A kind of preparation method of cellulose fiber

A cellulose fiber and cellulose technology, applied in the field of cellulose, can solve problems such as difficulty in realizing high-efficiency and low-consumption industrial production, unfavorable fiber homogeneity and mechanical properties, cumbersome equipment and process flow, etc., to achieve uniform and high-quality preparation , avoid repeated energy consumption problems, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

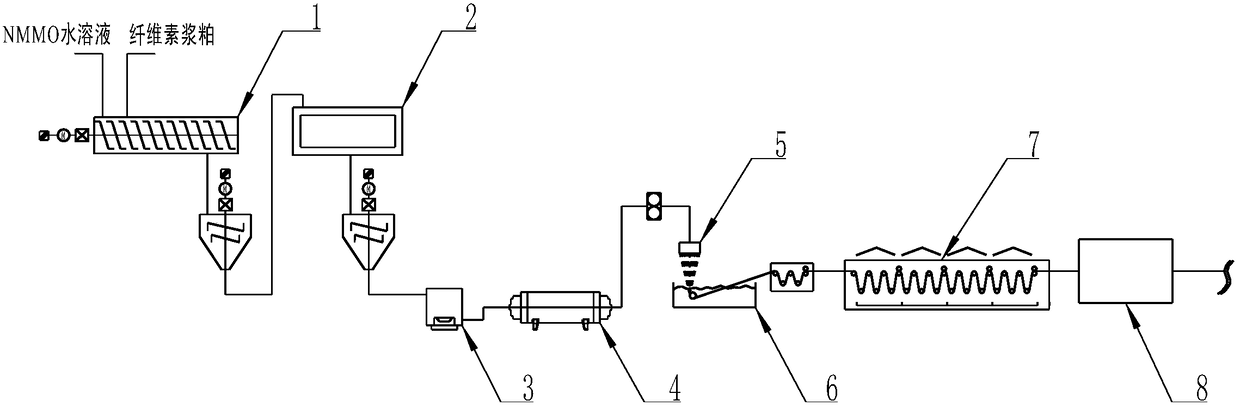

[0050] The NMMO aqueous solution with a mass concentration of 72% and the cellulose pulp without any treatment are directly and uniformly mixed, and mechanically stirred in the mixer 1 to obtain a uniform mixture. Among them, the pulp is mixed with high and low polymerization degrees of cellulose wood pulp, DP:800 and DP:450 wood pulp are mixed according to the mass ratio of 8:92, and the cellulose concentration is 12%.

