Regulation and control method and application of hydroxyapatite nanoparticle aggregate

A hydroxyapatite and nano-hydroxyapatite technology, applied in the field of materials, can solve the problem of long (usually dozens of hours, at least ten hours), and low production efficiency of hydroxyapatite nanoparticle aggregates. and other problems, to achieve the effect of simple and easy control method, shortened control period and high degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

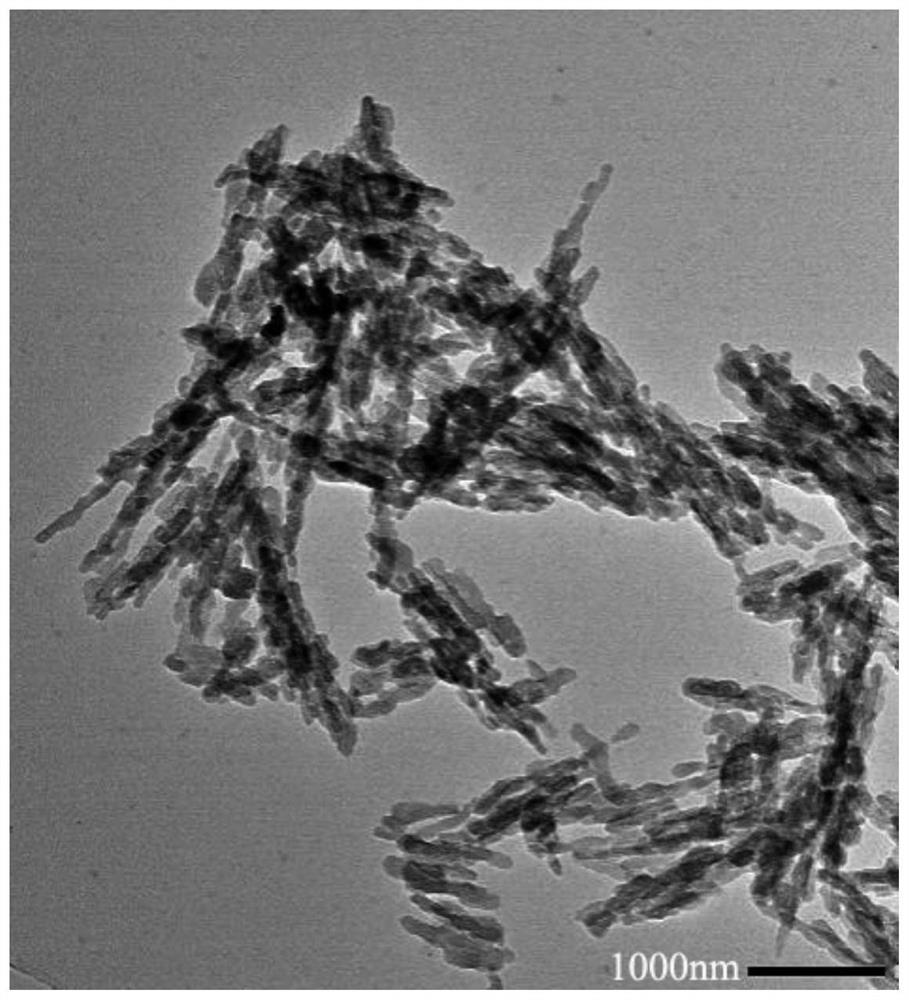

[0045] Preparation of nano-hydroxyapatite: first, prepare 0.0668mol / L calcium chloride aqueous solution and 0.04mol / L diammonium hydrogen phosphate aqueous solution respectively. Then, quickly pour 100 mL of diammonium hydrogen phosphate aqueous solution into 100 mL of calcium chloride aqueous solution under vigorous stirring, and adjust the pH value to 10-11 by adding ammonia water dropwise. After reacting with magnetic stirring at 80° C. for 60 minutes, the mixture was centrifuged and washed three times to remove impurity ions, and a white precipitate was obtained, which was lyophilized for use. The white precipitate is rod-shaped nano-hydroxyapatite particles, and its transmission electron microscope picture is shown in figure 1 ,Depend on figure 1 It can be seen that the diameter of nano-hydroxyapatite particles is 10-15 nm, and the length is 30-60 nm.

