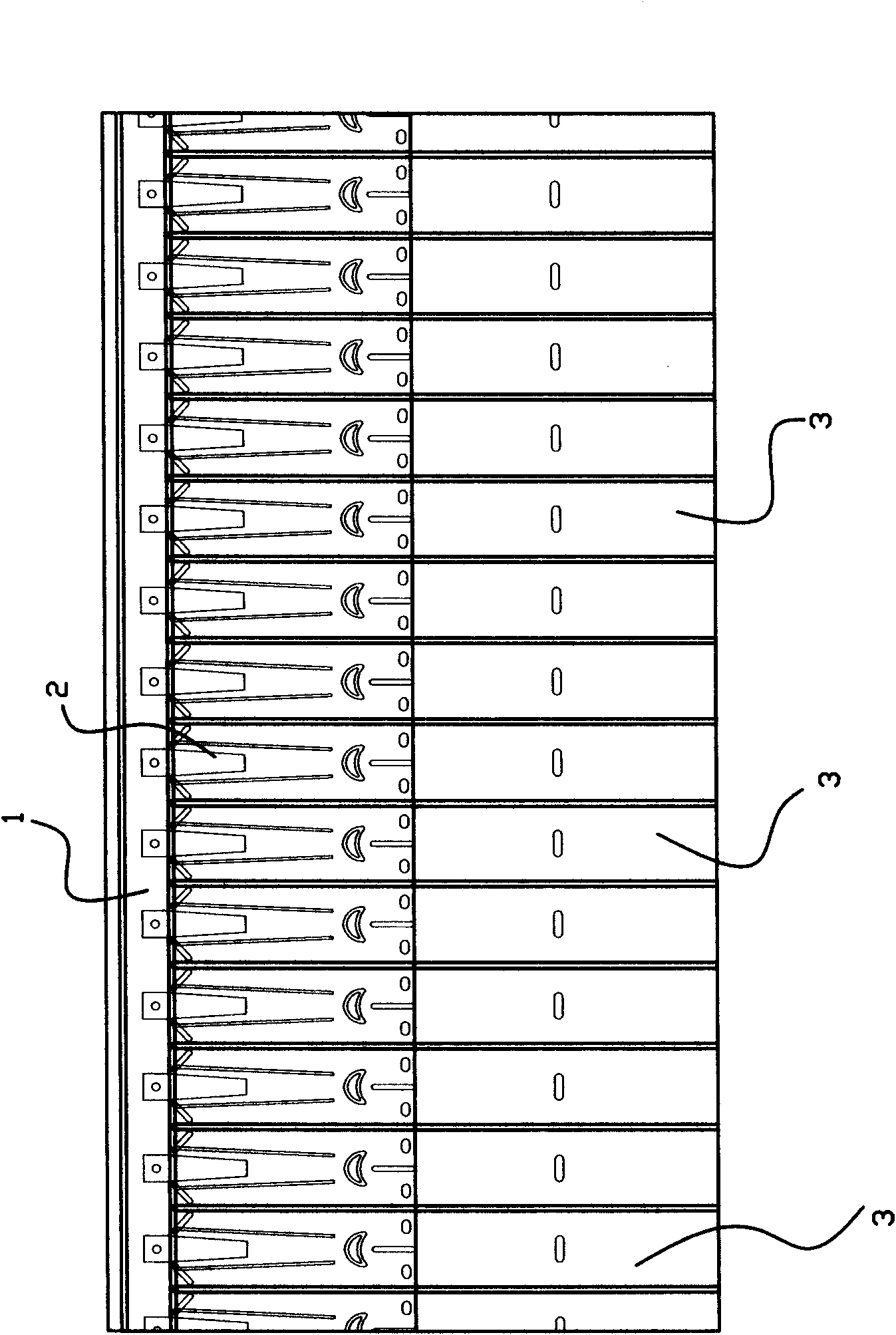

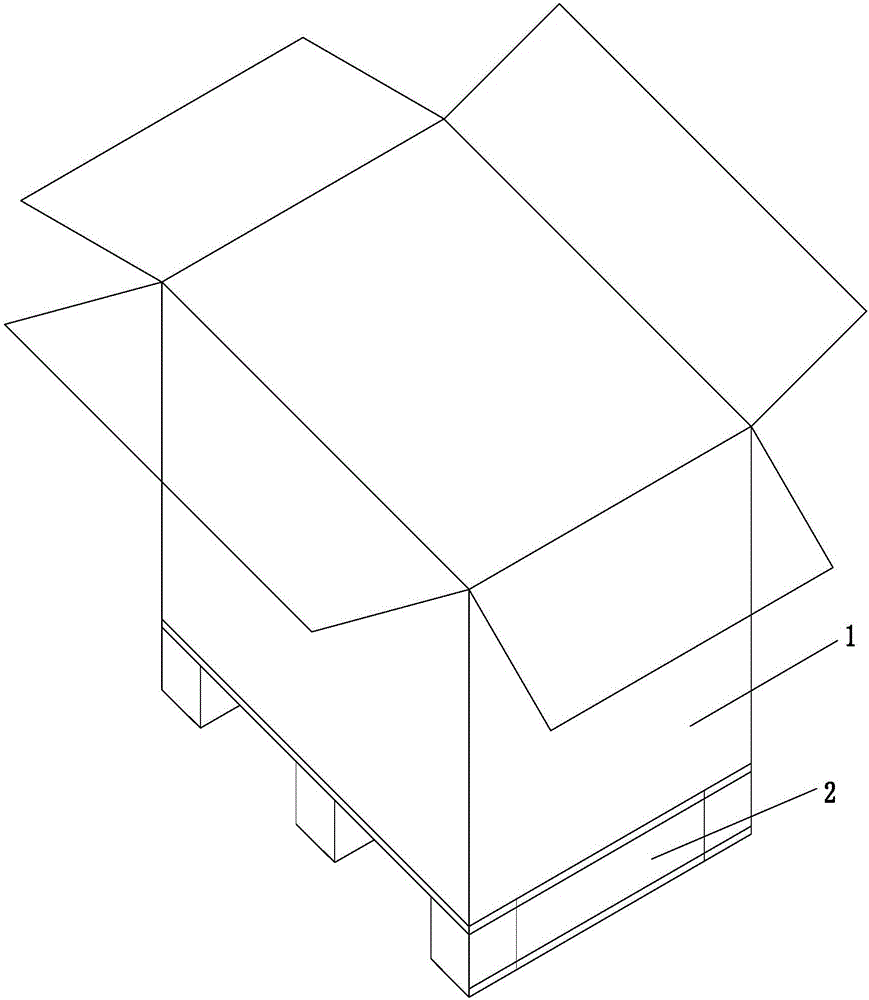

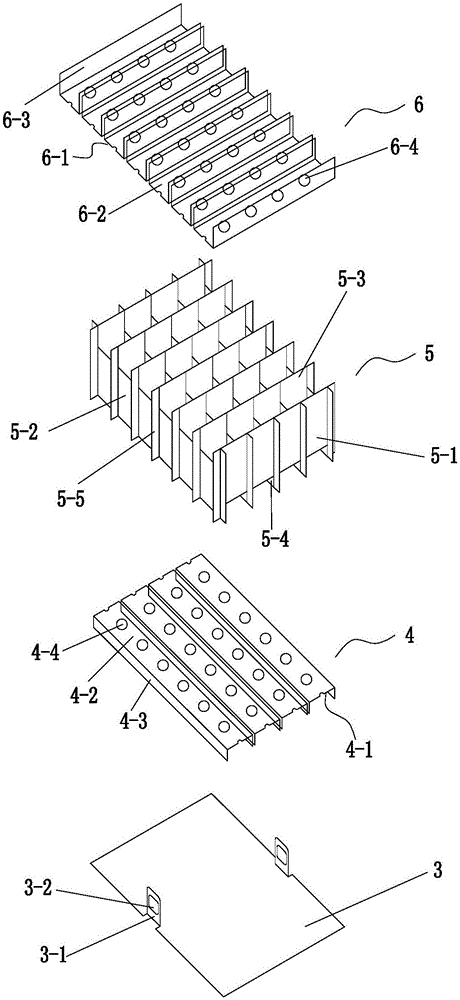

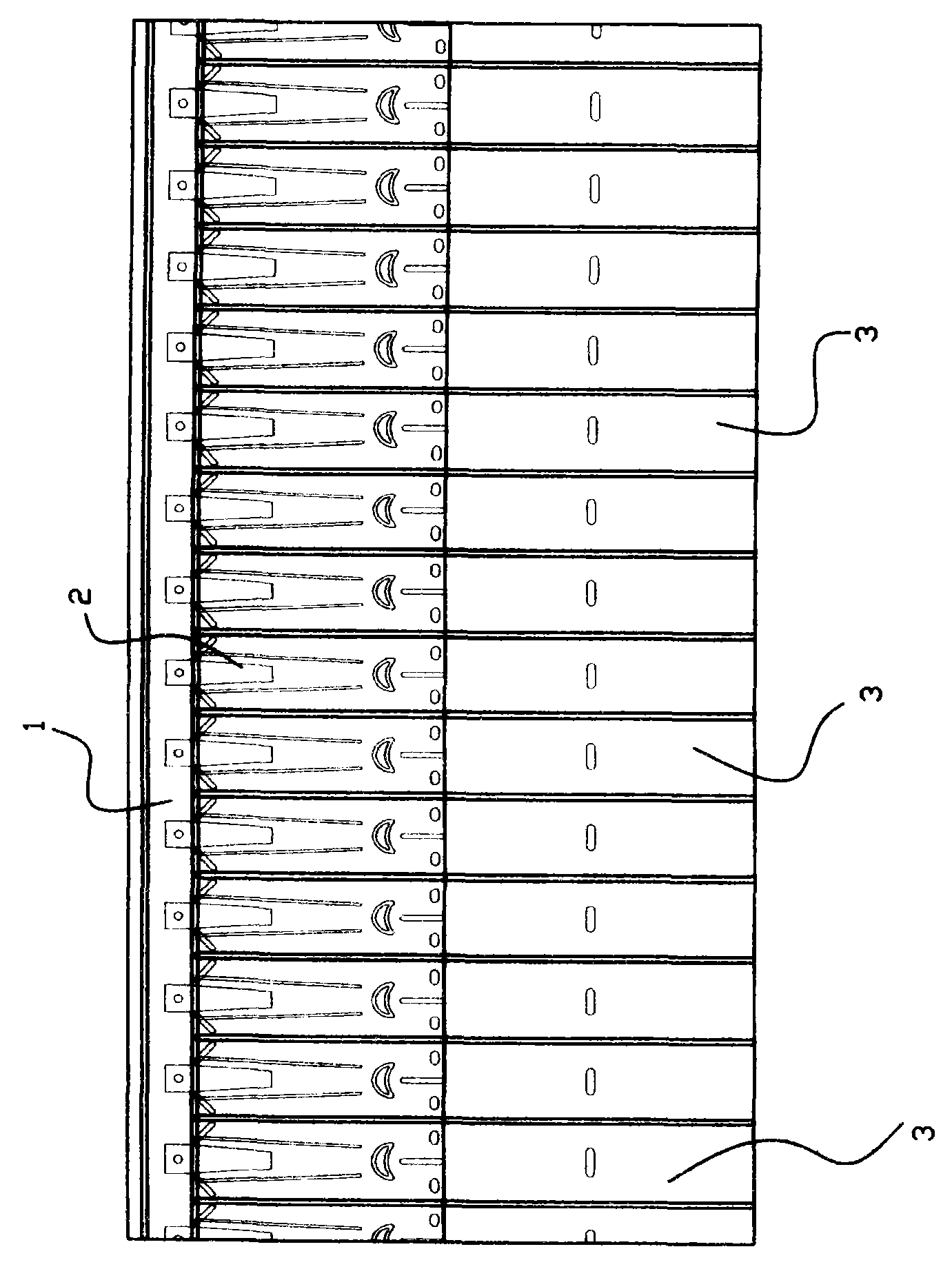

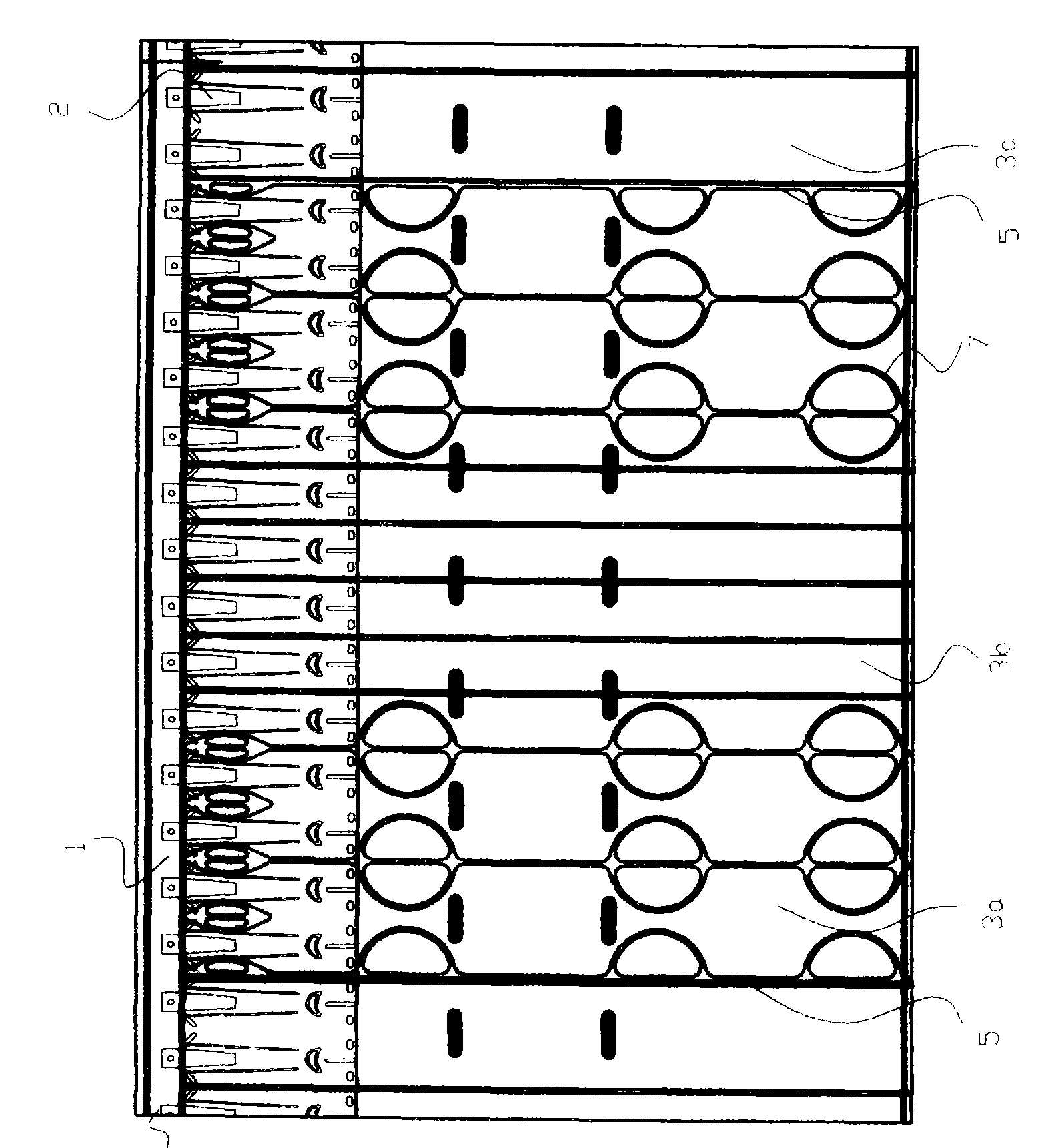

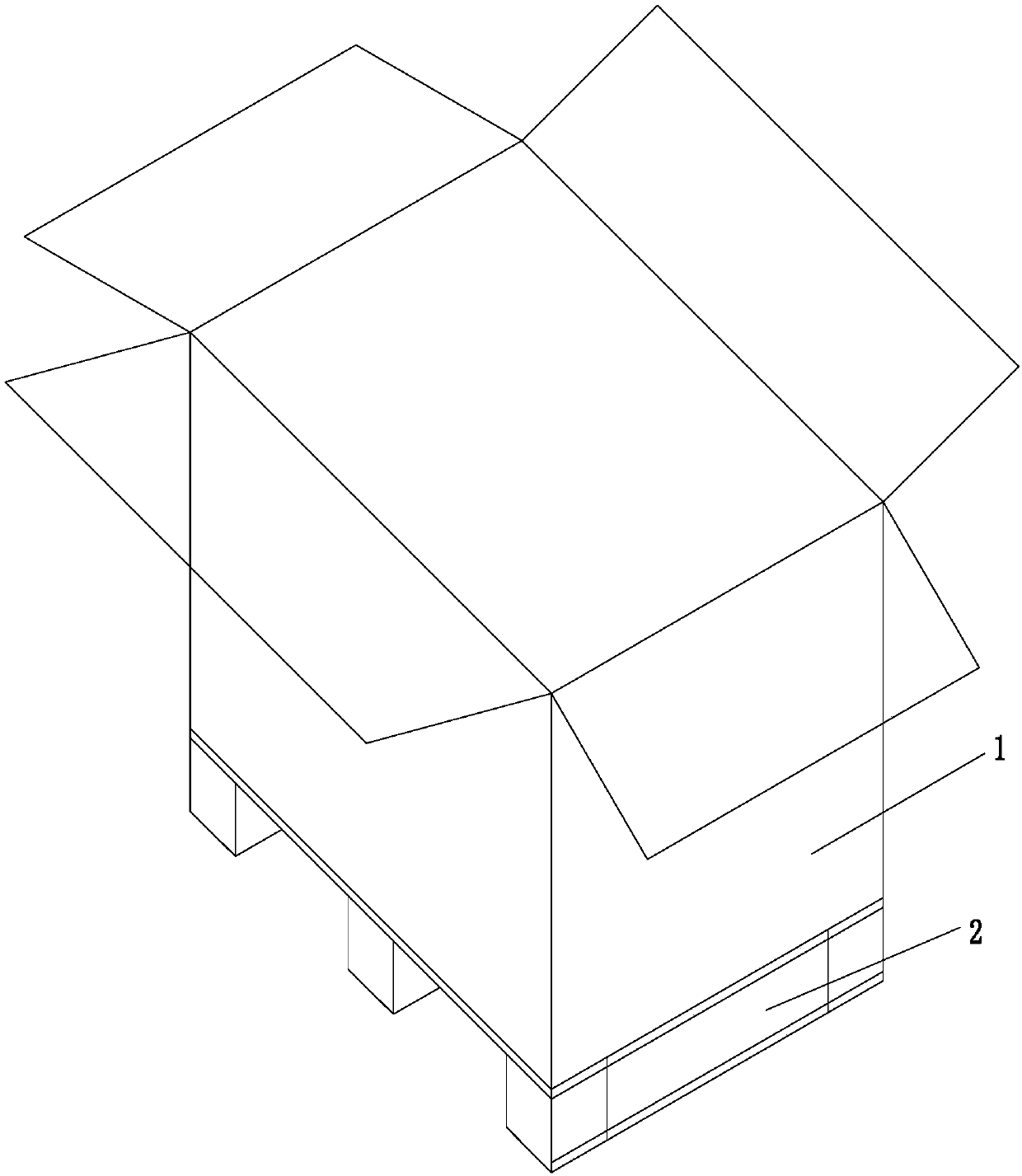

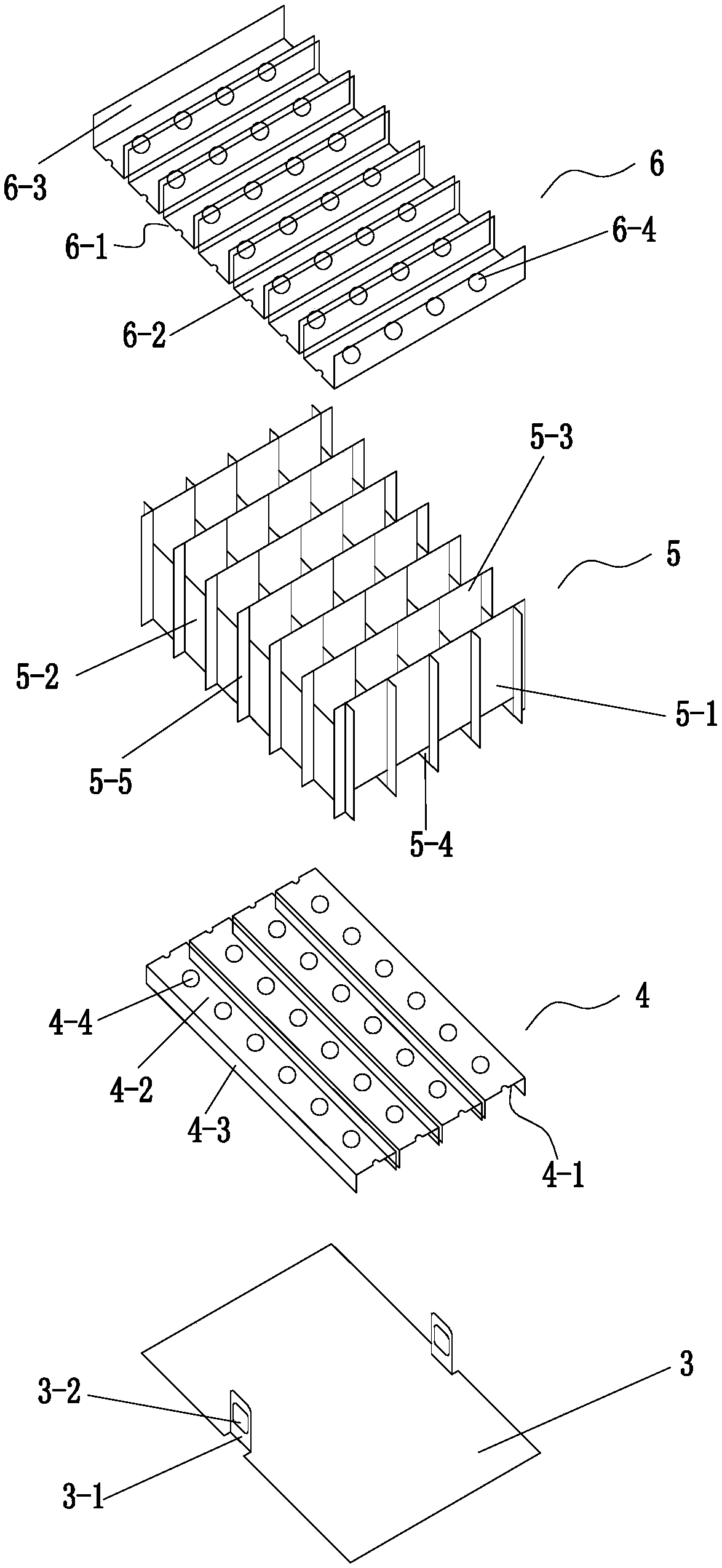

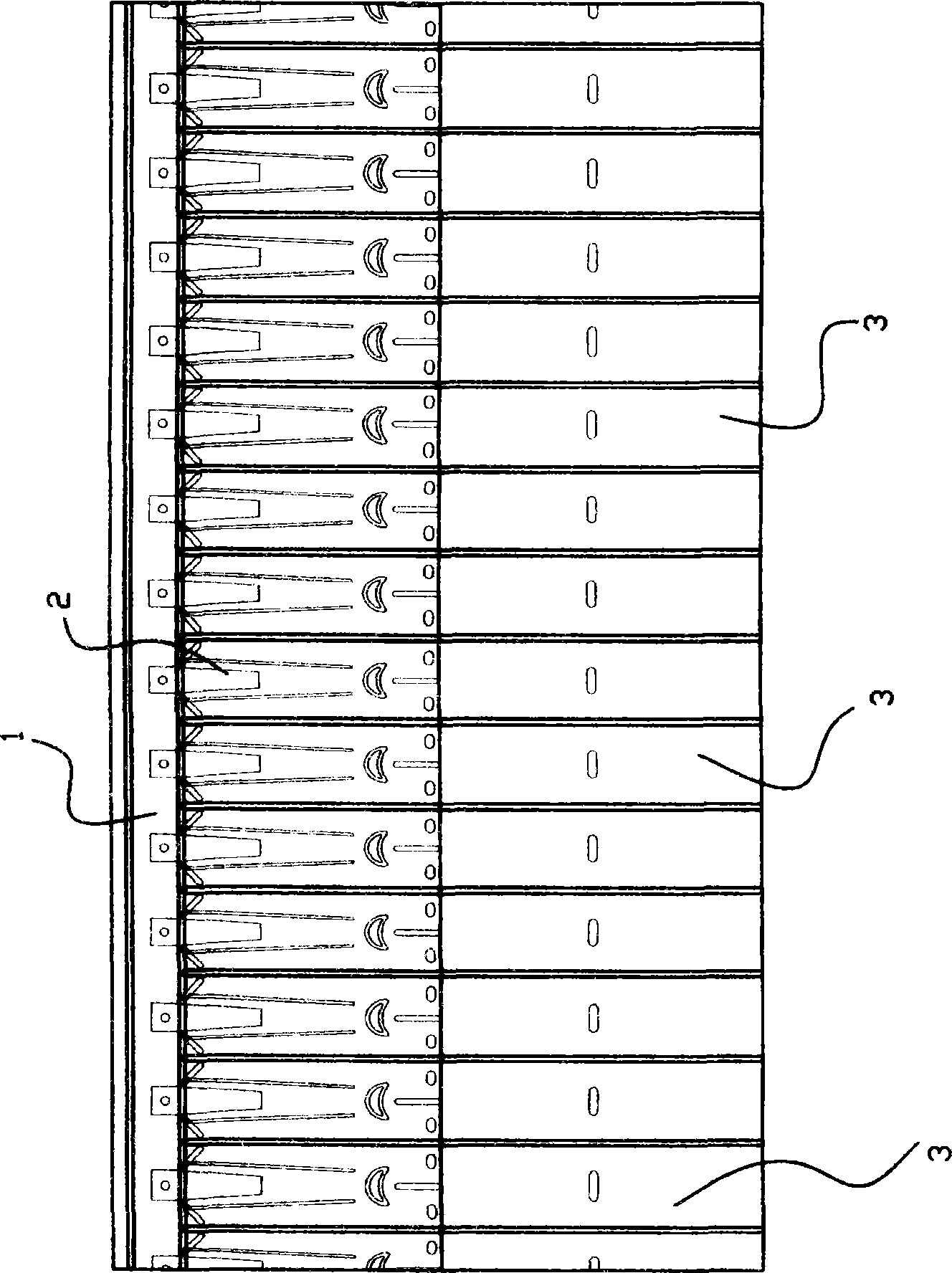

Vacuum pipe paper box device

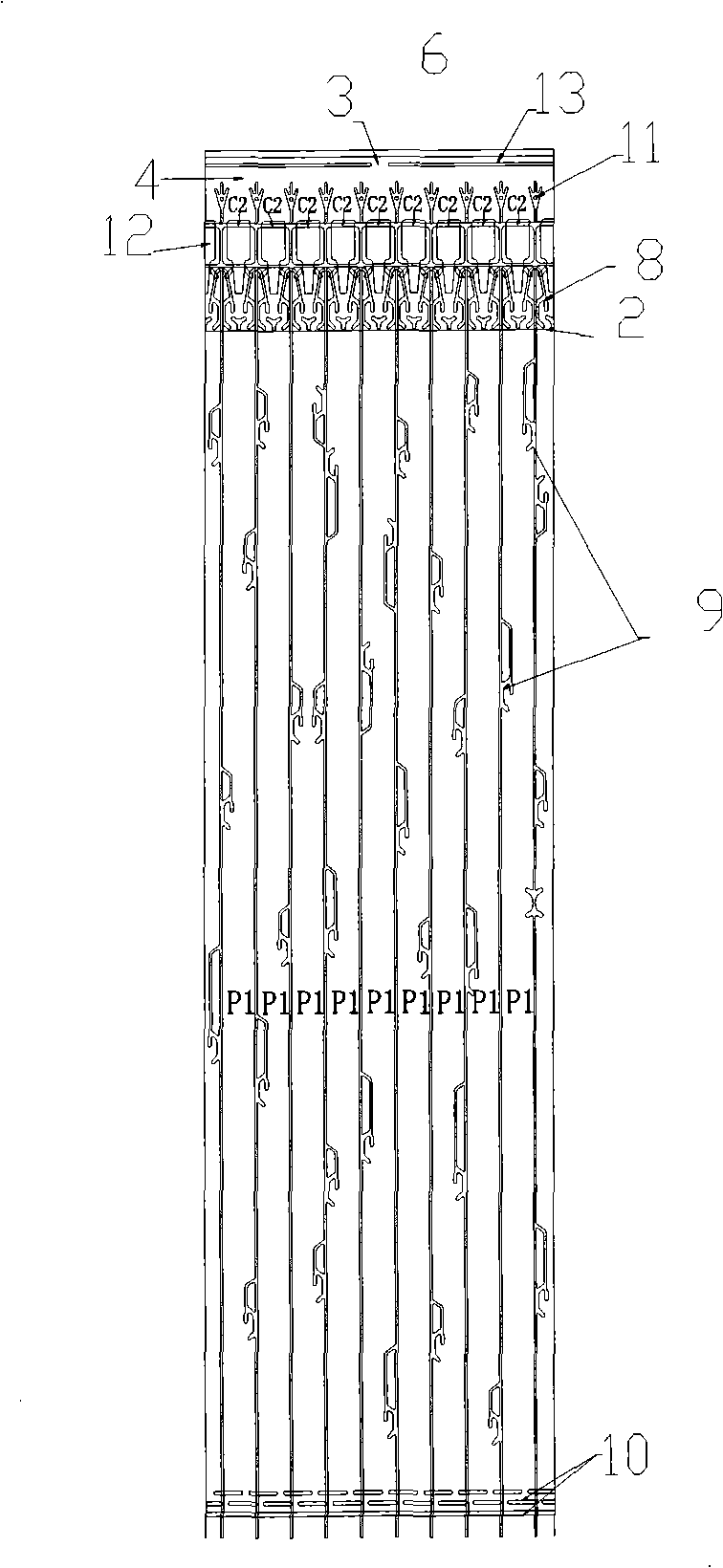

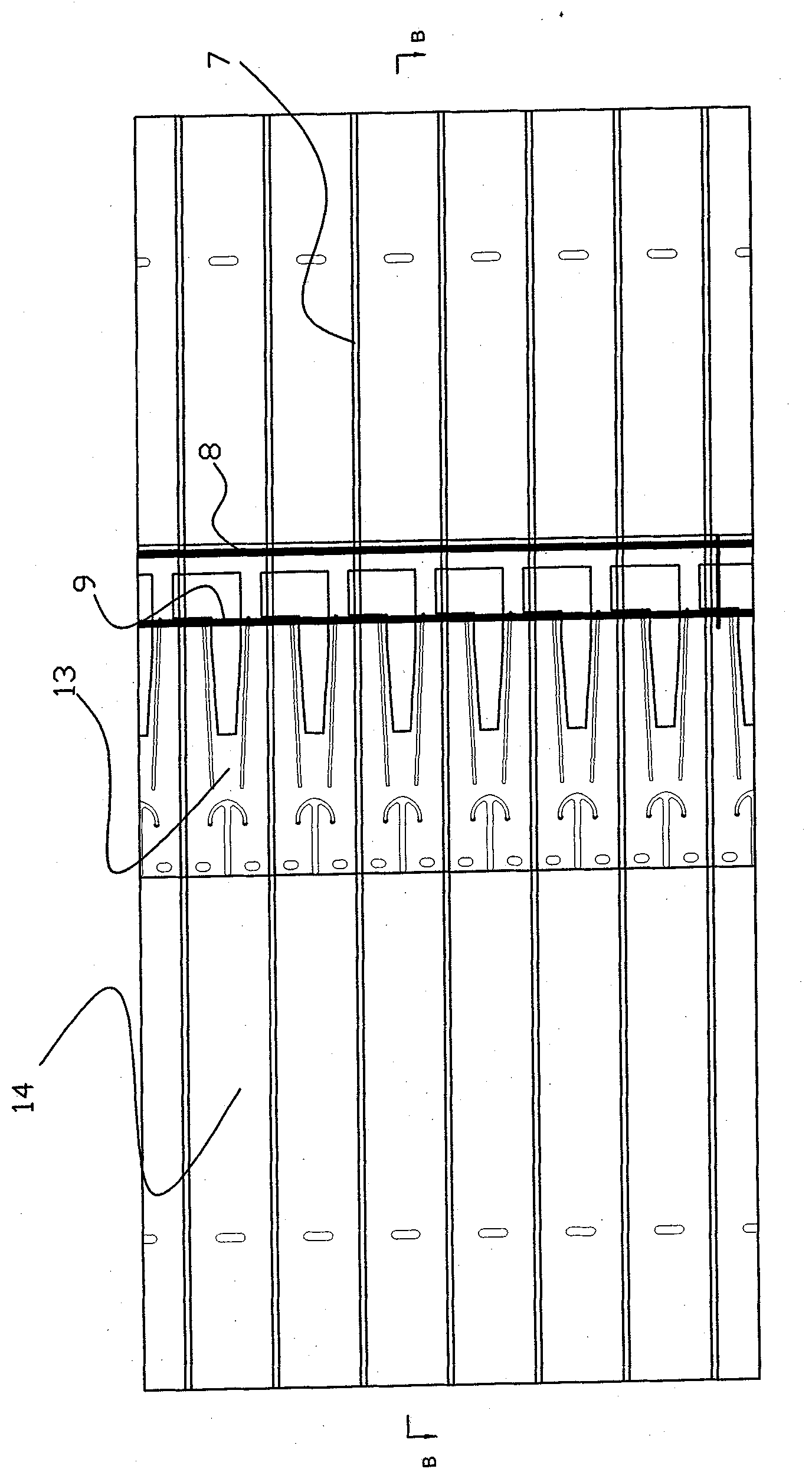

ActiveCN106184993AHigh compressive strengthGood protectionContainers to prevent mechanical damageExternal fittingsVacuum tubeCarton

The invention relates to a vacuum pipe paper box device. The vacuum pipe paper box device comprises a packaging box body. A plywood tray is arranged at the bottom of the packaging box body. The vacuum pipe paper box device is characterized in that one or two or more layers of packaging linings used for packaging vacuum pipes are arranged in the packaging box body; the packaging lining comprises a lower fixing part, an isolating and blocking part and an upper fixing part; in the blocking part, a plurality of cavities used for containing the vacuum pipes are formed through the staggered arrangement of transverse stop pieces and longitudinal stop pieces, the upper edges of the transverse stop pieces protrude out of the upper edges of the longitudinal stop pieces to form transverse connecting pieces, and the lower edges of the longitudinal stop pieces protrude out of the lower edges of the transverse stop pieces to form longitudinal connecting pieces; the upper fixing part comprises a plurality of transverse fixing pieces arranged in the longitudinal direction, and each transverse fixing piece is clamped between the corresponding two transverse connecting pieces; and the lower fixing part comprises a plurality of longitudinal fixing pieces arranged in the transverse direction, and each longitudinal fixing piece is clamped between the corresponding two adjacent longitudinal connecting pieces. According to the vacuum pipe paper box device, the inventory area can be reduced, resources are saved, and a protection function is achieved in the transporting process.

