Air packing device

A technology of air packaging and air, which is applied in the directions of transportation and packaging, packaging of vulnerable items, types of packaged items, etc., and can solve problems such as poor cushioning effect and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The air-packing device of the present invention will be further described below in conjunction with the drawings and specific embodiments.

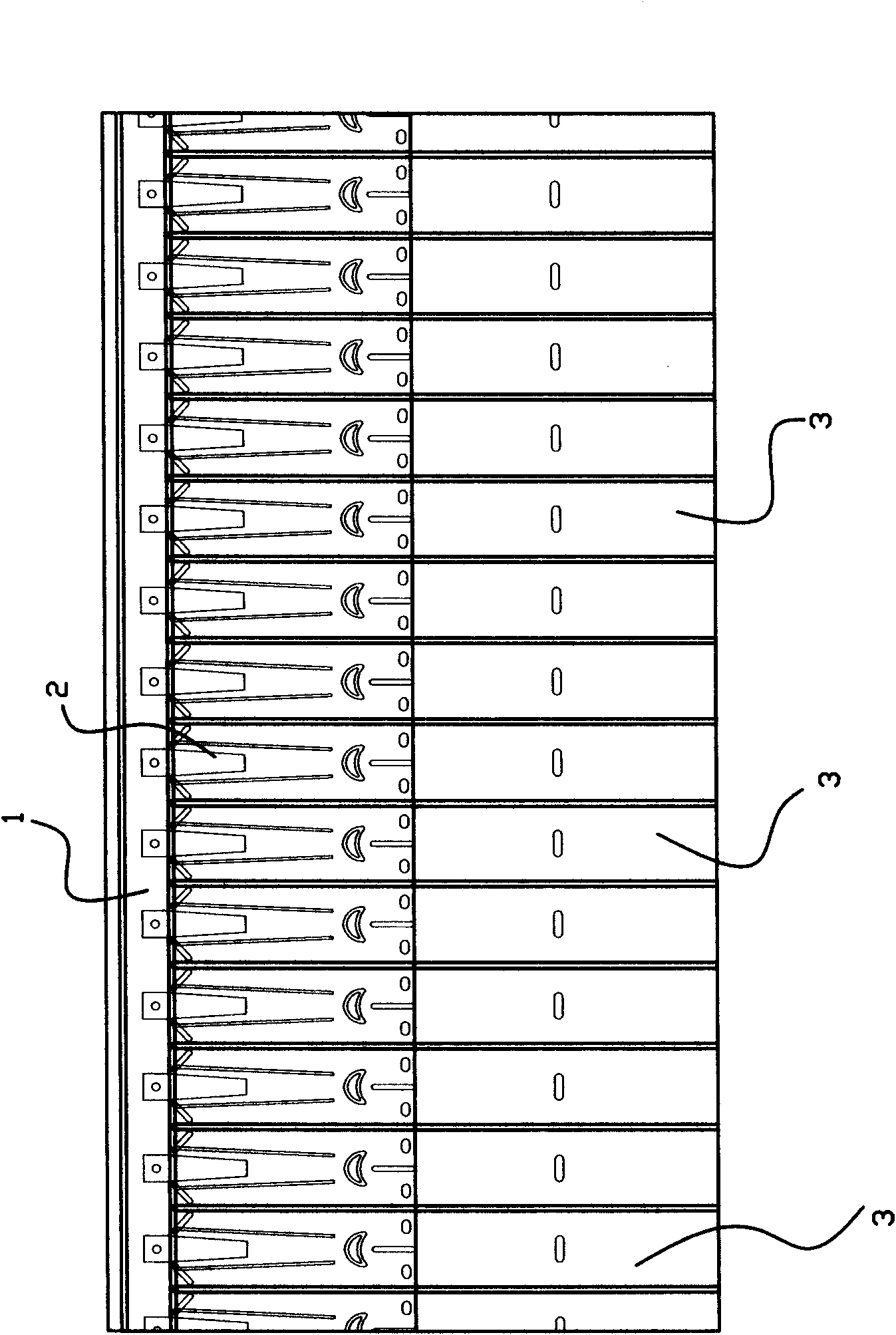

