Production of O-shaped self-adhering air-isolated packing bag

A technology of air packaging and manufacturing methods, applied in the directions of envelope/bag manufacturing machinery, packaging, transportation and packaging to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] 1. As long as there are four layers of resin film, using the principle of automatic adsorption of self-adhesive film and the barrier properties of special high-temperature resistant anti-stick printing barrier device, it can be produced through a series of simple local heat-sealing and bonding of special special-purpose heat-sealing equipment A series of related products from mucous membrane repelling air three-dimensional packaging materials.

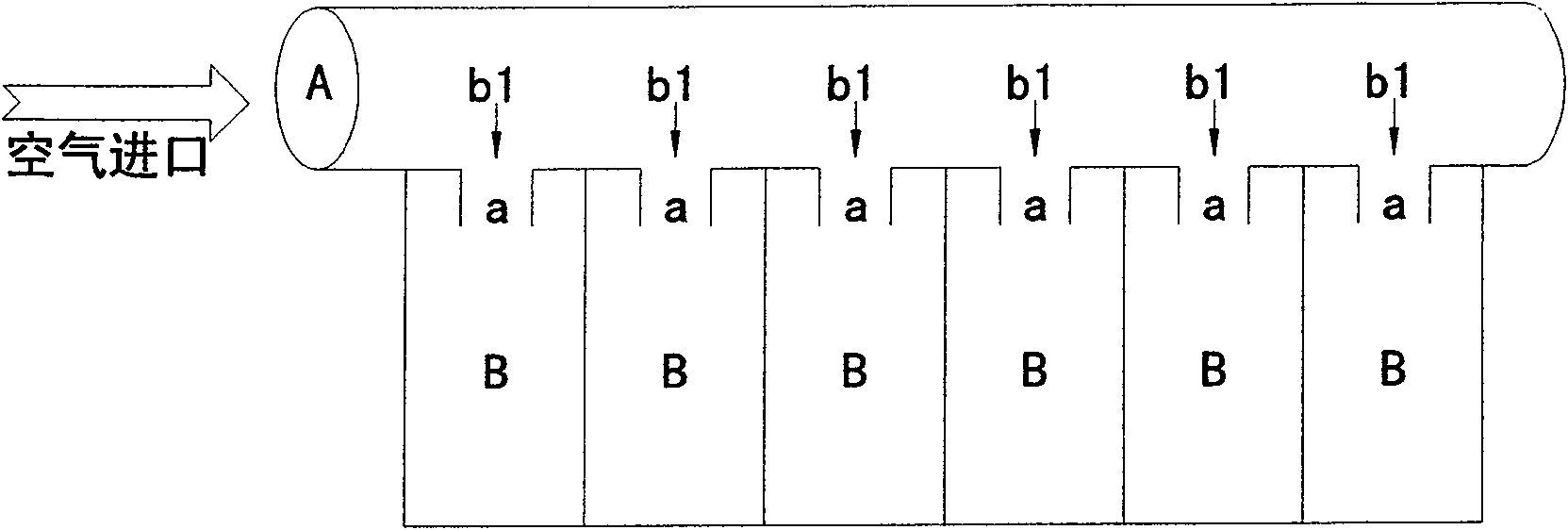

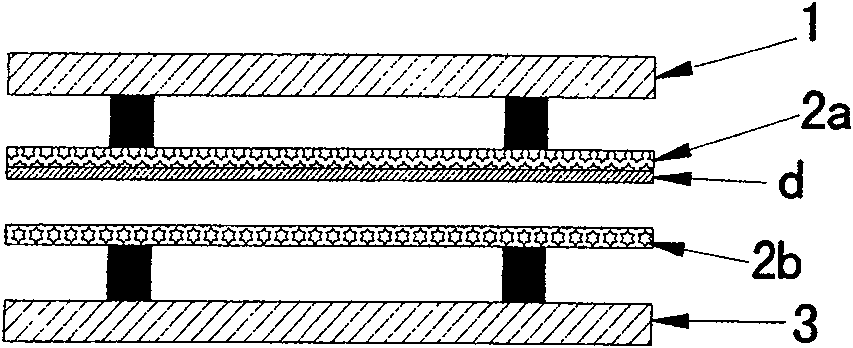

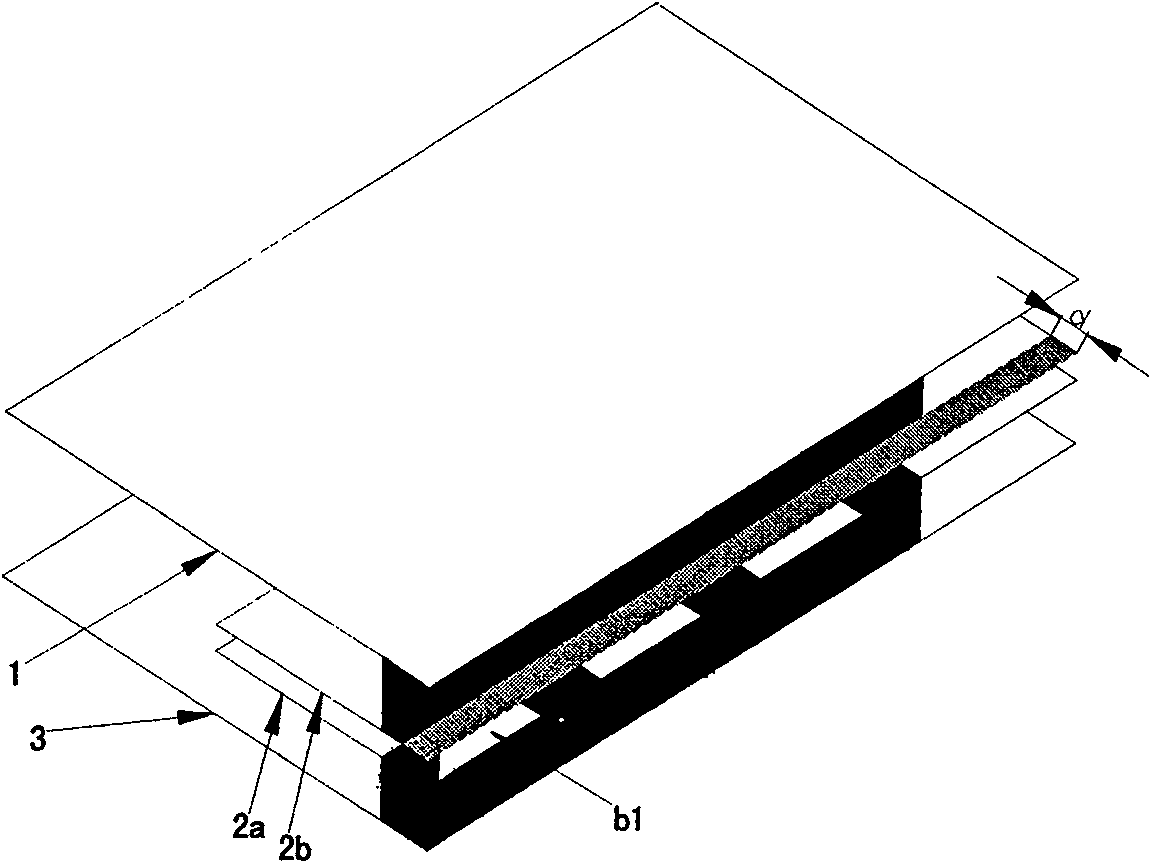

[0042] Such as Figure 4 As shown, take two polyethylene films of comparable size, one consists of two narrower polyethylene self-adhesive films with mutual self-absorption, two wider resin films, the first resin film 1, the fourth Layers of resin film 3 are respectively placed on the upper and lower surface layers, and resin film 2 is placed on the middle layer, wherein the second layer of resin film 2a is partially equipped with a special high temperature resistant anti-sticking printing barrier device d on the inner surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com