Owner:无锡欣盛包装材料科技有限公司

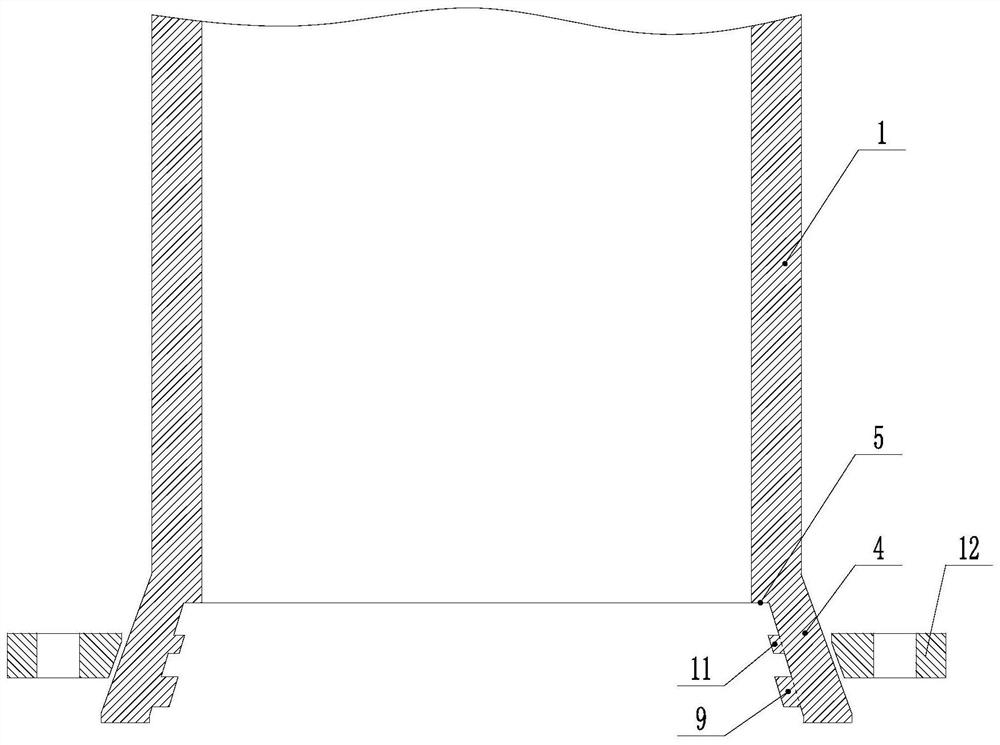

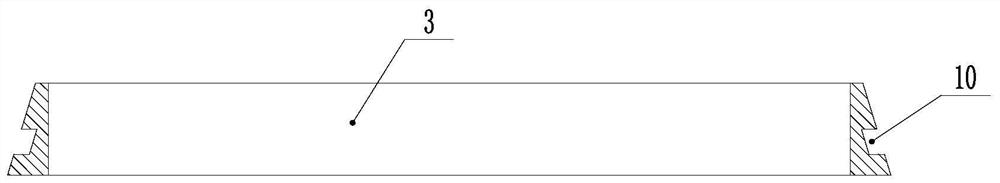

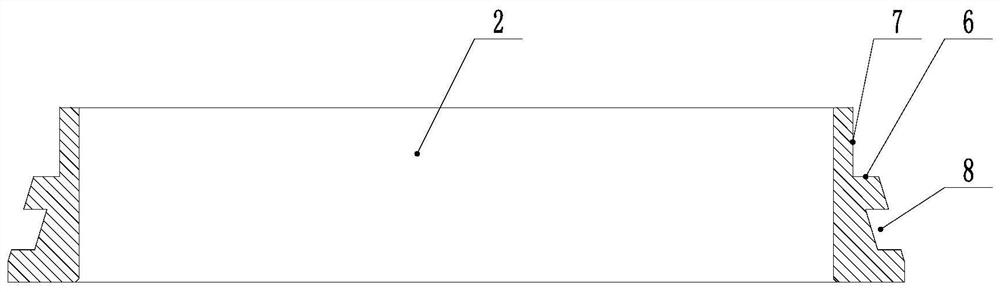

Corrosion-resistant plastic-steel door and window

The invention discloses a corrosion-resistant plastic-steel door and window which is formed by combining an uppermost-layer metal alloy layer, a middle-layer anticorrosion layer and a lowermost-layerchromium carbide alloy layer. A silicon alloy is adopted as the metal alloy layer, and the chromium carbide alloy layer comprises carbon, manganese, sulphur, aluminum, steel, chrome and iron. The metal alloy layer accounts for 21-37% of the corrosion-resistant plastic-steel door and window in total weight, the anticorrosion layer accounts for 18-25% of the corrosion-resistant plastic-steel door and window in total weight, and the chromium carbide alloy layer accounts for 45-54% of the corrosion-resistant plastic-steel door and window in total weight. The corrosion-resistant plastic-steel doorand window is resistant to extrusion, high in hardness, good in abrasion resistance, not prone to being corroded, long in service life and good in heat preservation.

Owner:苏州盈腾五金制品有限公司

Air packaging device and production method for same

ActiveCN102556502BIncrease production speedEasy to arrange productionContainers to prevent mechanical damageDamagable goods packagingThin membranePack material

Disclosed is an air packaging device. A space capable of storing air is formed by two thermoplastic films by means of two-time thermoplastic packaging. The air packaging device comprises a plurality of independent hermetic air chambers and a main passage, the main passage is provided with an air inlet, each hermetic air chamber is communicated with the main passage through a one-way valve consisting of two films, and two or more than two one-way valves are mounted in part of air chambers or all the air chambers. Buffers are added on main portions of the air packaging device, and the size of air columns is decreased on the portions which do not need too much protection, so that the size of the air packaging device can be effectively decreased, and transport cost is reduced. By means of direct forming at a use site of a user, transport space and cost can be greatly reduced, so that the problem of excessively high cost during long-distance transport of packaging materials is solved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