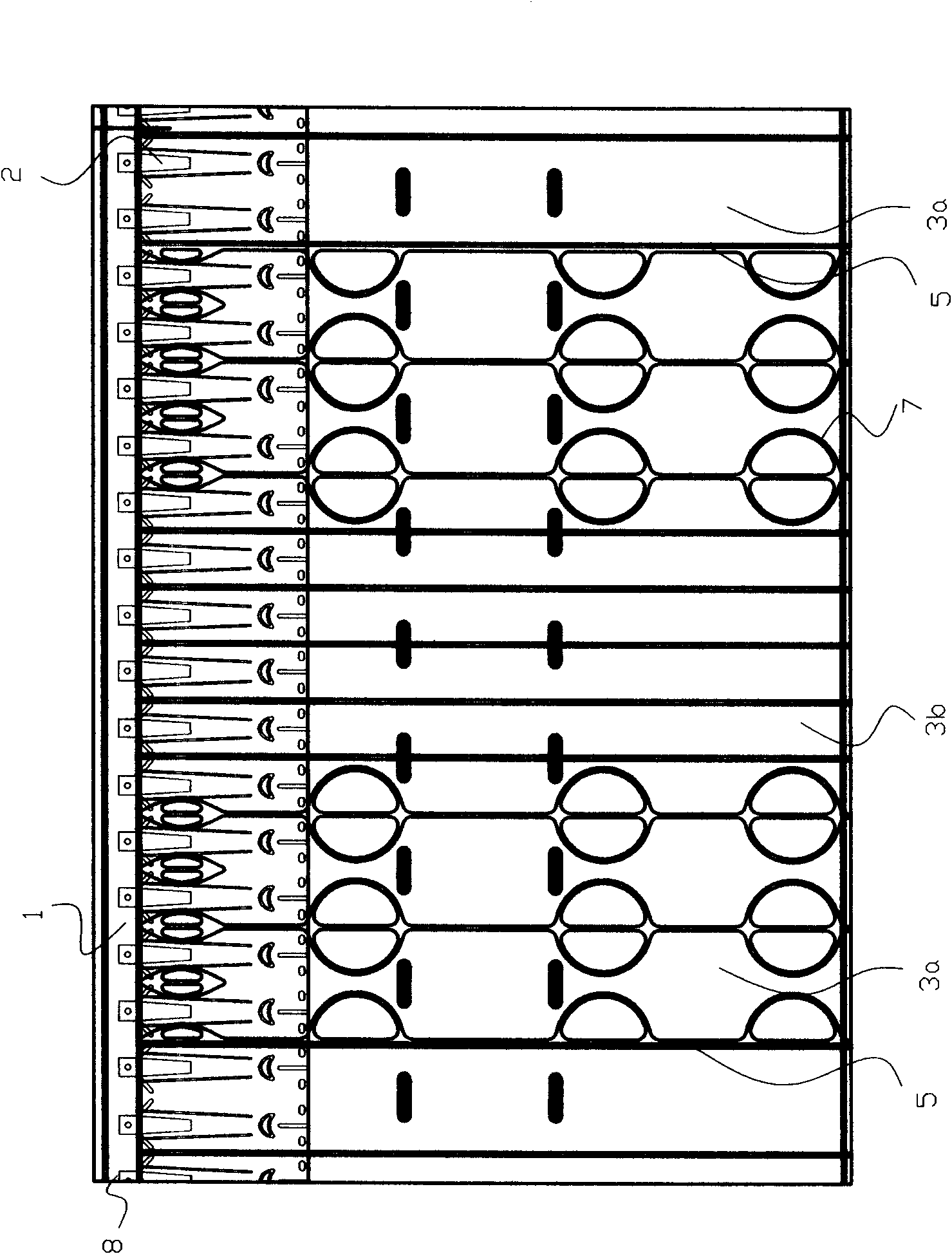

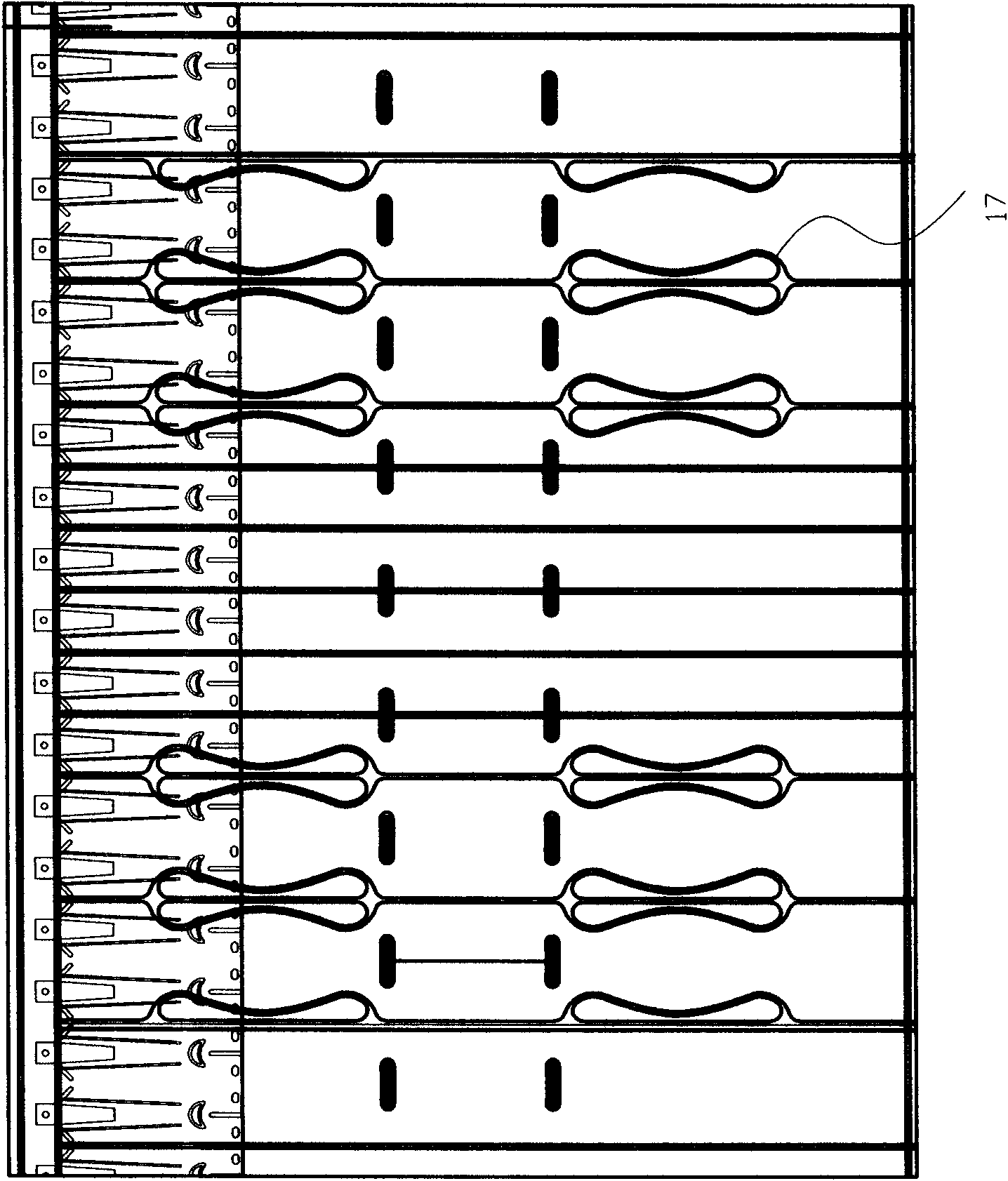

[0037] Primary plastic sealing refers to the process of sealing two layers of thermoplastic film and one-way valve to form a flat package that can store air. Secondary plastic sealing refers to folding the semi-finished product after primary plastic sealing and sealing it again along the secondary plastic sealing line. The process of forming a three-dimensional cushioning bag that can hold objects.

[0038] figure 2 It is a schematic diagram of the first embodiment of the air-packing device of the present invention before secondary plastic sealing. It is different from the prior art in that first, the main diameters of the air chambers 3a on both sides are the same and larger than the middle air chamber The main diameter of 3b; second, two check valves 2 are connected to the upper part of the air chamber 3a on both sides and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com