Patents

Literature

59results about How to "Increase mass concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for treating contaminated water

InactiveUS6159365AHigh purityIncrease mass concentrationTreatment using aerobic processesWater contaminantsIndustrial effluentNatural water

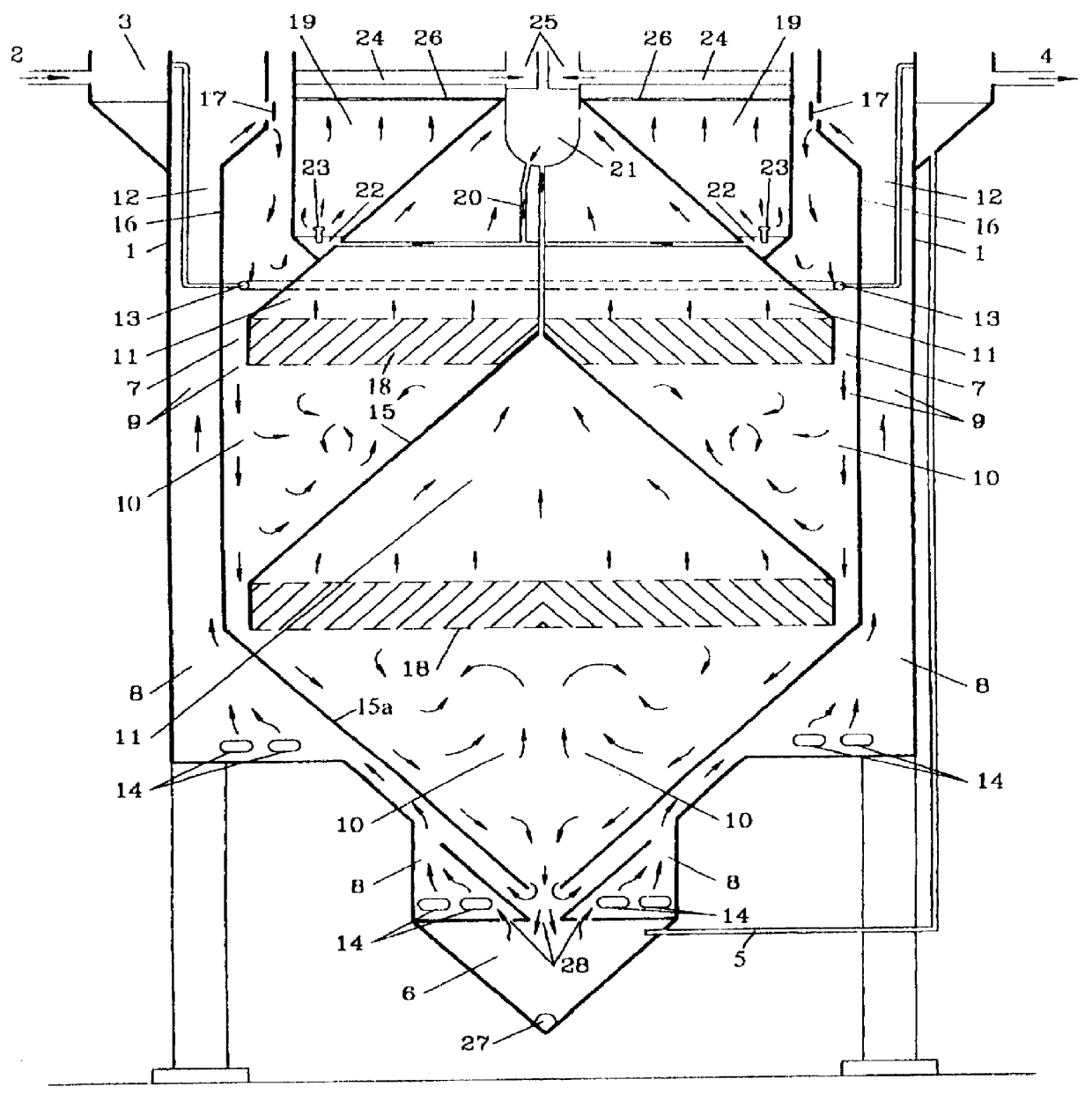

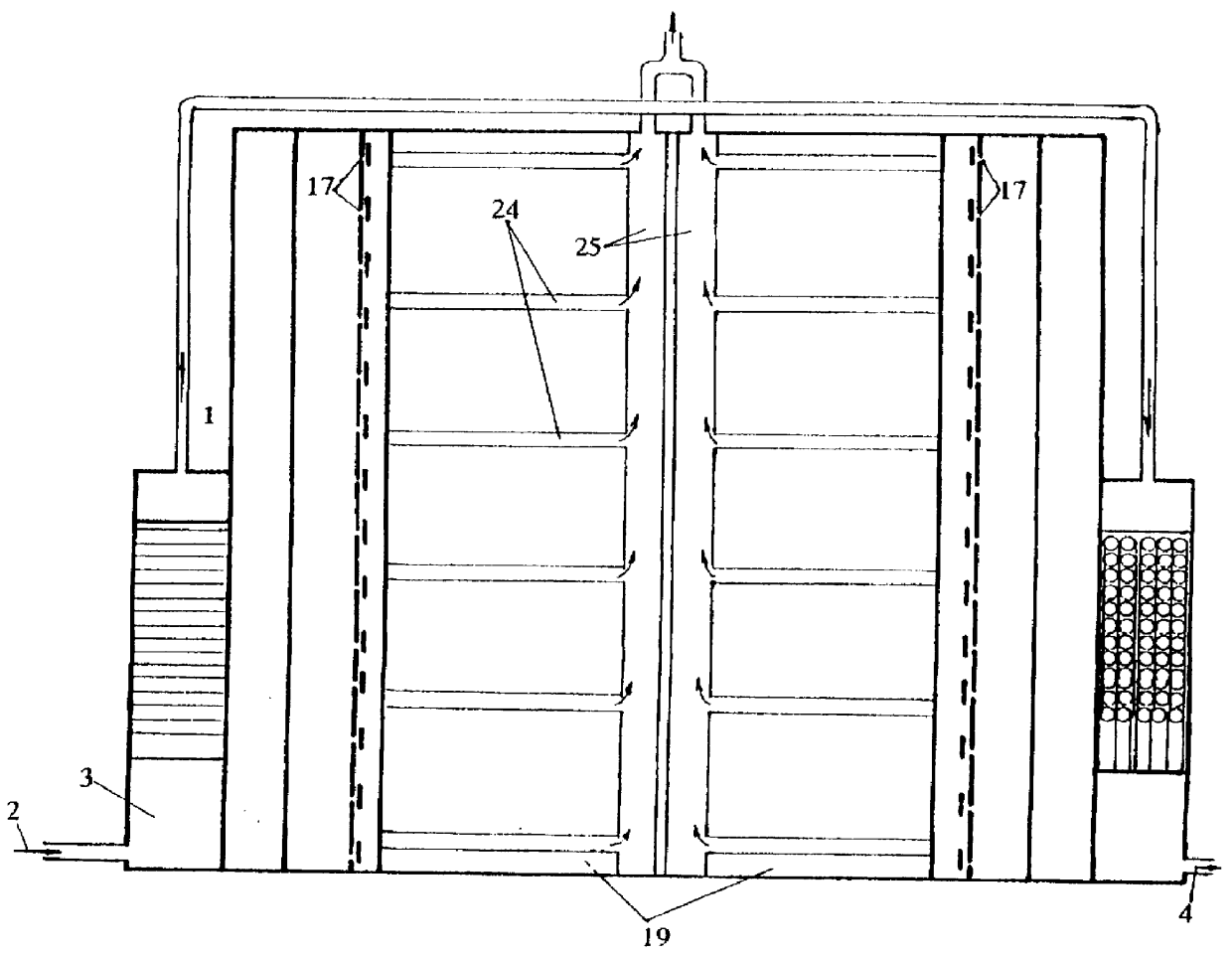

A method and apparatus for treating contaminated water are described wherein contaminated natural water or industrial wastewater is treated to remove contaminants in a packaged modular treatment unit.

Owner:AMERICAN ENVIROCARE

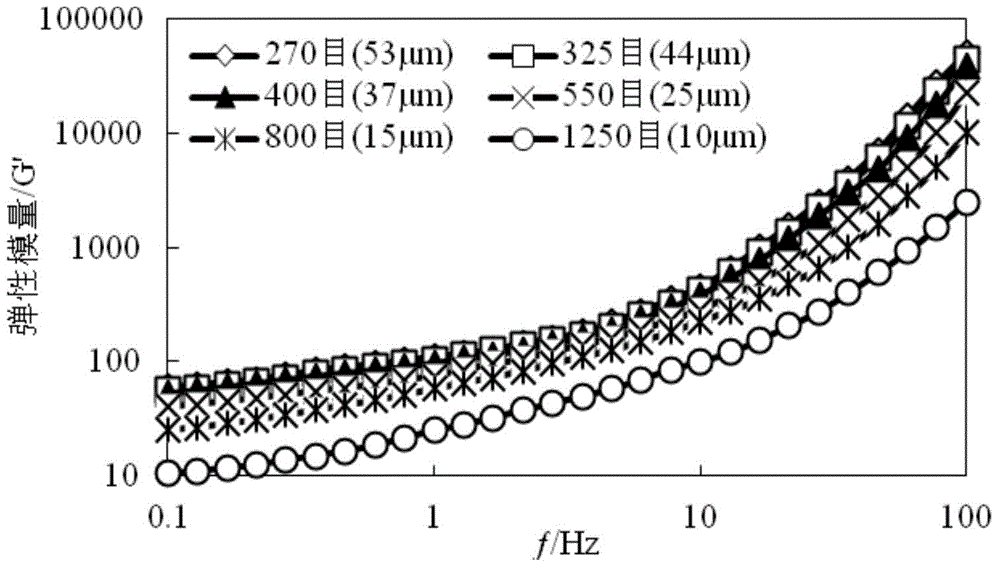

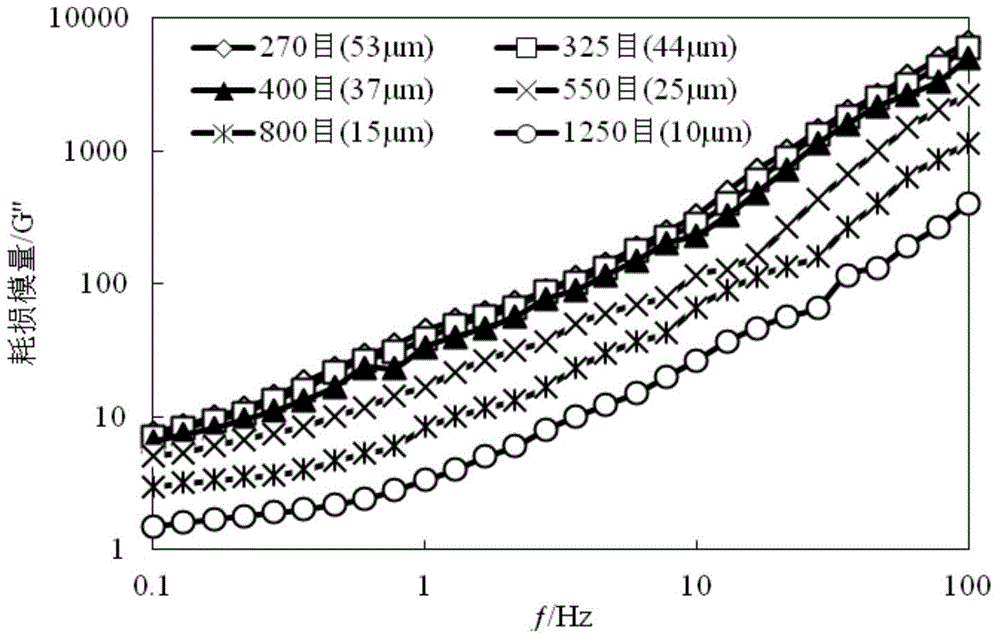

High-temperature-resistant and high-salt-resistant fine gel particle as profile control agent as well as preparation method and application of fine gel particle

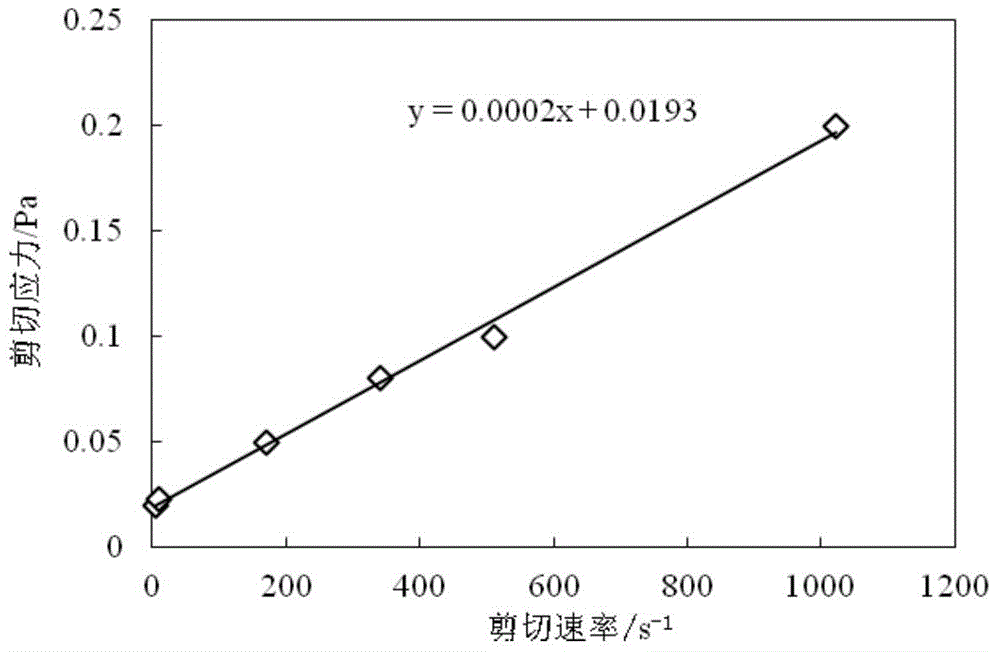

The invention discloses a high-temperature-resistant and high-salt-resistant fine gel particle as a profile control agent as well as a preparation method and an application of the fine gel particle. The preparation method of the fine gel particle comprises the following steps of firstly, adding modified starch, a monomer A, a monomer B, a crosslinking agent, an initiator and an accelerant into a reaction kettle according to a certain ratio; and after finishing the polymerization reaction of the six components to form integrated water-based gel, drying, crushing, granulating, screening and performing other process steps to obtain the fine gel particle. The application method of the high-temperature-resistant and high-salt-resistant fine gel particle is as follows: a certain quantity of fine gel particles prepared by using the preparation method are added into a Bingham fluid, the gel particles can be stably suspended without settling under static and dynamic conditions, and then, the whole fluid is injected to the stratum by means of pumping pressure. By using the high-temperature-resistant and high-salt-resistant fine gel particle and the application method thereof, disclosed by the invention, the construction success rate of the gel particle can be greatly increased, and a favorable deep profile control effect can be achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

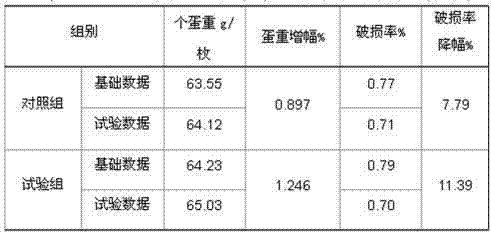

Compound feed for improving production performance of laying hen and egg quality

InactiveCN103039754AReduce breakage rateIncrease production capacityAnimal feeding stuffAnimal scienceFeed conversion ratio

The invention belongs to the technical field of feed, and particularly relates to compound feed for improving the production performance of laying hen and the egg quality. The compound feed consists of corn, lard oil, soybean meal, rape seed cake, peanut meal, gunite bran, mountain flour, calcium hydrophosphate, lysine, methionine, liquid phytase, liquid xylanase and premix. The compound feed provided by the invention can obviously improve the production performance of laying hen and improve the laying rate and the egg quality, and can increase the weight of a single egg and reduce the damage rate of eggs; and moreover, after being eaten by the laying hen, the compound feed can promote digestive absorption, improve the feed conversion rate and the feed-gain ratio, and increase the economic benefits of laying hen farming.

Owner:河南商都生物技术股份有限公司

High-bending strength oxidized carbon nanomaterial/carbon fiber/epoxy resin composite material and preparation method thereof

The invention provides a high-bending strength fiber-reinforced epoxy resin composite material. The preparation method comprises the following steps: simply stirring for rapidly transferring an oxidized carbon nanomaterial from an aqueous phase to an epoxy resin mixture containing N,N-diglycidyl p-hydroxylaniline glycidyl ether; performing water removal and high-temperature treatment, adding a curing agent, compounding with carbon fibers, curing and forming. The composite material is simple and high-efficiency, the oxidized carbon nanomaterial does not need to be subjected to acylating chlorination and other chemical modifications, any organic solvent is not used, the processing time is short, the energy consumption is low, and industrialization is easily realized; and meanwhile, the carbon nanomaterial is high in content and uniform in dispersion, the mechanical property of the composite material is outstanding, the bending strength can be 2.5GPa or over, and the increase amplitude is over 1-fold (the highest amplitude can reach 160 percent). The composite material disclosed by the invention can be used for preparing high-strength and high-modulus carbon fiber reinforced composite materials and can be widely applied to the fields such as aerospace, automobiles, building or bridge reinforcement, power electronics and sport equipment.

Owner:ZHEJIANG UNIV

Method for preparing 5-hydroxymethyl furfural by utilizing biomass as raw material

InactiveCN102617524AHigh yieldReduce generationOrganic chemistryAlternative fuelsHydroxymethylfurfural

The invention provides a method for efficiently preparing 5-hydroxymethyl furfural (HMF) utilizing biomass widely existing in a natural world as a raw material. The method includes the following steps: utilizing a two-phase system composed of low-boiling point organic matter and water, adopting acid salt of sulfuric acid and sulfuric acid metal normal salt as a catalyst in synergy mode to form a catalyst system, adding the biomass raw material capable of being degraded to hexose to a reaction system and preparing the HMF by reaction. The reaction process of the method has high HMF selectivity. The catalyst is low in price, mild in operation condition, simple in process and low in separation energy consumption. The biomass raw material with a wide source is utilized as the reaction raw material, preparation of biomass-based chemical and alternative fuel with the biomass as the raw material can be favorably promoted, and the method has high industrialized prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Catalyst and Method for Synthesis of Carbon Nanomaterials