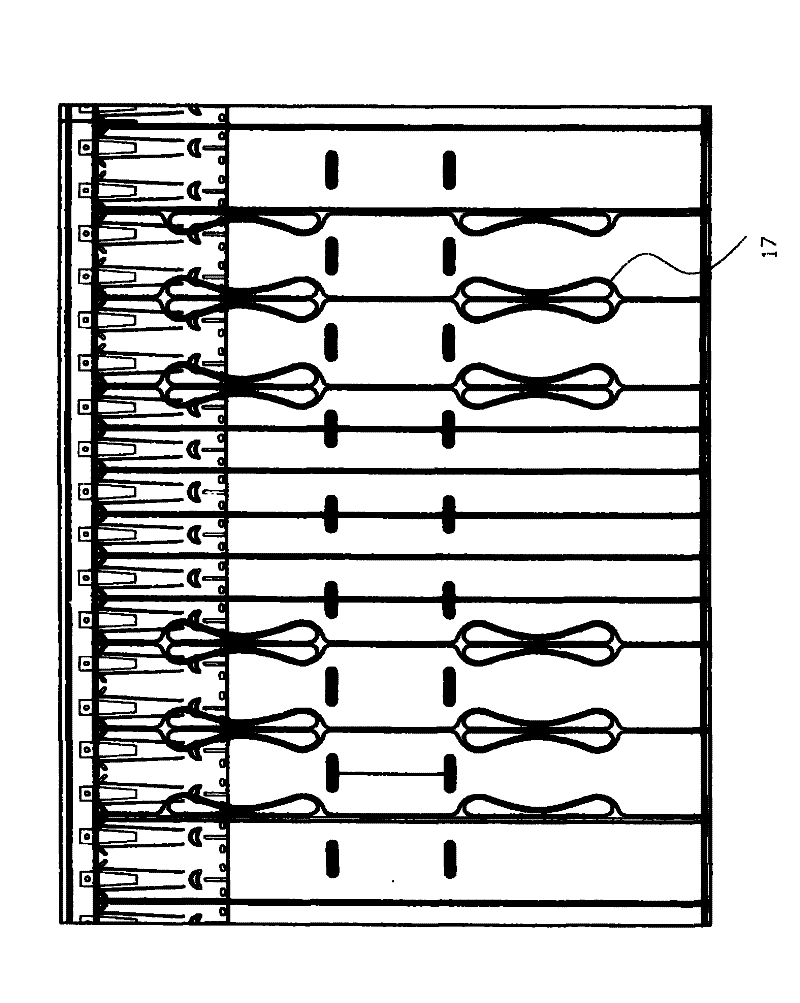

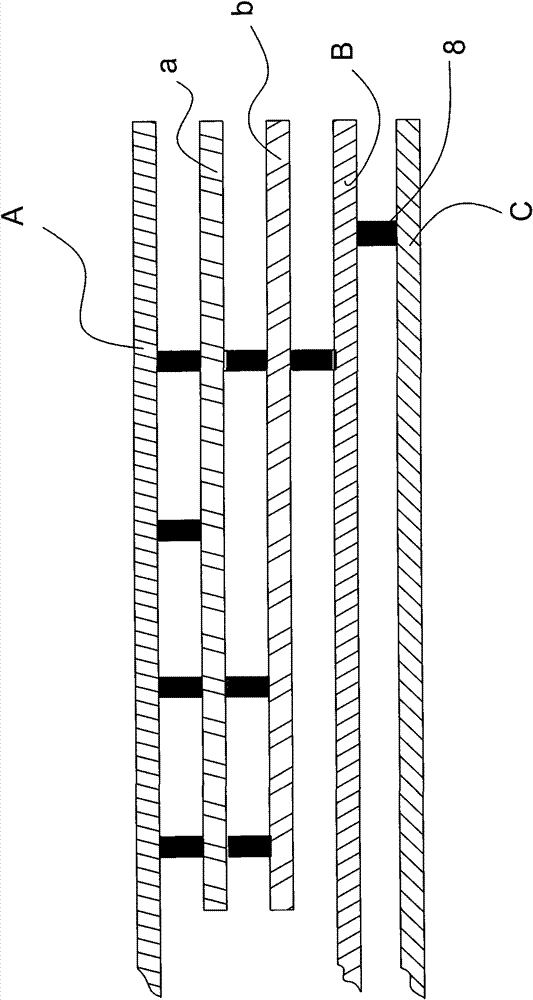

Three-layer air packing device and production method thereof

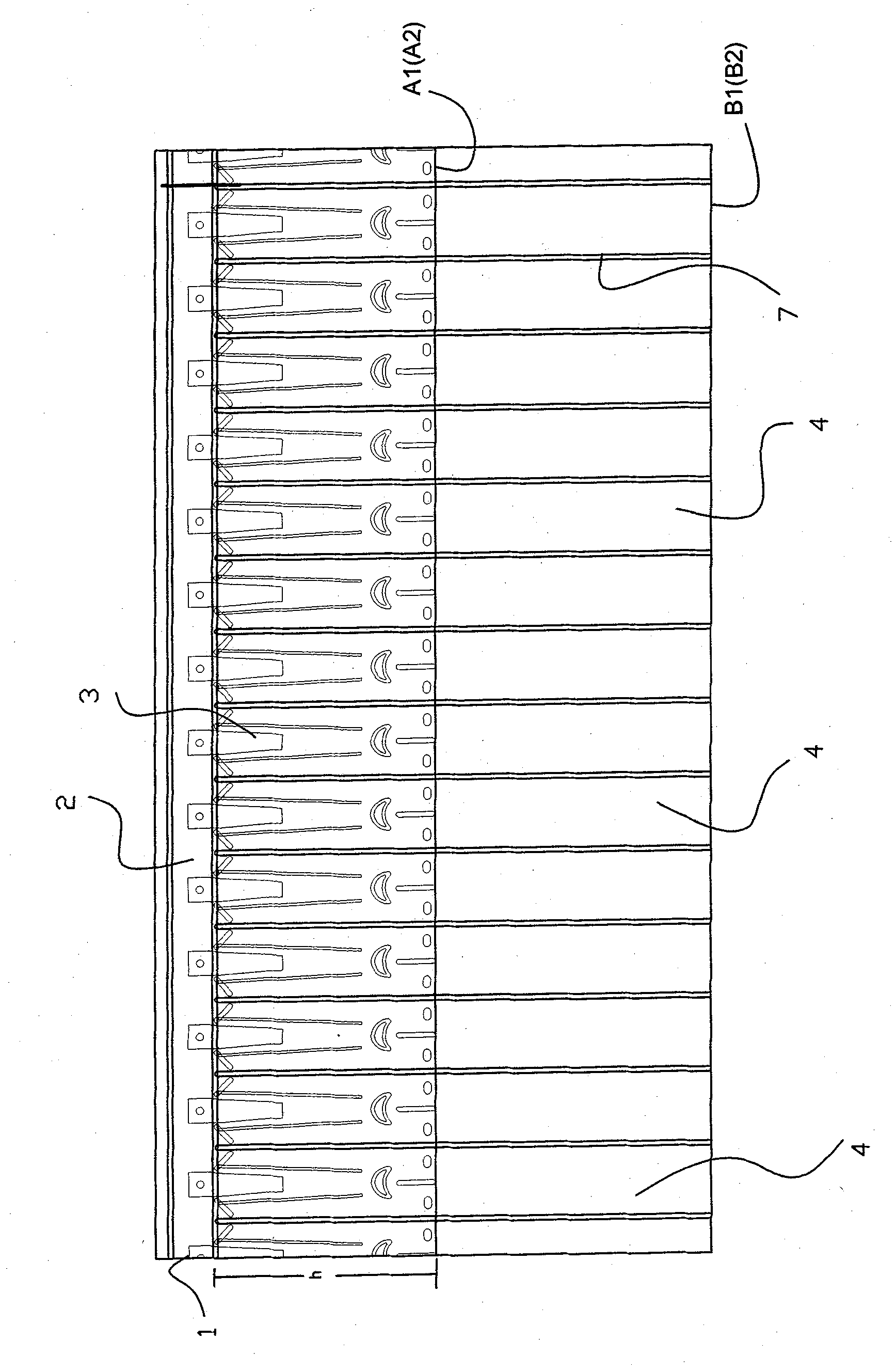

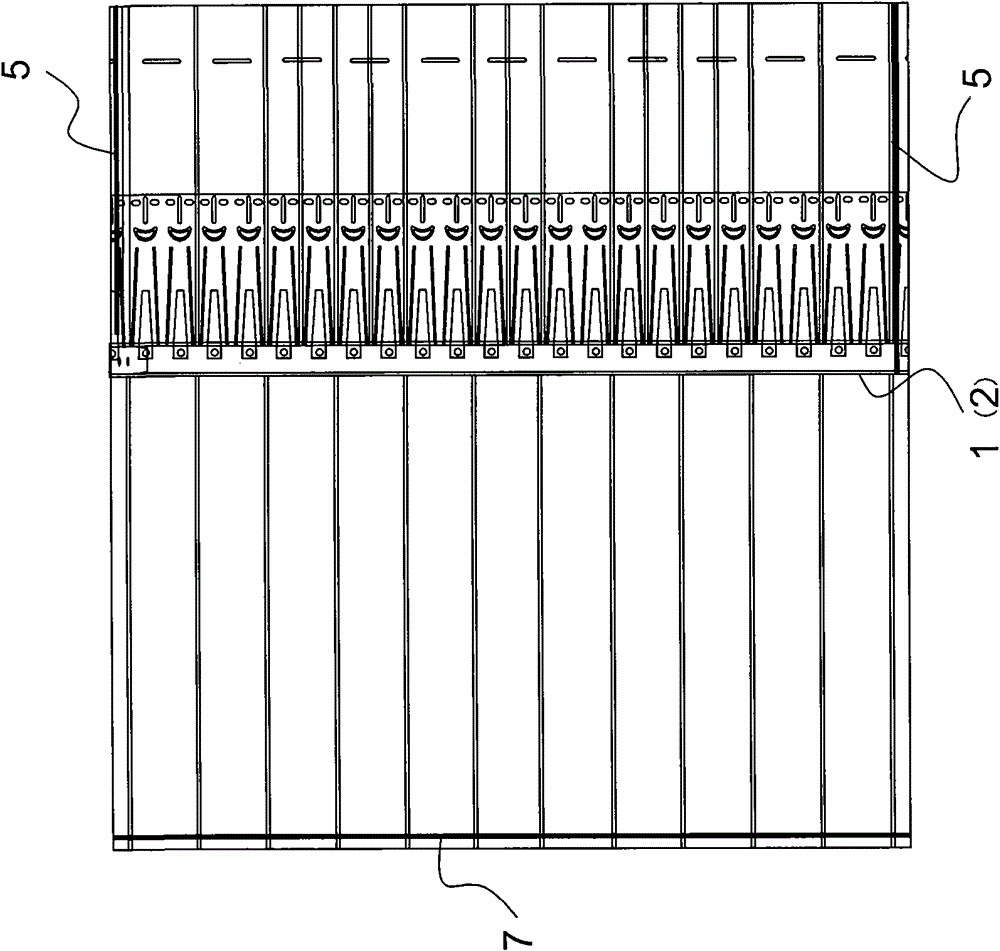

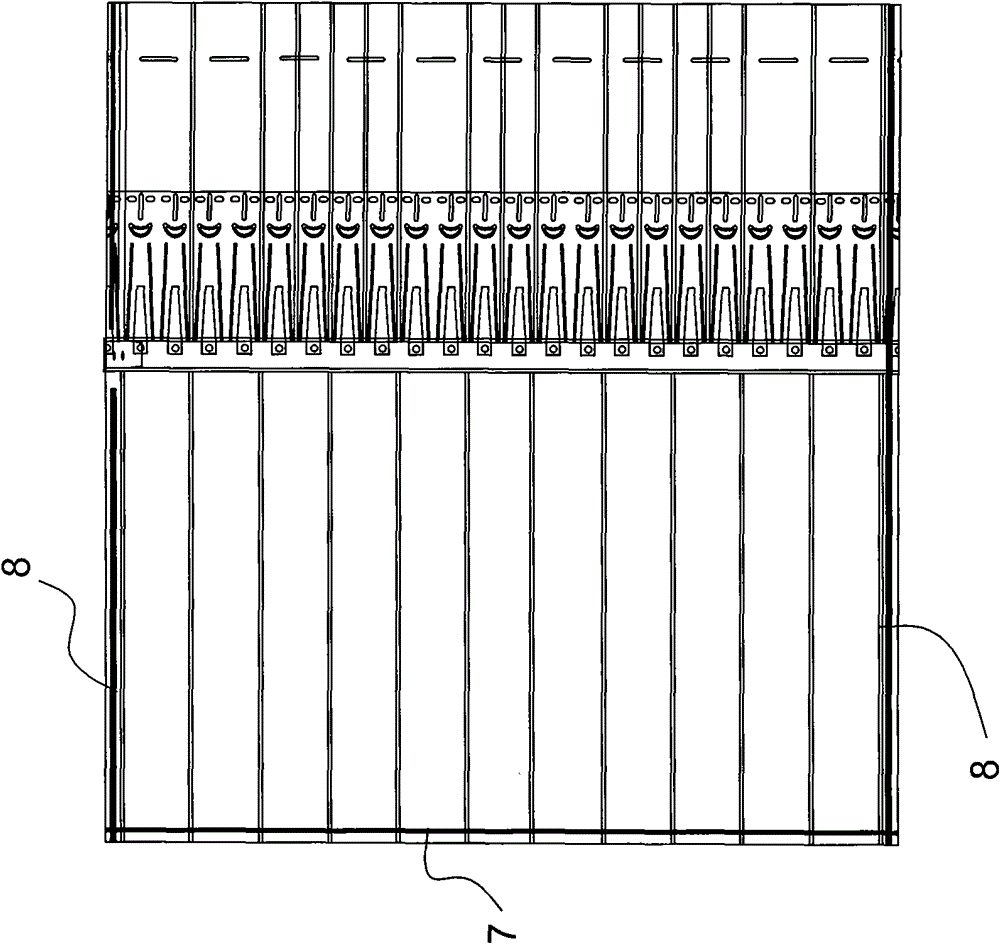

ActiveCN102233981BImprove reliabilitySave packing timePaper-makingBox making operationsAntistatic bagMain channel

The invention discloses a three-layer air packing device. Two rectangular thermoplastic films are subjected to secondary hot laminating to form a three-dimensional packaging body which is provided with an opening and can seal air; the three-dimensional packaging body comprises a plurality of independent sealed air chambers and a main channel; the main channel is provided with an air inlet; each sealed air chamber is communicated with the main channel through a one-way valve consisting of a one-way valve film; the inner side of the three-dimensional packaging body is provided with an inner bag; and the inner bag is formed by fixing four sides of a rectangular lightproof and / or antistatic thermoplastic film on the four sides of the rectangular thermoplastic film on the inner side of the outside three-dimensional packaging body. By the packing device, the consumption of lightproof or antistatic bags for packaging objects to be packaged is reduced, a procedure of sleeving the lightproof or antistatic bag is eliminated, the packaging time is greatly shortened, and possible accidents in the packaging process are further reduced, so that the cost is saved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Acoustic insulation and deodorization sandwich layer for automobile interior decoration

InactiveCN108944722AReduce weightImprove sound insulationAir-treating devicesSuperstructure subunitsEngineeringNoise reduction

