Acoustic insulation and deodorization sandwich layer for automobile interior decoration

A car interior and interlayer technology, which is applied to vehicle parts, upper structures, transportation and packaging, etc., can solve the problems of inability to purify the air, gaps that cannot be filled, and poor sound insulation effect, so as to improve the sound insulation effect, improve the compressive strength, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

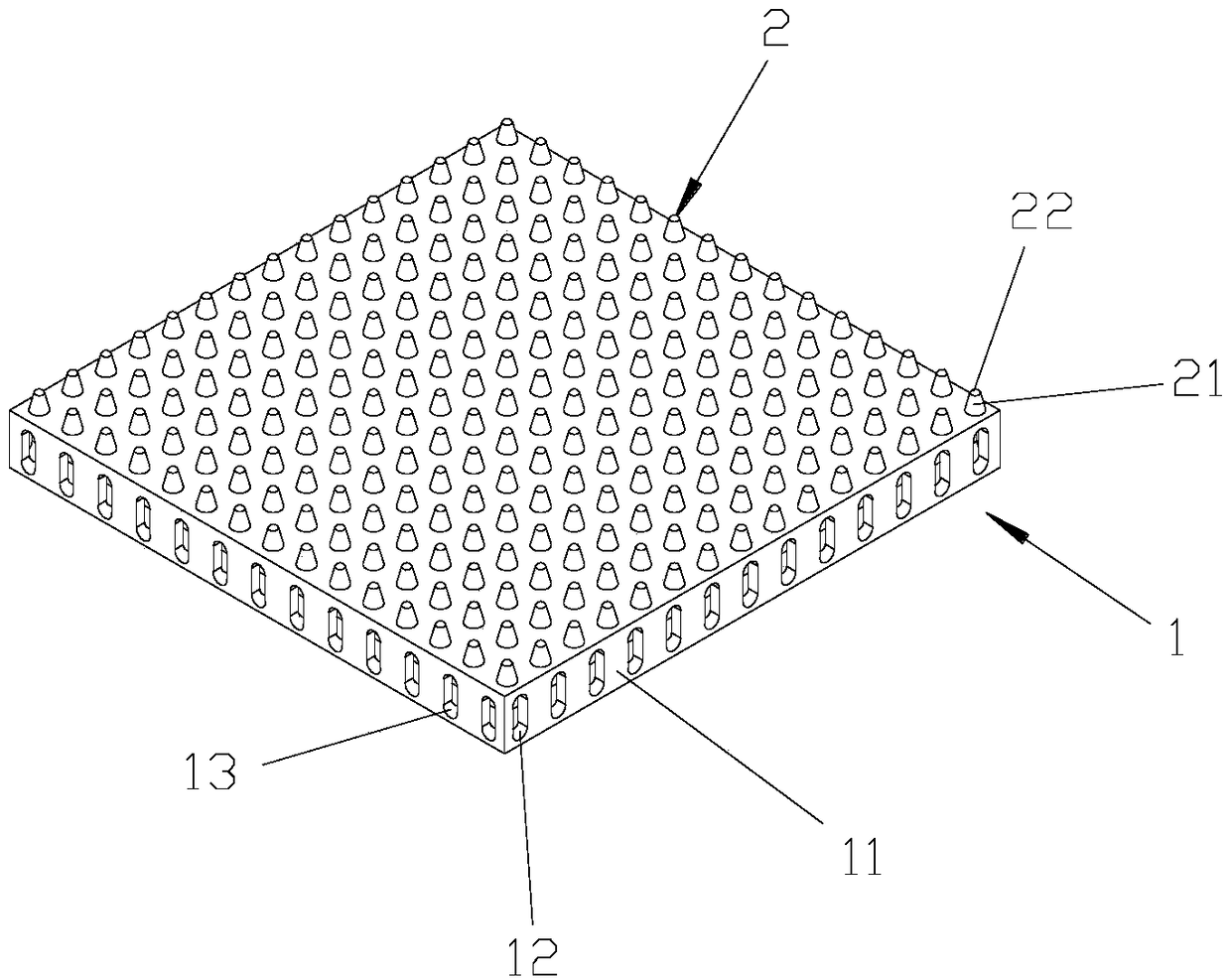

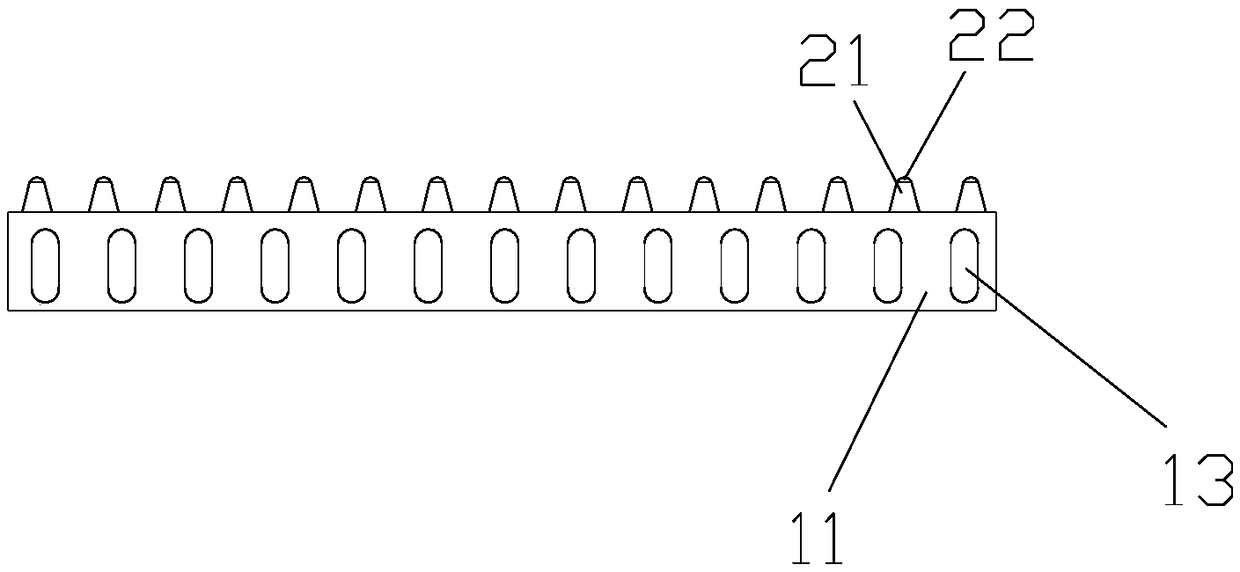

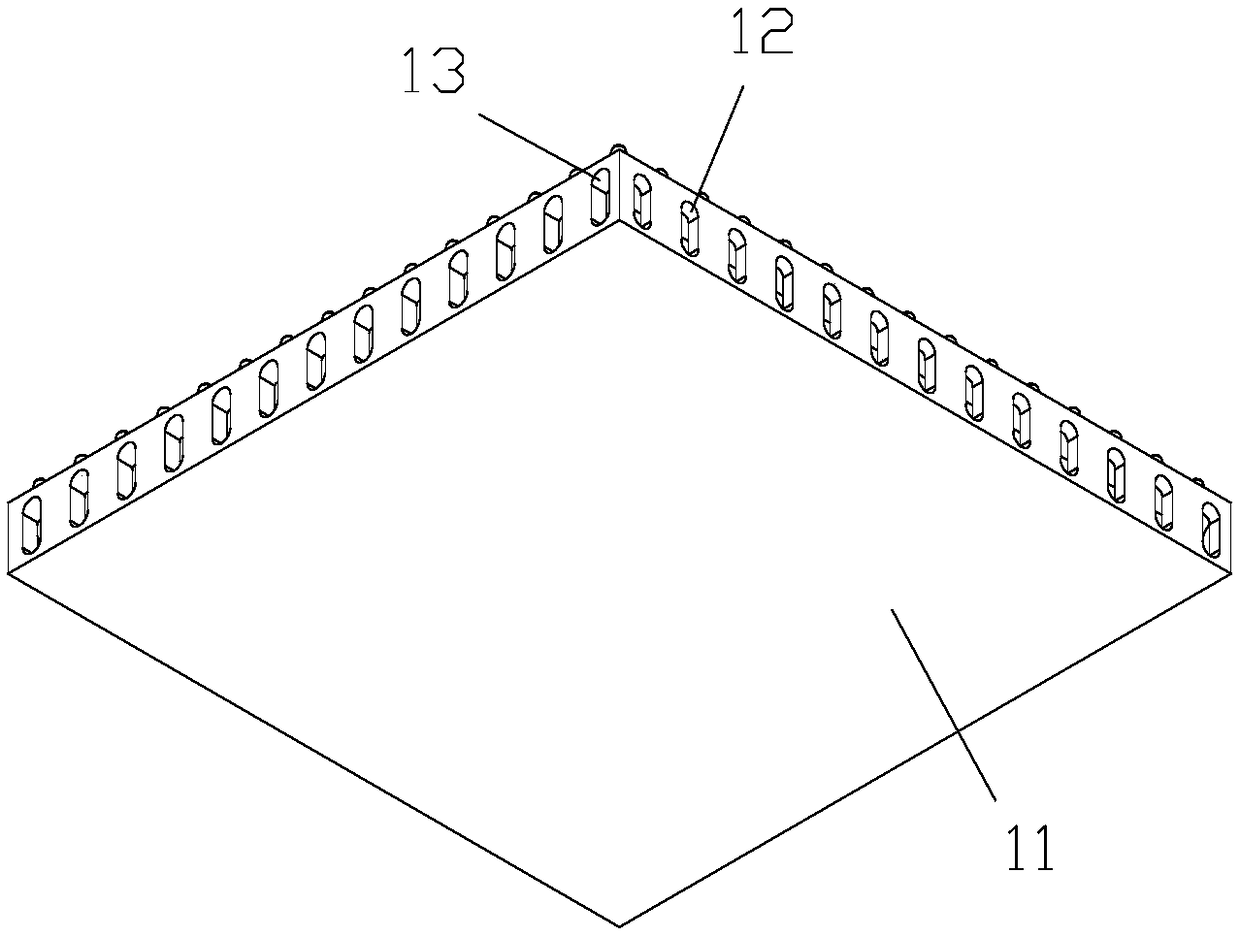

[0023] A sound insulation and deodorant interlayer for automobile interior decoration, such as Figure 1-3 As shown, it includes a sound-proof rubber sheet 1 and bumps 2 arranged on the sound-proof rubber sheet 1 and fixed to the sound-proof rubber sheet 1 to buffer pressure; the sound-proof rubber sheet 1 includes a rubber sheet body 11, and The first transverse hole 12 penetrates the rubber sheet body 11 to reduce the weight of the rubber sheet body 11 and improve the sound insulation effect of the rubber sheet body 11, and penetrates the rubber sheet body 11 to reduce the weight of the rubber sheet body 11 and