Patents

Literature

71results about How to "Reduce mass concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

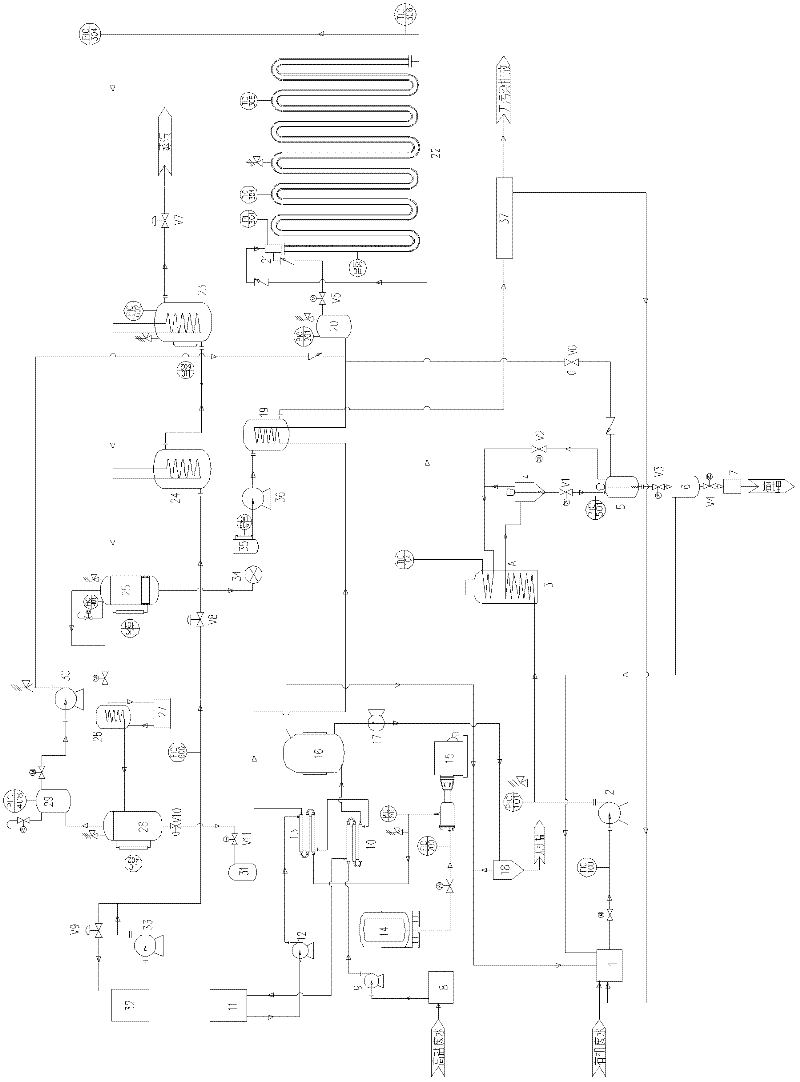

Supercritical water oxidization treatment system for high-salinity organic waste water

InactiveCN102642947AGuaranteed heat transfer coefficientAvoid cloggingSolidificationLiquefactionCycloneReaction temperature

The invention discloses a supercritical water oxidization treatment system for high-salinity organic waste water. The high-salinity waste water is subjected to cooling crystallization through cold energy of liquid oxygen to reduce mass concentration of inorganic salt in the waste water; a large amount of solid salt grains separated out from the waste water are removed by using a hydraulic cyclone device under a supercritical water condition to effectively prevent a subsequent pipeline and a reactor of the hydraulic cyclone device from plugging; and a desalting device is arranged at the lower part of the hydraulic cyclone device to continuously remove the inorganic salt from the system. In addition, excessive oxygen and CO2 product gas are recovered through a separation recovery part; the reaction time and the reaction temperature of supercritical water oxidization are reduced through arranging a simple subsequent treatment unit; and the system recovers heat energy of the reacted high-temperature fluid in a steam mode through the arrangement of a water softening device, so that the operation cost of the system is reduced. The system can be widely applied to the innocent treatment process of the high-salinity organic waste water.