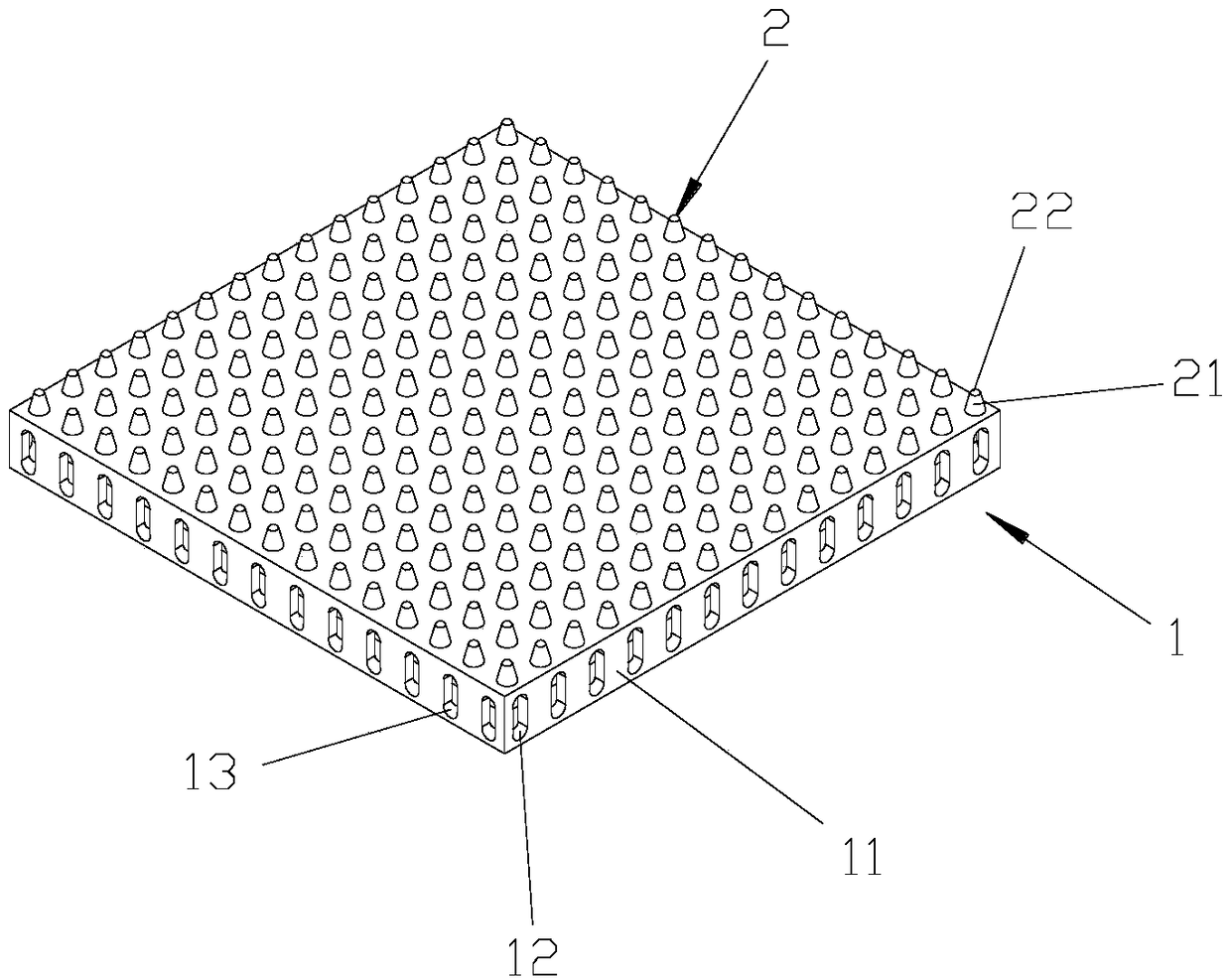

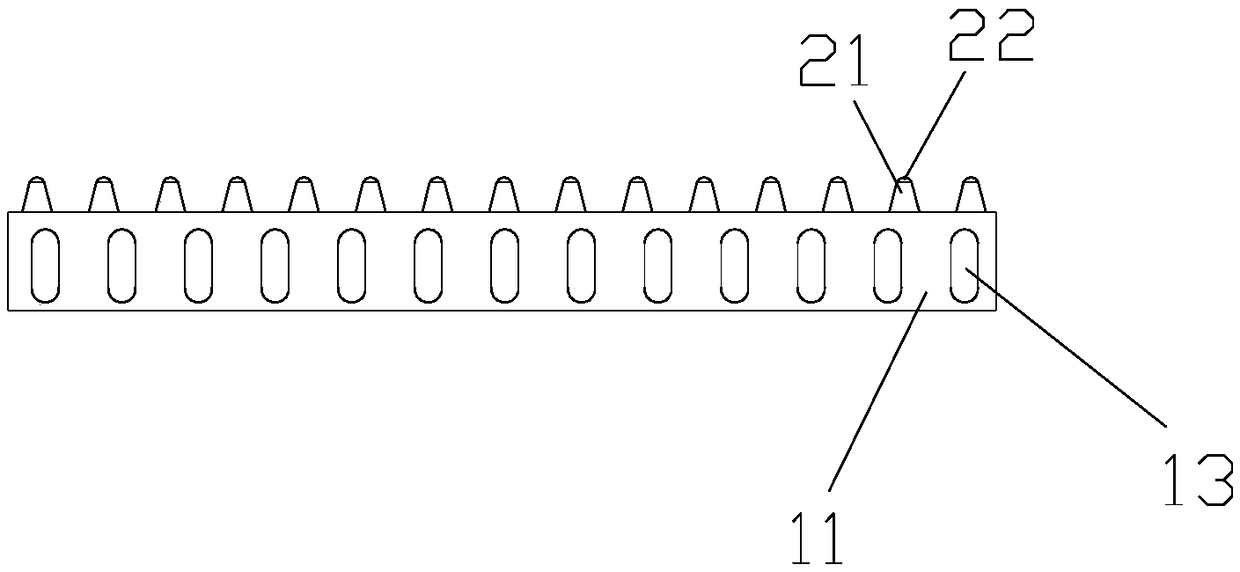

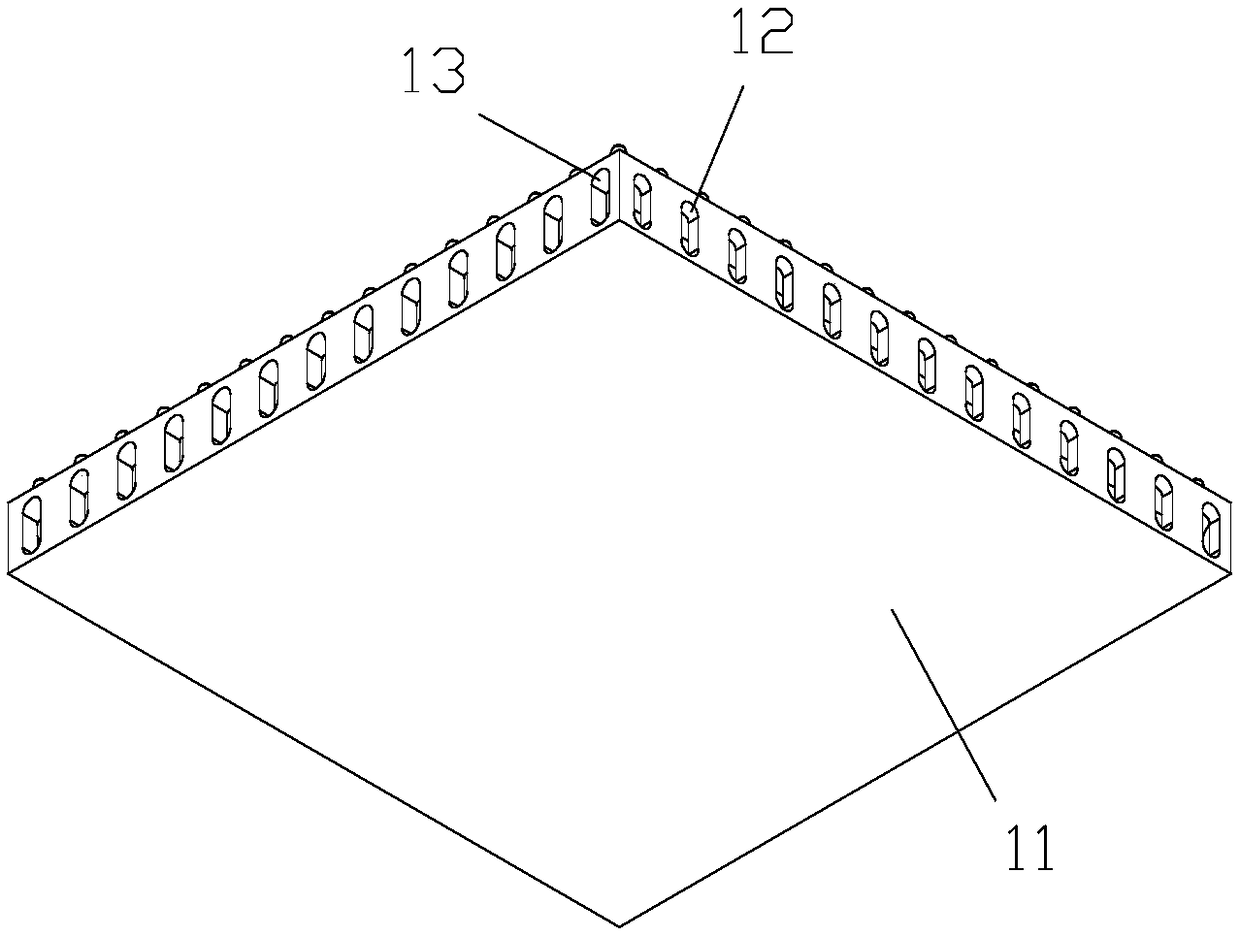

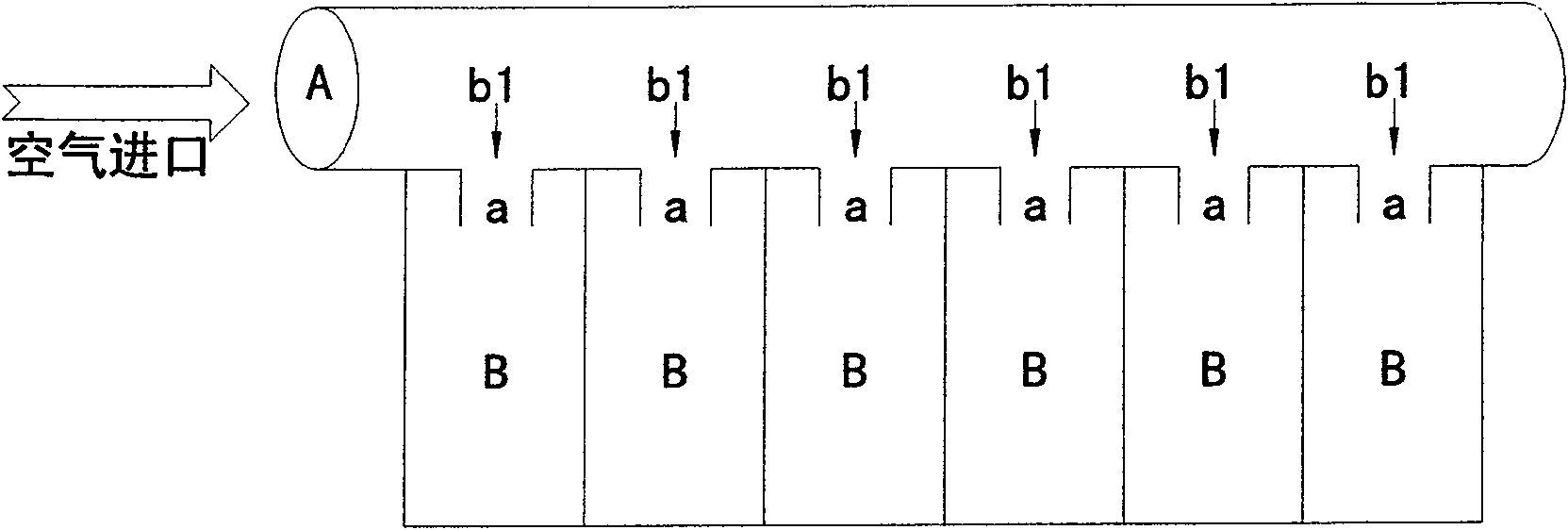

The invention discloses an acoustic insulation and deodorization sandwich layer for automobile interior decoration, which comprises an acoustic insulation rubber plate and bumps arranged on the acoustic insulation rubber plate and fixed with the acoustic insulation rubber plate and used for buffering pressure; The sound insulation rubber plate comprises a rubber plate body, a first transverse holepenetrating the rubber plate body and used for reducing the weight of the rubber plate body and improving the sound insulation effect of the rubber plate body, and a second transverse hole penetrating the rubber plate body for reducing the weight of the rubber plate body and improving the sound insulation effect of the rubber plate body and penetrating the first transverse hole; The bump includesa conical protrusion fixed with the rubber plate body, and a dome arranged on the top of the conical protrusion and fixed with the conical protrusion for reducing friction force; The sound insulationand deodorization sandwich layer for automobile interior decoration has the advantages of light weight, squeeze resistance, long service life, sound insulation, noise reduction and air purification,and is suitable for automobile interior decoration.

Owner:广州极慧技术服务有限公司

A kind of glass wool and preparation method thereof

ActiveCN106277805BGood heat insulationHigh strengthNon-woven fabricsGraft polymer adhesivesGlass fiberFiber

The invention discloses a preparation method of glass wool. The method comprises the following steps of: producing glass wool filaments by adopting a centrifugal blowing method, uniformly atomizing glass wool adhesive onto the surface of the glass wool filaments, collecting wool of the glass wool fibers by virtue of a wool collection machine, transporting to a curing furnace, and performing the curing at the temperature of 220 to 270 DEG C, wherein the weight ratio of the glass wool filaments to the glass wool adhesive is (4 to 6): (94 to 96). The invention aims at providing glass wool and a preparation method of the glass wool. The glass wool has high strength and good thermal insulating performance.