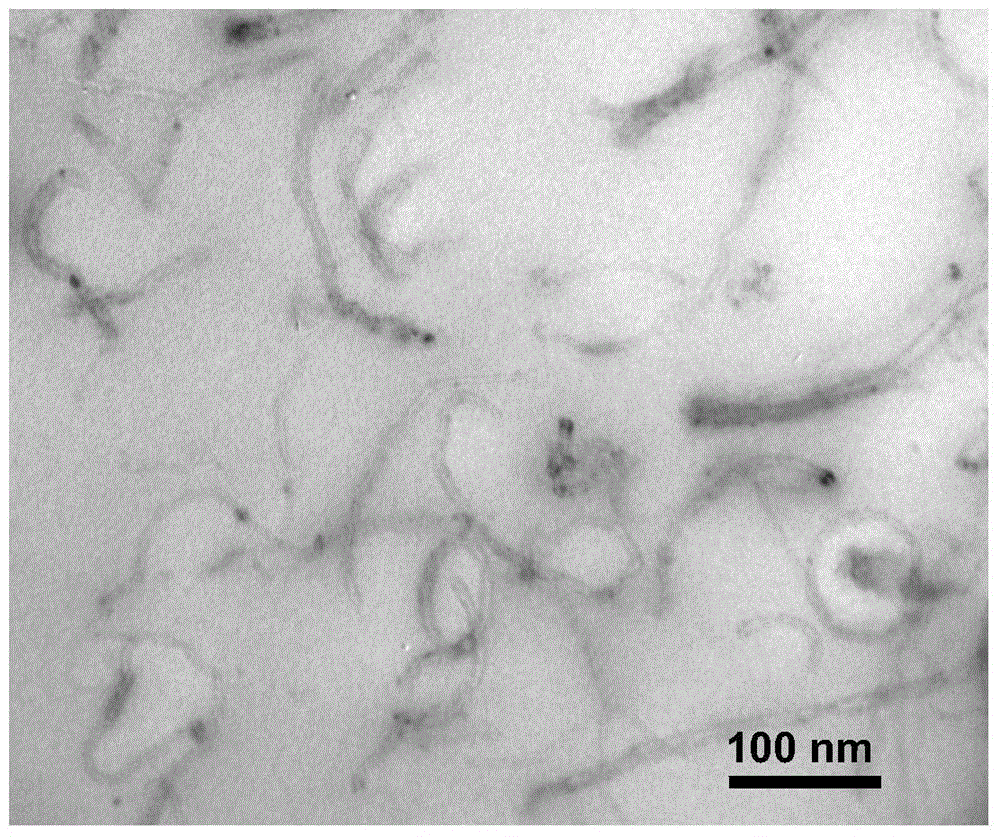

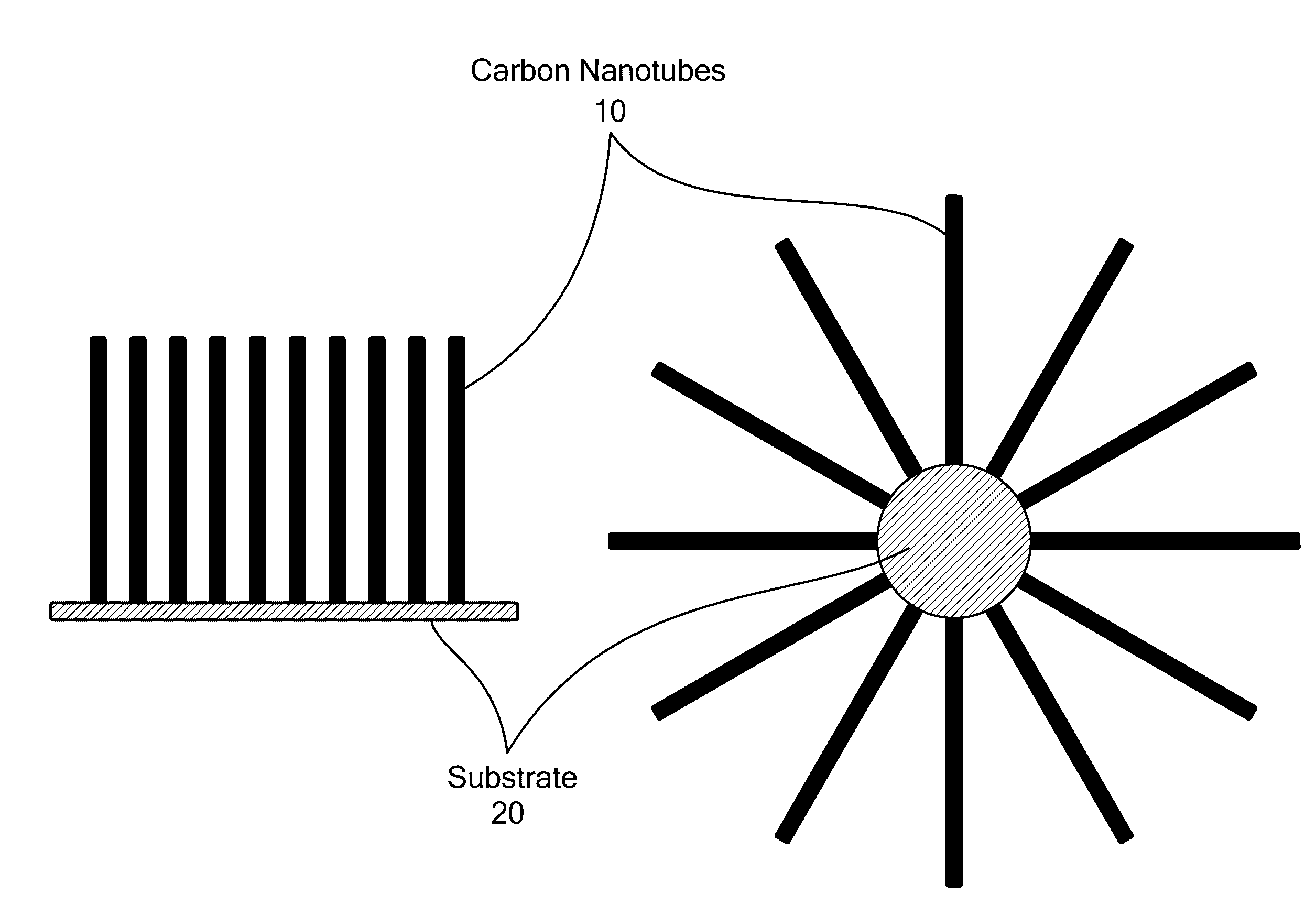

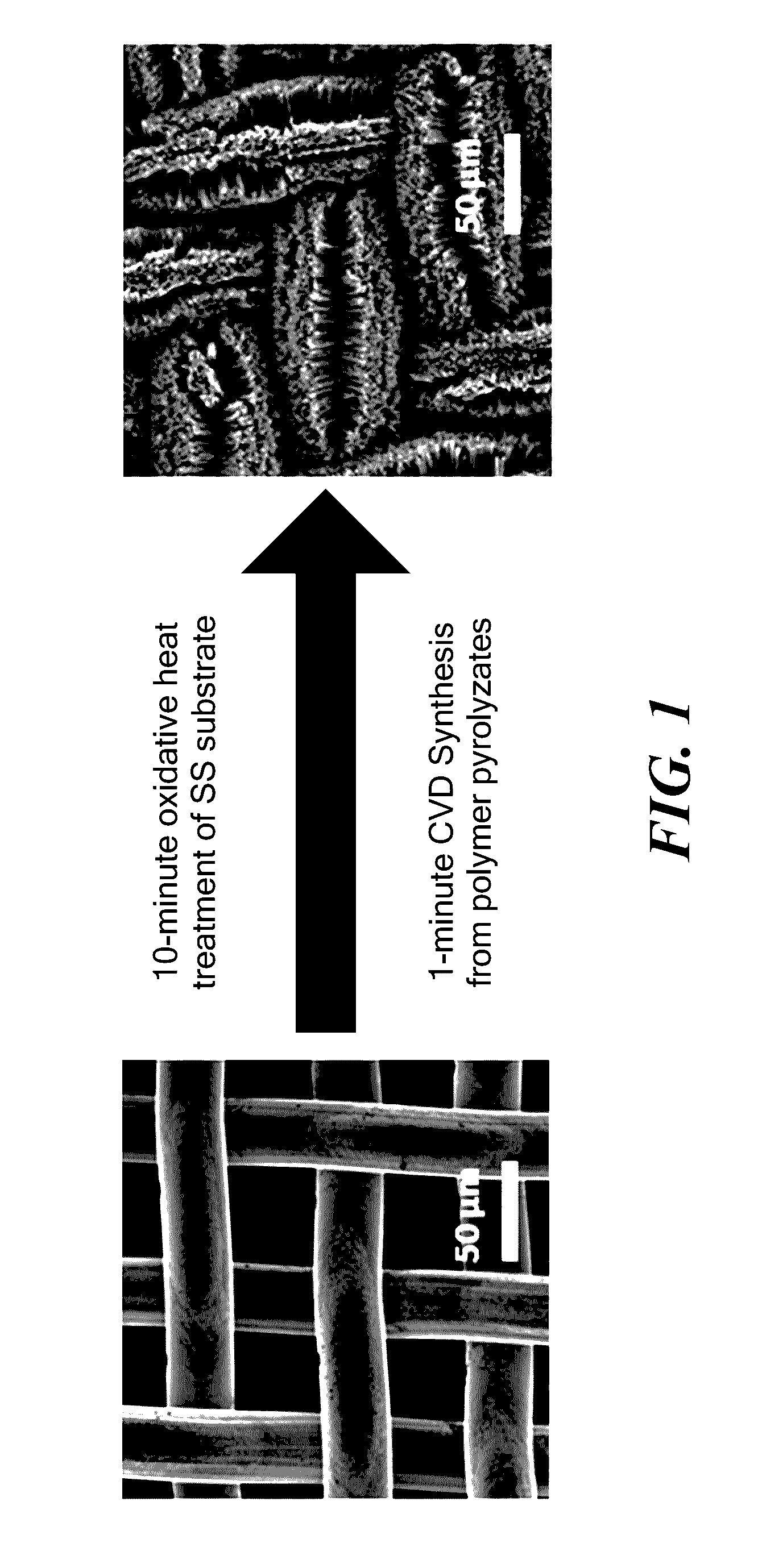

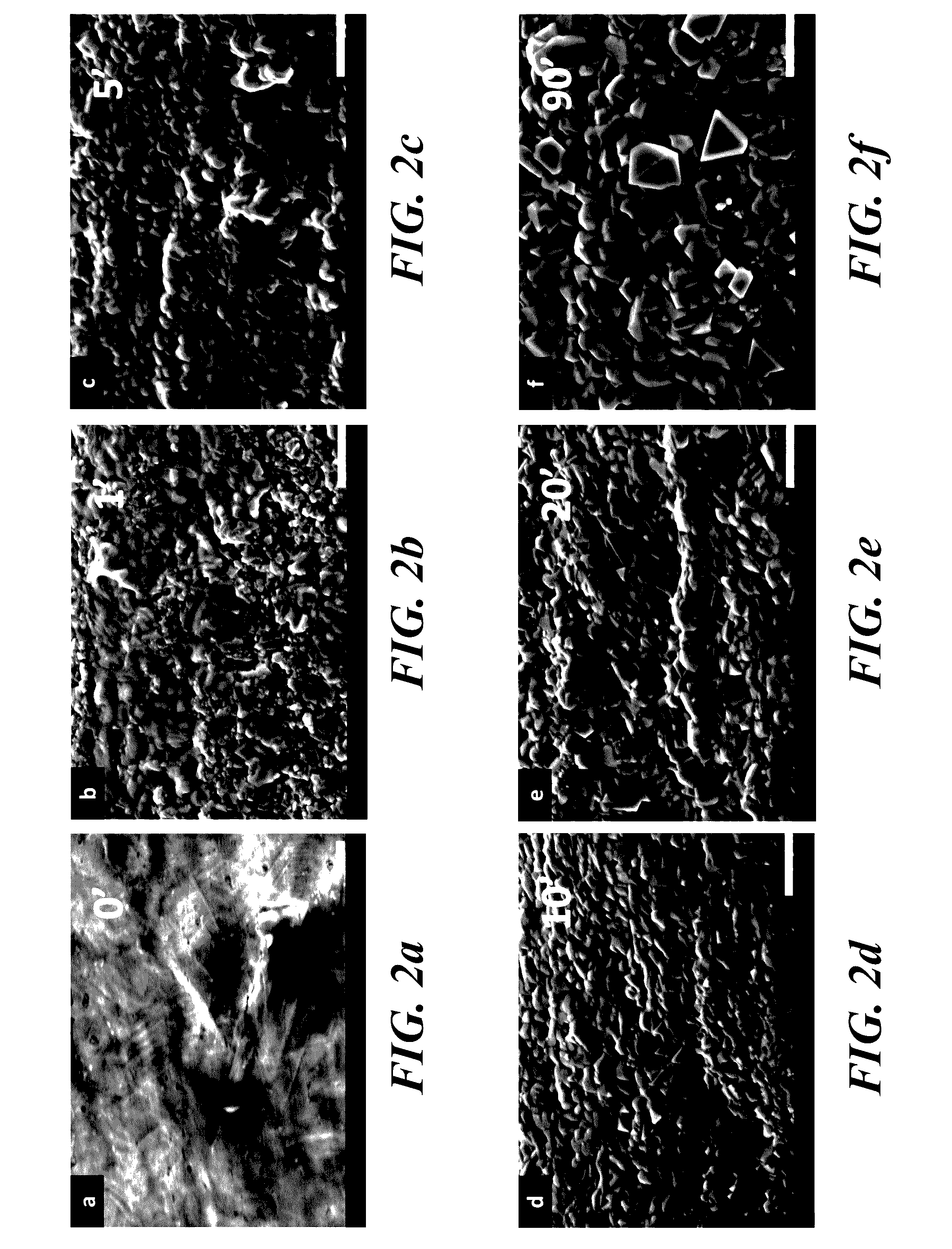

InactiveUS20160367971A1Improve surface roughnessEasy to synthesizeMaterial nanotechnologyCatalyst activation/preparationGas phaseAlloy substrate

Methods for activating the surface of steel alloys to produce catalytic substrates for the synthesis of carbon nanomaterials by chemical vapor deposition are provided. Steel alloy substrates in a variety of forms are activated by brief (10 sec to 30 min) pre-treatment at high temperature (600-1000° C.) in an oxidizing environment (e.g., air) to activate the catalyst. Upon high temperature oxidative treatment, the initially smooth and protective chromium oxide coating layer of the steel alloy is destroyed, and the catalyst surface roughness progressively increases. Upon exposure of the pre-treated SS substrates to pyrolyzed hydrocarbon gases in nitrogen, carbon nanotubes are readily formed, and their diameters correlate with substrate surface roughness. Forests of vertically aligned nanotubes can be prepared with the method.

Owner:NORTHEASTERN UNIV

Purification method of p-dichlorobenzene

InactiveCN103772137AGood for melting outPrevent collapseSolution crystallizationHalogenated hydrocarbon preparationPurification methodsEngineering

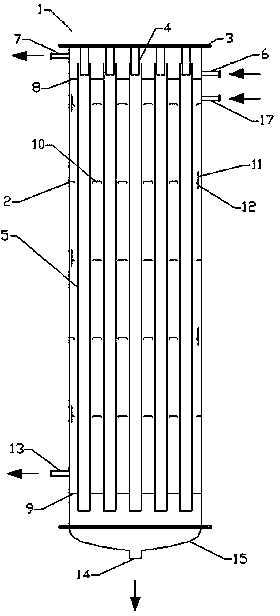

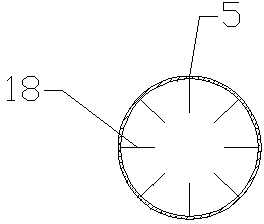

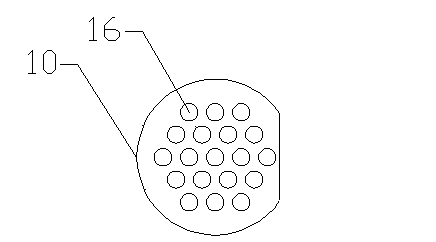

The invention discloses a purification method of p-dichlorobenzene, which mainly solves the problems of unstable product purity and difficult industrial amplification of a p-dichlorobenzene purification technology in the prior art. The purification method of p-dichlorobenzene adopts the technical scheme that mixed dichlorobenzene enters the top of a crystallizer through a material inlet, a part of mixed dichlorobenzene enters a crystallization pipe through a distributor at the top of the crystallizer, the other part of mixed dichlorobenzene flows out from a material overflow port, a cooling medium enters the crystallizer and forms a cooling medium liquid film on an external wall of a falling film crystallization pipe through cooling medium guide holes in a cooling medium distribution tray, an overflow weir and a downcomer are arranged on the cooling medium distribution tray, the redundant cooling medium flows down to a tray of a next stage through the downcomer and is finally discharged from a cooling medium outlet, the mixed dichlorobenzene liquid film precipitates p-dichlorobenzene crystals on the wall of the crystallization pipe with the fall of temperature, and uncrystallized residual liquid is discharged from a material outlet at the bottom of a tower, so that the problems are better solved, and the method can be used for industrial production of p-dichlorobenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

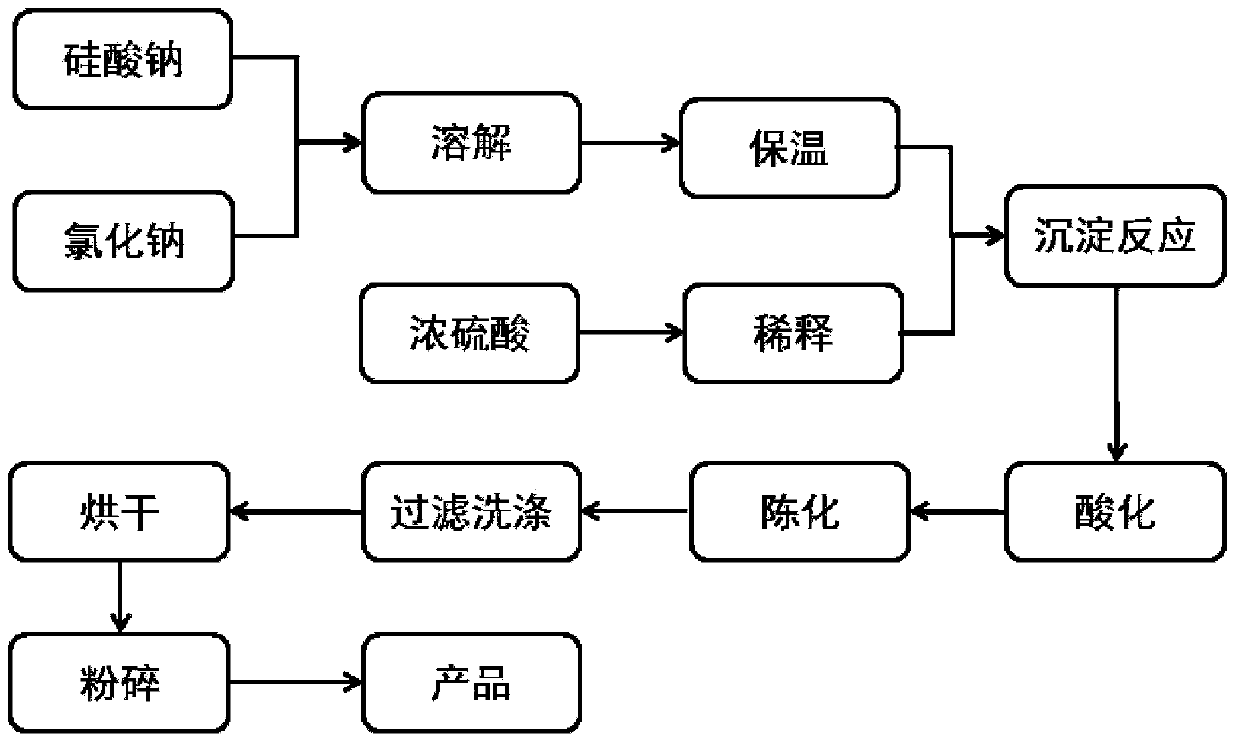

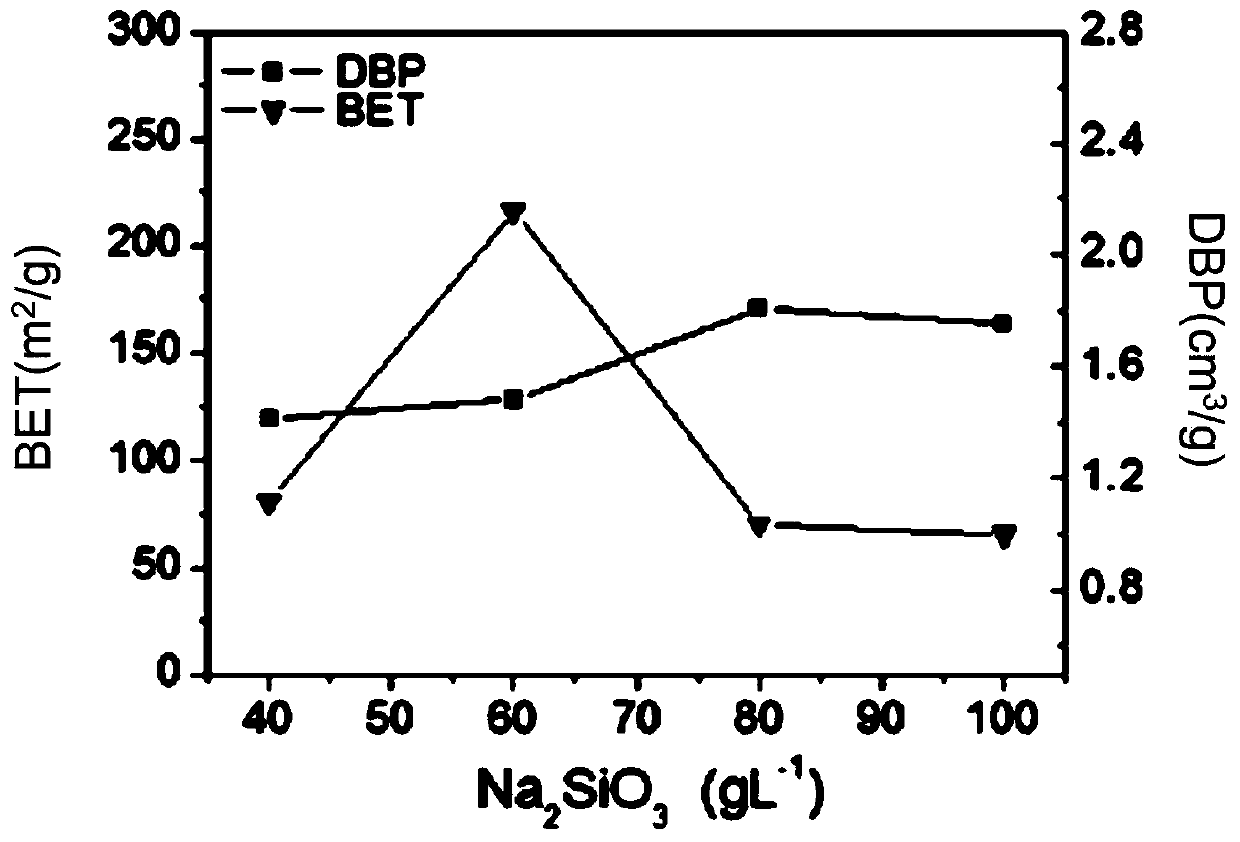

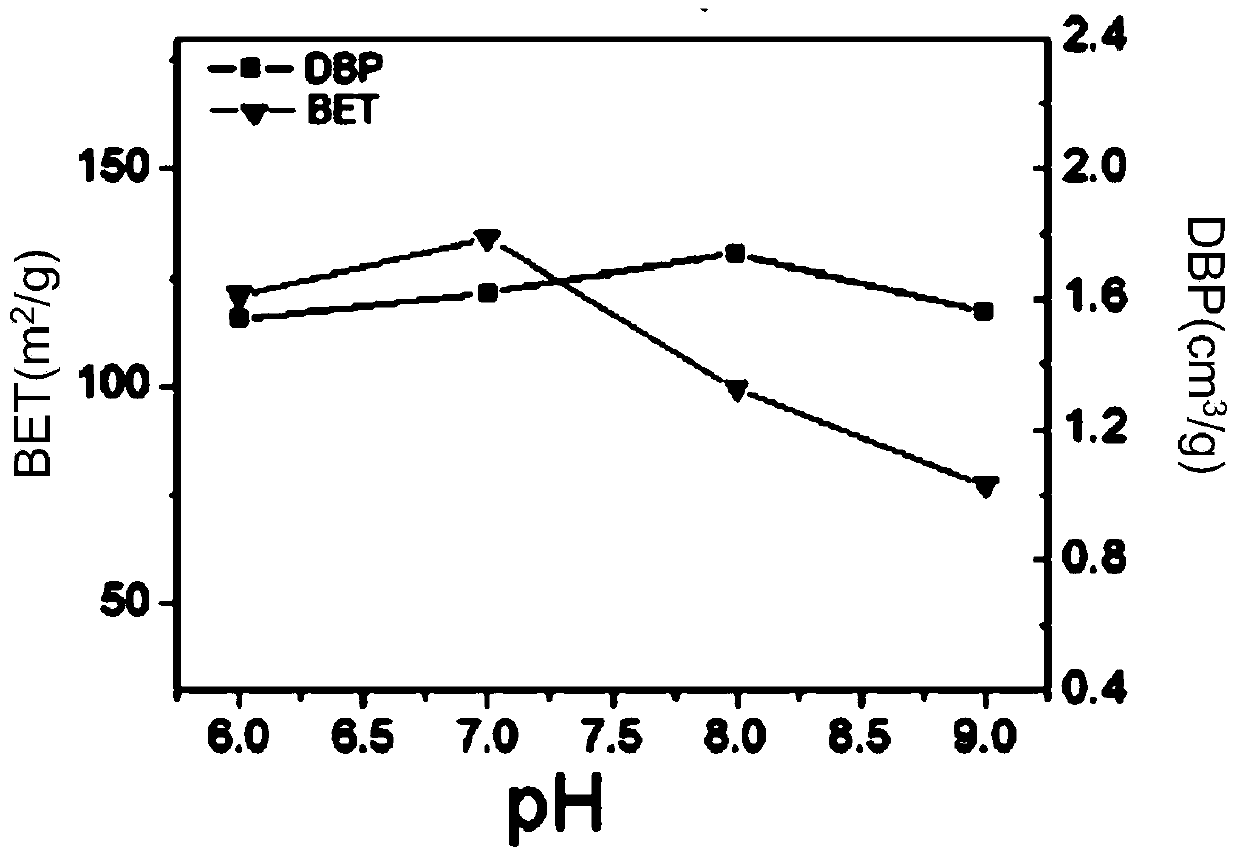

Method for reducing specific surface area BET (Brunauer Emmet Teller) of white carbon black prepared by using sulfuric acid precipitation method

ActiveCN103466640AIncrease mass concentrationSmall specific surface areaSilicon oxidesIncrease phSodium silicate

The invention discloses a method for reducing the specific surface area BET (Brunauer Emmet Teller) of white carbon black prepared by using a sulfuric acid precipitation method. The method comprises the following steps of improving the mass concentration of sodium silicate for reaction, and / or increasing pH value during aging. Specifically, the specific surface area BET of the white carbon black prepared by adopting the sulfuric acid precipitation method can be reduced by improving the mass concentration of the sodium silicate to 20-35 percent and increasing the pH value during aging to 4-10. According to the method, not only can the specific surface area BET of the white carbon black be remarkably reduced, but also accurate control over the specific surface area BET of the white carbon black can be realized, and the requirements on the white carbon black with lower specific surface area in related fields are met. The method disclosed by the invention is simple to operate, easy to implement and suitable for large-scale industrial production.