Owner:XI AN JIAOTONG UNIV +1

Slurry disperse dye and preparation method and appliance

The invention discloses a slurry disperse dye and a preparation method and an appliance, wherein the slurry disperse dye comprises liquid disperse dyes, functional prepolymers and synthetic thickeners, the synthetic thickeners and functional additives are added into the slurry disperse dye to prepare trace printing paste, and can complete printings of polyester fabrics on a common rotary screen printing machine or a screen printing machine, then printed polyester fabrics are prepared through a heat-setting stenter in 180 DEG C-210 DEG C for 45-120s. The slurry disperse dye has the advantages of short printing process when being used for polyester fabric printings, is soft in fabric handing, does not need post process, saves a lot of water and energy consumption, nearly does not have discharge amount of waste water, uses common equipment as process equipment, and is a green printing process technology.

Owner:SUZHOU UNIV

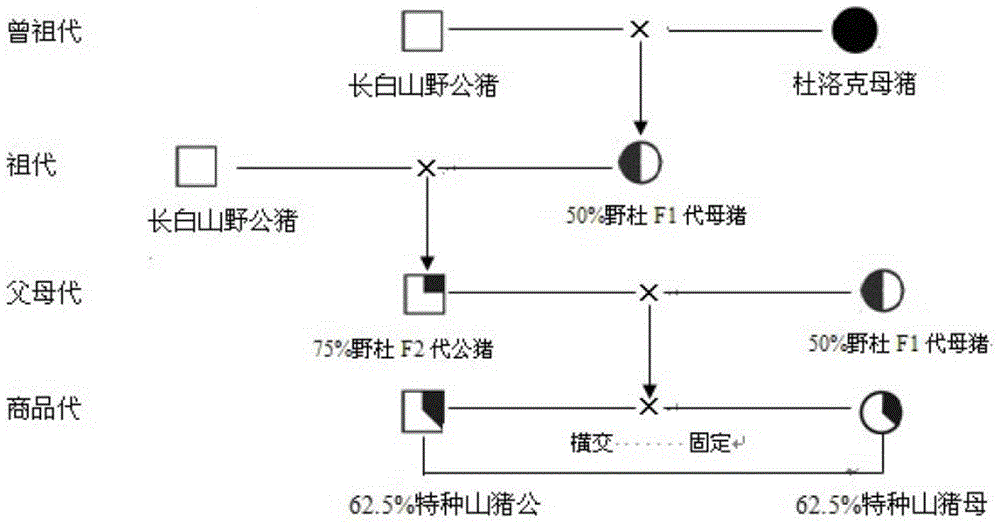

Sow feeding method of special wild pig

The invention relates to a sow feeding method of a special wild pig. The method comprises the following steps: (1) feeding sows to reach sexual maturity when the sows are 6-7 months old and are 75-80 kg weight and reach body maturity when the sows are 7-8 months old and 80-90 kg weight and mating the sows; feeding and mating 4-6 non-pregnant sows in each pigsty; feeding each sow at the first trimester of pregnancy in a limiting pigsty or in an independent pigsty, 2-4 sows at the mid trimester of pregnancy in each pigsty and 1-2 sows at the later trimester of pregnancy in each pigsty, and feeding the sows on obstetric tables from 7 days before parturition to weaning; (2) reinforcing sow feeding management, meeting nutritional requirements in the non-pregnant to-be-mating period, the first trimester of pregnancy, the mid trimester of pregnancy, the later trimester of pregnancy and the suckling period, preparing daily rations for the different periods, feeding different feeds, and paying attention to rational matching of green and coarse fodders and concentrated feeds. According to the sow feeding method, the feed and the control for feeding are optimized, so that the sows rut quickly, the farrowing rate is high, normally 12-14 piglets are born by each sow, and the survival rate is over 90 percent.