Owner:清远瀚江玻璃棉科技有限公司

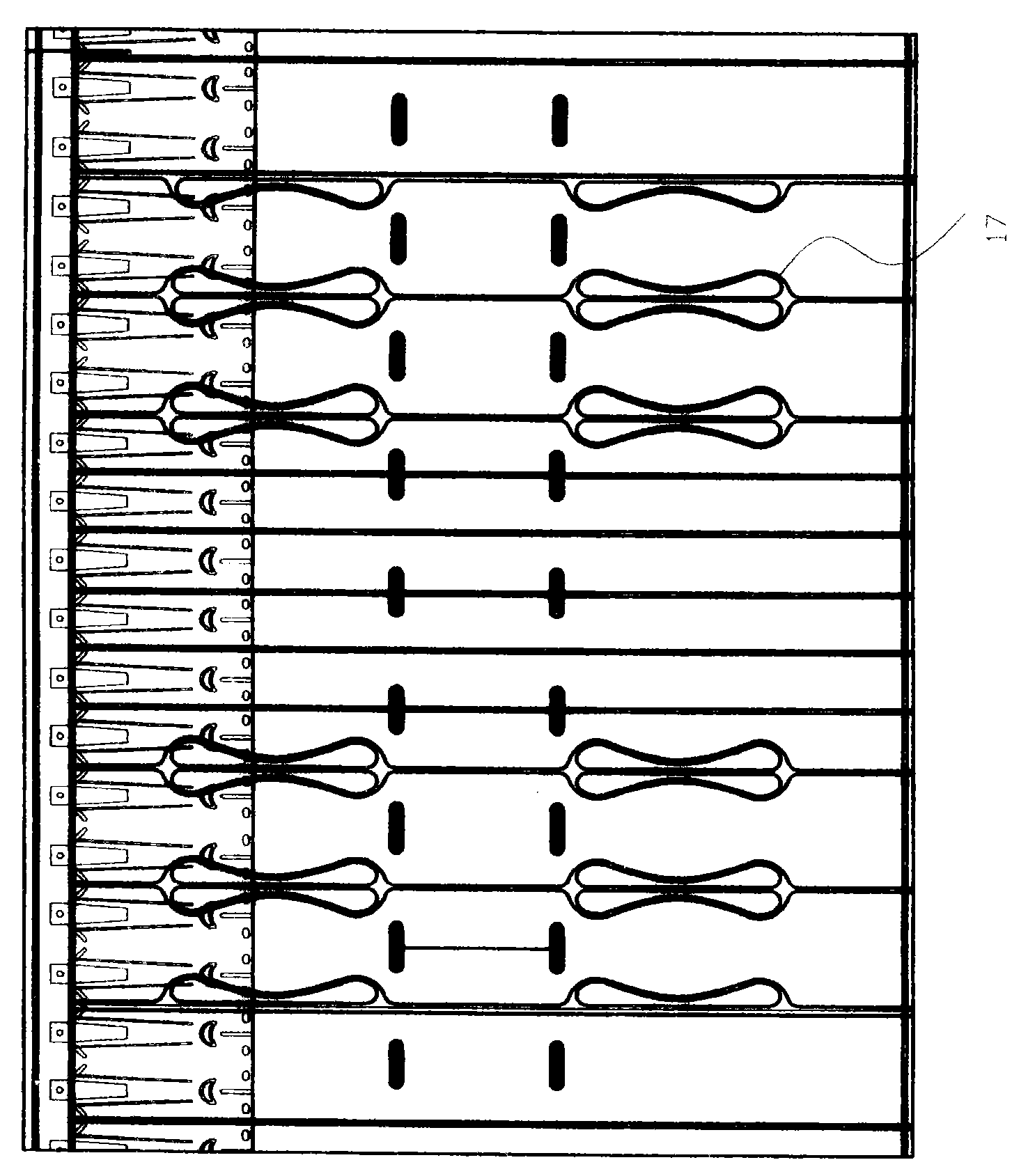

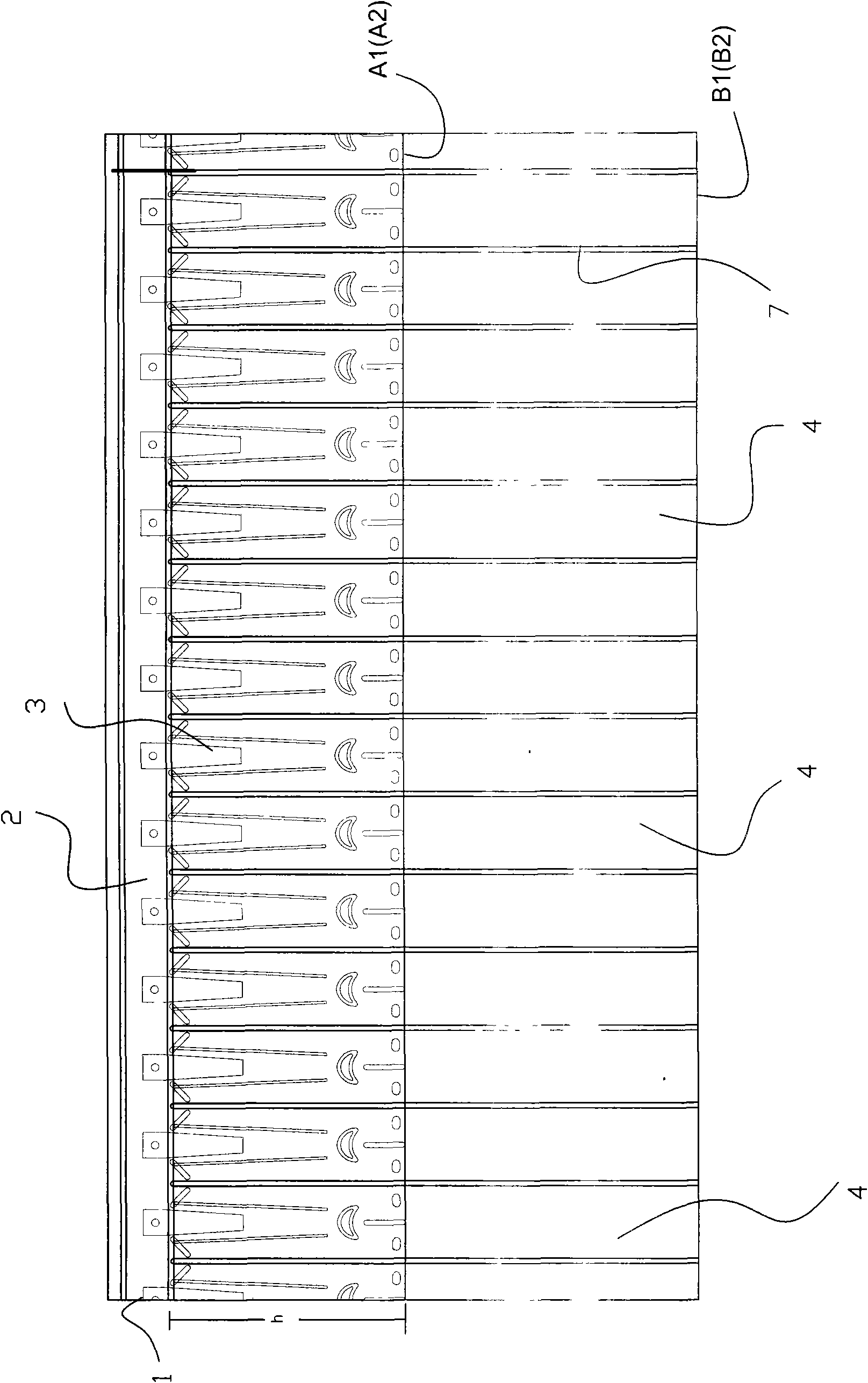

Production of O-shaped self-adhering air-isolated packing bag

ActiveCN100569502CExtrusion resistantAnti-vibrationEnvelopes/bags making machineryHigh resistanceEngineering

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Reusable multifunctional three-dimension sealing and packing material and method for preparing same

ActiveCN101513952BSolve the problem of high cost of long-distance transportationExtrusion resistantEnvelopes/bags making machineryPackage recyclingPolymer scienceThin membrane

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Production of O-shaped self-adhering air-isolated packing bag

ActiveCN1895878AExtrusion resistantAnti-vibrationEnvelopes/bags making machineryHigh resistanceOverwrap

A method for preparing the air-isolating 3D packing bag from O-type self-adhering film features that on the basis of the self-sucking performance of self-adhering film and the characteristics of print isolating device, a series of dedicated thermal sealing apparatuses is used for simple and local thermal adhering and sealing and the distributing technique of supplying trunk is also used. The resultant packing bag has high resistance to squeeze, vibration and impact and excellent buffering performance.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Multi-buffer air packing device

ActiveCN101891037BReduce impactReduce falling speedContainers to prevent mechanical damageDamagable goods packagingThin membraneMain channel

The invention discloses a multi-buffer air packing device. In the device, two layers of thermoplastic films are subjected to two times of thermal plastic sealing to form a three-dimensional packing body capable of sealing the air, the packing body comprises a plurality of independent sealed air chambers and a main channel with an air inlet, each sealed air chamber is communicated with the main channel through a one-way valve formed by two layers of films, the sealing chambers have turning points, the packing body is divided into a main bearing face and a lateral bearing face by a turning point line formed by the turning points, the diameter of the middle part of the sealed air chamber of the main bearing face formed after inflation is smaller than the diameters of the sealed air chambers on two sides. In the air packing device of the invention, higher air chambers, when a packed object falling onto the ground is impacted, contact the ground first and then the lower air chambers in the middle contact the ground to produce a secondary buffering effect, so the impact of the packed object is relieved considerably and the impact performance of the packing device is improved. Compared with packing devices of the same volume, the multi-buffer air packing device has much higher impact performance.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

An Improved Air Packing Device

ActiveCN101934892BImprove securitySolve the problem of high cost of long-distance transportationContainers to prevent mechanical damageDamagable goods packagingEngineeringCheck valve

The invention relates to an improved air packaging device. Two layers of thermoplastic films are subjected to secondary thermoplastic packaging to form a stereoscopic packaging body which can be sealed. The improved air packaging device comprises a plurality of independent seal air chambers and a main passage, wherein the main passage is provided with an air inlet; and each seal air chamber is communicated with the main passage by a check valve formed by two layers of films. The improved air packaging device is characterized in that the check valve and the main passage for inflating the check valve are formed by carrying out thermoplastic packaging on the two layers of films and one layer of thermoplastic film of the packaging body into a whole and can be arranged in any position of the seal air chambers. Meanwhile, because the two layers of check valve films are only fixed on any layer of thermoplastic film, and the check valve films are adhered to the thermoplastic film after inflated and do not bear any tension, the tearing risk does not exist, and the safety of the packaging device is greatly improved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Air-isolated and self-adhering packing material and its preparation

ActiveCN100551790CEasy and natural accessExtrusion resistantFlexible coversWrappersEngineeringPack material

The invention relates to a self-adhesive film air-rejecting three-dimensional packaging material and a manufacturing method thereof. The packaging material is composed of four layers of resin films, including two wider resin films and two narrower resin films. Subpartial heat sealing and a series of folds form multiple spaces that can store air medium, and use the interaction of the film's own viscosity and air pressure to prevent air from leaking out, thus forming a self-contained air medium by air and film. Mucous membranes reject air and three-dimensional packaging materials. Compared with the prior art, the air three-dimensional packaging material of the present invention has excellent comprehensive protection properties such as extrusion resistance, shock resistance, drop resistance and buffering, and can be used as a filling packaging material for articles, as a partition for parts or important parts of articles. It is used for all-round outer packaging of pads and articles.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Return plug type air packaging device and manufacturing method thereof

ActiveCN102233980BImprove reliabilityImprove impact resistanceBagsSacksPlastic packagingMain channel

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Vacuum tube carton device

ActiveCN106184993BExtrusion resistantShockproofContainers to prevent mechanical damageExternal fittingsCartonEngineering

The invention relates to a vacuum pipe paper box device. The vacuum pipe paper box device comprises a packaging box body. A plywood tray is arranged at the bottom of the packaging box body. The vacuum pipe paper box device is characterized in that one or two or more layers of packaging linings used for packaging vacuum pipes are arranged in the packaging box body; the packaging lining comprises a lower fixing part, an isolating and blocking part and an upper fixing part; in the blocking part, a plurality of cavities used for containing the vacuum pipes are formed through the staggered arrangement of transverse stop pieces and longitudinal stop pieces, the upper edges of the transverse stop pieces protrude out of the upper edges of the longitudinal stop pieces to form transverse connecting pieces, and the lower edges of the longitudinal stop pieces protrude out of the lower edges of the transverse stop pieces to form longitudinal connecting pieces; the upper fixing part comprises a plurality of transverse fixing pieces arranged in the longitudinal direction, and each transverse fixing piece is clamped between the corresponding two transverse connecting pieces; and the lower fixing part comprises a plurality of longitudinal fixing pieces arranged in the transverse direction, and each longitudinal fixing piece is clamped between the corresponding two adjacent longitudinal connecting pieces. According to the vacuum pipe paper box device, the inventory area can be reduced, resources are saved, and a protection function is achieved in the transporting process.