Embodiment 2

[0047] A method for regulating hydroxyapatite nanoparticle aggregates, comprising the following steps:

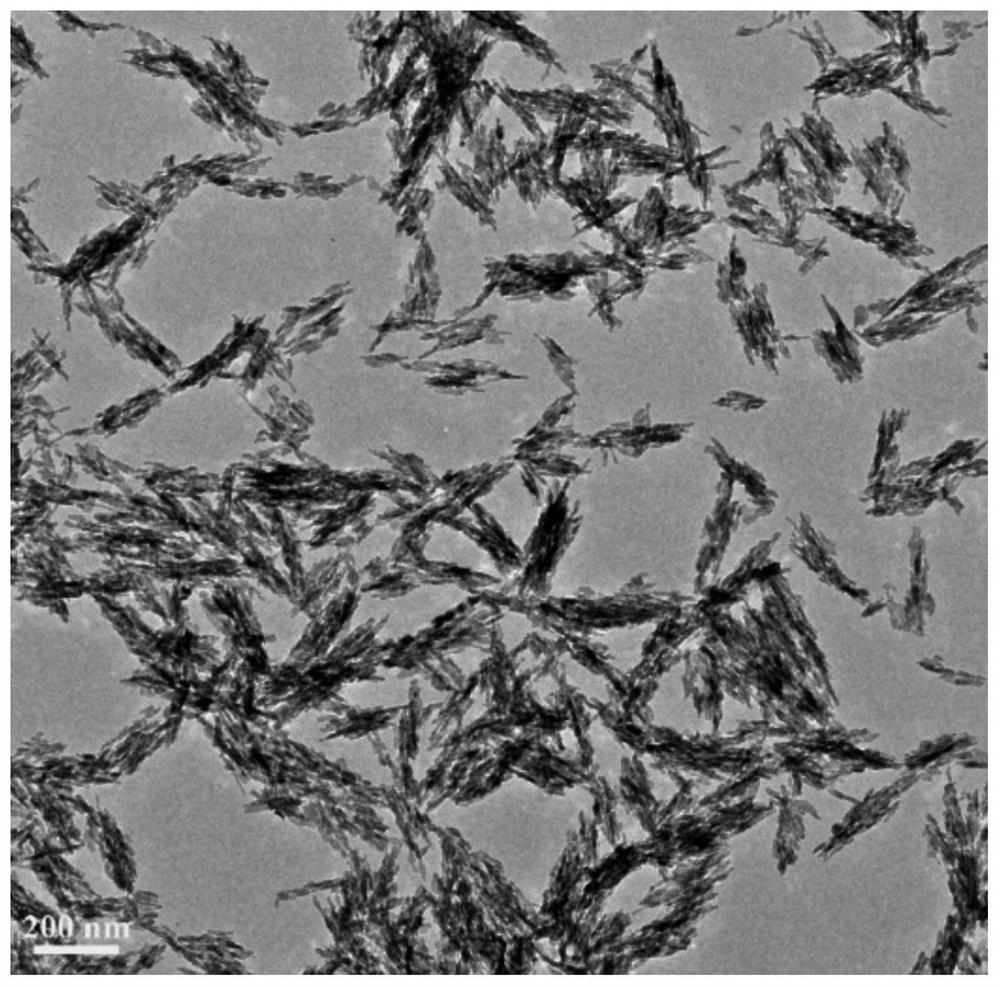

[0048] Dissolve polyacrylic acid (PAA) powder in water, adjust its pH value to 8 with sodium hydroxide, and prepare an acrylic acid solution with a concentration of 0.2 g / L. Weigh 134.0 mg of nano-hydroxyapatite particles (HAP) prepared in Example 1, add them to 20 mL of acrylic acid solution, and use 600W power ultrasonic dispersion for 5 minutes to obtain a suspension (that is, hydroxyapatite nano particle aggregates). The molar ratio of PAA / HAP in the suspension was 0.01665, and the mass concentration of nano-hydroxyapatite particles was 6.7g / L. figure 2 is the transmission electron microscope image of the hydroxyapatite nanoparticle aggregates, such as figure 2 As shown, the nano-hydroxyapatite particles in the suspension are in the form of shuttle-type aggregates, the central diameter of which is 77.8±17.1nm, and the length is 278.6±53.0nm.