Owner:四川惠远农牧科技有限公司

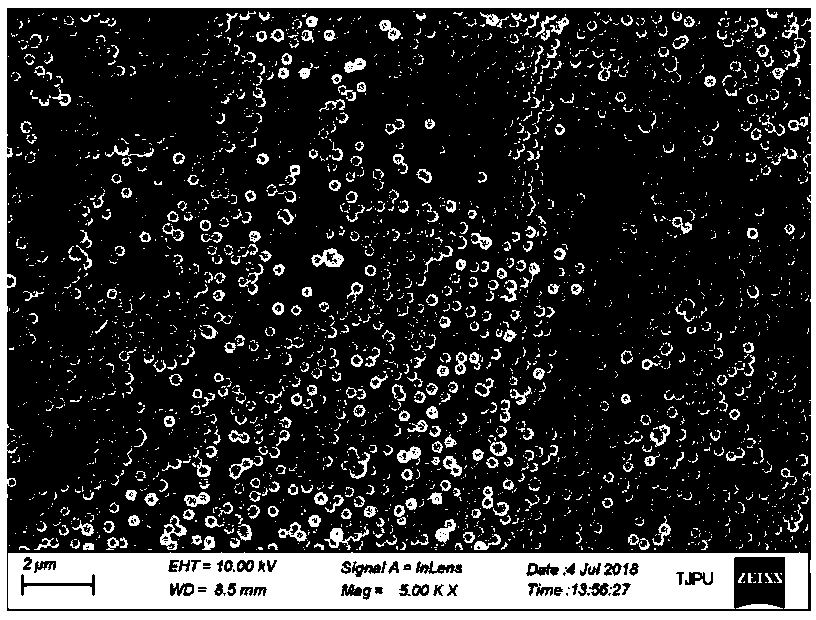

Wetting-resisting super-hydrophobic membrane and preparation method thereof

ActiveCN109012199AImprove hydrophobicityReduce infiltrationMembranesDistillationNanoparticleWater production

The invention relates to a wetting-resisting super-hydrophobic membrane and a preparation method thereof. Combined nanoparticles are coated with a low surface energy solution to form a rough structure, and a PDMS-SiO2-PDMS sandwich compound layer is formed on the surface of the membrane. The compound layer has the advantages of rough structure and low surface energy, the membrane has super hydrophobicity, and the membrane further has high wetting resistance in a membrane distilling process. The membrane can be utilized to perform direct contact type membrane distillation to treat a water bodycontaining a surface active agent, so that membrane distillation operation time is obviously prolonged, stable operation time is 20 times or more of that of a PVDF original membrane, and water production capacity can be improved by 15 times or more.

Owner:TIANJIN POLYTECHNIC UNIV

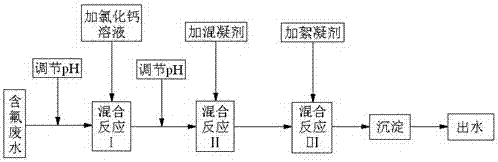

Treatment method of fluorine-containing wastewater

InactiveCN107162253AReduce mass concentrationImprove settlement performanceWater contaminantsMultistage water/sewage treatmentLow speedWastewater

The invention discloses a treatment method of fluorine-containing wastewater. The treatment method comprises the following steps: (100) adding a sodium hydroxide solution or a hydrochloric acid solution into the fluorine-containing wastewater to be treated to adjust the pH value of the fluorine-containing wastewater; (200) performing mixing reaction I: adding a calcium chloride solution into the fluorine-containing wastewater with the adjusted pH value according to [Ca<2+>] / [F<->]=1.5 to 2, and stirring the solution at medium speed for 27 to 32 minutes; (300) performing mixing reaction II: adjusting the pH value again to 7.5, adding a coagulant, and stirring the solution at medium speed for 8 to 12 minutes; (400) performing mixing reaction III: adding a flocculant, and stirring the solution at low speed for 8 to 12 minutes; and (500) precipitating the solution for 1 hour, and discharging the water. Due to the mode, the mass concentration of residual fluorine ions in the wastewater can be reduced to 10 mg / l or below, a relatively precipitating effect is achieved, and the environmentally-friendly discharging standard can be met.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS

