Reusable multifunctional three-dimension sealing and packing material and method for preparing same

A technology of sealed packaging and three-dimensional packaging, which is applied in the direction of sustainable packaging industry, sustainable manufacturing/processing, envelope/bag manufacturing machinery, etc., and can solve the problem that the air retention time is not very long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

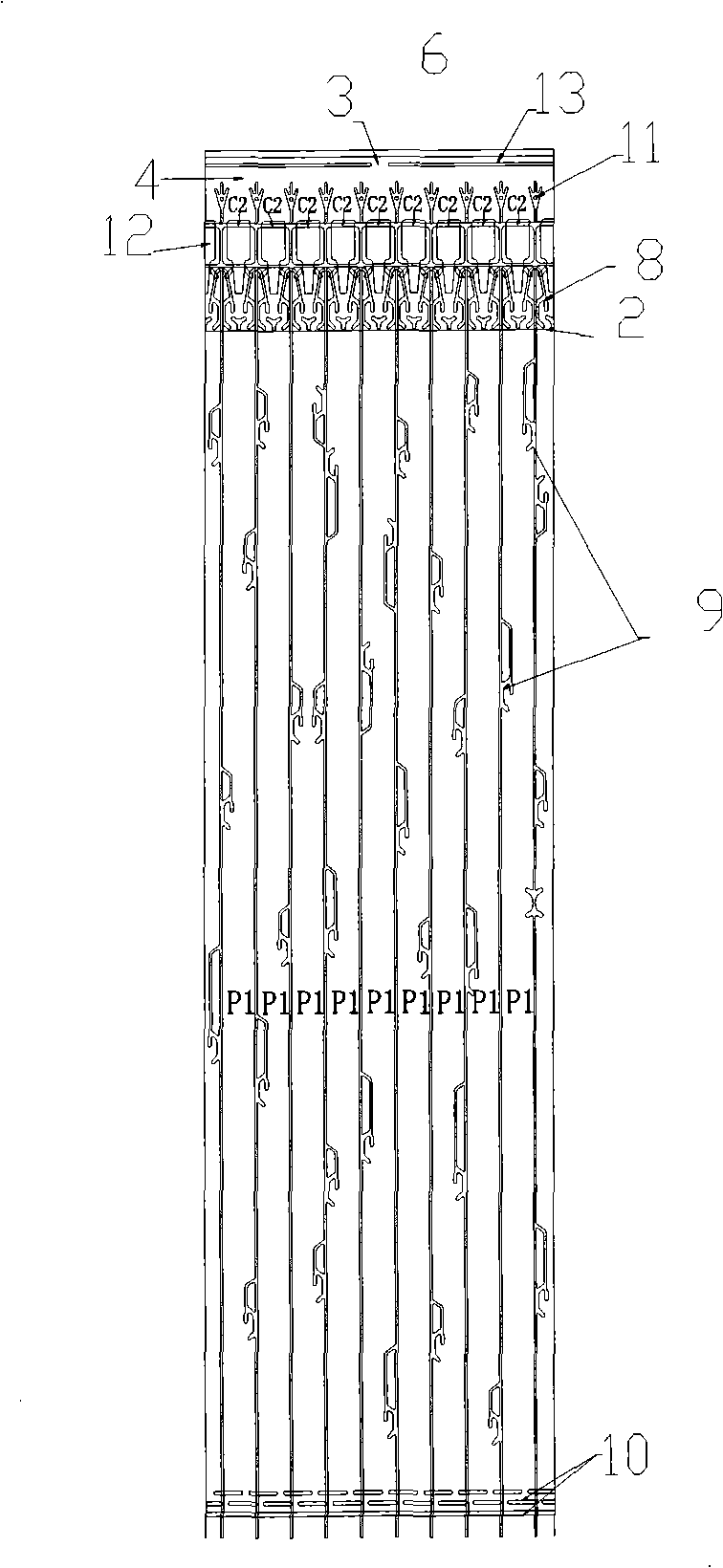