increase the rubber sheet The second transverse hole 13 of the main body 11 that has a sound insulation effect and penetrates the first transverse hole 12; the convex point 2 includes a tapered protrusion 21 fixed to the rubber body 11, and a top of the tapered protrusion 21 And a dome 22 fixed to the tapered protrusion 21 for reducing friction. The tapered protrusion...

Embodiment 2

[0036] A sound insulation and deodorant interlayer for automobile interior decoration, such as Figure 1-3 As shown, it includes a sound-proof rubber sheet 1 and bumps 2 arranged on the sound-proof rubber sheet 1 and fixed to the sound-proof rubber sheet 1 to buffer pressure; the sound-proof rubber sheet 1 includes a rubber sheet body 11, and The first transverse hole 12 penetrates the rubber sheet body 11 to reduce the weight of the rubber sheet body 11 and improve the sound insulation effect of the rubber sheet body 11, and penetrates the rubber sheet body 11 to reduce the weight of the rubber sheet body 11 and increase the rubber sheet The second transverse hole 13 of the main body 11 that has a sound insulation effect and penetrates the first transverse hole 12; the convex point 2 includes a tapered protrusion 21 fixed to the rubber body 11, and a top of the tapered protrusion 21 And a dome 22 fixed to the tapered protrusion 21 for reducing friction. The tapered protrusion...

Embodiment 3

[0049] A sound insulation and deodorant interlayer for automobile interior decoration, such as Figure 1-3 As shown, it includes a sound-proof rubber sheet 1 and bumps 2 arranged on the sound-proof rubber sheet 1 and fixed to the sound-proof rubber sheet 1 to buffer pressure; the sound-proof rubber sheet 1 includes a rubber sheet body 11, and The first transverse hole 12 penetrates the rubber sheet body 11 to reduce the weight of the rubber sheet body 11 and improve the sound insulation effect of the rubber sheet body 11, and penetrates the rubber sheet body 11 to reduce the weight of the rubber sheet body 11 and increase the rubber sheet The second transverse hole 13 of the main body 11 that has a sound insulation effect and penetrates the first transverse hole 12; the convex point 2 includes a tapered protrusion 21 fixed to the rubber body 11, and a top of the tapered protrusion 21 And a dome 22 fixed to the tapered protrusion 21 for reducing friction. The tapered protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com