Owner:WUXI HENGCHENG SILICON IND CO LTD

Novel reverse-osmosis scale inhibitor

ActiveCN104906961AHigh anti-scaling efficiencyReduce dosageSemi-permeable membranesScale removal and water softeningHexamethylenetetramineRoom temperature

The invention discloses a novel reverse-osmosis scale inhibitor which comprises the following raw materials in parts by weight: 2-8 parts of sodium citrate, 33-45 parts of hydrolytic polymaleic anhydride, 28-37 parts of polyepoxysuccinic acid salt, 9-15 parts of urotropine, 13-20 parts of polylactic acid, and 40-50 parts of water. A preparation method comprises the following steps: adding sodium citrate, hydrolytic polymaleic anhydride, polyepoxysuccinic acid salt, urotropine and half of water into a reaction kettle, heating to 40-50 DEG C, and stirring for uniformly dissolving; dissolving polylactic acid with the rest water to obtain a polylactic acid solution; heating the materials in the reaction kettle to 70-75 DEG C, dropwise adding the polylactic acid solution, and keeping the temperature for 3-4h after the dropwise adding is finished; and cooling to room temperature so as to obtain the novel reverse-osmosis scale inhibitor. The novel reverse-osmosis scale inhibitor disclosed by the invention has the scale inhibition rate being up to 95%, is small in adding amount, environmentally friendly, stable in property, and long in storage period, and can be used for solving the problems that existing reverse-osmosis inhibitors mainly are foreign products and are limited in treatment capacity, complex in synthesis, relatively high in production cost, and the like in the prior art.

Owner:浙江川宁环保科技有限公司

Hybrid intestinal micro-ecologic preparation and preparation method thereof

InactiveCN105475988AImprove the immunityIncrease mass concentrationFood ingredient functionsBacillus licheniformisIsomaltooligosaccharide

The invention provides a hybrid intestinal micro-ecologic preparation and a preparation method thereof. The preparation method comprises the following steps: carrying out third-stage fermentation culture on probiotics butyric acid bacteria, lactobacillus acidophilus, Bacillus coagulans and Bacillus licheniformis, adding a freeze drying protection gent, freeze-drying the obtained culture product, carrying out microcapsule embedding, freeze-drying the embedded product, and mixing the embedded product with isomaltooligosacharide, fructooligosaccharide and vitamins to obtain the micro-ecologic preparation. Butyric acid bacteria and other probiotics can be directly supplemented to the human body intestinal tract, so all the probiotics are propagated and intergrow in the intestinal tract and have synergism, and the intestine controlling, cancer preventing, immunity improving, digestion helping and harmful bacterium and corrupted group growth breeding inhibiting effects of the composite bacterium preparation are effectively performed, thereby the beneficial physiologic effects of the probiotics on human bodies are greatly improved; and the preparation method can effectively guarantee the quantity of live bacteria of the probiotics, the activity of the probiotics and the preservation time of the probiotics.

Owner:HENAN JINBAIHE BIOTECH CO LTD

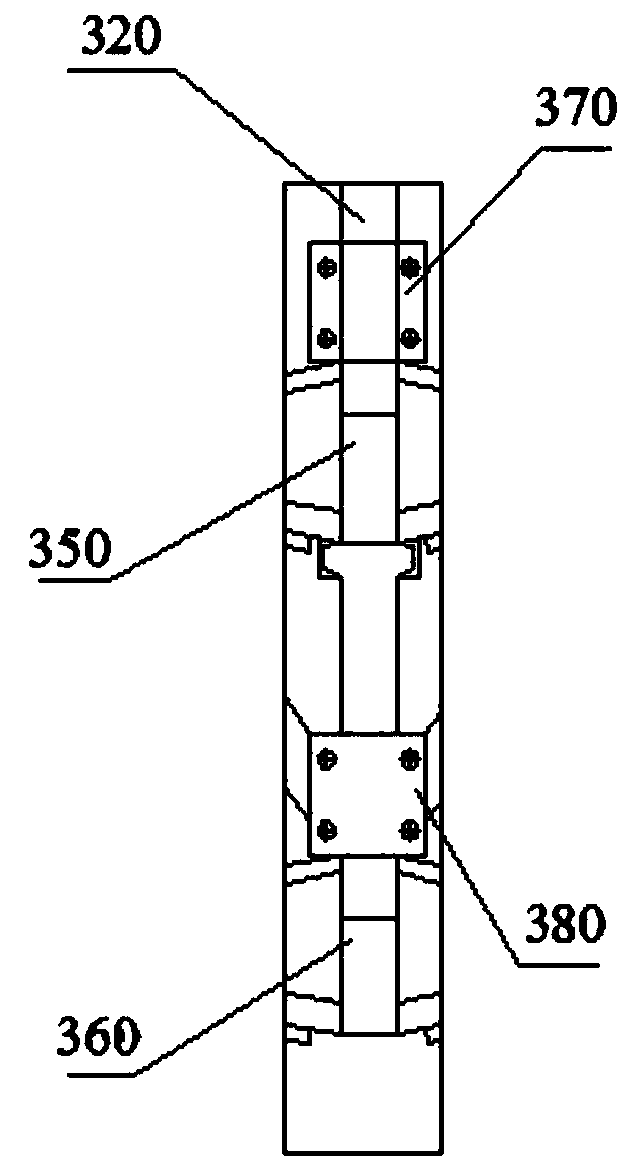

Sensible heat recycling method and device in xylose production process

The invention belongs to the technical field of xylose production, and discloses a sensible heat recycling method in a xylose production process; pretreated wash water, hydrolyzate and hydrolysis residue sugar wash water are respectively flashed; the temperature of the hydrolyzate is reduced to 65 to 75DEG C after flashing, and a decoloring procedure is directly carried out; the decolored hydrolyzate enters an evaporator to be concentrated after ion exchange; and steam produced in the flashing of the pre-treated wash water, the hydrolyzate and the hydrolysis residue sugar wash water enters the evaporator as a heat source for evaporating and concentrating the hydrolyzate. The invention recycles the sensible heat carried by the pre-treated wash water, the hydrolyzate and the hydrolysis residue sugar wash water with higher temperature in the xylose production process, is mainly used for the evaporation and the concentration of the hydrolyzate, thereby greatly reducing the steam used in the concentration of the hydrolyzate and the underground water used before decoloring, reducing the emission of waste liquid, meeting the national policies of energy saving and emission reduction, and having wide application value.

Owner:PUYANG YANGUANG PENGCHENG BIO PRODS

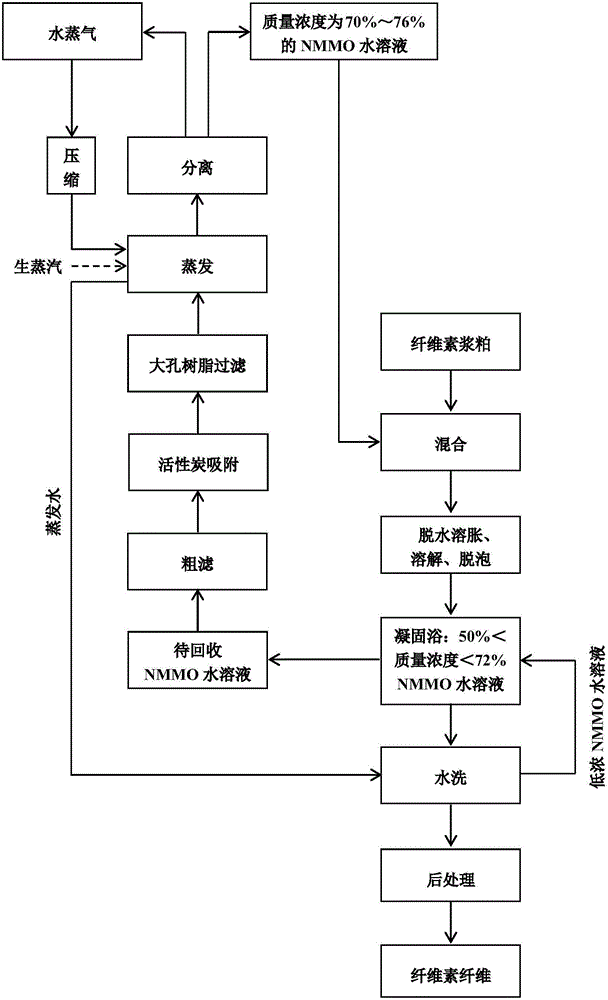

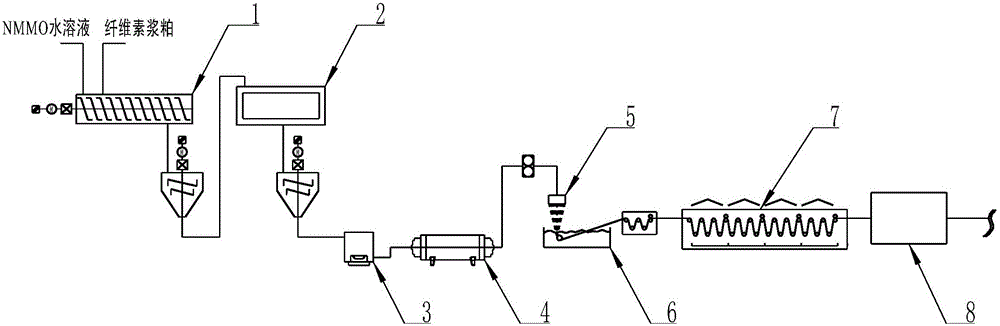

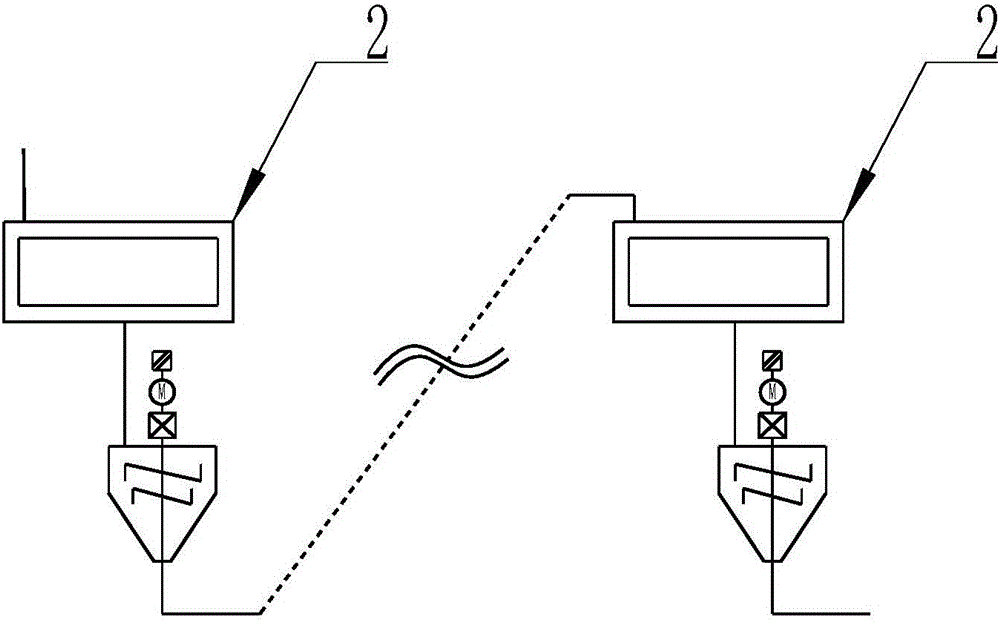

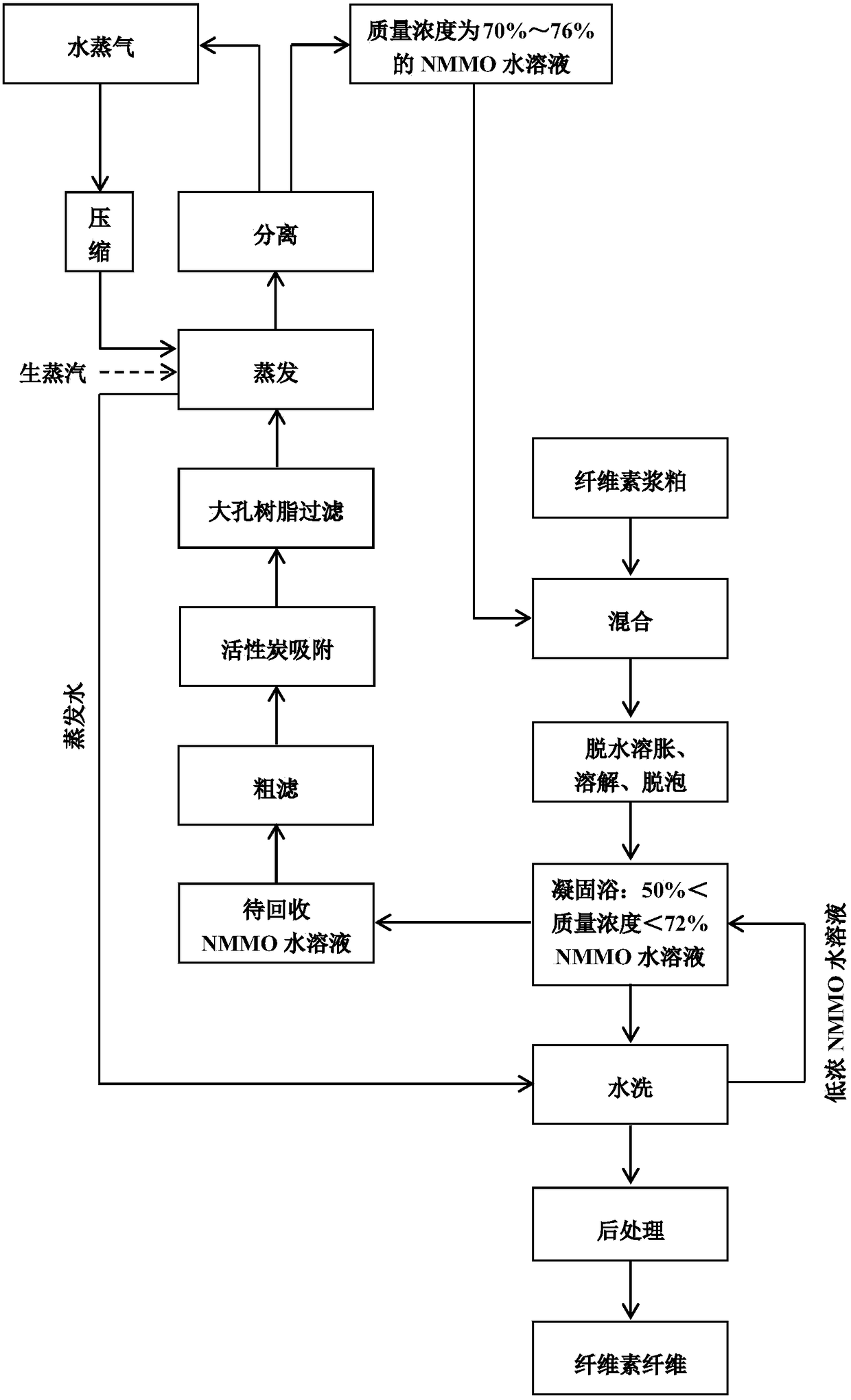

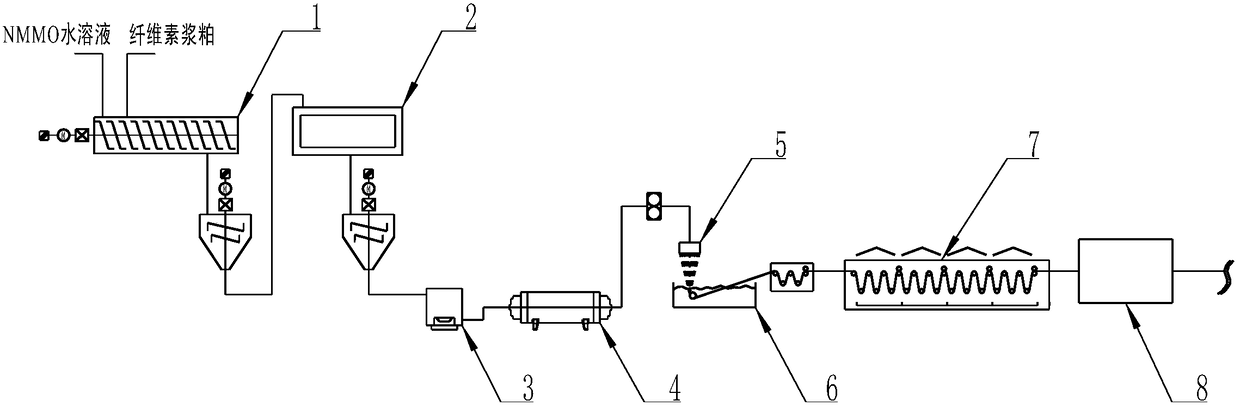

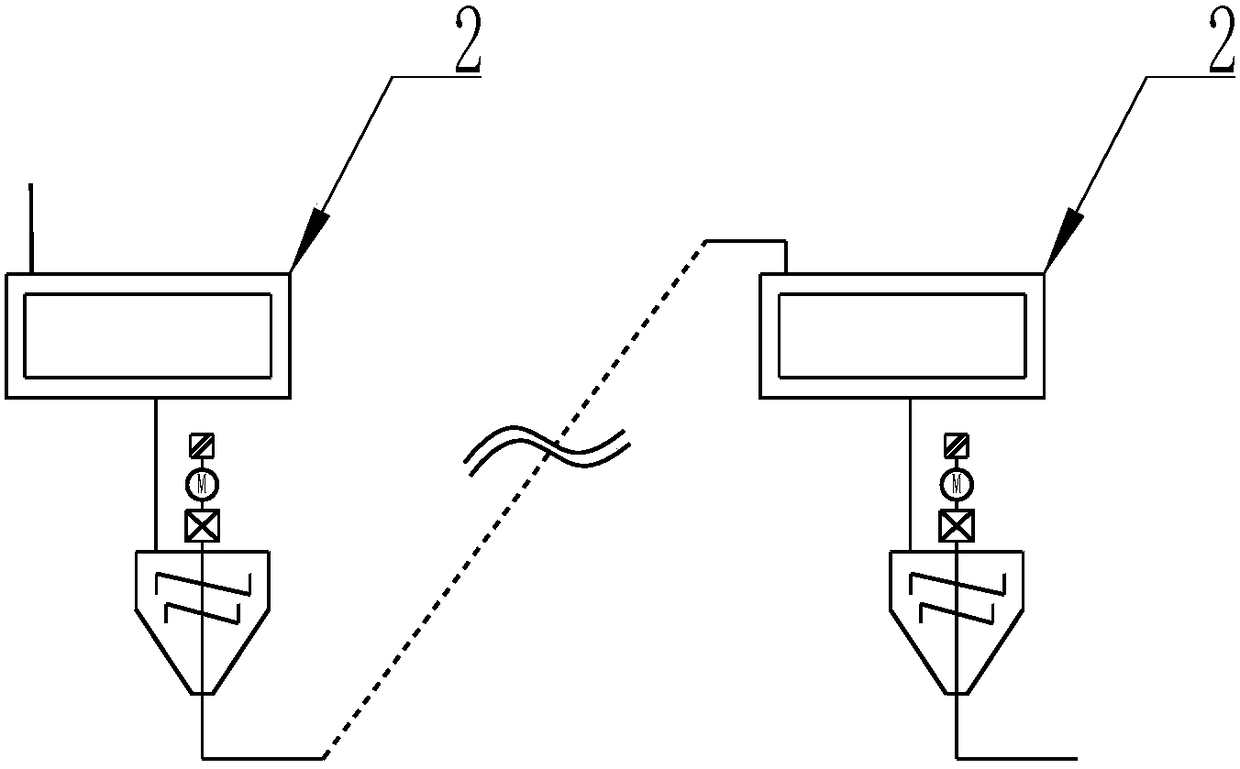

Preparation method of cellulosic fibers

ActiveCN106222771ASimple preparation processEliminate security risksArtificial filament recoveryArtificial filament washing/dryingCellulose fiberDissolution

The invention discloses a preparation method of cellulosic fibers. The preparation method includes the following steps that 1, cellulose pulp is mixed with an NMMO water solution with the mass concentration of 60%-85%, preferably 70%-76% to obtain a uniform mixture; 2, the obtained uniform mixture is subjected to dehydration swelling and dissolution defoaming to obtain a cellulose spinning solution; 3, the obtained cellulose spinning solution is filtered and subjected to heat exchange and then enters a spinning machine, after the cellulose spinning solution is extruded through a spinning assembly and air-cooled, the cellulose spinning solution enters a solidification system and is solidified in an NMMO solidification bath with the mass concentration larger than 50% and smaller than 72%, and nascent fibers are obtained; 4, the obtained nascent fibers are washed to obtain cellosilk bundles, and then the cellulosic fibers are obtained through subsequent section treatment. Equipment investment can be greatly reduced, the process is simplified, energy consumption and industrialization cost are reduced, safety production is promoted, the homogeneity and mechanical performance of the fibers are improved, and therefore the preparation method is more suitable for efficient low-consumption industrial production.