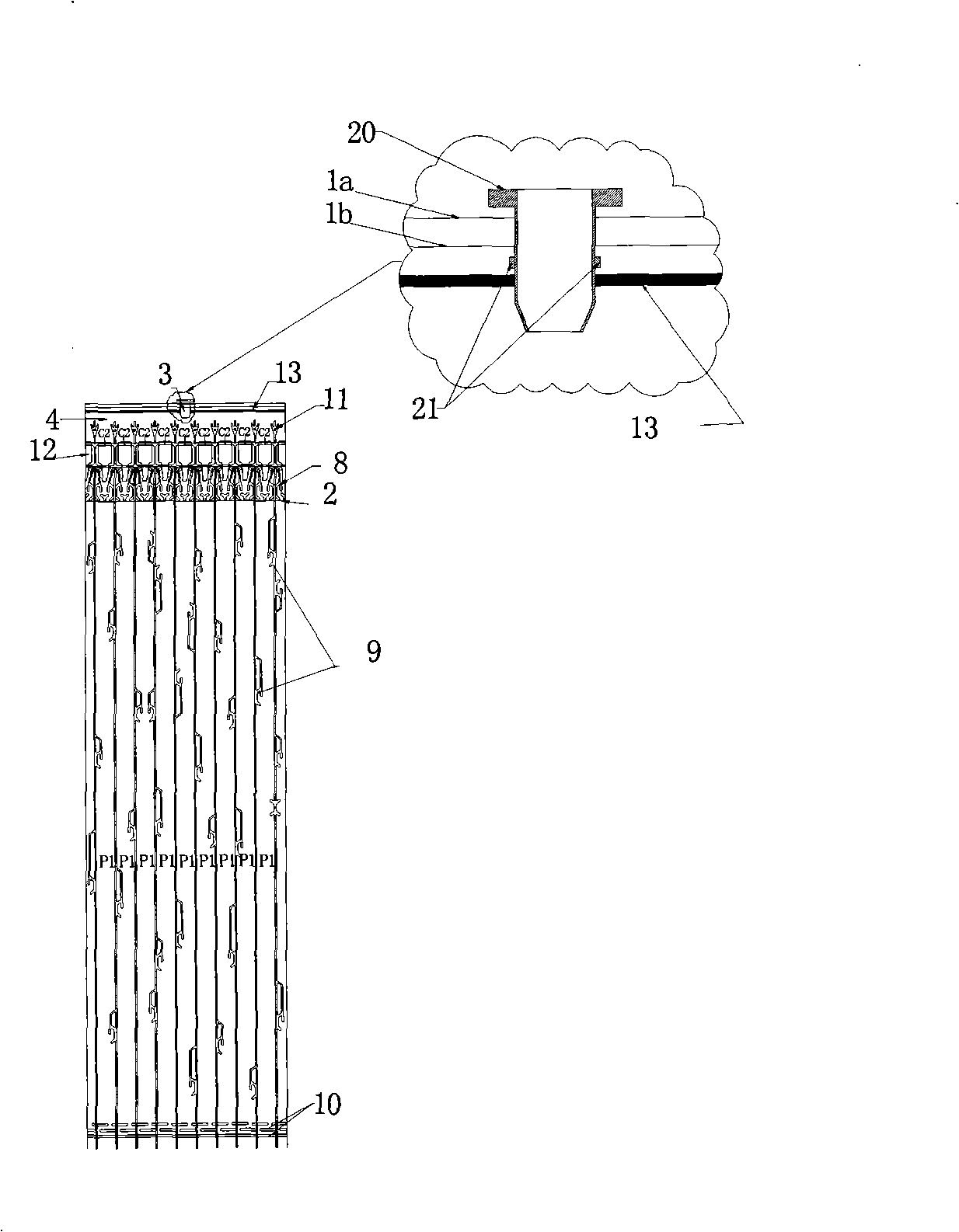

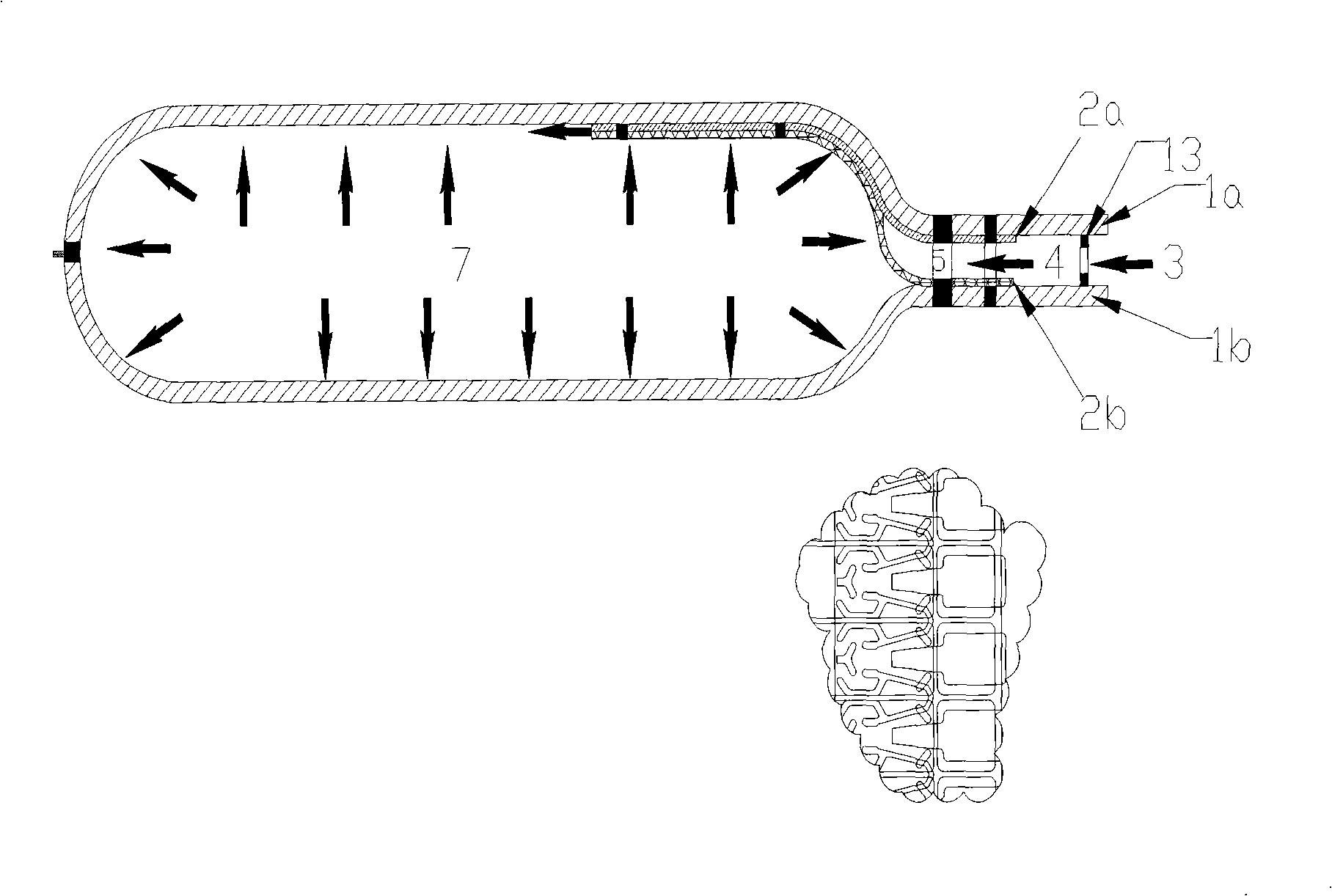

[0054] like figure 1 , image 3 , Figure 4 and Figure 5 Shown, the first to the fourth content of the present invention, this product is pre-designed as reusable, light-proof, waterproof type multifunctional cushioning packaging material bag 6 according to the size requirement of the packaged object, and the air is provided by the distribution supply main pipe during use The opening 3 of 4 enters, passes through the channel opening of the false heat seal 5 through the gap between 2a and 2b, and passes through 8 to make the air circulate according to the designed circuit, and enters each space 7 smoothly from the air channel between 2a and 2b. As the air flow increases, the space 7 begins to expand gradually. When the inflation is stopped, the gap between 2a and 2b will automatically stick together due to the special properties of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com