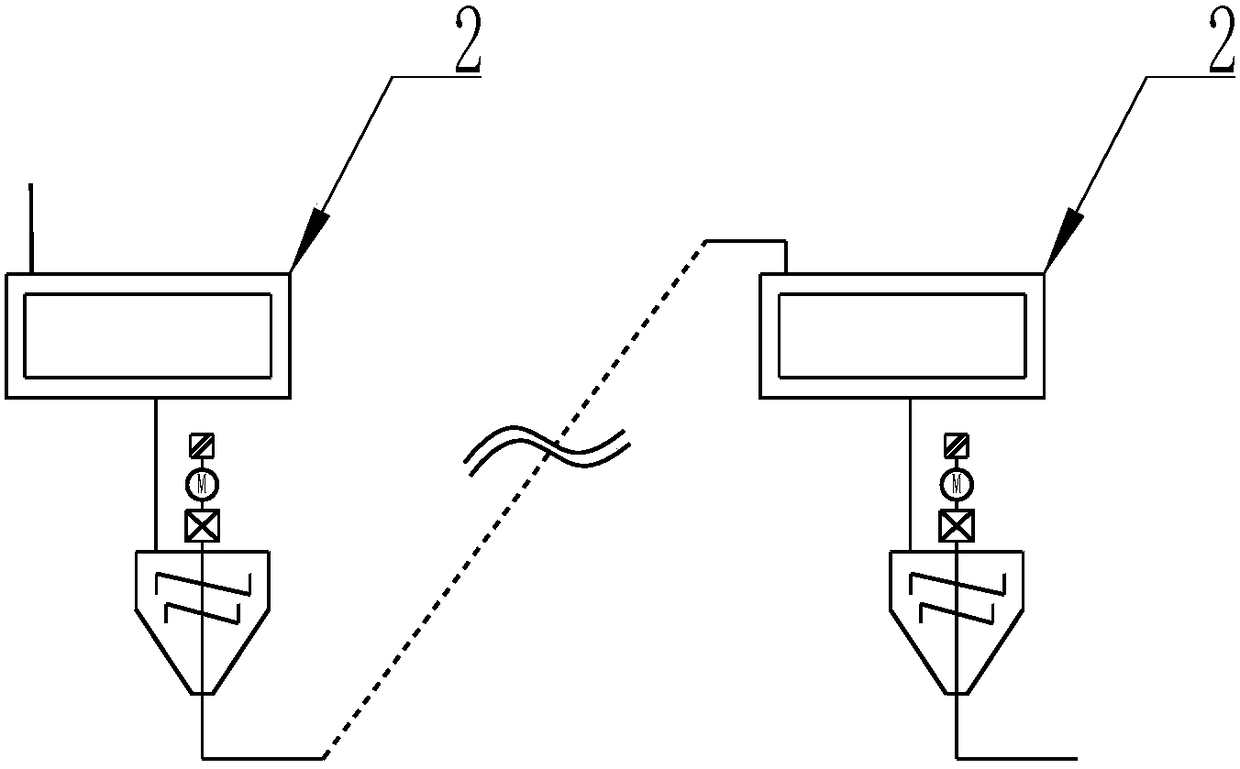

[0051] The obtained homogeneous mixture is fully swollen, dissolved and defoamed through continuous two-step evaporation dehydration in the dehydration device 2 to obtain the cellulose spinning stock solution, such as image 3 shown. The first step of evaporative dehydration process is mainly a process of full swelling and mixing, and the residence time is 20 minutes; the second step of evaporative dehydration process mainly removes excess water to dissolve cellulose into a homogeneous solution, which is the spinning stock solution. The refraction of the spi...

Embodiment 2

[0057] Cellulose fiber is prepared according to the same conditions as in Example 1, except that:

[0058] The NMMO aqueous solution with a mass concentration of 76% is fed; the pulp is mixed with cellulose wood pulp DP:400 and bamboo pulp DP:300, the mixing ratio is 52:48, and the cellulose concentration is 16%. Gained homogeneous mixture obtains cellulose spinning dope through continuous three-step evaporation dehydration in dehydration device 2, such as image 3 As shown, the residence time of the first two steps is 9min, the refraction of the spinning dope is 1.48623, and the viscosity is 2849Pa·S.

[0059] The prepared spinning dope heat exchange equipment 4 is heat exchanged to 95°C, and after being extruded through the spinneret assembly, it enters the coagulation system 6, and the coagulation system is a three-stage coagulation system, such as Figure 4 shown. The concentration of NMMO in the primary coagulation bath is 70%, and the temperature is 35 °C; the concentr...

Embodiment 3

[0064] Cellulose fiber is prepared according to the same conditions as in Example 1, except that:

[0065] The NMMO aqueous solution with a mass concentration of 74% is used for feeding; the pulp is cellulose wood pulp, DP: 300, and the cellulose concentration is 18%. Gained homogeneous mixture obtains cellulose spinning dope through continuous two-step evaporation dehydration in dehydration device 2, such as image 3 As shown, the residence time of the first step is 25min, the refraction of the spinning dope is 1.48714, and the viscosity is 2415Pa·S.

[0066] The prepared spinning stock solution is heat-exchanged to 90°C through the heat exchanger 4, and after being extruded through the spinneret assembly, it enters the coagulation system 6, and the coagulation system 6 is a three-stage coagulation system, such as Figure 4 shown. The concentration of NMMO in the primary coagulation bath is 65%, and the temperature is 30°C; the concentration of NMMO in the secondary coagula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refraction | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com