Owner:CHINESE TEXTILE ACAD

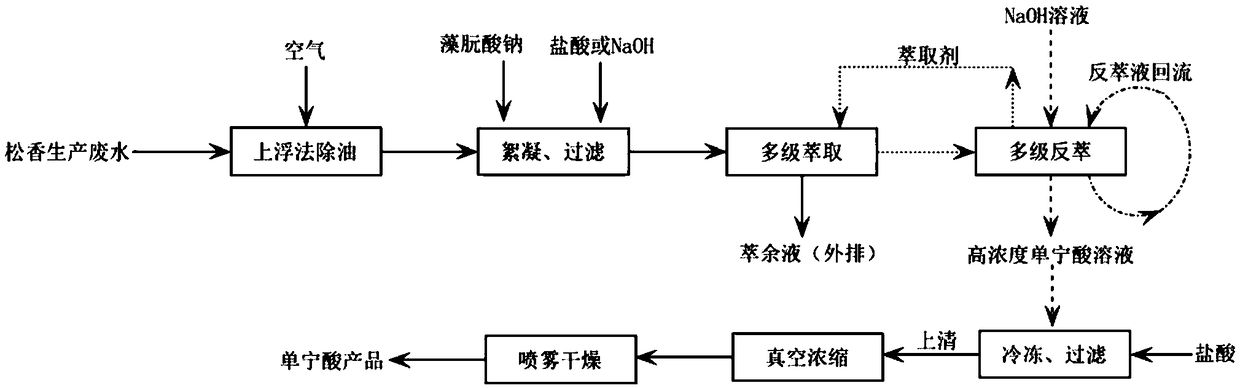

Method for recovering tannic acid from rosin production wastewater

ActiveCN108658351ASimple processEfficient recyclingTreatment involving filtrationWater/sewage treatment by neutralisationCounter currentRosin

The invention discloses a method for recovering tannic acid from rosin production wastewater. Multistage extraction and multistage back extraction methods are adopted for recovering tannic acid from the rosin production wastewater. The method comprises the following steps: firstly, removing oil from the wastewater in an up-float manner; adjusting the pH of the wastewater to 1 to 6; then, adding asodium alginate flocculant to flocculate the wastewater; filtering and performing multi-stage counter-current extraction on filtrate by using di(octan-2-yl)methylphosphonate; performing multi-stage counter-current back extraction treatment on extraction liquid loaded with tannic acid with a NaOH solution; lastly, purifying, concentrating and drying a strip liquor to obtain industrial tannic acid,wherein tannic acid is 75 to 82 percent in purity. By adopting the method, tannic acid is recovered, the biodegradability of the wastewater is improved, and the subsequent biochemical treatment difficulty is lowered.

Owner:HANDAN COLLEGE

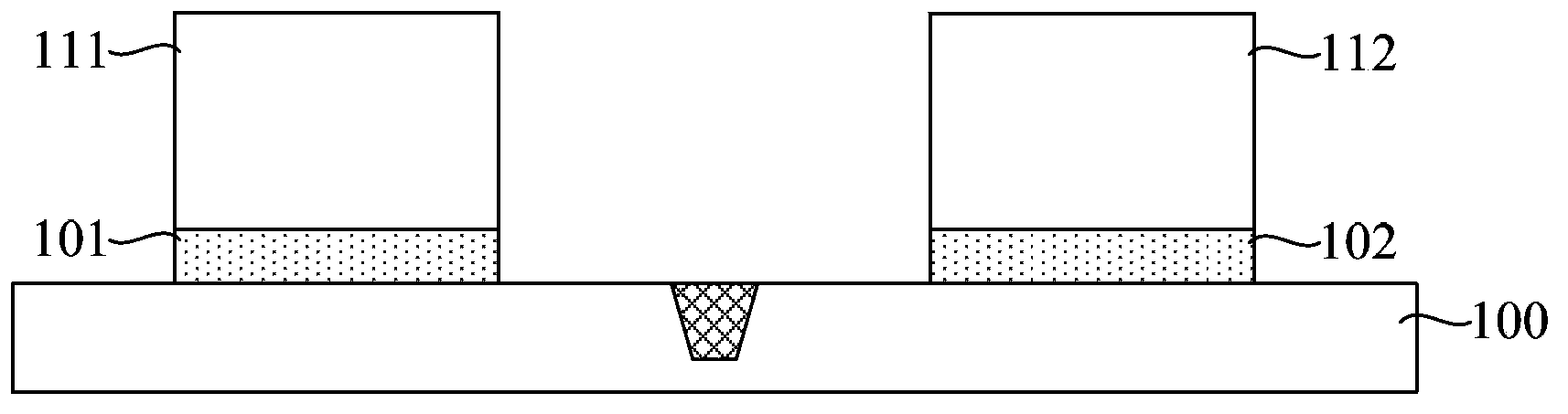

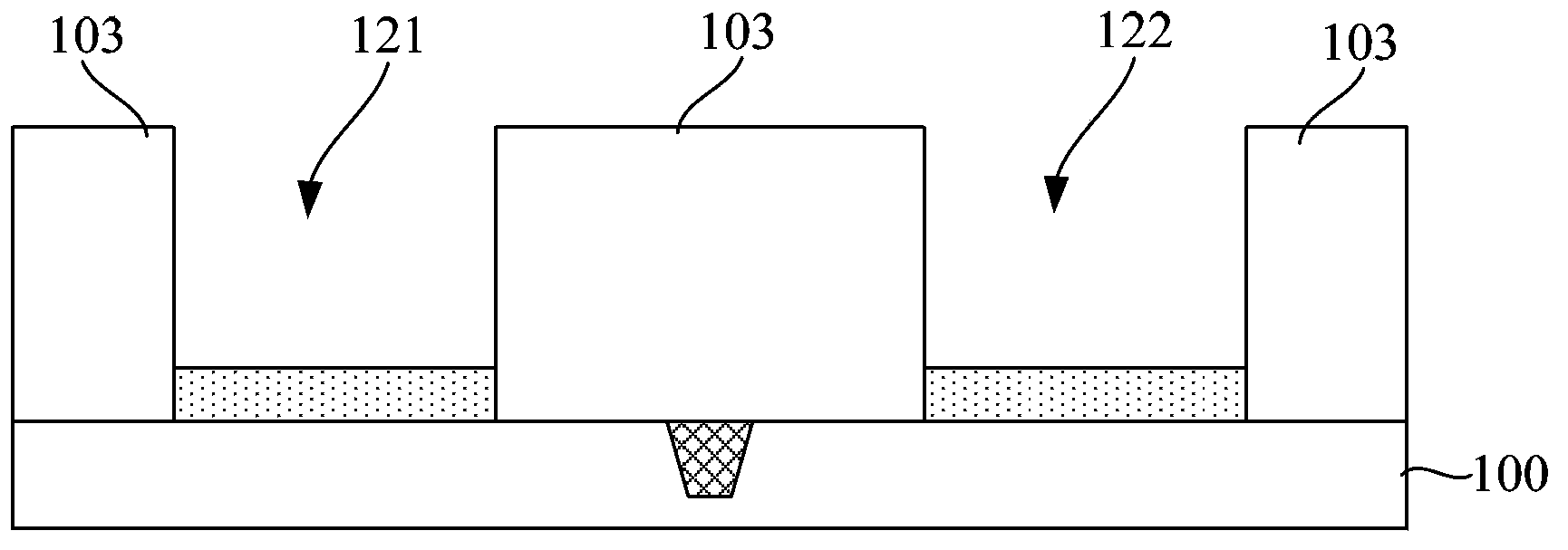

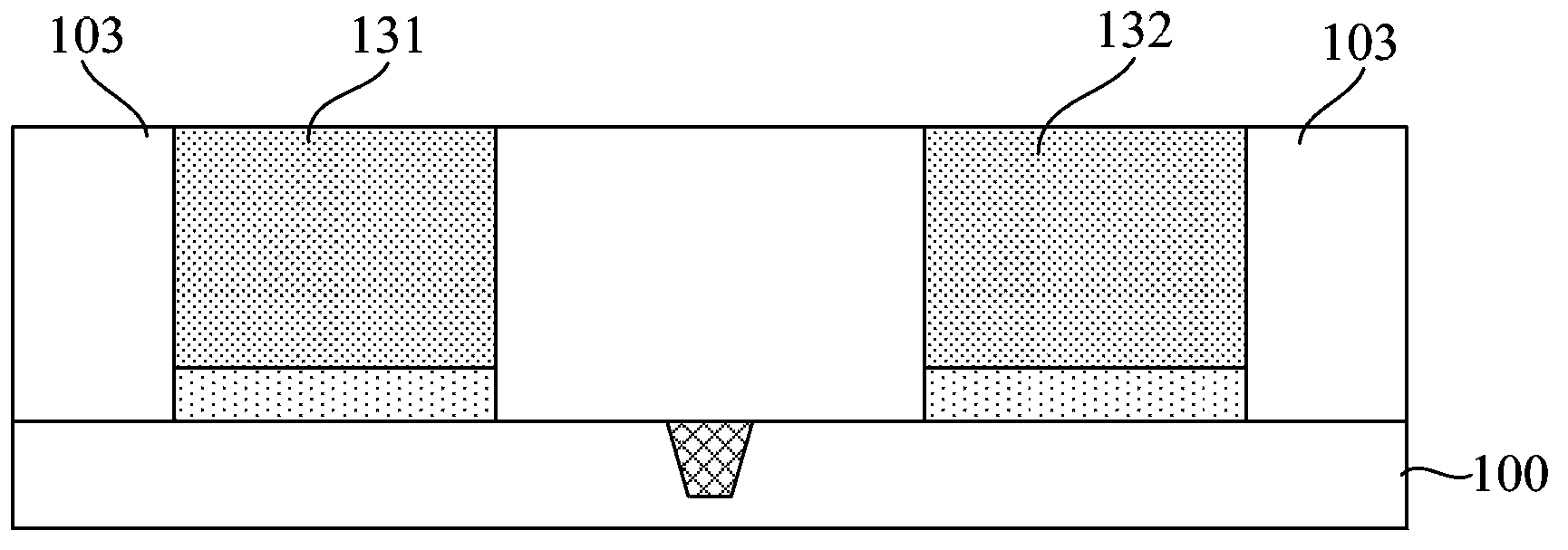

Semiconductor device formation method

ActiveCN104347507AImprove performanceIncrease mass concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesMedia layerDielectric layer

The invention relates to a semiconductor device formation method. The semiconductor device formation method comprises steps that a substrate is provided, the substrate has a first active region and a second active region, and the first active region and the second active region have opposite types; a first dummy grid electrode structure at the first active region and a second dummy grid electrode structure at the second active region are formed on the substrate, the first dummy grid electrode structure comprises a first grid medium layer and a first dummy grid electrode, and the second dummy grid electrode structure comprises a second grid medium layer and a second dummy grid electrode; an interlayer dielectric layer is formed on the substrate, and the upper surface of the interlayer dielectric layer is level with the upper surface of the first dummy grid electrode and the upper surface of the second dummy grid electrode; the first dummy grid electrode is removed to form a first dummy grid slot; the second dummy grid electrode is removed to form a second dummy grid slot; third grid dielectric layers are formed at the bottom portion and side walls of the second dummy grid slot. According to the semiconductor device formation method, parameters of material composition and thickness of the first grid dielectric layer and the third grid dielectric layers can be respectively adjusted, and thereby performance of transistors of the corresponding first grid dielectric layer and the third grid dielectric layers is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

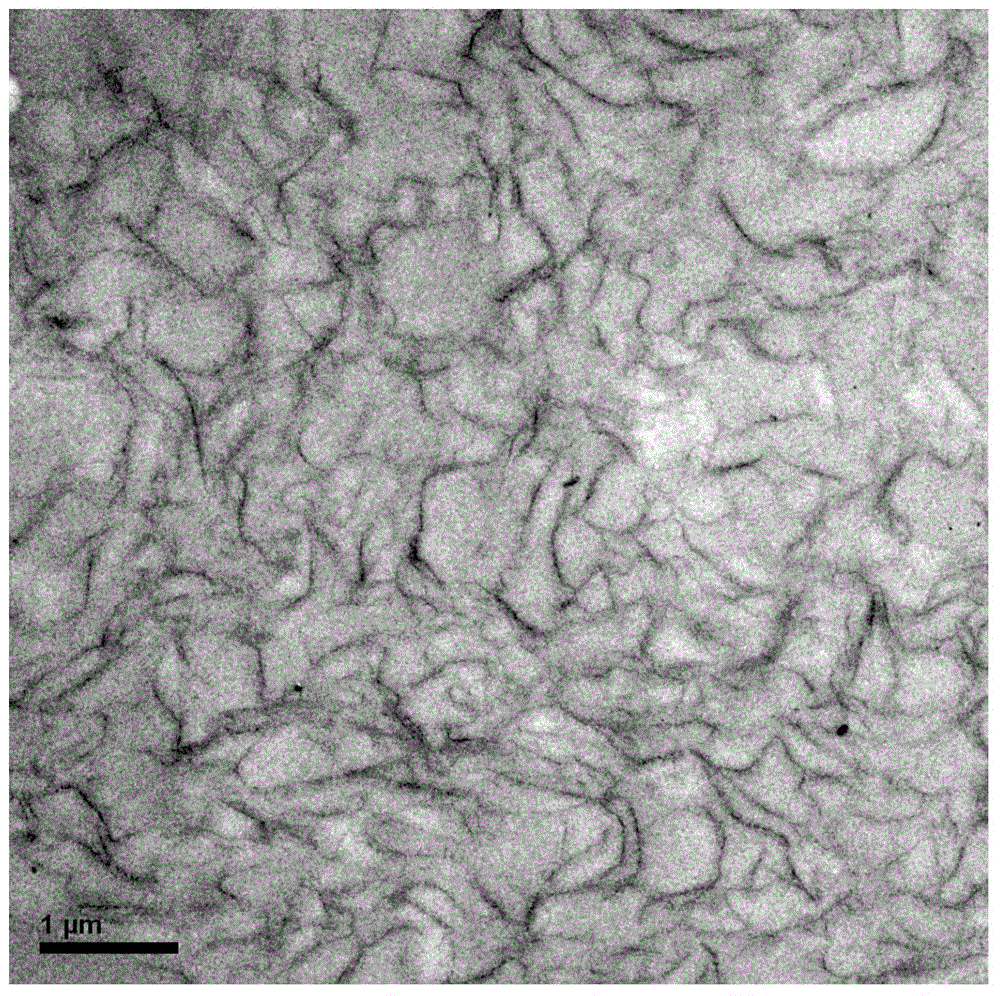

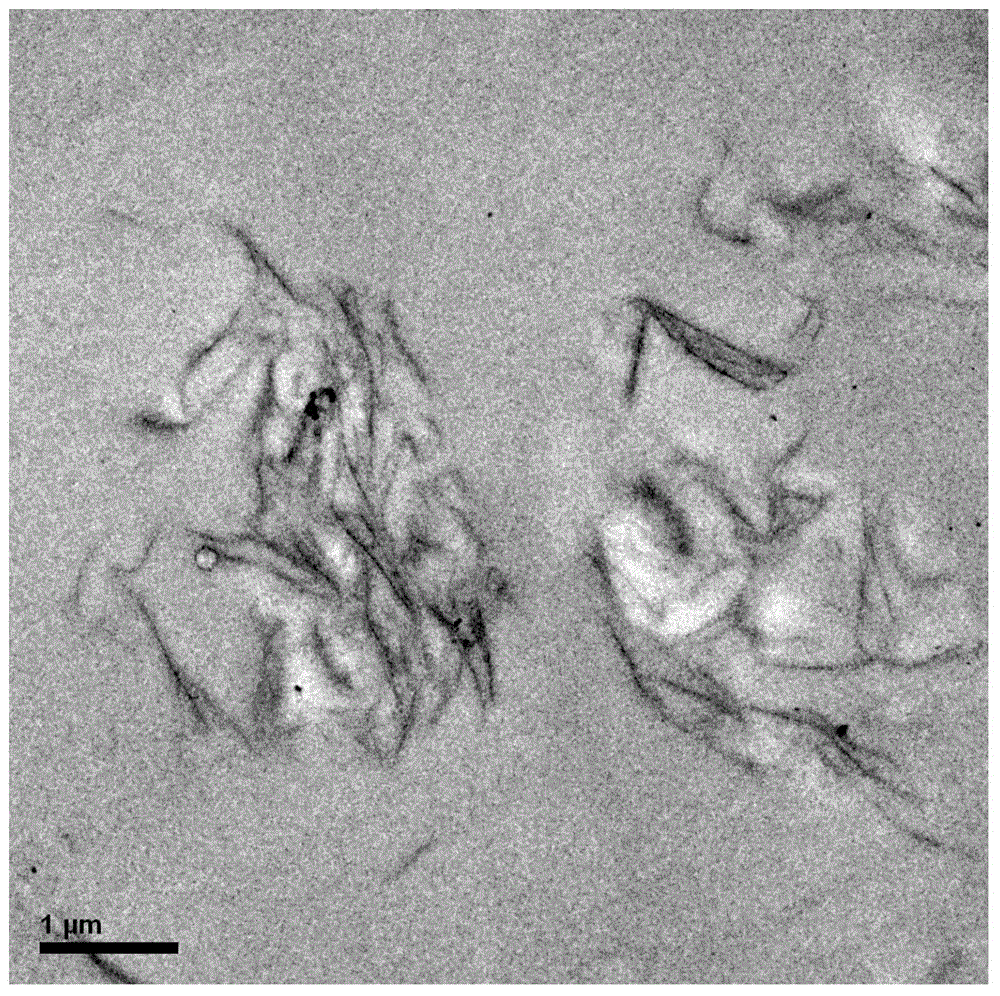

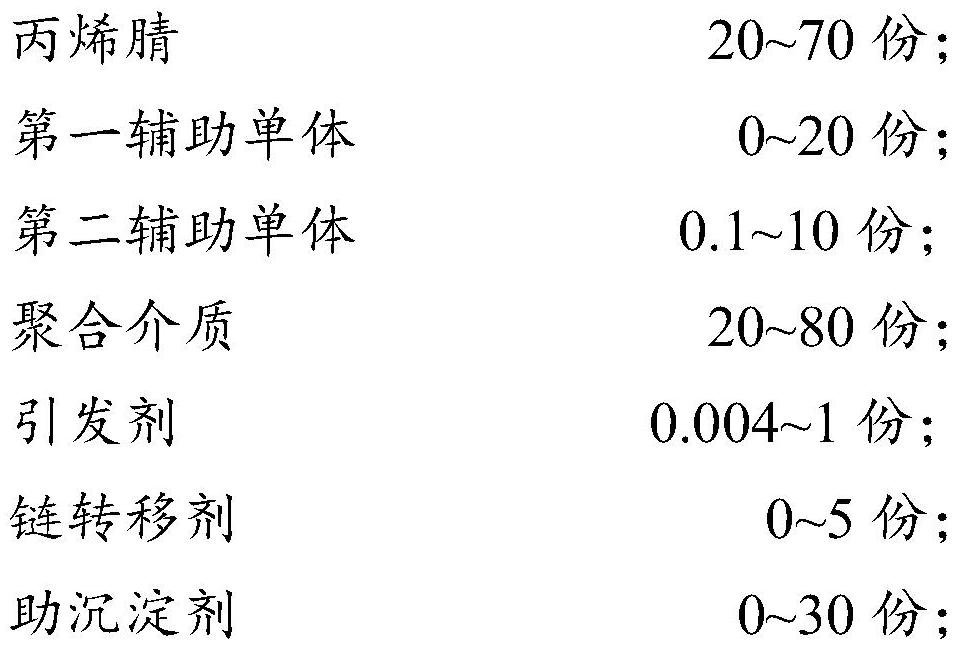

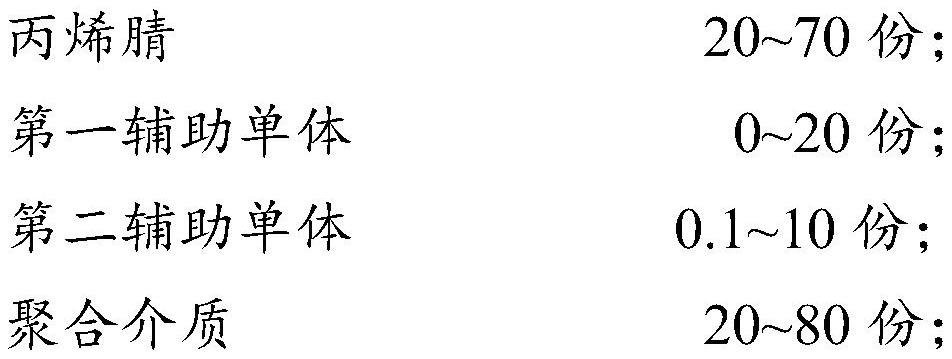

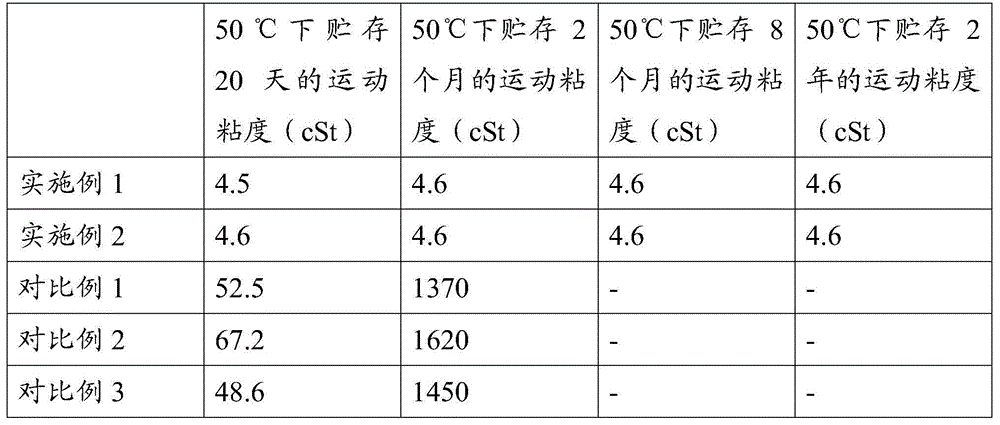

Polyacrylonitrile suspension with high solid content and low viscosity, preparation method and application thereof, and preparation method of polyacrylonitrile-based carbon fiber

ActiveCN113072658AIncrease mass concentrationRelieve pressureMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

The invention belongs to the technical field of carbon fibers, and particularly relates to a polyacrylonitrile suspension with high solid content and low viscosity, a preparation method and application thereof, and a preparation method of a polyacrylonitrile-based carbon fiber. The polyacrylonitrile suspension with high solid content and low viscosity provided by the invention has the advantages of high monomer concentration and low viscosity of a polymerization system, and is beneficial to the rate of uniform dispersion of supplemented polymerization monomers during continuous polymerization and the transfer of polymerization reaction heat; and the formed small particles are beneficial to long-time survival of active free radical chains, rapid polymerization and preparation of polyacrylonitrile with high molecular weight can be realized, and a homogeneous polyacrylonitrile spinning solution with low viscosity and high mass concentration can be further formed through subsequent demonomerisation and defoaming. The polyacrylonitrile fiber and the polyacrylonitrile-based carbon fiber which are prepared by spinning with the high-mass-concentration homogeneous polyacrylonitrile spinning solution provided by the invention have relatively high monofilament tensile strength.

