Three-layer air packing device and production method thereof

A technology of air packaging and production methods, which is applied in the direction of packaging, transportation and packaging, and packaging item types, etc., can solve the problems of increasing costs and wasting packaging time, and achieve the effects of saving costs, reducing troubles, and saving packaging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The three-layer air-packing device of the present invention will be further described below in conjunction with the drawings and specific embodiments.

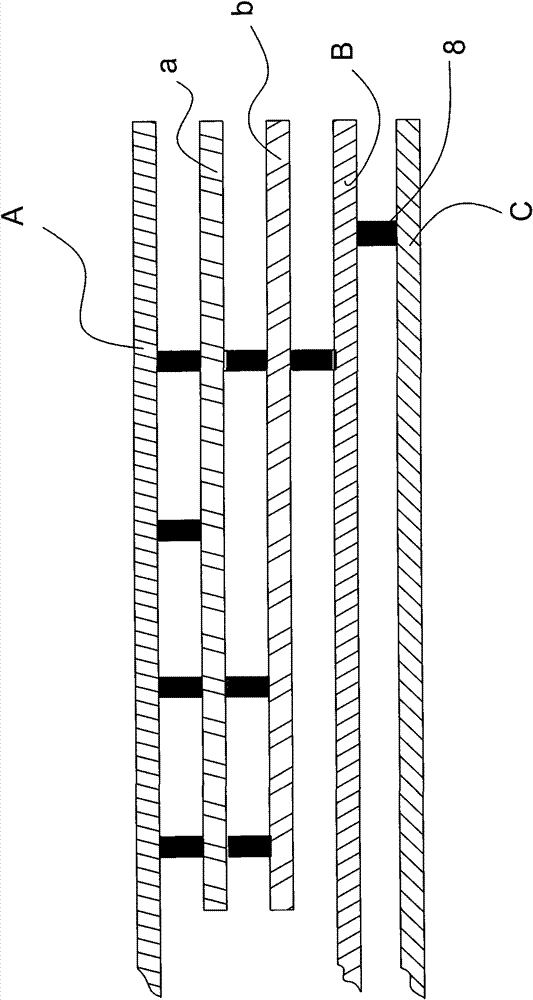

[0033] Primary plastic sealing refers to the process of sealing two layers of thermoplastic film and one-way valve to form a flat bag that can store air. Secondary plastic sealing refers to folding the semi-finished product after primary plastic sealing and sealing it again along the secondary plastic sealing line. The process of forming a three-dimensional bag that can hold objects.

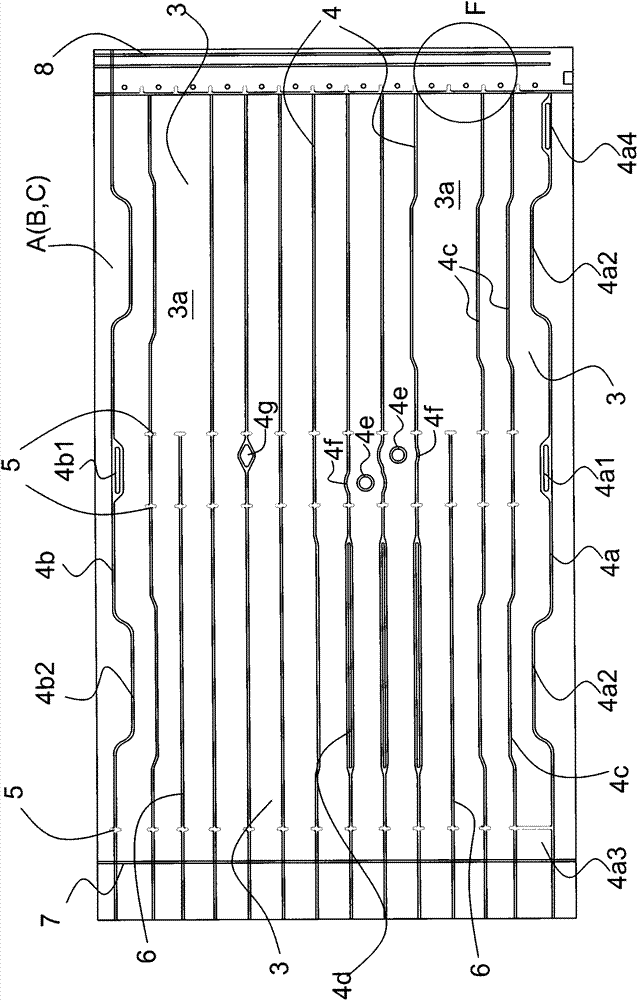

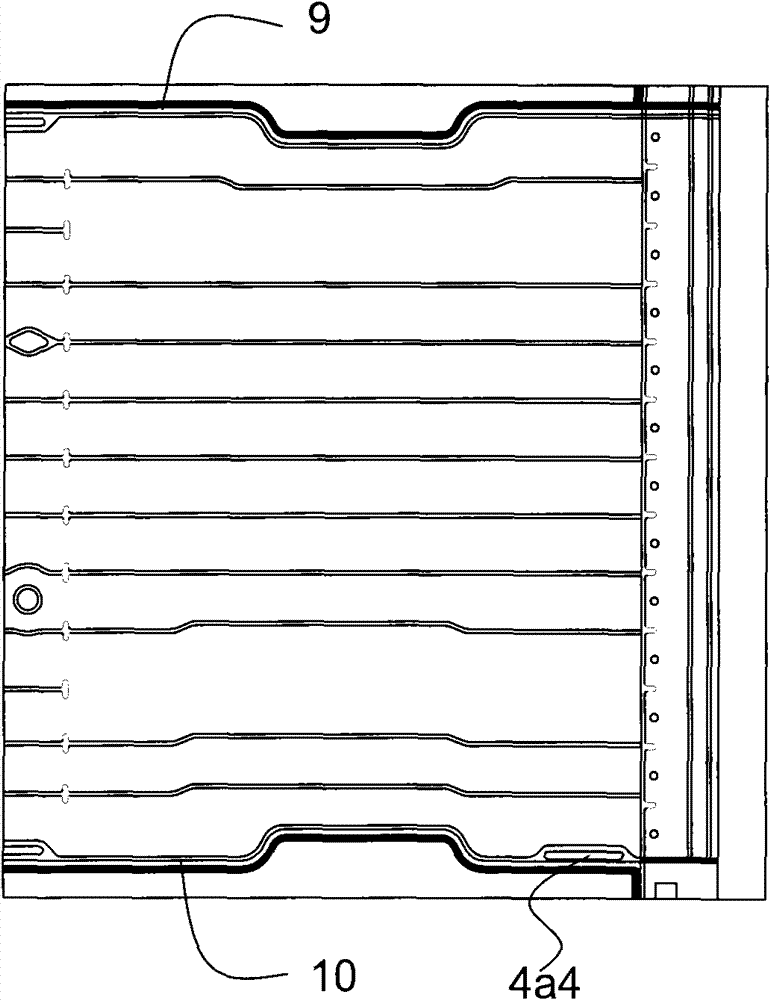

[0034] Such as Figure 1-3 Shown, is an embodiment of the present invention, figure 1 It is a schematic diagram of the three-layer air packaging device of the present invention before secondary plastic sealing; figure 2 yes figure 1 The air packaging device shown is a schematic diagram of the upper and lower ends after being folded left and right in half; image 3 yes figure 1 Longitudinal sectional view at middle F. The three-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com