Owner:无锡欣盛包装材料科技有限公司

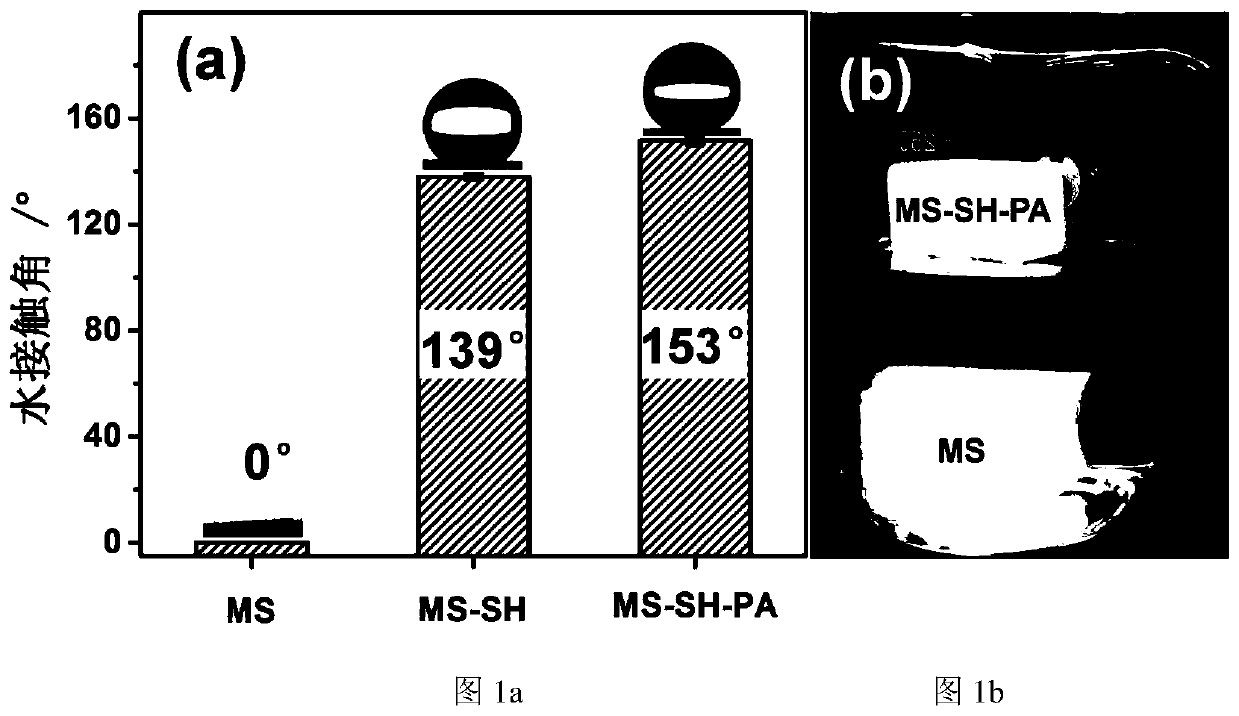

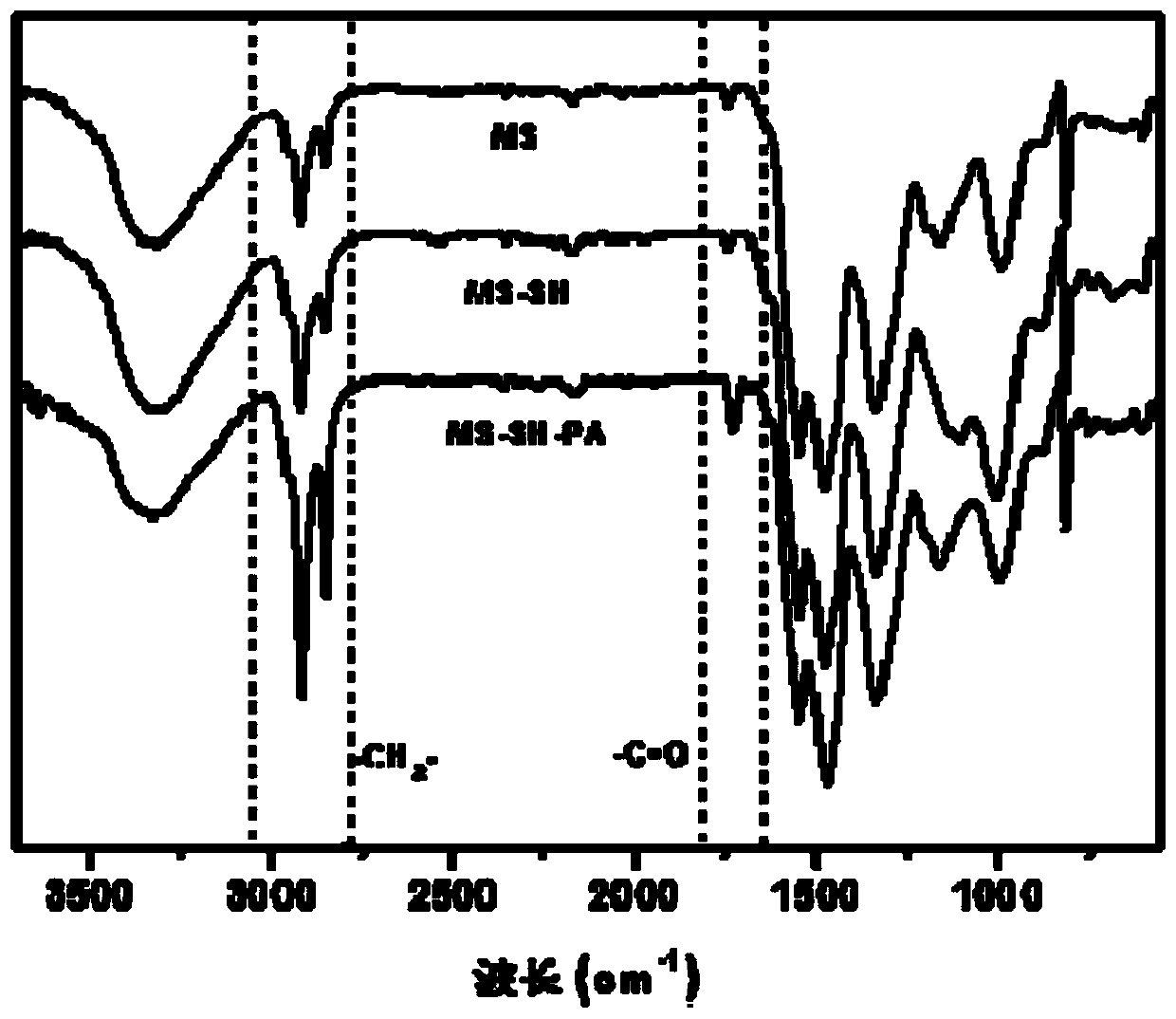

A kind of superhydrophobic superoleophilic melamine foam and its preparation method and application

ActiveCN107011534BHigh utility valueExtrusion resistantOther chemical processesAlkali metal oxides/hydroxidesAlkaneChemical reaction

The invention discloses super-hydrophobic and super-oleophylic melamine foam and a preparation method and application thereof. The super-hydrophobic and super-oleophylic melamine foam is prepared by the following steps of using porous melamine foam as a substrate; chemically grafting the substrate with a substance of one or a mixture of trimethoxysilylpropanethiol and 3-mercaptopropyltriethoxysilane to activate the substrate; under the existence of ultraviolet light and light initiator, enabling the thiol and the vinyl of long-chain alkane acrylic ester to generate clicking chemical reaction, so as to enrich C-C long chains on the substrate, so that the surface energy of the substrate is reduced, the roughness is improved, the hydrophobic property is greatly improved, and the oil and water selectivity is obviously improved. The preparation method has the advantages that the hydrophobic modification on the melamine foam is precise, the efficiency is high, the operation is simple and convenient, the implementing is easy, the consumption time is short, the cost is low, and the method is suitable for large-scale production. The super-hydrophobic and super-oleophylic melamine foam can be directly applied to the sea oil overflow, recycling of leaked chemicals, separation of oil and water mixture, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Flared type seamless connector with composite ring

PendingCN111706731AWear-resistantCorrosion resistantFlanged jointsWear resistantMechanical engineering

The invention relates to a seamless connector, in particular to a flared type seamless connector with a composite ring. The flared type seamless connector with the composite ring has the characteristics of being wear resistant, corrosion resistant, high in strength and extrusion resistant; and in the meantime, the seamless connector is further characterized by being light in weight, simple in structure, easy to machine, low in the fabrication cost, easy to recycle in an environment-friendly manner, easy to popularize and easy to install and transport. The flared type seamless connector with the composite ring comprises a connection pipe, a first lining ring and a second lining ring. A flared opening is arranged at an end of the connection pipe. A first shoulder portion is arranged at the connecting position of the flared opening and the connection pipe. A first abutting-connected portion which is connected with the inner wall of the flared opening in an abutting manner is arranged at an end of the first lining ring, and a second shoulder portion is arranged at the other end of the first lining ring. A support portion for supporting the second lining ring is arranged on one side ofthe second shoulder portion. A second abutting-connected portion which is connected with the inner wall of the flared opening in an abutting manner is arranged on the periphery of the second lining ring. One end of the second lining ring is connected with the second shoulder portion in an abutting manner, and the other end of the second lining ring is connected with the first shoulder portion in an abutting manner.

Owner:山东三玄橡塑科技股份有限公司

Air packaging device and production method for same

ActiveCN102556503BIncrease production speedEasy to arrange productionContainers to prevent mechanical damageDamagable goods packagingEngineeringMethods of production

Disclosed is an air packaging device. A space capable of storing air is formed by two thermoplastic films by means of two-time thermoplastic packaging. The air packaging device comprises a plurality of independent hermetic air chambers and a main passage, the main passage is provided with an air inlet, each hermetic air chamber is communicated with the main passage through a one-way valve consisting of two films, and two or more than two one-way valves are mounted in parts of air chambers or all the air chambers. Buffers are added on main portions of the air packaging device, and the size of air columns is decreased on the portions which do not need too much protection, so that the size of the air packaging device can be effectively decreased, and transport cost is reduced. By means of direct forming at a use site of a user, transport space and cost can be greatly reduced, so that the problem of excessively high cost during long-distance transport of packaging materials is solved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

An air-packing device with a lateral air valve and method of use thereof

ActiveCN101992893BReduce manufacturing costImprove securityContainers to prevent mechanical damageThermoplasticEngineering

The invention relates to an air package device with a transverse air valve. A three-dimensional package body capable of sealing air is formed by two layers of thermoplastic films through secondary thermoplastic sealing, and the air package device comprises a plurality of independent sealing air chambers and a main passage, wherein the main passage is provided with an air inlet, each sealing air chamber is communicated with the main passage through a one-way valve air inlet at an air inlet sealing line part of the one-way valve formed by the two layers of one-way valve films, a plurality of outlet pre-setting points are arranged at the outlet of the one-way valve, the pre-setting points of the outlet of the one-way valve are discontinuous straight lines, and broken points in the middle of the straight lines provide air outlet passages for each one-way valve. The air package device of the invention can reduce the height of the one-way valve films because of the adoption of the transverse air valve in one aspect, and greatly save the cost of the one-way valve films. In addition, the universality of the transverse air value is high, and unlike the traditional one-way valve which needs to correspondingly use one mold according to the diameter of the air chambers, the package devices of air chambers in various widths can use one set of one-way valve mold, thus the cost of the mold is reduced.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

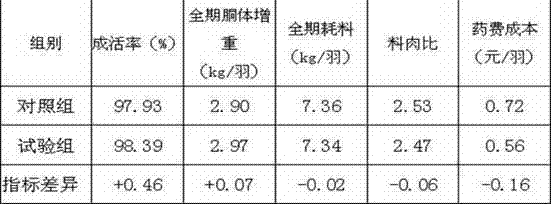

Method for preparing feed additive by using bacillus licheniformis

ActiveCN103109981BReduce manufacturing costHigh cost of industrializationBacteriaMicroorganism based processesBacillus licheniformisFood additive

The invention provides a method for preparing a feed additive by using bacillus licheniformis. The method comprises the following steps of: preparing and activating a strain, preparing a strain with an inclined surface, preparing a triangular flask liquid strain, fermenting a canned solid and the like so as to obtain the feed additive. By adopting a unique culture medium and a solid fermentation technique, the strain propagation speed is accelerated, the fermentation period is shortened, the production cost is lowered, and the spore forming rate of a product is increased; a cheap medium such as bran is used as a main culture substrate, so that the production cost is effectively lowered; the production process has the unique advantages of water conservation, energy conservation, small quantity of byproducts and environment friendliness; and the production cost is low, the product is resistant to high temperature, acid, alkali and extrusion, is small in damage in the preparation process of the feed, small in adding quantity and remarkable in feeding effect, so that the method belongs to a sanitary production technique and has large-scale popularization and application values.

Owner:高唐华农生物工程有限公司

Special material for compact wire rope core and preparation of rope core

ActiveCN101463165BExtended service lifeImpact resistantMonocomponent polyolefin artificial filamentTextile cablesElastomerFiber

The invention relates to a rope core of a compacted steel wire rope, which is applied to the technical field of processing of the steel wire rope. The invention is characterized in that the weight portions of the compositions of the special material of the rope core are as follows: 69 portions to 71 portions of polypropylene, 14 portions to 16 portions of high density polyethylene, 4 portions to 6 portions of polyolefin elastomer, 4 portions to 6 portions of ethylene propylene diene rubber, 3 portions to 5 portions of nylon 6, 0.4 portion to 0.6 portion of ultraviolet absorbent and 0.4 portion to 0.6 portion of antioxidant. The compact steel wire rope has the effects that the fiber of the steel wire core has no shatter and fracture. The steel wire core has the advantages of shock resistance, extrusion resistance, and ageing resistance. By changing the manufacturing materials and manufacturing technique of the rope core of the compacted steel wire rope, the shock resistance of the rope core is improved, the rope core has good supporting effect in the using process of the compacted steel wire rope and the service life of the compacted steel wire rope is prolonged.

Owner:XIANYANG BOMCO STEEL TUBE & WIRE ROPE

Reusable atmospheric packaging device

ActiveCN101891036BLow costSolve the problem of high cost of long-distance transportationPackage recyclingContainers to prevent mechanical damageMain channelThin membrane

The invention relates to a reusable atmospheric packaging device. A solid packaging body capable of sealing air is formed by performing secondary thermoplastic packaging on two layers of thermoplastic films. The reusable atmospheric packaging device comprises a plurality of independent sealing air chambers and a main channel, wherein an air inlet is formed on the main channel; and each sealing air chamber is communicated with the main channel through an air intake one-way valve consisting of two layers of films. The reusable atmospheric packaging device is characterized by further comprising air release devices which are arranged on the sealing air chambers and are used for exhausting air in the sealing air chambers. Due to the adoption of the atmospheric packaging device, when a packaging task is finished, the air release devices are opened, and the air in the removed atmospheric packaging device is exhausted, and the removed atmospheric packaging device can be used again through air inflation, so that the atmospheric packaging device can be reused and the packaging cost is largely saved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com