Owner:吉林碳谷碳纤维股份有限公司

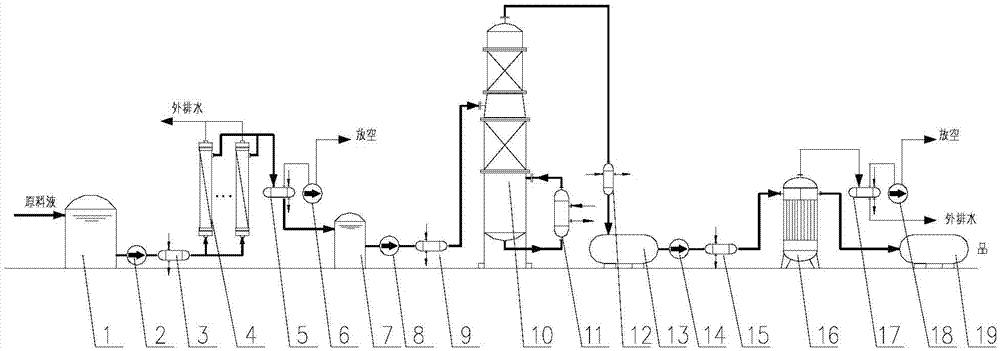

Device and method for recycling low-concentration organic solvent

ActiveCN103613480AReduce operating energy consumptionImprove economyOrganic compounds purification/separation/stabilisationChemical industryDistillationHigh energy

The invention discloses a device and method for recycling a low-concentration organic solvent, belonging to the technical field of environmental protection and solving the technical problems of high energy consumption, low purity of the recycled organic solvent and the like of the prior art. The device comprises a separation system, a concentration system and a dehydration system, wherein the separation system comprises a raw material liquid tank, a first delivery pump, a first heater, a pervaporation membrane component, a first condenser and a first vacuum pump; the concentration system comprises a separation liquid tank, a second delivery pump, a second heater, a distillation tower and a second condenser; the dehydration system comprises a concentration liquid tank, a third delivery pump, a third heater, a vapor permeation membrane component, a third condenser, a second vacuum pump and a product tank. In the device and method disclosed by the invention, the energy consumption for recycling the low-concentration organic solvent is low, and a high-purity organic solvent can be recycled, thereby saving the energy, protecting the environment and realizing an effect on turning waste into wealth.

Owner:上一环保科技(杭州)有限公司

Preparation process of polymer modification silicon sol

ActiveCN104150491AReduce production processIncrease mass concentrationOther chemical processesSilicon compoundsPolymer modifiedC constant

The invention discloses a preparation process of polymer modification silicon sol. The preparation process is characterized by comprising the following steps: (1) placing 2,400 mass parts of silicon sol into a reaction container, adding 240 mass parts of deionized water into the reaction container, heating until the temperature rises up to 80 DEG C, and keeping the temperature of 80 DEG C constant until the reaction is completed to form a uniform stable system; (2) keeping the temperature of the system in the reaction container to be 80 DEG C, slowly adding 72 mass parts of polymer modifier which needs to be completely added within 30 min into the reaction container under a stirring state, continuously stirring the reaction system for 5 h at a constant temperature until the reaction is completed to obtain the polymer modification silicon sol, and modifying the pH value of the reaction system to be in a range of 10-11 by using a pH modifier at time intervals of 30 min within 5 h. The process is simple and efficient, and the prepared silicon sol is high in polishing speed, good in hardness, excellent in thermal stability under a long-time storage state, and high in repeated utilization rate.

Owner:JIANGSU HAIXUN IND GROUP SHARE

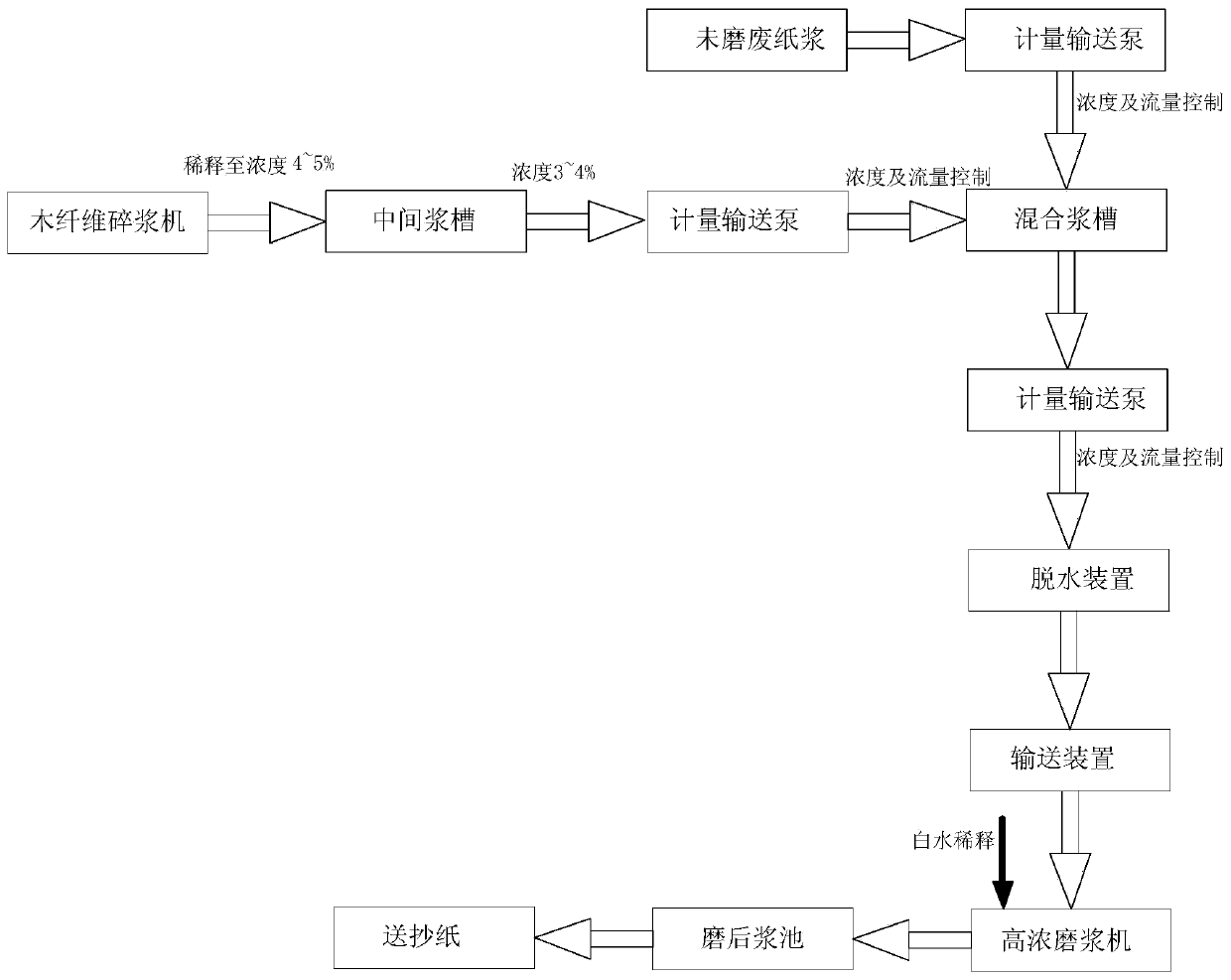

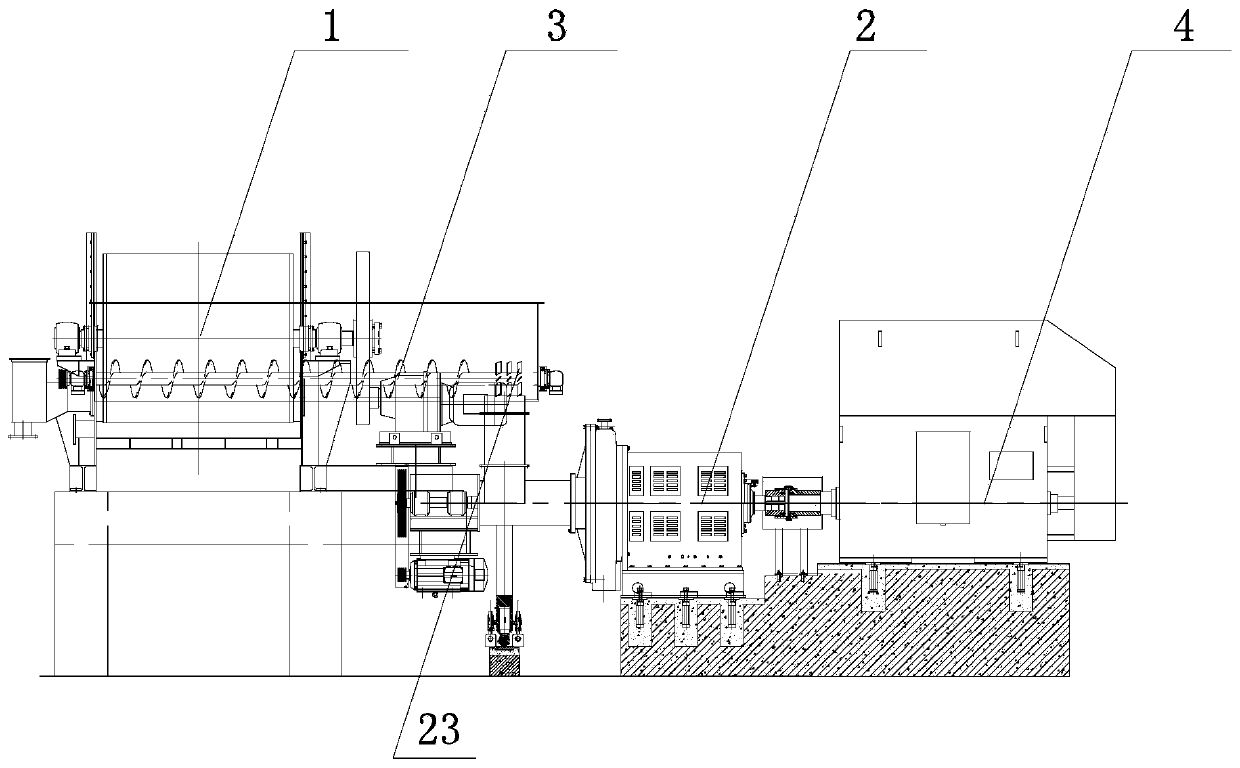

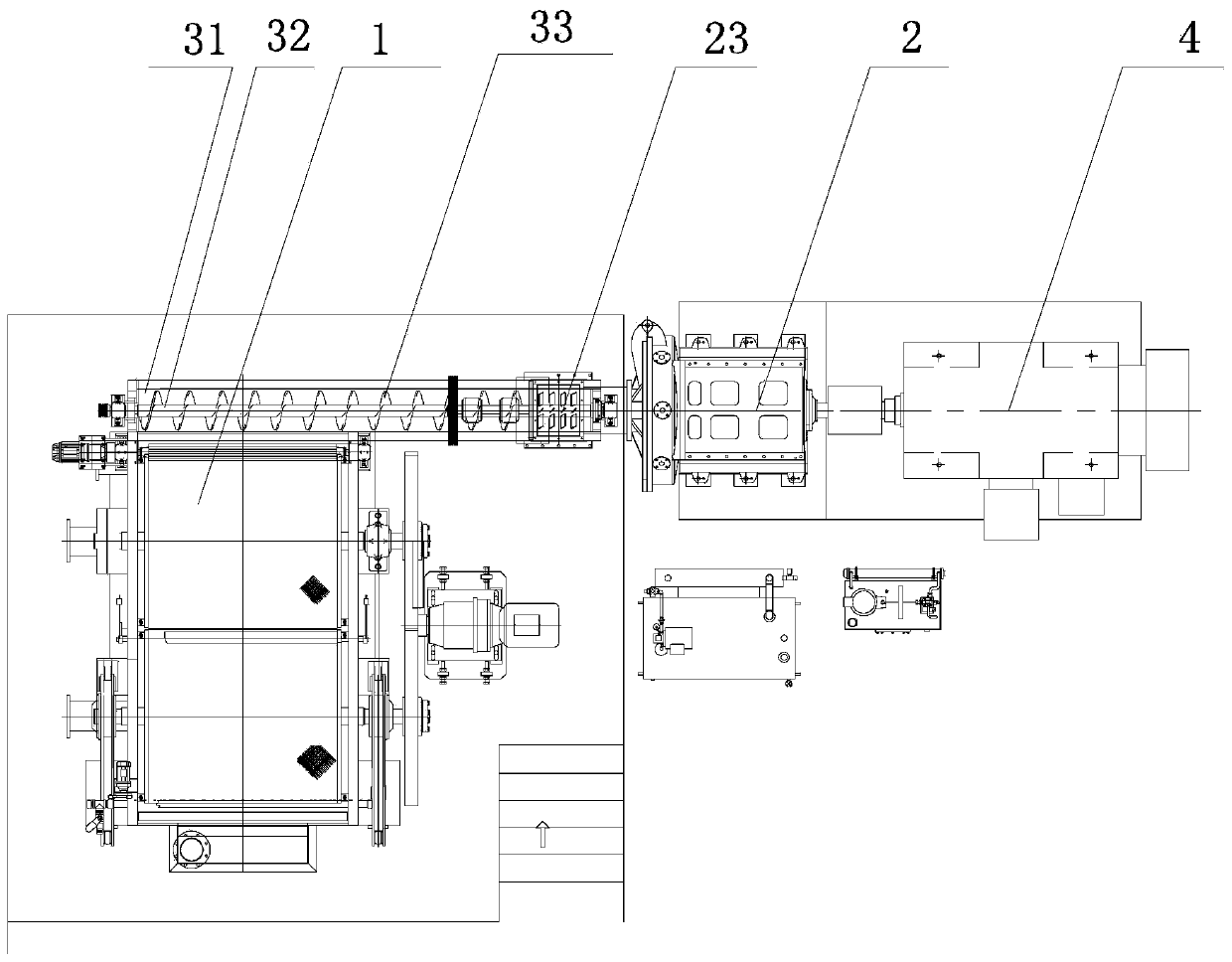

Corrugated paper preparing process and device

InactiveCN109750554AIncrease dosageWay to increasePulp de-wateringPulp beating/refining methodsWood fibrePulp and paper industry

The invention discloses a corrugated paper preparing process. The corrugated paper preparing process comprises the following steps of S1, raw material treatment including processing the raw materialsof wastepaper and wood fiber into pulp, S2, pulp mixing including uniformly mixing the wastepaper pulp and the wood fiber pulp, S3, dewatering including dewatering the mixed pulp to reach a mass concentration of 18-25%, S4, pulp grinding including grinding the dewatered pulp, and S5, manufacturing including preparing the ground pulp into a finished product, namely, corrugated paper. The inventionfurther discloses a device applied to the corrugated paper preparing process. The device comprises a dewatering device, a pulp grinding device, and a conveying device communicating the discharging port of the dewatering device and the feeding port of the pulp grinding device. The corrugated paper preparing process and device has the advantages of being convenient to operate, low in cost, good in major physical indexes of finished paper and the like.

