Multi-buffer air packing device

An air-packing and air-sealing technology, which is applied in the directions of transportation and packaging, packaging of vulnerable items, types of packaged items, etc., can solve the problems of increasing transportation costs, increasing the overall volume, and poor cushioning effect, achieving excellent protection performance and reducing The effect of impact and impact performance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The air-packing device with multi-stage cushioning of the present invention will be further described below in conjunction with the drawings and specific embodiments.

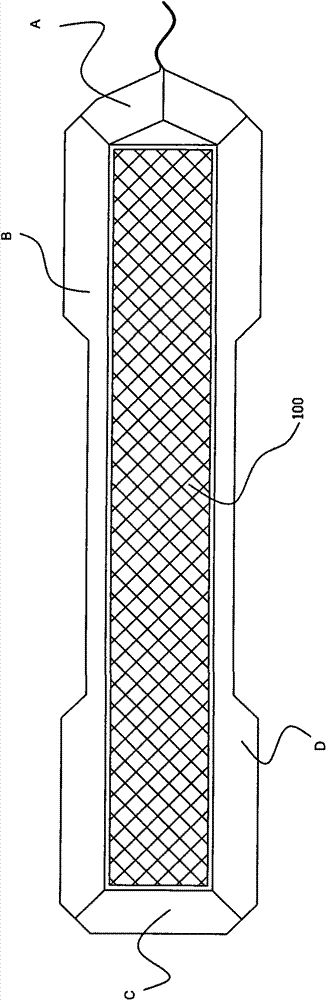

[0034] The primary heat sealing refers to the process of thermally sealing two layers of thermoplastic film and the one-way valve to form a flat bag that can store air. The secondary heat sealing refers to the secondary heat sealing after folding the semi-finished product after the primary heat sealing. The process of plasticizing the thread again to form a three-dimensional bag that can hold objects.

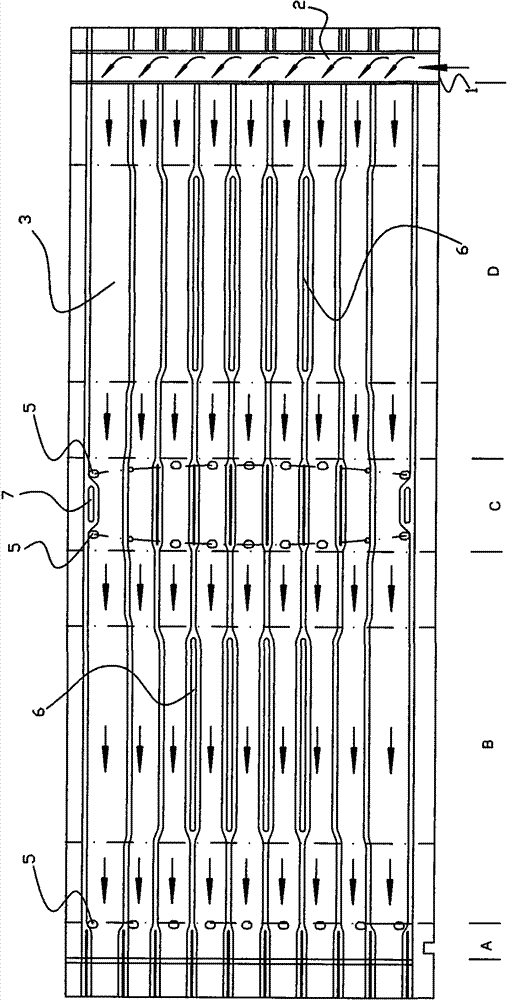

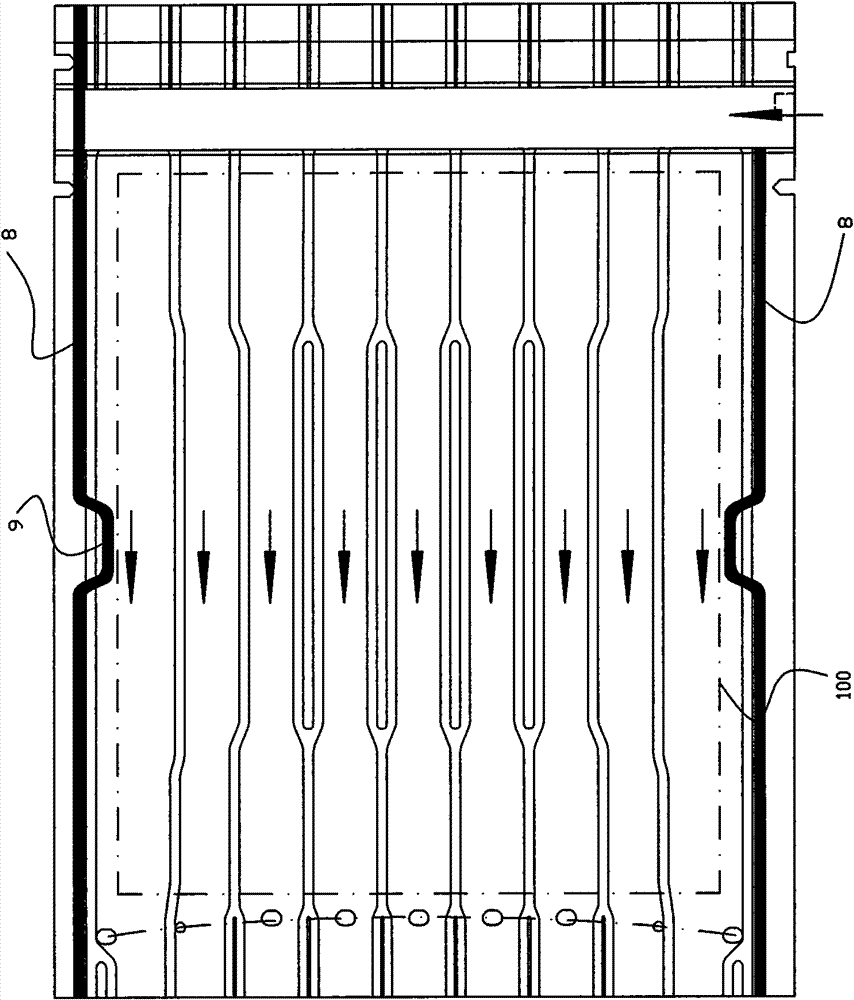

[0035] figure 1 Shown is the schematic diagram of the first embodiment of the air-packing device with multi-stage cushioning of the present invention before the second heat sealing. The double line shows the first heat sealing line formed by the first heat sealing of the abrasive tool. As shown by the arrow in the figure, the air enters the main channel 2 through the air inlet 1, and then enters each sealed ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com