Air package device with transverse air valve and use method thereof

A technology of air packaging and air valve, which is applied in the direction of transportation and packaging, packaging of vulnerable items, types of packaged items, etc. It can solve problems such as air leakage, increased packaging costs, and excessive packaging, so as to increase safety, save costs, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The air-packing device with a horizontal air valve of the present invention will be further described below in conjunction with the drawings and specific embodiments.

[0030] One-time heat sealing refers to the process of forming a flat bag that can store air by heat-sealing two layers of thermoplastic film and a one-way valve. The process of thermoforming again to form a three-dimensional bag that can hold objects.

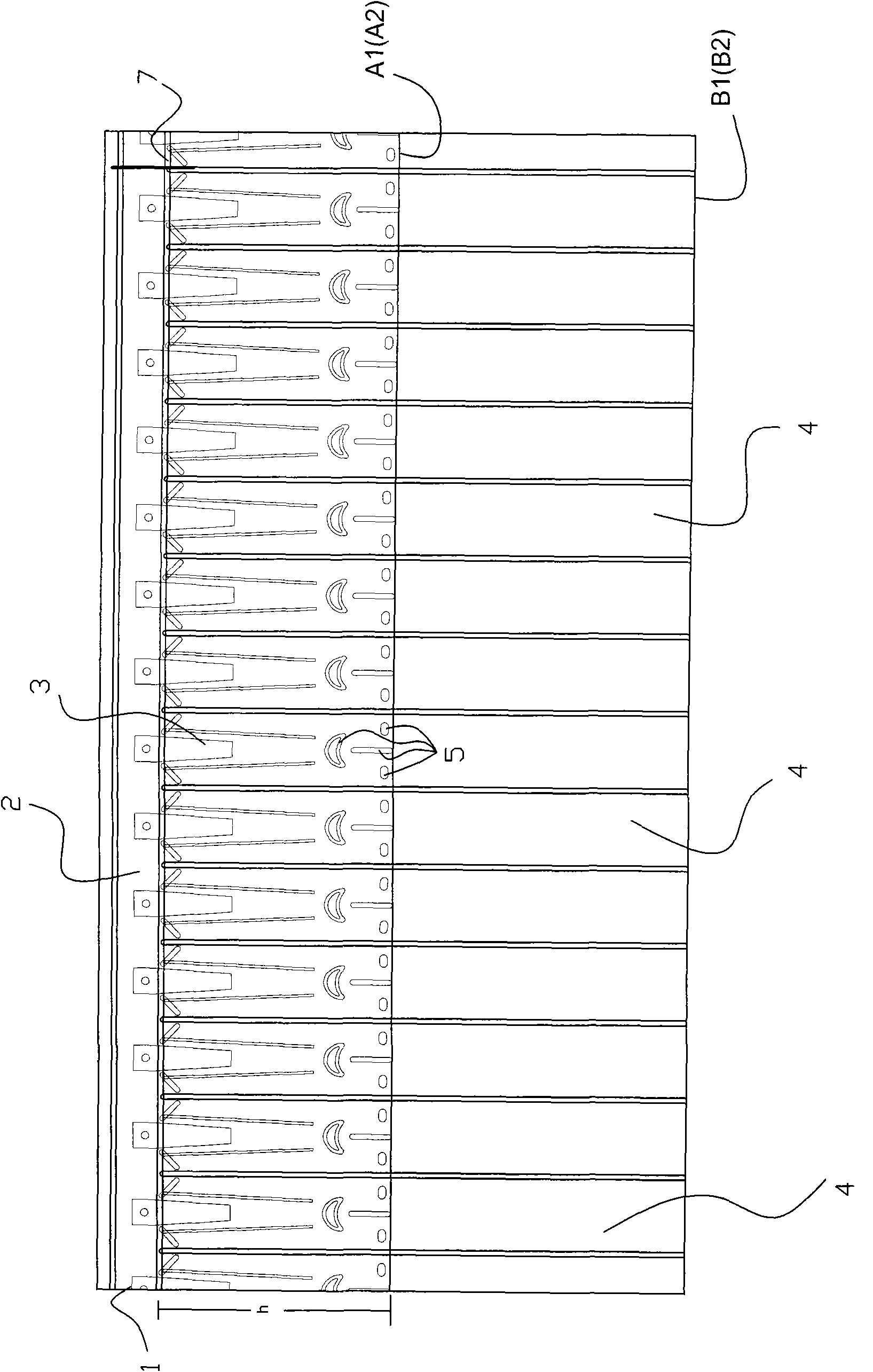

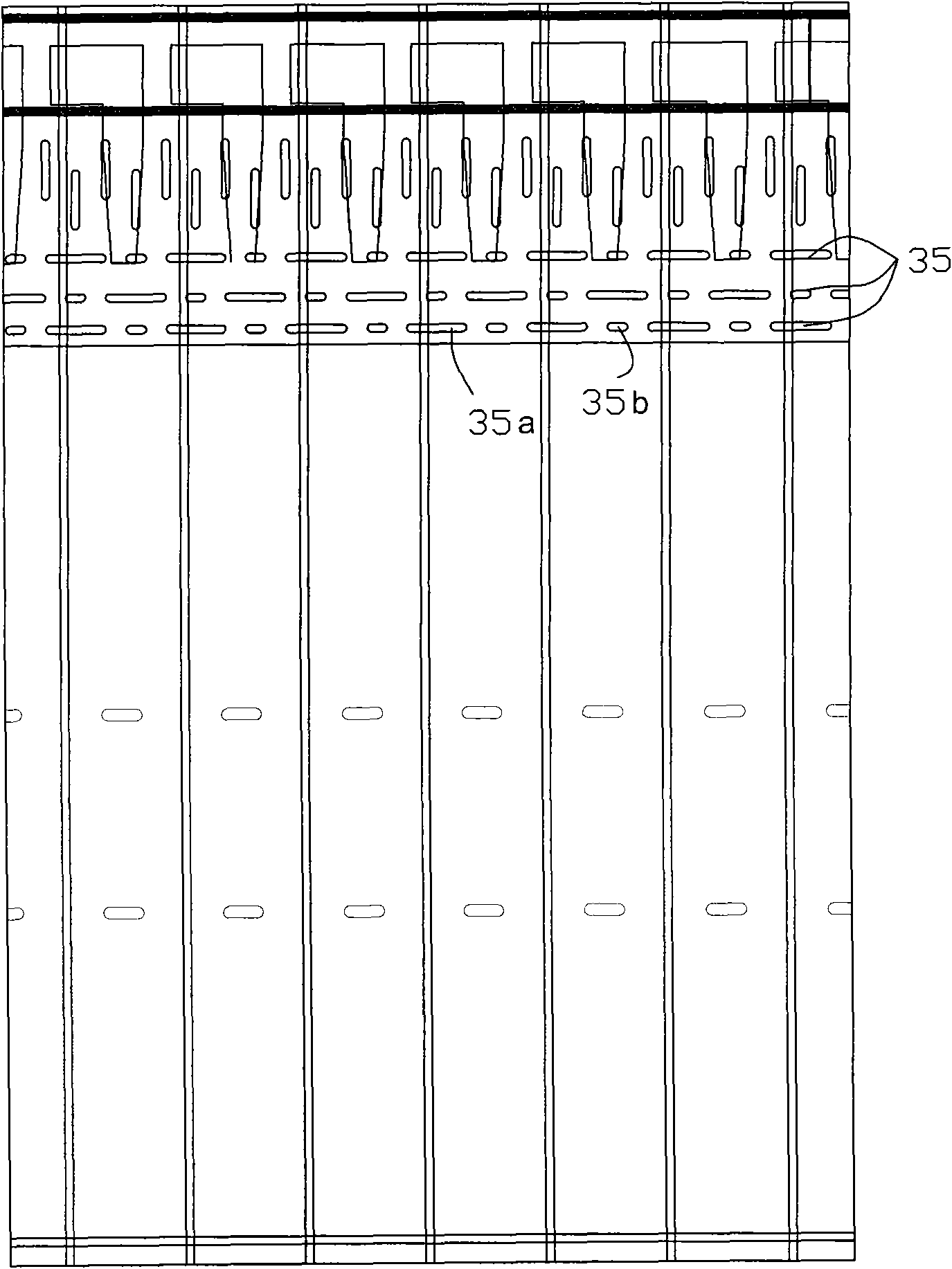

[0031] image 3 It is an embodiment of the air-packing device with a horizontal air valve of the present invention, and figure 1 The difference of the packaging device is that it uses a horizontal air valve, such as image 3 As shown, the check valve outlet preset point 35a is a long horizontal line segment, and the preset point 35b is a short horizontal line segment. The preset points 35a and 35b are alternately set to form a horizontal discontinuous straight line 35, and the discontinuous straight line 35 is in each There are two discontinuities in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com