Owner:CHANGSHA CC PAPER MACHINERY

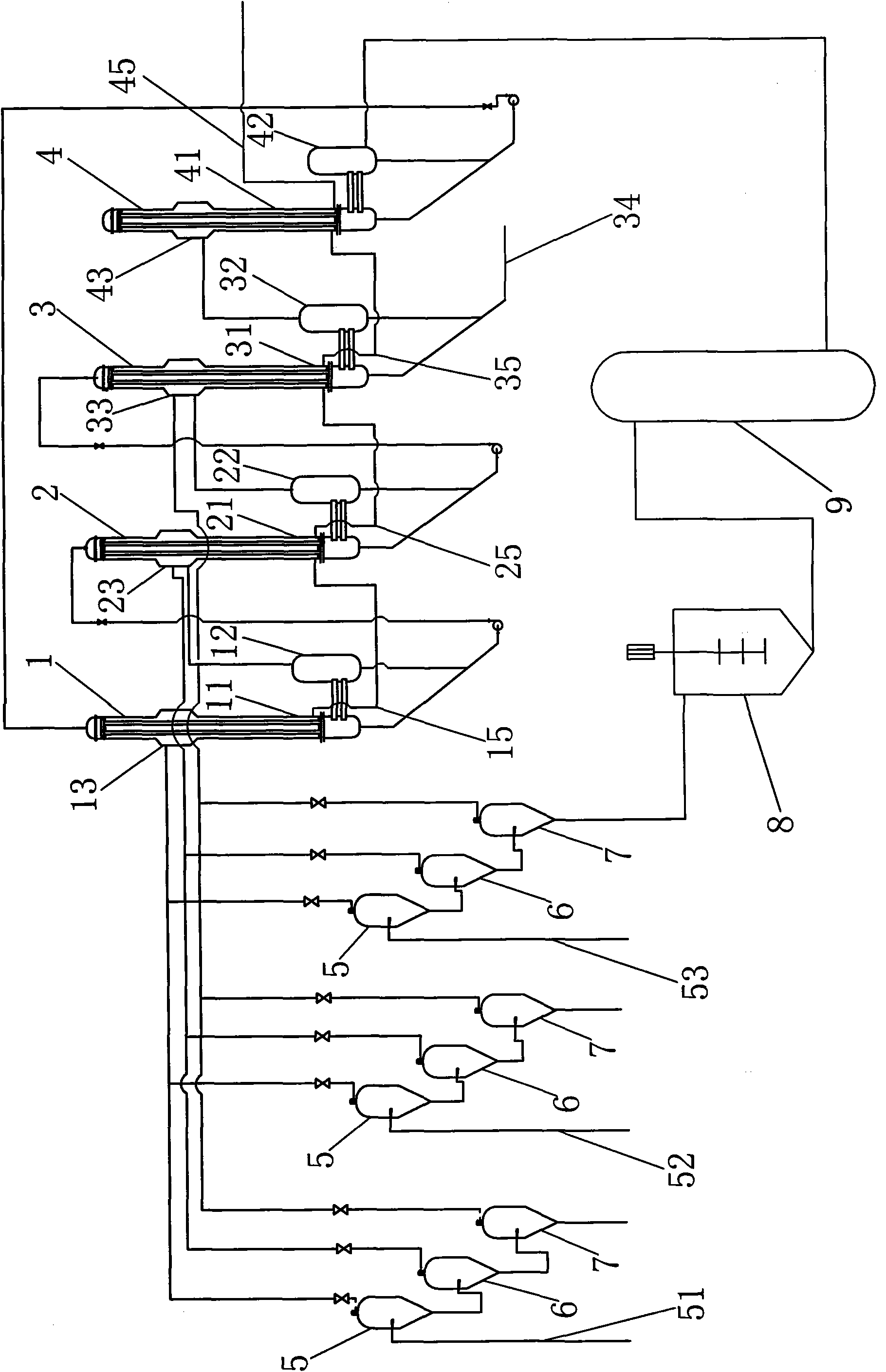

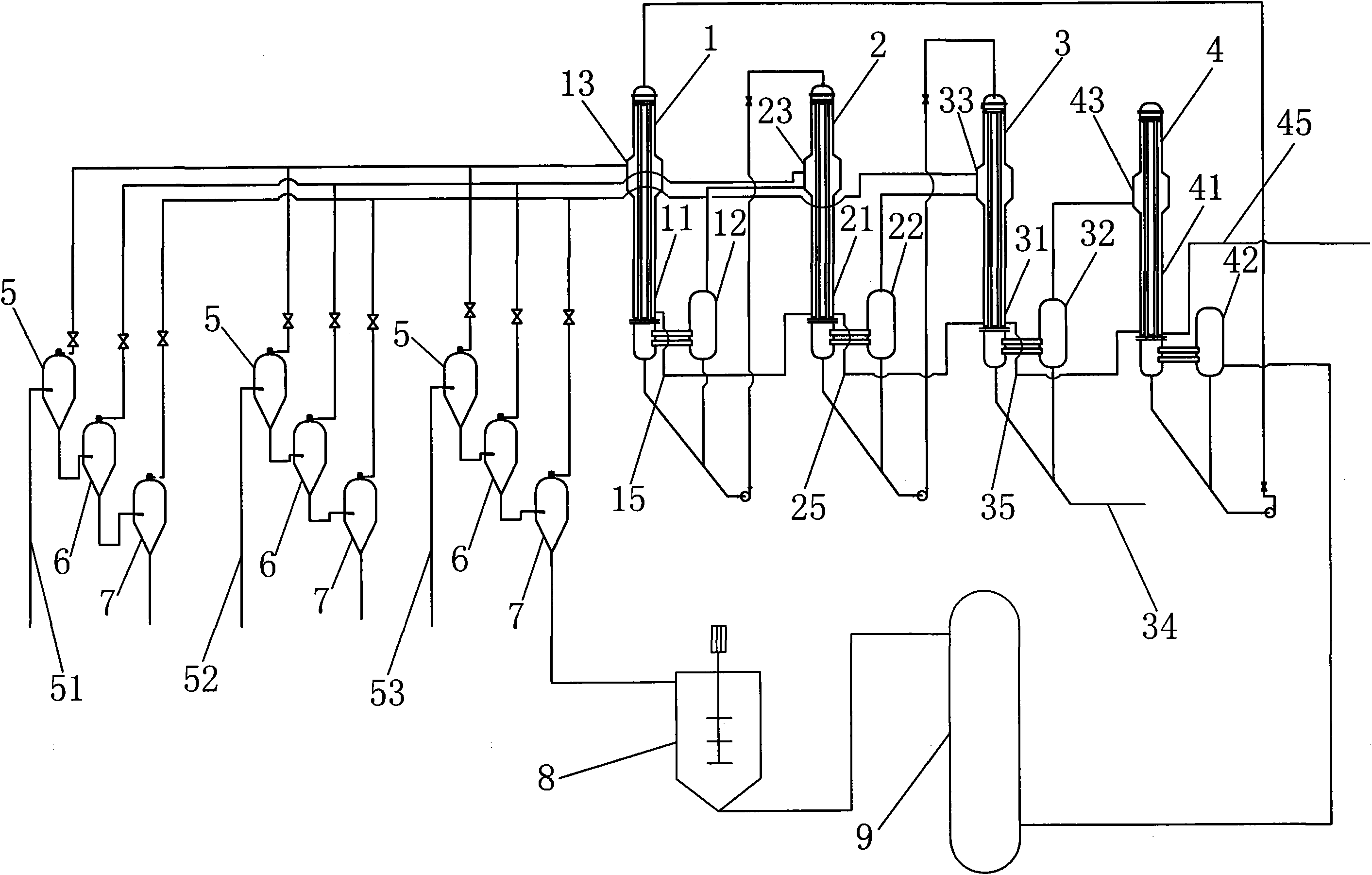

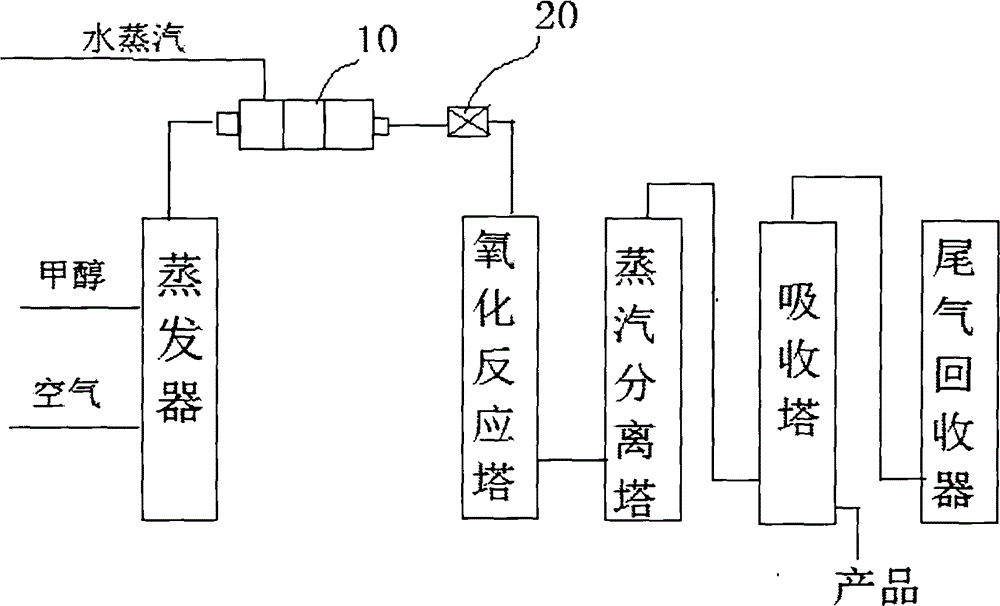

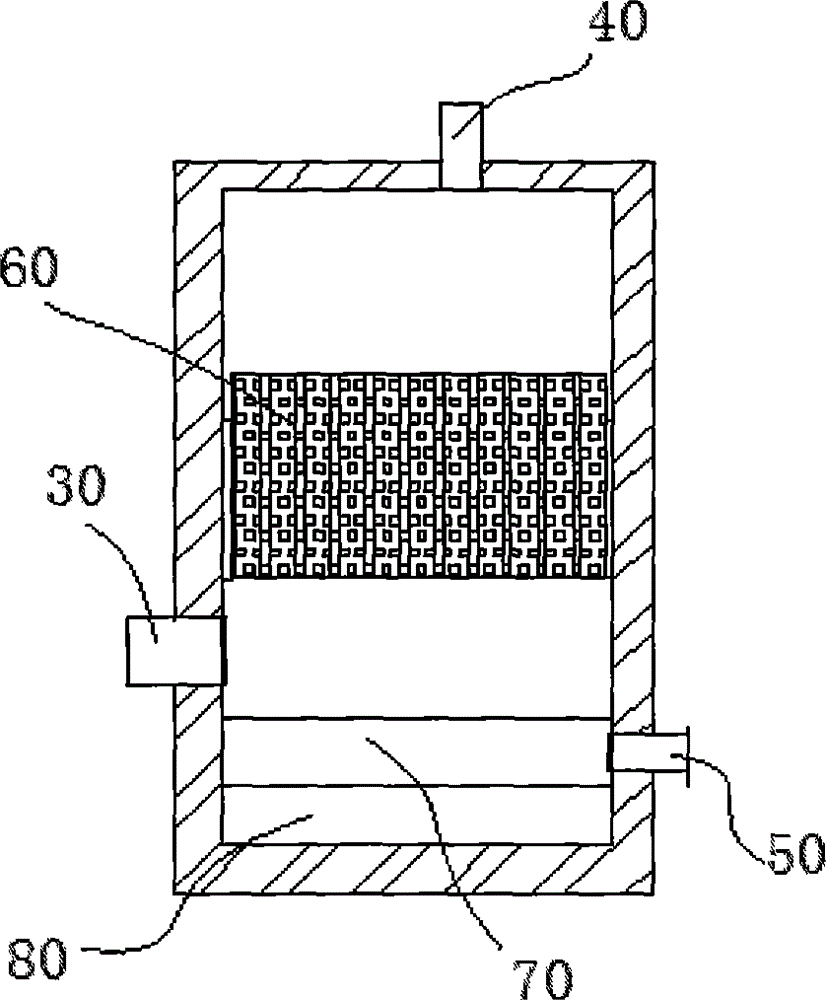

Energy-saving formaldehyde production system

InactiveCN105884593AEfficient removalIncrease mass concentrationOrganic compound preparationCarbonyl compound preparationFormaldehyde productEngineering

The invention relates to an energy-saving formaldehyde production system which comprises an evaporator, a gas mixer, an oxidizing reaction tower, a steam separation tower, an adsorption tower and a tail gas recycling device. The evaporator is connected with the gas mixer, the gas mixer is connected with a steam source, an outlet of the gas mixer is connected with a steam inlet of the oxidizing reaction tower, and a steam outlet of the oxidizing reaction tower is connected with a steam inlet of the steam separation tower. A steam exhaust port of the steam separation tower is connected with an inlet of the adsorption tower, a tail exhaust port of the adsorption tower is connected with a tail gas recycling device, and the steam separation tower comprises a tower body. The upper portion in the tower body is provided with at least one piece of metal regular filler through a frame, a liquid suction disc is arranged on the lower portion of the metal regular filler, and a water circulating cooling pond is arranged on the lower portion of the liquid suction disc. A large amount of steam in a formaldehyde gas mixture can be effectively removed through the steam separation tower, and therefore the mass concentration of produced formaldehyde products can be effectively improved.

Owner:TIANJIN FORINT TRANSCENDENTAL TECH DEV CO LTD

A kind of preparation method of cellulose fiber

ActiveCN106222771BIncrease mass concentrationSimple preparation processArtificial filament recoveryArtificial filament washing/dryingCellulose fiberCoagulation system

The invention discloses a preparation method of cellulose fiber, comprising the following steps: 1) mixing cellulose pulp with an NMMO aqueous solution with a mass concentration of 60% to 85%, preferably 70% to 76%, to obtain a uniform mixture; 2) ) The obtained homogeneous mixture is dehydrated, swelled, dissolved and defoamed to obtain a cellulose spinning stock solution; 3) The obtained cellulose spinning stock solution enters the spinning machine after filtration and heat exchange, is extruded through the spinneret assembly, and after air cooling, enters The coagulation system is coagulated in an NMMO coagulation bath of 50%<mass concentration<72% to obtain nascent fibers; 4) the obtained nascent fibers are washed with water to obtain fiber tows, and then processed in subsequent stages to obtain the cellulose fibers. The invention can greatly reduce equipment investment, simplify process, reduce energy consumption and industrialization cost, facilitate safe production, improve fiber homogeneity and mechanical properties, and thus be more suitable for high-efficiency and low-consumption industrialized production.

Owner:CHINESE TEXTILE ACAD

Drag reducer for fracturing and preparation method thereof

InactiveCN111499796AHigh drag reduction rateHigh monitoring efficiencyDrilling compositionFracturing fluidOil phase

The invention discloses a drag reducer for fracturing and a preparation method thereof. The drag reducer for fracturing consists of, in percentage by mass, 10%-30% of a water-soluble monomer, 5%-35% of water, 30%-65% of base oil, 5%-30% of an emulsifier, 1%-3% of an electrolyte with a salting-out effect and 0.001%-0.1% of an initiator. Under the initiation of the initiator, a water-in-oil system formed by an aqueous phase solution and an oil phase solution is subjected to a reversed-phase microemulsion polymerization reaction. According to the invention, the drag reducer for a fracturing fluidis synthesized by adopting a reversed-phase emulsion polymerization mode; the fracturing fluid is a water-soluble polymer with a small amount of hydrophobic groups on a hydrophilic macromolecular chain, and the solution has special thickening and shearing-resistant effects due to the specific amphiphilic molecular structure of the fracturing fluid; and the drag reducer has the advantages of highdrag reduction rate, strong compatibility, shearing resistance, low friction resistance, low damage and wide application range.

Owner:SHAANXI YUTENG IND

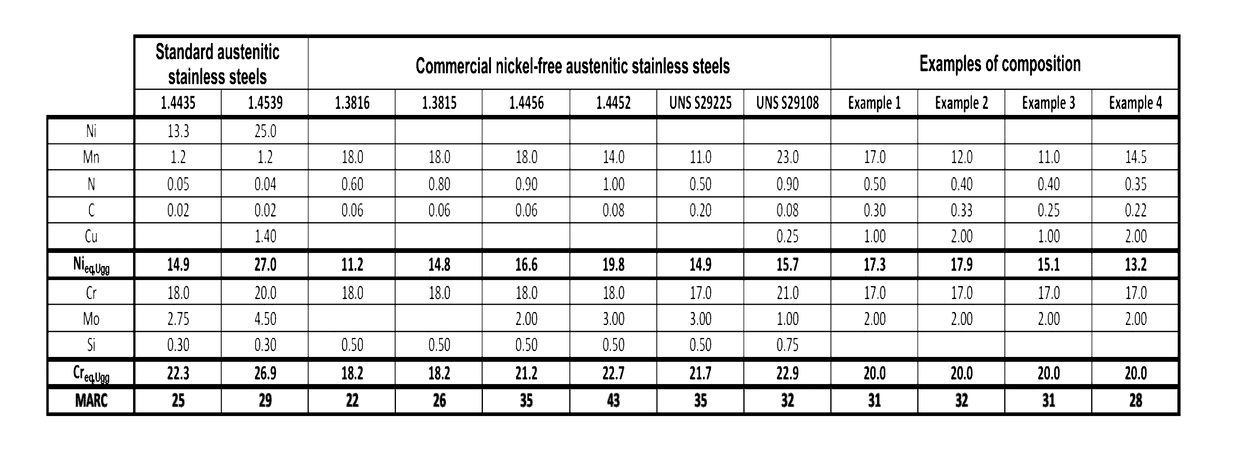

Nickel-free austenitic stainless steel

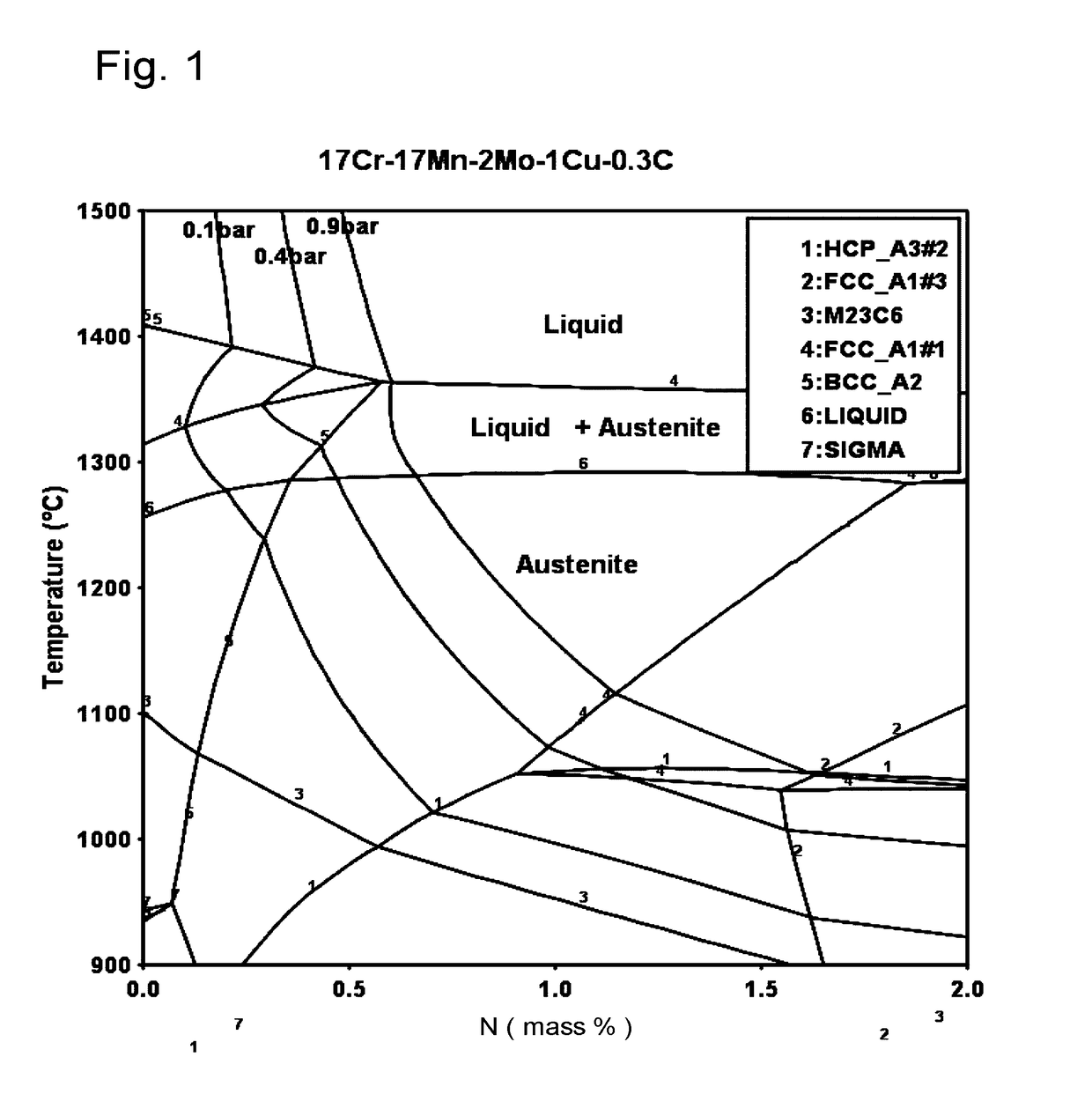

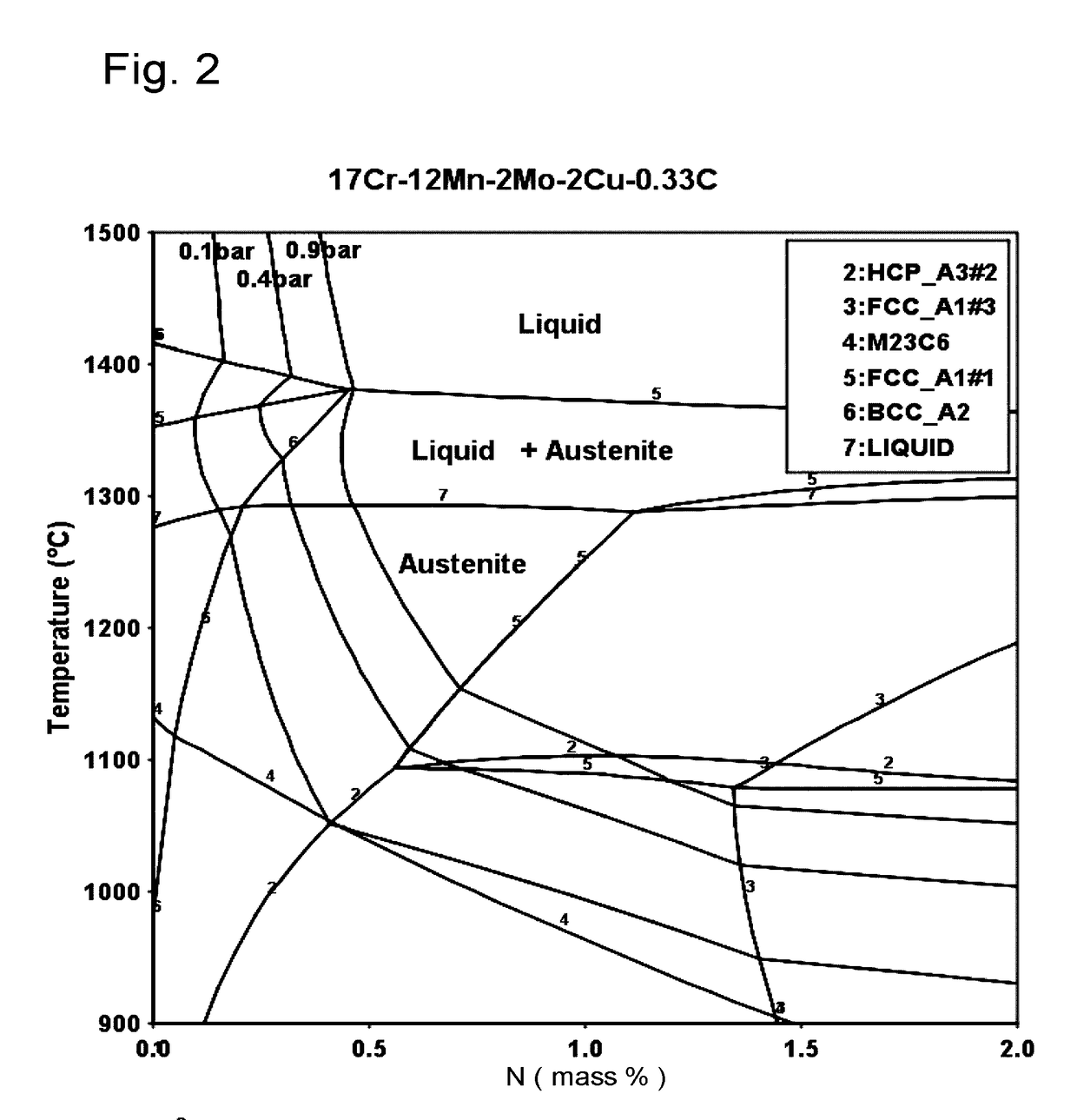

InactiveUS20170088923A1Solve the lack of corrosion resistanceEasy to operateJewelleryManganeseNitrogen

Nickel-free austenitic stainless steel comprising, in mass percent:chromium in amounts of 10<Cr<21%;manganese in amounts of 10<Mn<20%;molybdenum in amounts of 0<Mo<2.5%;copper in amounts of 0.5≦Cu<4%;carbon in amounts of 0.15<C<<%;nitrogen in amounts of 0<N≦1, andthe remainder being formed by iron and any impurities from the melt.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

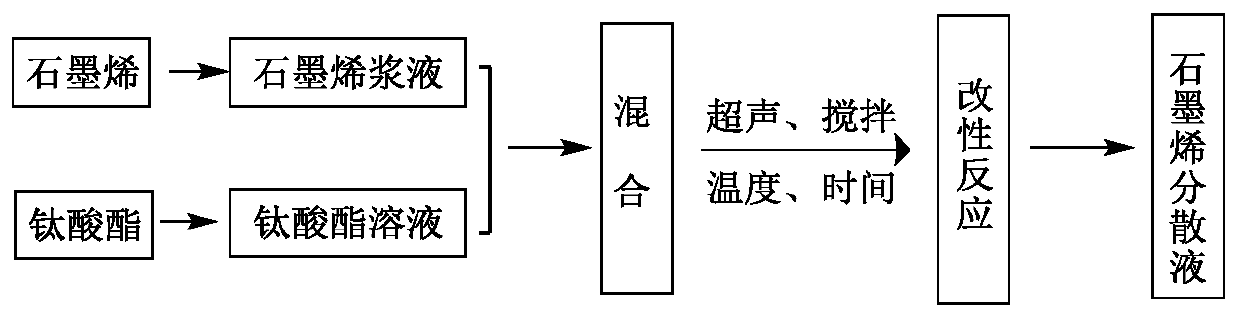

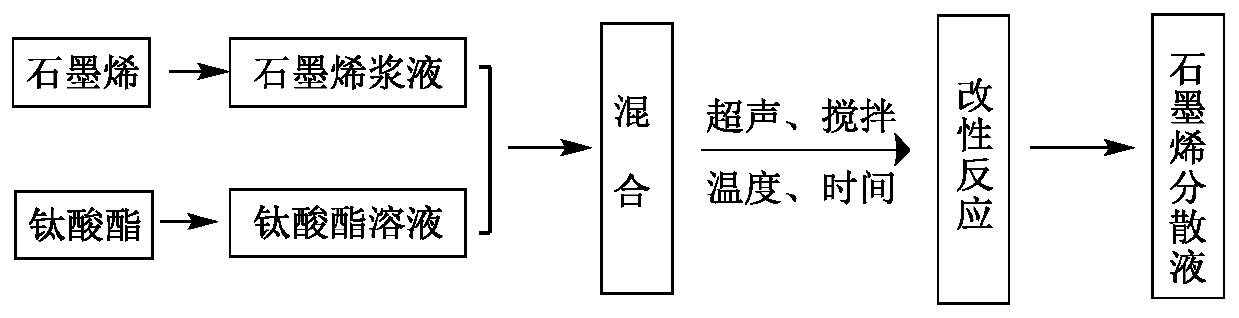

Water-based graphene dispersion liquid and preparation method thereof

The invention discloses a water-based graphene dispersion liquid and a preparation method thereof, and belongs to the technical field of graphene modification. The water-based graphene dispersion liquid is a durable stable dispersion liquid prepared by taking single-layer and / or double-layer and / or multi-layer nano graphene as a raw material to carry out a reaction with a chelating-type titanate under the action of ultrasonic waves and mechanical stirring. The water-based graphene dispersion liquid prepared by the preparation method is good in dispersion liquid stability, and no sedimentationphenomenon occurs when the dispersion liquid is placed for 30 days; the dispersion liquid is low in viscosity and good in liquidity, the dispersion medium is water, and no polymer is added or generated, so that the application field is wide; the preparation process of the dispersion liquid is simple, the reaction is mild, the modification time is short, and industrial application is easier; the dispersion liquid is an environment-friendly product, no harmful impurities are introduced in the preparation process, and a used coupling agent can be wound or bonded with a composite material to forma whole substance in subsequent processing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