Embodiment 3

[0050] A method for regulating hydroxyapatite nanoparticle aggregates, comprising the following steps:

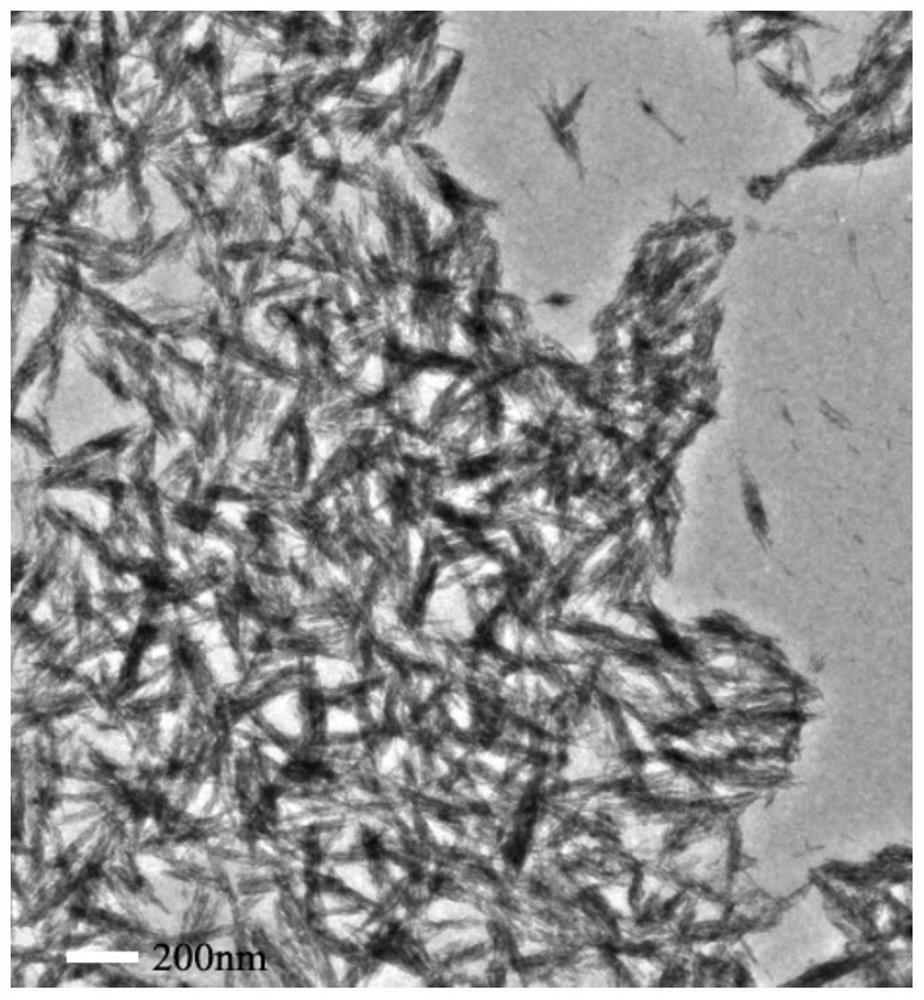

[0051] Dissolve polyacrylic acid (PAA) powder in water, adjust its pH value to 7 with sodium hydroxide, and prepare a PAA solution with a concentration of 0.6 g / L. Weigh 134.0mg of the nano-hydroxyapatite particles (HAP) prepared in Example 1, add it to 20mL of PAA solution, and use 600W power ultrasonic dispersion treatment for 5 minutes to obtain a suspension (that is, the aggregation of hydroxyapatite nanoparticles) body). The molar ratio of PAA / HAP in the suspension was 0.05, and the mass concentration of nano-hydroxyapatite particles was 6.7g / L. image 3 is the transmission electron microscope image of the hydroxyapatite nanoparticle aggregates, such as image 3 As shown, the nano-hydroxyapatite particles in the suspension are in the form of shuttle aggregates, the central diameter of which is 55.2±9.6nm, and the length is 284.5±47.9nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com