High-adsorption electronic-grade ammonia water manufacturing system

A manufacturing system and electronic-grade technology, which is applied in the field of manufacturing electronic-grade ammonia water, can solve the problems of low metal ion content, ammonia water impurities and energy consumption of multiple equipment, and achieve the effects of simple preparation process, good directional adsorption, and excellent and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

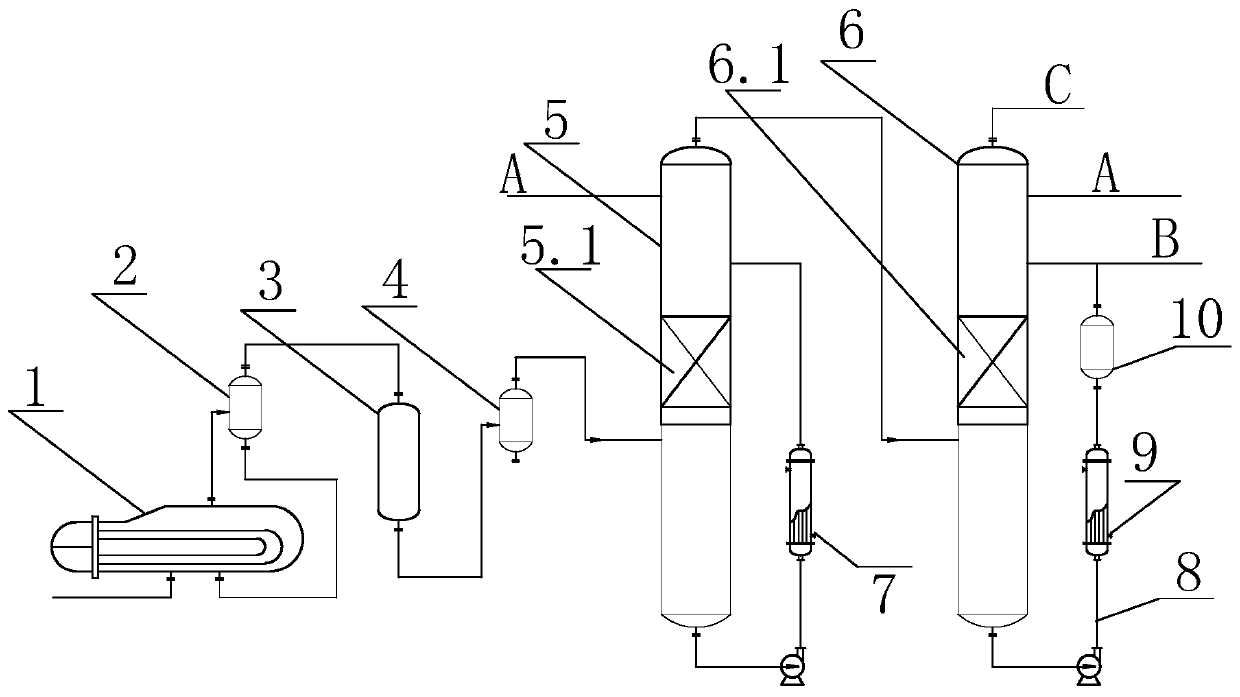

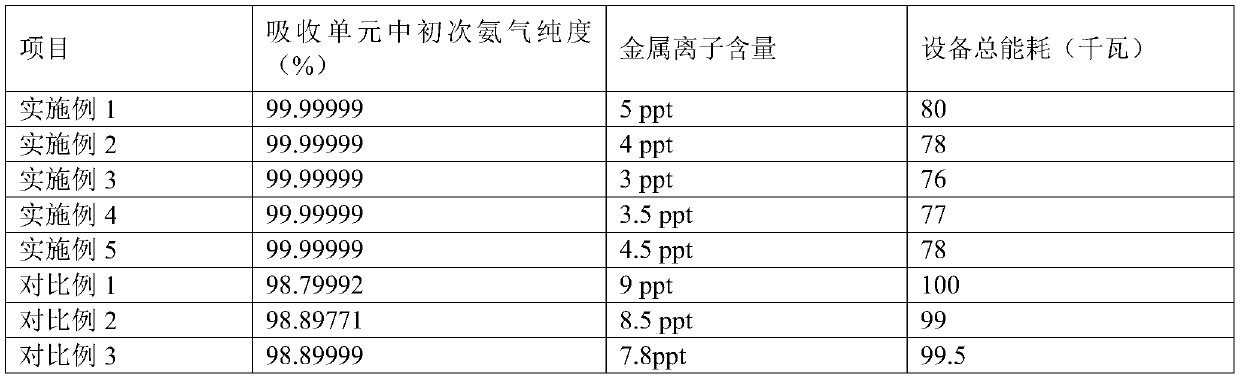

[0040] A high-adsorption electronic-grade ammonia production system method is characterized in that it includes an evaporator 1, a first gas-liquid separator 2, an adsorption unit 3, a second gas-liquid separator 4, a washing unit 5 and an absorption unit 6, the above-mentioned The devices are connected in sequence, the adsorption unit 3 is provided with a modified adsorption material, and the washing unit 5 is provided with a washing packing area 5.1, and the washing packing area 5.1 is located between the inlet and the outlet of the washing unit 5 , An absorption packing area 6.1 is provided between the inlet and the outlet inside the absorption unit 6 . A first circulation unit 7 is provided outside the washing unit 5, one end of the first circulation unit 7 is connected to the bottom of the washing unit 5, and the other end is connected between the washing packing area 5.1 and the outlet of the washing unit 5. A circulation loop 8 is arranged outside the absorption unit 6,...

Embodiment 2

[0049] The difference with Example 1 is that the modified adsorption material is permanent magnetic chitosan modified activated carbon, and its preparation method includes: (1) Activated activated carbon: adding activated carbon to 60 ℃ deionized water for 0.6h, and then adding activated carbon Put it into a nitric acid solution with a mass content of 11% for activation for 22 minutes, wash it with deionized water and set aside;

[0050] (2) Preparation of magnetic chitosan gel: Chitosan is placed in a container, acetic acid with a mass fraction of 4.5% is added, heated in a water bath at 32°C for 42min, and mechanically stirred at 860rpm at the same time, then 3,5 -Dimethyl-2-pyrrole formaldehyde, while the temperature rises to 66°C at 2.5°C / min, and the temperature is stirred at 1300rpm for 6.2h at a constant temperature, and then Fe is added to the solution 3 o 4 -Rare earth magnet nanoparticles, stirring at 820rpm for 0.9h at room temperature to obtain a uniform magnetic ...

Embodiment 3

[0054] The difference with Example 1 is that the modified adsorption material is a permanent magnetic chitosan modified activated carbon, and its preparation method comprises:

[0055] (1) Activation of activated carbon: Add activated carbon to 60°C deionized water for 0.7h, then put the activated carbon into a nitric acid solution with a mass content of 12% to activate for 25min, wash with deionized water and set aside;

[0056] (2) Preparation of magnetic chitosan gel: Chitosan is placed in a container, acetic acid with a mass fraction of 5% is added, heated in a water bath at 35°C for 45min, and mechanically stirred at 880rpm at the same time, then 3,5 -Dimethyl-2-pyrrole formaldehyde, at the same time the temperature rises to 68°C at 3°C / min, and the constant temperature is stirred at 1350rpm for 6.5h, and then Fe is added to the solution 3 o 4 -Rare earth magnet nanoparticles, stirring at 850rpm for 1.0h at room temperature to obtain a uniform magnetic chitosan gel solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com