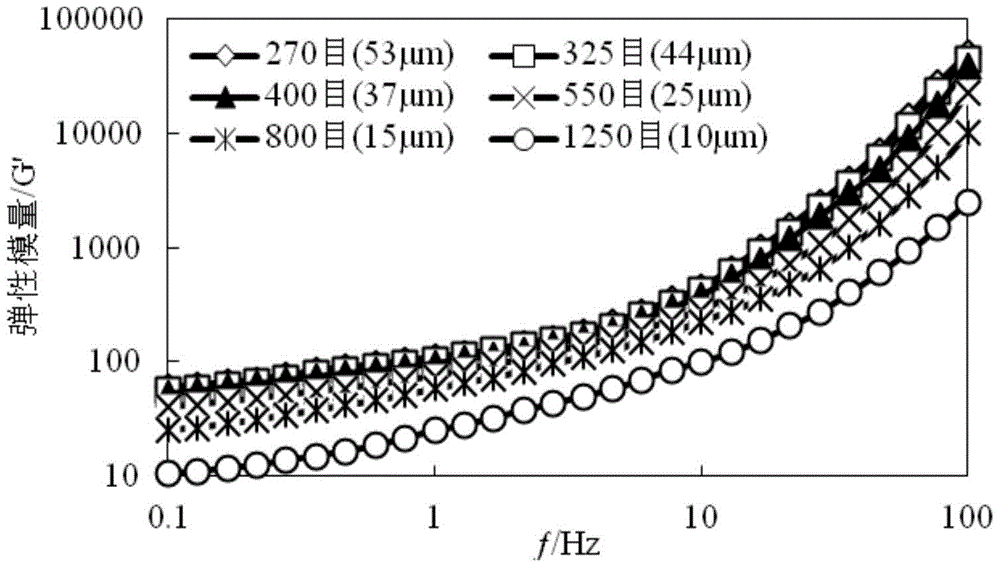

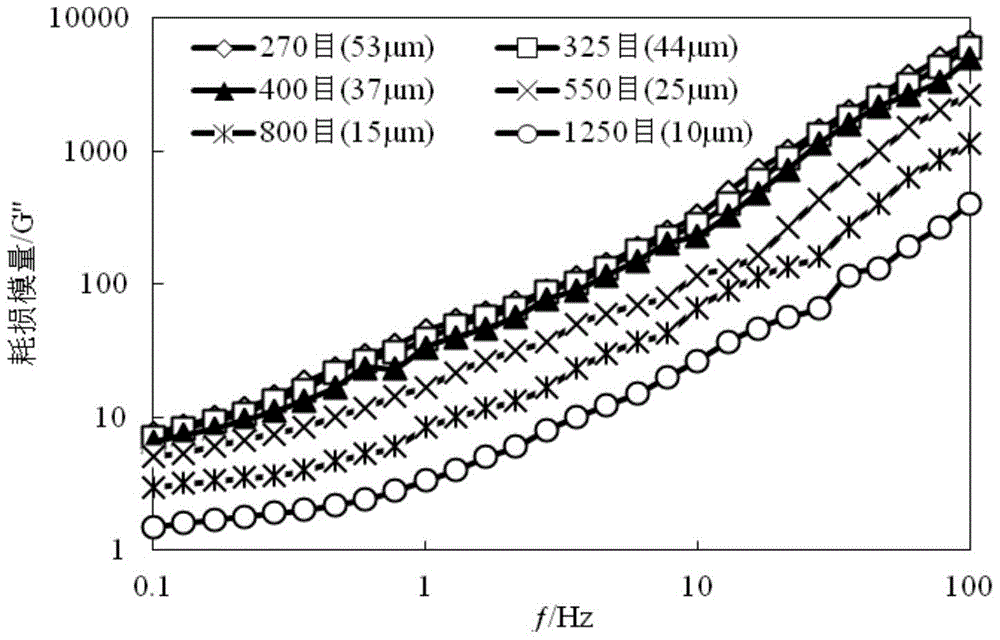

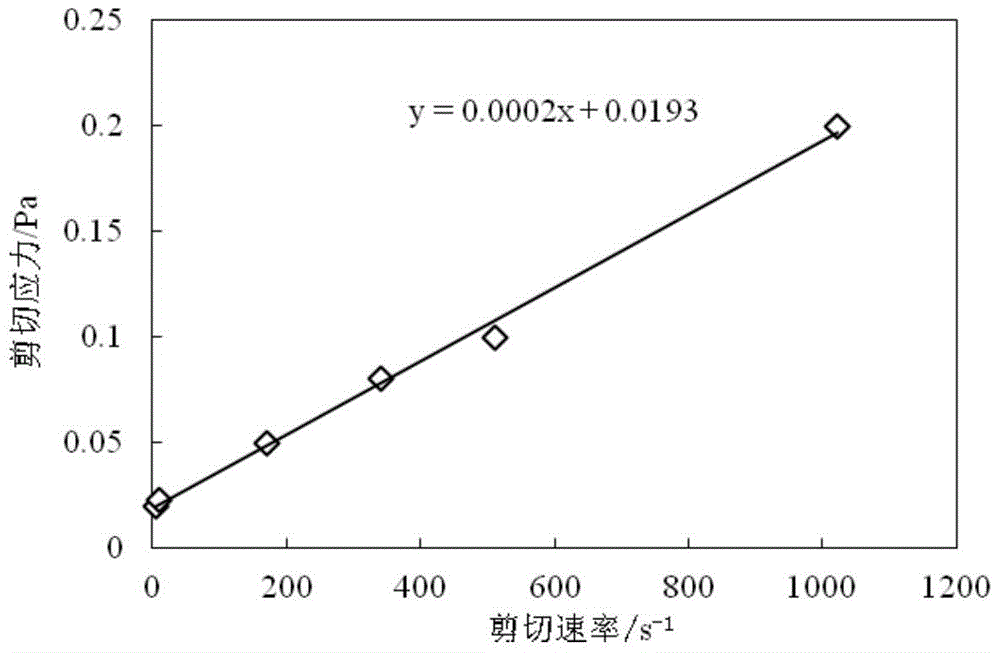

A high-temperature and high-salt fine gel particle profile control agent and its preparation method and application

The invention discloses a high-temperature-resistant and high-salt-resistant fine gel particle as a profile control agent as well as a preparation method and an application of the fine gel particle. The preparation method of the fine gel particle comprises the following steps of firstly, adding modified starch, a monomer A, a monomer B, a crosslinking agent, an initiator and an accelerant into a reaction kettle according to a certain ratio; and after finishing the polymerization reaction of the six components to form integrated water-based gel, drying, crushing, granulating, screening and performing other process steps to obtain the fine gel particle. The application method of the high-temperature-resistant and high-salt-resistant fine gel particle is as follows: a certain quantity of fine gel particles prepared by using the preparation method are added into a Bingham fluid, the gel particles can be stably suspended without settling under static and dynamic conditions, and then, the whole fluid is injected to the stratum by means of pumping pressure. By using the high-temperature-resistant and high-salt-resistant fine gel particle and the application method thereof, disclosed by the invention, the construction success rate of the gel particle can be greatly increased, and a favorable deep profile control effect can be achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

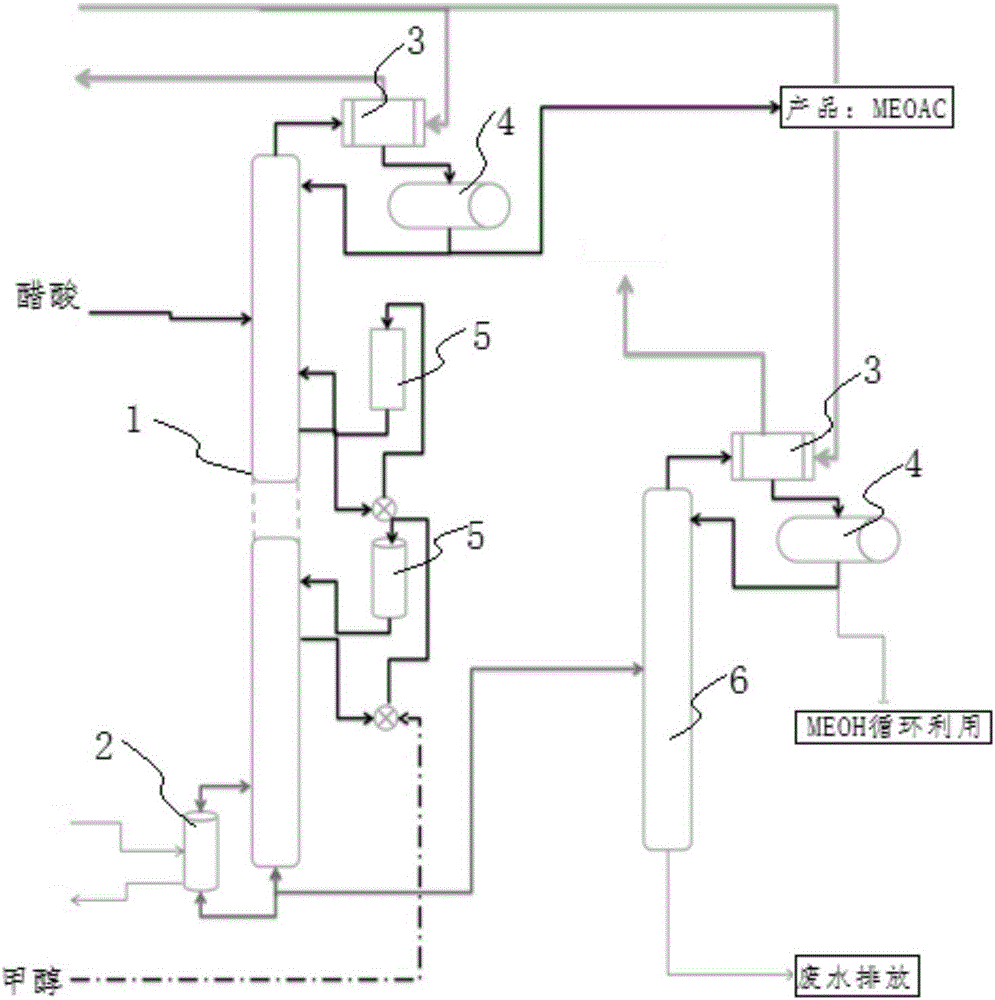

High-purity methyl acetate production process device and method

InactiveCN105968007AImprove conversion rateIncrease concentrationOrganic compound preparationChemical industryAlcoholReboiler

The invention discloses a high-purity methyl acetate production process device and method. The high-purity methyl acetate production process device comprises a reactive distillation column and a plurality of external reactors, wherein the reactive distillation column is dividend into a methyl alcohol separation section, a multilayer reaction section, an extraction section and a rectifying section from bottom to top. The multilayer reaction section is of a multilayer tower plate structure. The reaction section of each layer of tower plate is circularly connected with the corresponding external reactor through a pipeline. The extraction section is communicated with the multilayer reaction section and is provided with an acetic acid inlet. The top of the rectifying section is further connected with a condenser and a return tank. The separation section is provided with a methyl alcohol inlet, and the bottom of the separation section is circularly connected with a reboiler. Reaction and separation are organically combined, so that a reaction rate is increased, reverse reaction is suppressed, and a conversion rate is effectively improved. Therefore, the mass concentration of methyl acetate products is improved, and the device can be used for producing high-purity (97% or more) methyl acetate products and has the advantages of simplicity, high efficiency, remarkable economic benefits and the like.

Owner:湖北三里枫香科技有限公司

Antiscalant for reverse osmosis

ActiveCN104906961BBiodegradableGood retarding effectSemi-permeable membranesScale removal and water softeningHexamethylenetetramineReverse osmosis

The invention discloses a novel reverse-osmosis scale inhibitor which comprises the following raw materials in parts by weight: 2-8 parts of sodium citrate, 33-45 parts of hydrolytic polymaleic anhydride, 28-37 parts of polyepoxysuccinic acid salt, 9-15 parts of urotropine, 13-20 parts of polylactic acid, and 40-50 parts of water. A preparation method comprises the following steps: adding sodium citrate, hydrolytic polymaleic anhydride, polyepoxysuccinic acid salt, urotropine and half of water into a reaction kettle, heating to 40-50 DEG C, and stirring for uniformly dissolving; dissolving polylactic acid with the rest water to obtain a polylactic acid solution; heating the materials in the reaction kettle to 70-75 DEG C, dropwise adding the polylactic acid solution, and keeping the temperature for 3-4h after the dropwise adding is finished; and cooling to room temperature so as to obtain the novel reverse-osmosis scale inhibitor. The novel reverse-osmosis scale inhibitor disclosed by the invention has the scale inhibition rate being up to 95%, is small in adding amount, environmentally friendly, stable in property, and long in storage period, and can be used for solving the problems that existing reverse-osmosis inhibitors mainly are foreign products and are limited in treatment capacity, complex in synthesis, relatively high in production cost, and the like in the prior art.

Owner:浙江川宁环保科技有限公司

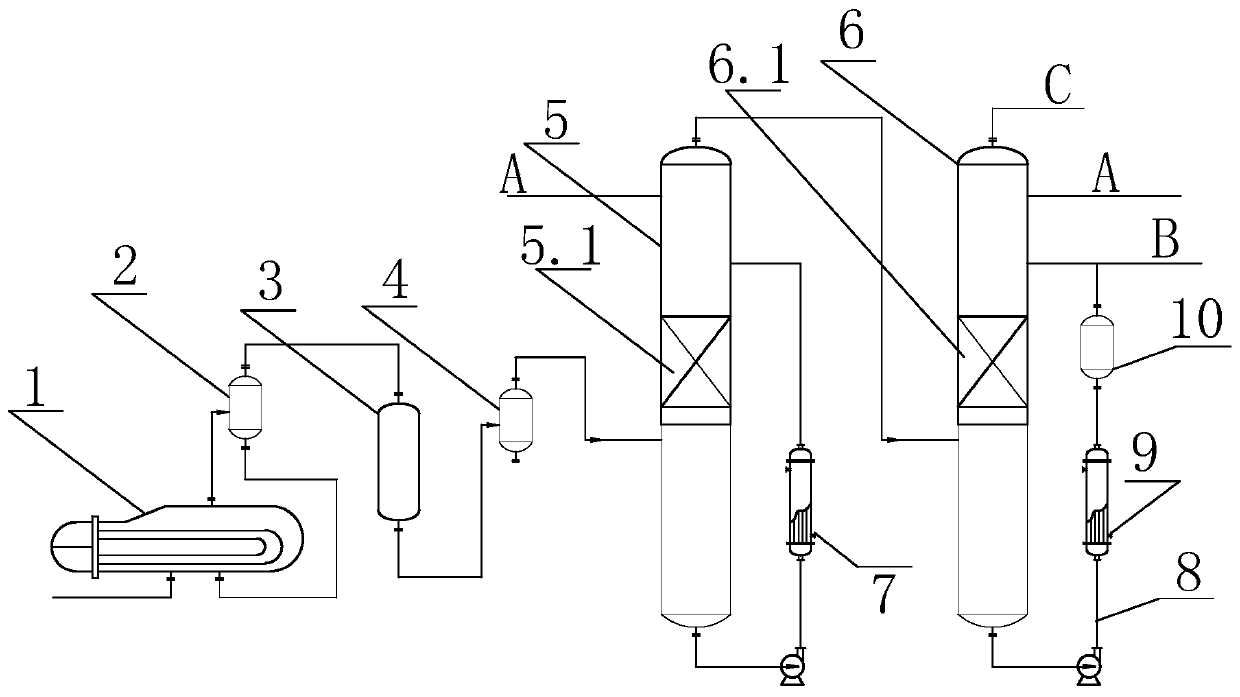

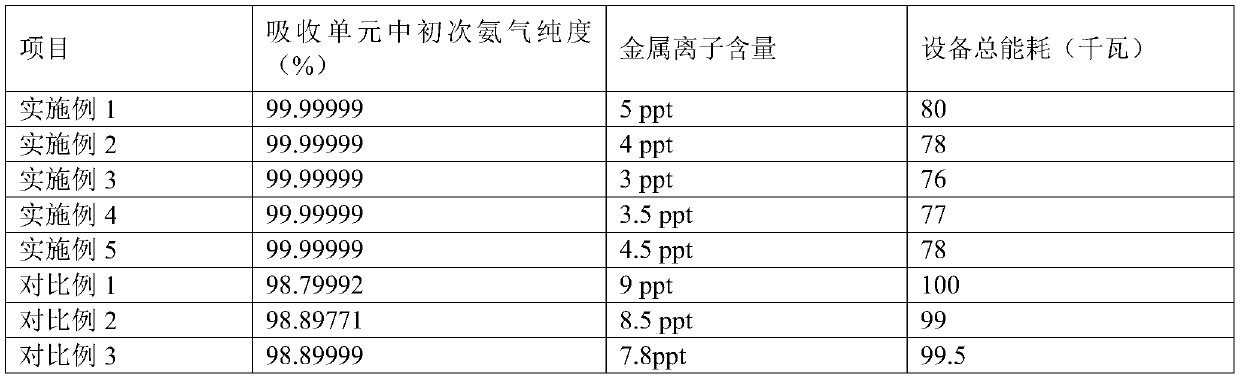

High-adsorption electronic-grade ammonia water manufacturing system

PendingCN111498867AImprove adsorption efficiencyIncrease mass concentrationAmmonia preparation/separationVapor–liquid separatorPhysical chemistry

The invention relates to the technical field of manufacturing of electronic-grade ammonia water. The problems that in the prior art, ammonia water contains many impurities, and equipment energy consumption is high are solved. The invention discloses a high-absorption-rate electronic-grade ammonia water manufacturing system that comprises an evaporator, a first gas-liquid separator, an adsorption unit, a second gas-liquid separator, a washing unit and an absorption unit, wherein the devices are sequentially connected, a modified adsorption material is arranged in the adsorption unit, a washingfiller area is arranged in the washing unit, the washing filler area is positioned between an inlet and an outlet of the washing unit, and an absorption filler area is arranged between the inlet and the outlet on the inner side of the absorption unit. The manufacturing system with high impurity adsorption efficiency is prepared, washing and absorption in the preparation process of the system are carried out under normal pressure or micro-positive pressure, a modified adsorption material with magnetic directional adsorption capacity and super-large specific surface energy is adopted, and finally electronic-grade ammonia water with high ammonia water mass concentration, low metal ion content and excellent and stable performance is obtained.

Owner:浙江建业微电子材料有限公司 +1

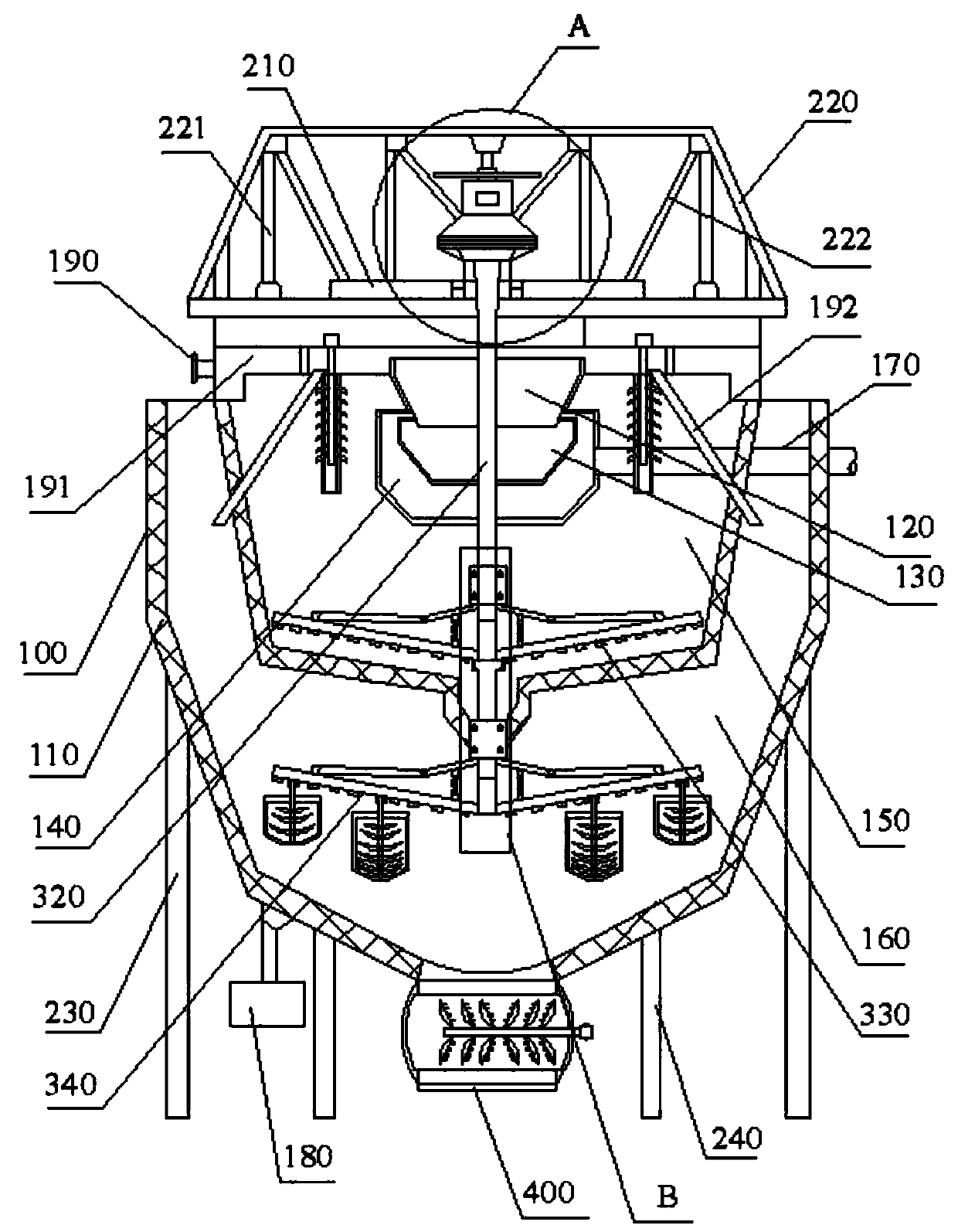

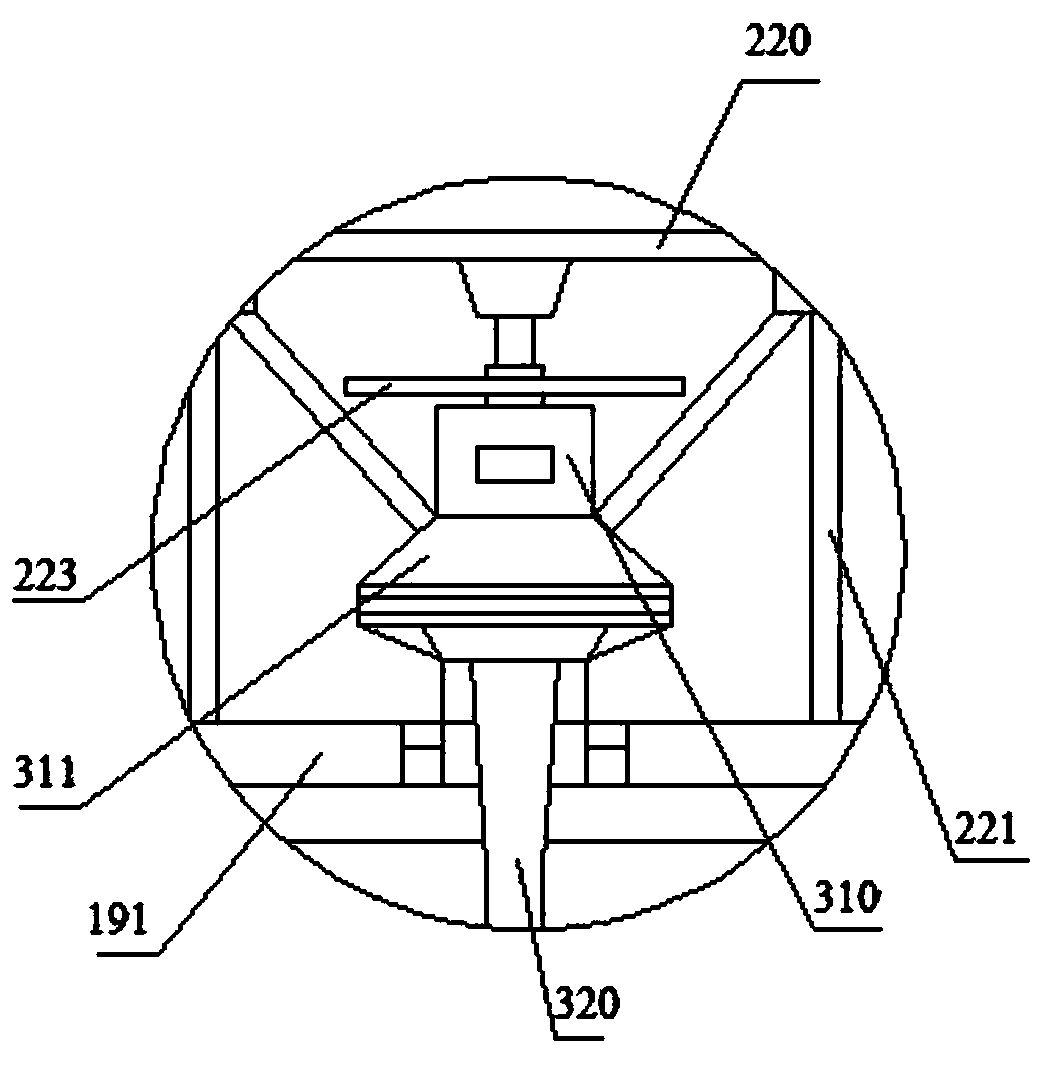

Thickener capable of treating high-concentration ore pulp

ActiveCN110237578AProcessing speedExtended service lifeSettling tanks feed/dischargeSedimentation settling tanksFlocculationHigh concentration

The invention discloses a thickener capable of treating high-concentration ore pulp. The thickener comprises a reaction cavity, a mounting mechanism, a transmission mechanism and a discharging mechanism, wherein the reaction cavity comprises a peripheral cavity, a fall pressure chamber, a primary treatment chamber, a secondary treatment chamber, a primary sedimentation cavity and a secondary sedimentation cavity; when the thickener works, ore pulp materials enter the primary treatment chamber along a feed pipe, solids with larger particle sizes are deposited in the primary treatment chamber and enter the primary sedimentation cavity through a screen, the sedimentation and flocculation of the materials are accelerated by the rotation of primary inclined main boards, and sedimentation flocculates enter the secondary sedimentation cavity through a screen at the bottom of the primary sedimentation cavity; and secondary inclined main boards in the secondary sedimentation cavity drive stirring shafts, stirring frames and stirring blades to stir, so that secondary sedimentation of the materials is promoted. The thickener can treat ore pulp with the mass concentration of more than 45-55%, the treatment speed of the high-concentration ore pulp is high, the power consumption and the abrasion degree of a reaction cavity and a rake plate are low, and the service life of the thickener is prolonged.

