Air-isolated and self-adhering packing material and its preparation

A technology of three-dimensional packaging and packaging materials, applied in packaging, wrapping paper, transportation and packaging, etc., to achieve the effect of improving work efficiency, cushioning protection performance, and anti-drop protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

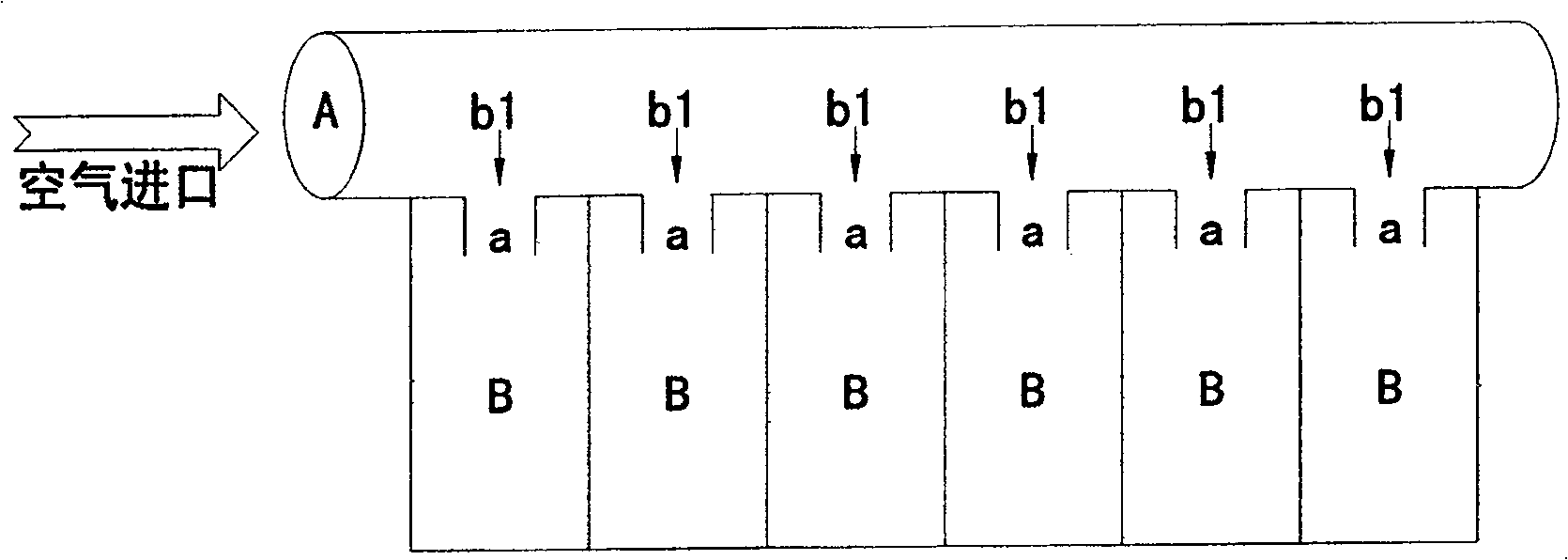

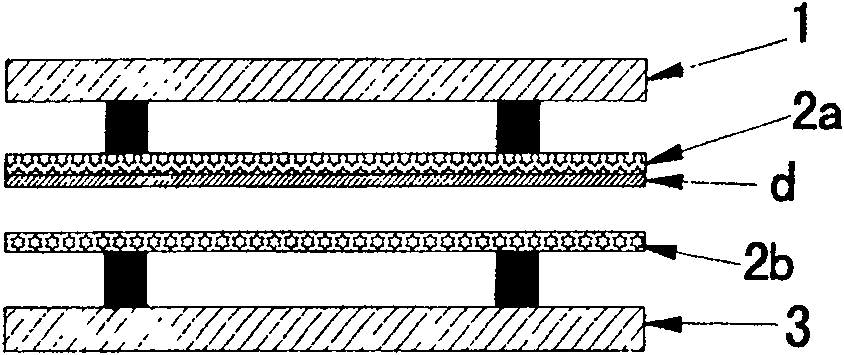

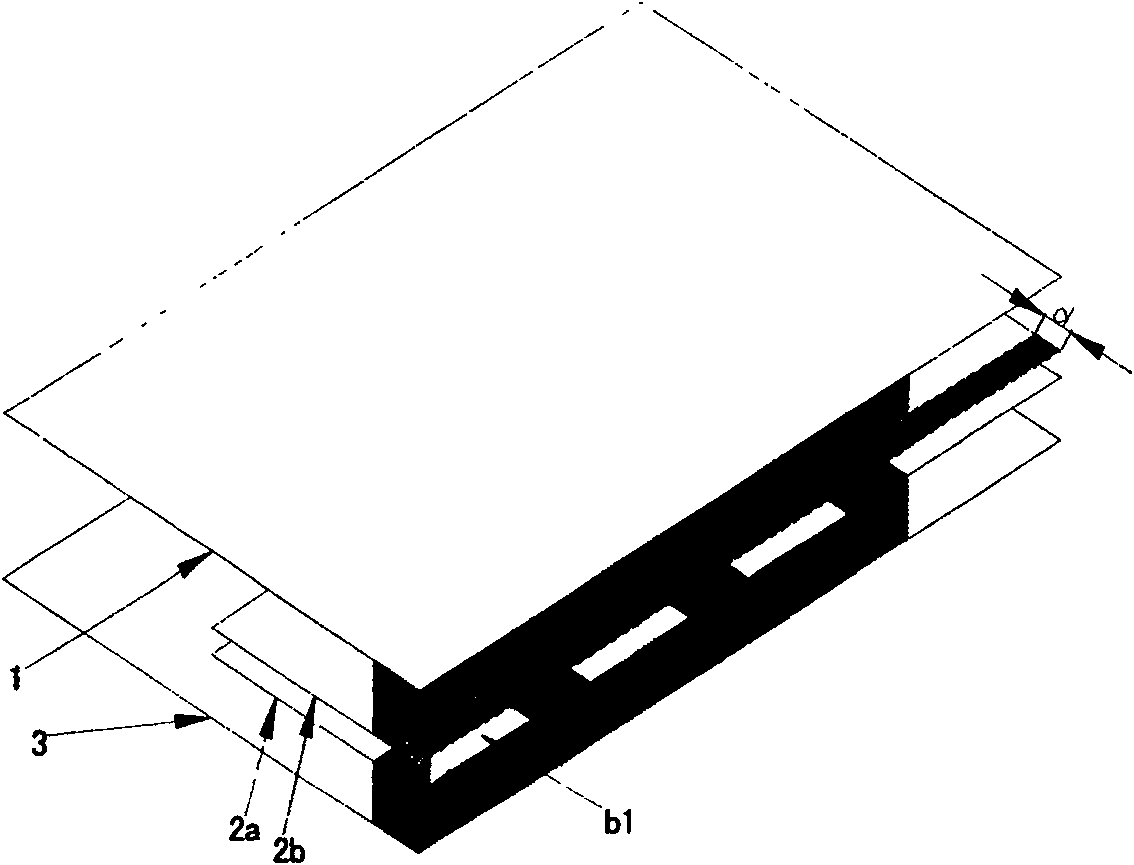

[0033] Combine below figure 1 , figure 2 , image 3, Figure 4 , Figure 5 The self-adhesive air-repelling three-dimensional packaging material and its manufacturing method are further described.

[0034] 1. As long as there are four layers of resin film, using the principle of automatic adsorption of self-adhesive film and the barrier properties of special high-temperature resistant anti-stick printing barrier device, it can be produced through a series of simple local heat-sealing and bonding of special special-purpose heat-sealing equipment A series of related products from mucous membrane repelling air three-dimensional packaging materials.

[0035] Such as Figure 4 As shown, take two polyethylene films of comparable size, one is composed of two narrower polyethylene self-adhesive films with mutual self-absorption, and two wider resin films are the first layer of resin film 1, the second Four layers of resin films 3 are respectively placed on the upper and lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com