Owner:ANHUI ZHONG NENG MACHINERY MFG

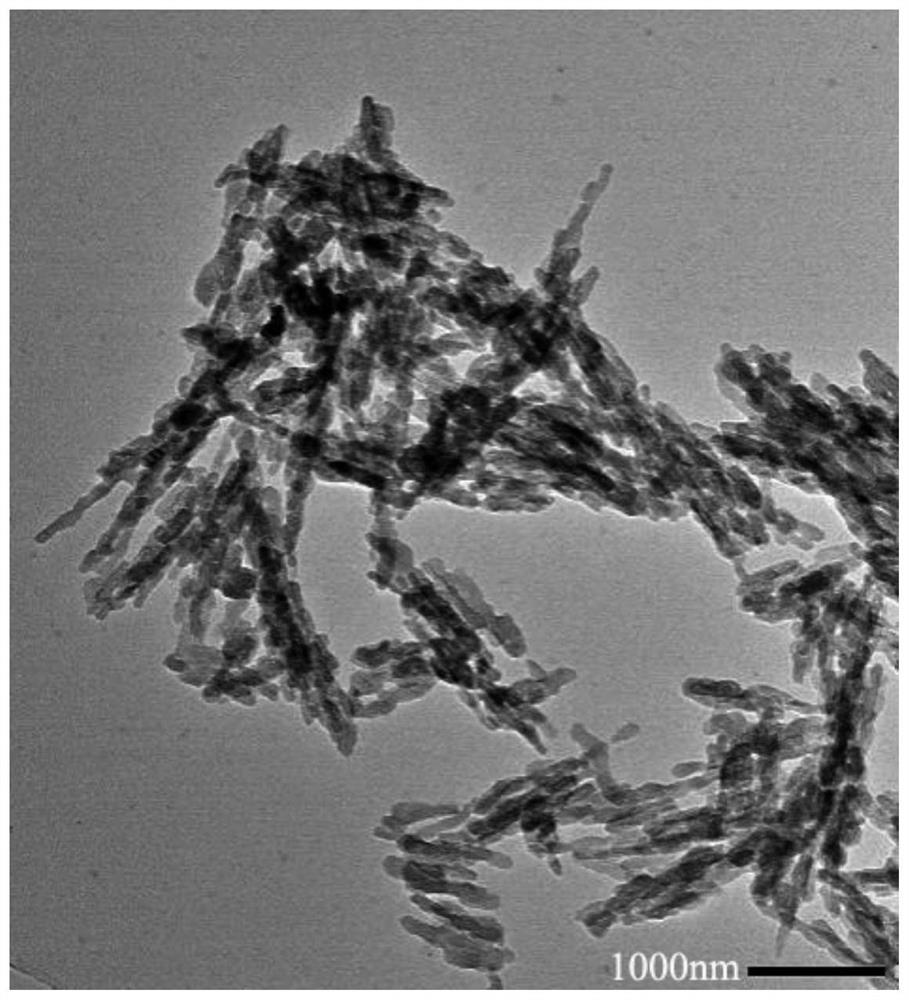

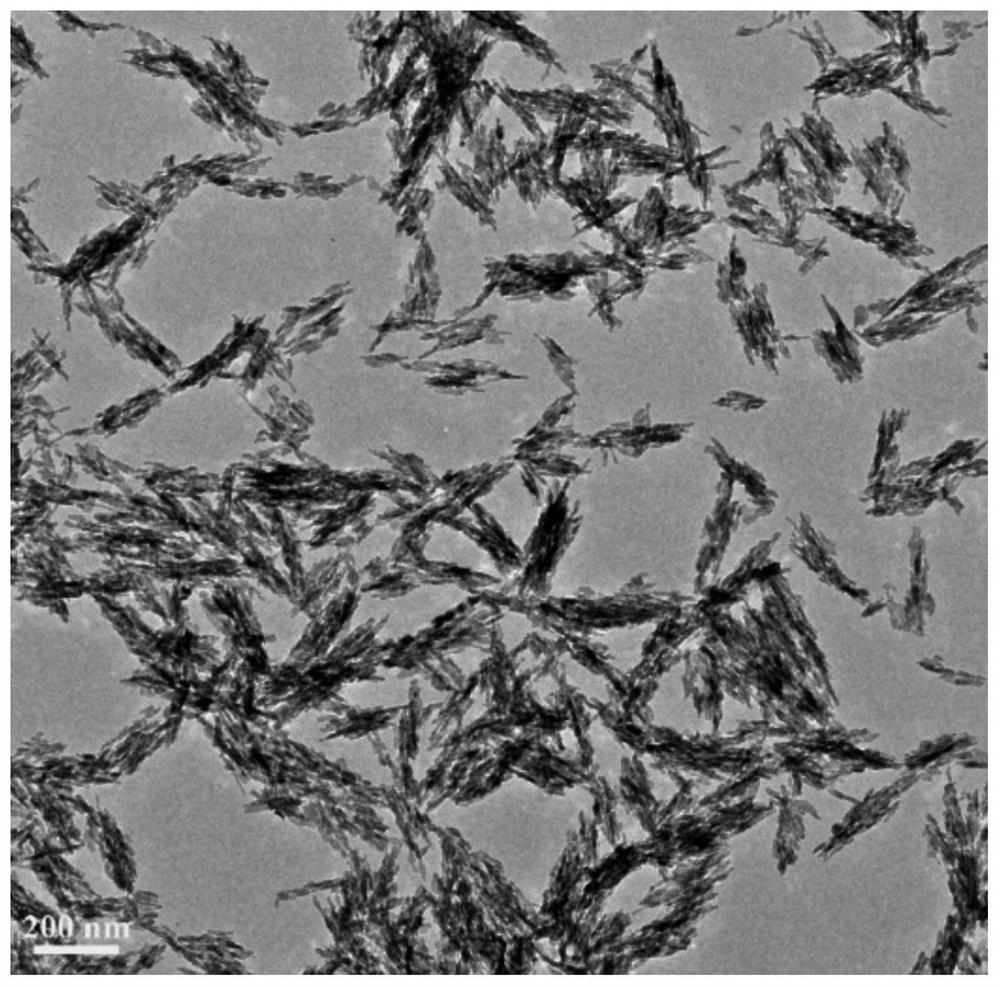

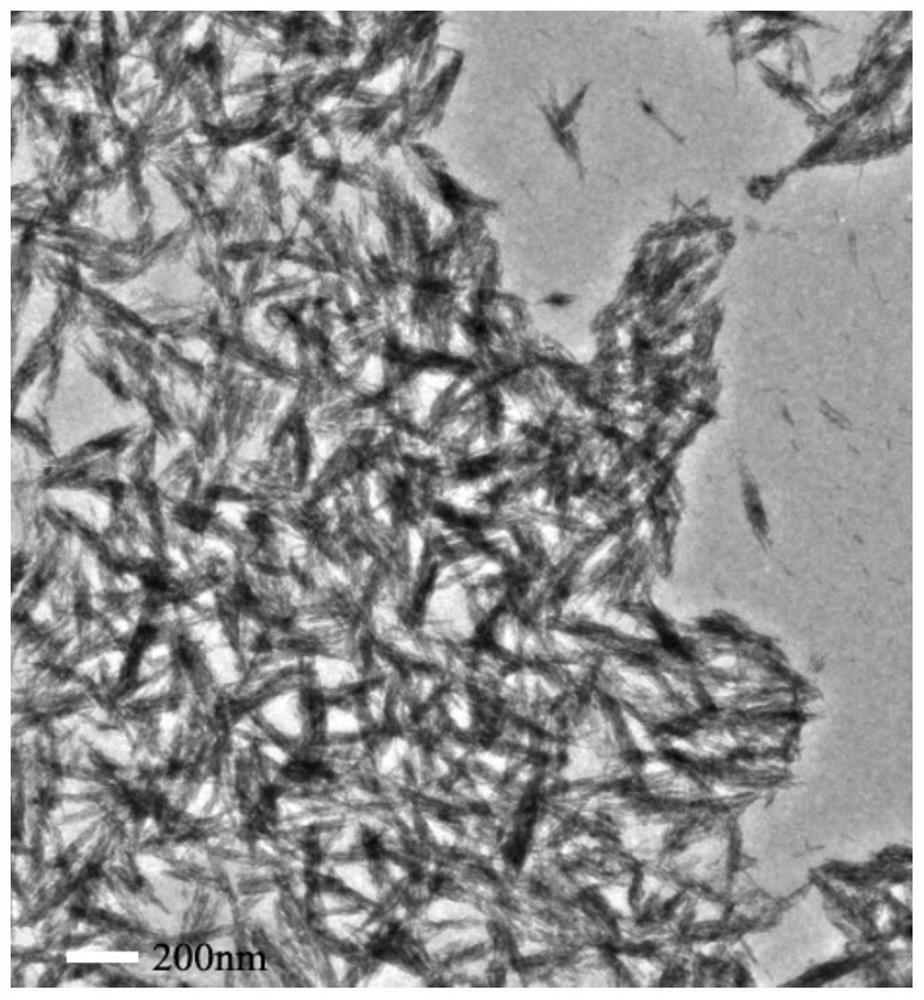

Regulation and control method and application of hydroxyapatite nanoparticle aggregate

ActiveCN113603933AIncrease mass concentrationGood dispersionMonocomponent synthetic polymer artificial filamentNon-woven fabricsEngineeringUltrasonic dispersion

The invention belongs to the technical field of materials, and discloses a regulation and control method and application of a hydroxyapatite nanoparticle aggregate. The regulation and control method comprises the following steps of: (a) dissolving polyacrylic acid, and regulating the pH value to be neutral or alkaline to obtain a polyacrylic acid solution; and (b) adding nano-hydroxyapatite into the polyacrylic acid solution in the step (a), and mixing under an ultrasonic condition to obtain the hydroxyapatite nanoparticle aggregate. According to the regulation and control method and application of the hydroxyapatite nanoparticle aggregate disclosed by the invention, by combining the ultrasonic dispersion with the polyacrylic acid, nano-hydroxyapatite is regulated to form a shuttle-shaped hydroxyapatite nano-particle aggregate in water, and the dispersity of theaggregate is high. The regulation and control method is simple and easy to implement and high in production efficiency. According to the hydroxyapatite nano-particle aggregate prepared by the regulation and control method, the compounding uniformity of nano-hydroxyapatite and a high polymer material can be remarkably improved, and a composite material with the nano-hydroxyapatite proportion as high as 75.4% is prepared.

Owner:佛山仙湖实验室

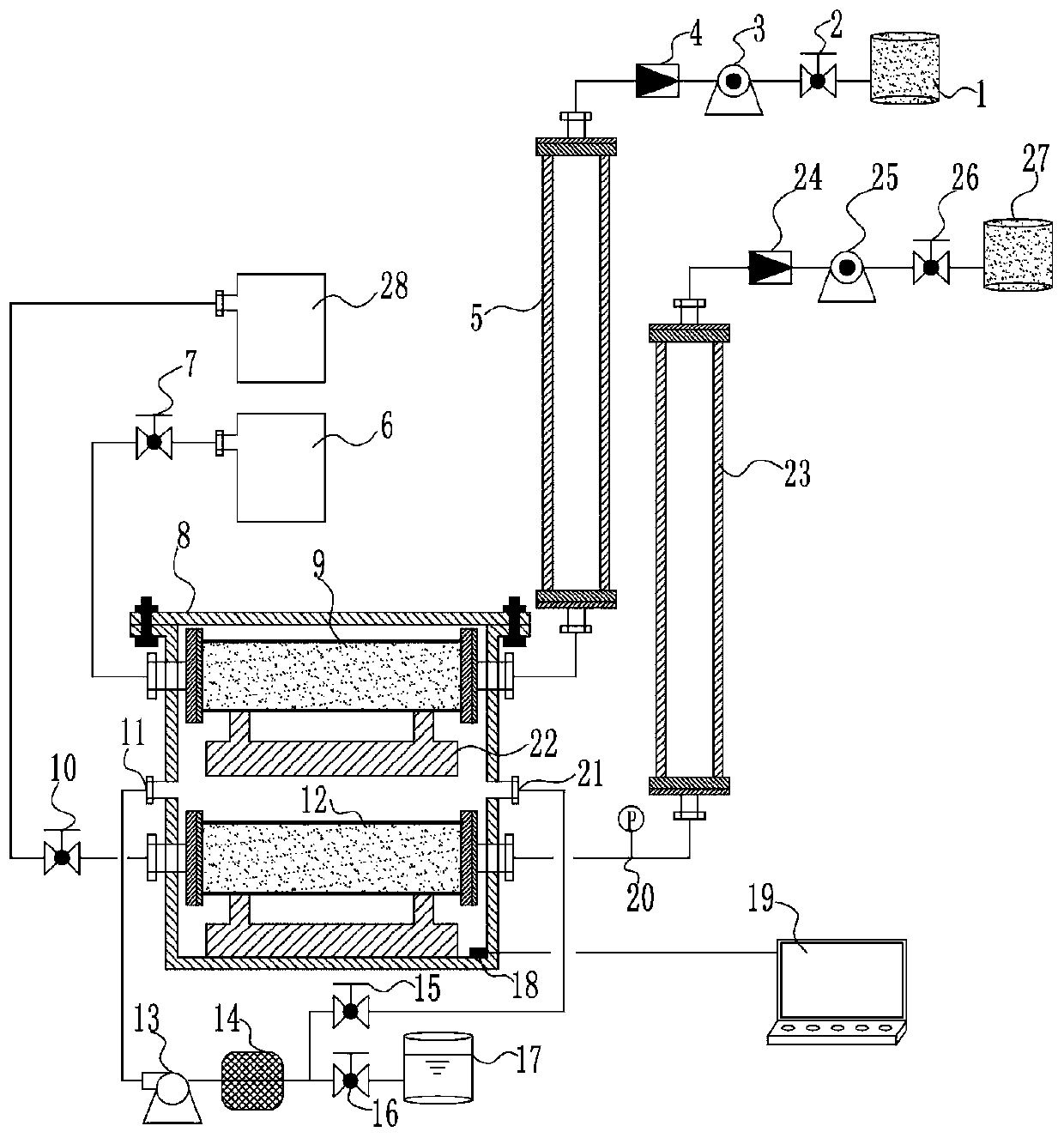

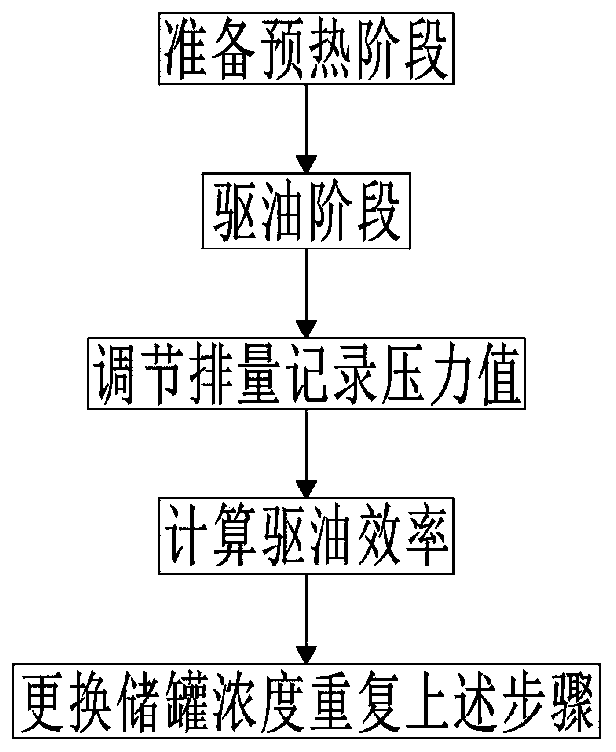

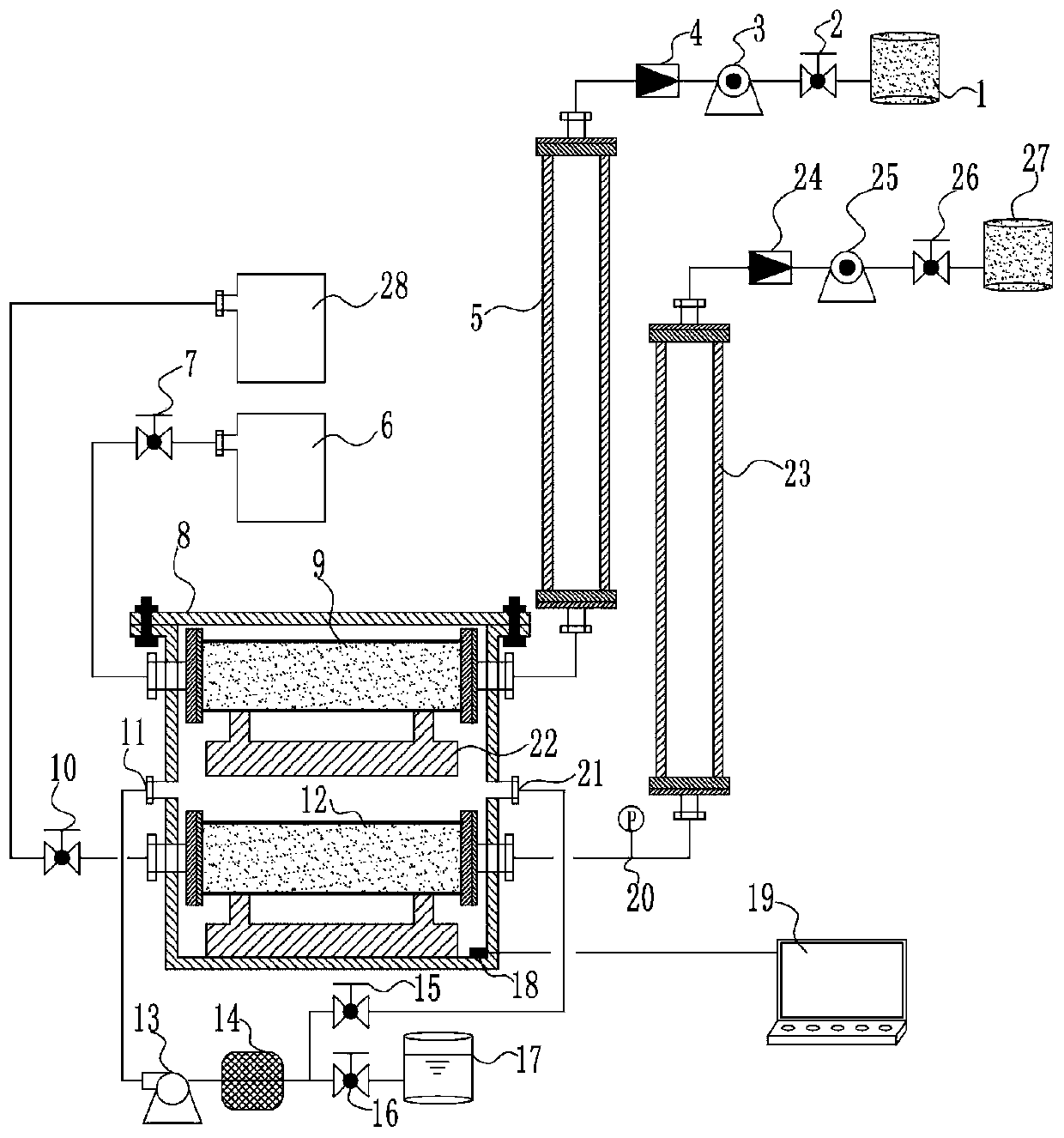

Device and method for measuring reinjection oil displacement of sulfur-containing sewage by using ultra-high molecular polymer

InactiveCN111175453AEasy to observeReduce mass concentrationMaterial analysisRock coreWater storage tank

The invention discloses a device and a method for measuring reinjection oil displacement of sulfur-containing sewage by using an ultra-high molecular polymer. A first ultra-high molecular polymer storage tank is sequentially connected with a first ball valve, a first pressure pump, a first ultrasonic flowmeter and a first PC pipe, and a second ultra-high molecular polymer storage tank is sequentially connected with a sixth ball valve, a second pressure pump, a second ultrasonic flowmeter and a second PC pipe; a first rock core and a second rock core are arranged in a PC box body, and a water storage tank and a fifth ball valve are connected in series, then connected with a fourth ball valve in parallel and then connected with a steam generator, a small screw pump and a hot steam inlet together. The method comprises the steps: 1, a preheating stage; 2, an oil displacement stage; 3, displacement adjustment and pressure value record; 4, oil displacement efficiency calculation; and 5, thechange of the concentration of the storage tank and the repeat of the above steps. The method is good in simulation effect, and the result provides guiding significance for the reinjection oil displacement of the sulfur-containing sewage by adopting the high-molecular polymer under actual working conditions on site.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com