Trace amount of printing paste and preparation method and application thereof

ActiveCN105113284AReduce water consumptionReduce sewage dischargeDyeing processPrepolymerEnergy consumption

The invention discloses a trace amount of printing paste and a preparation method and application thereof. The printing paste is composed of liquid disperse dyes, a function prepolymer, a synthetic thickener, a functional addition agent and water. The trace amount of prepared printing paste can finish printing of a polyester fabric on a conventional rotary screen printing machine or a screen printing machine; high-temperature processing is performed through a tentering heat setting machine, the temperature is 180-210 DEG C, the time is 45-120 seconds, and a polyester printing fabric is prepared. The printing paste is used for printing and is characterized in that the printing process is short, the fabric is soft in touch, afttertreatment is not needed, plenty of water resources are saved, plenty of energy consumption is reduced, and there is almost no waste water emission. Processing devices are all conventional devices, and the preparation method is a green printing processing technology.

Owner:SUZHOU UNIV

Function prepolymer and preparation method and application thereof

The invention discloses a function prepolymer and a preparation method and application thereof. The function prepolymer is a butyl acrylate polymer and prepared from a monomer, modified matter and an emulsifying agent through emulsion polymerization. A synthetic thickener, liquid disperse dye and the function prepolymer are mixed with water and evenly stirred to obtain printing paste; printing and drying of a polyester fabric are achieved through the obtained printing paste on a rotary screen printing machine or a mobile screen printing machine, then high-temperature processing is carried out on a tentering heat setting machine, and a printed polyester fabric is obtained. According to the technical scheme, the printing process is short, the hand feeling of the fabric is soft, postprocessing is not needed, a large amount of water and energy are saved, almost no wastewater is drained, processing equipment is conventional, and the printing processing technology is environmentally friendly.

Owner:SUZHOU UNIV

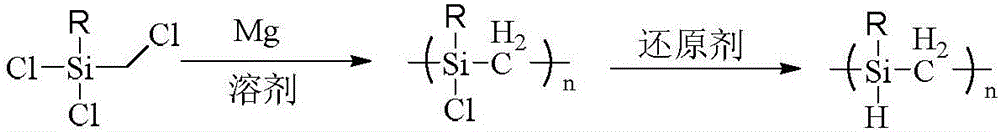

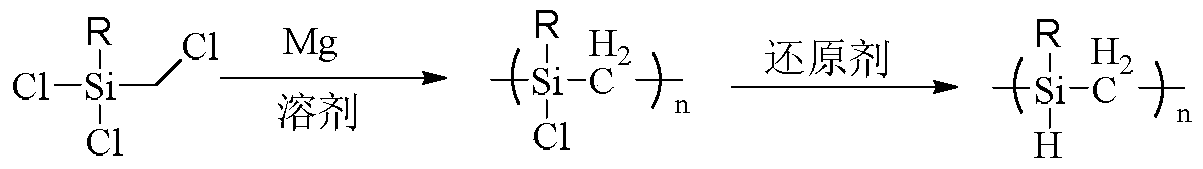

Preparation method of polycarbosilane

The invention relates to the technical field of organosilicon and provides a preparation method of polycarbosilane in order to solve the problems in polycarbosilane preparation at present. The preparation method is characterized by taking chloromethyl chlorosilane as a raw material, synthesizing a polycarbosilane intermediate in an organic solvent and then preparing the polycarbosilane by using a reducing agent. The preparation method provided by the invention has the advantages that the operation is convenient, and the time is shortened; meanwhile, the number-average molecular weight of the prepared polycarbosilane is higher, and the demands of preparing an organic functional material can be met.

Owner:湖南昌威新材料科技有限公司

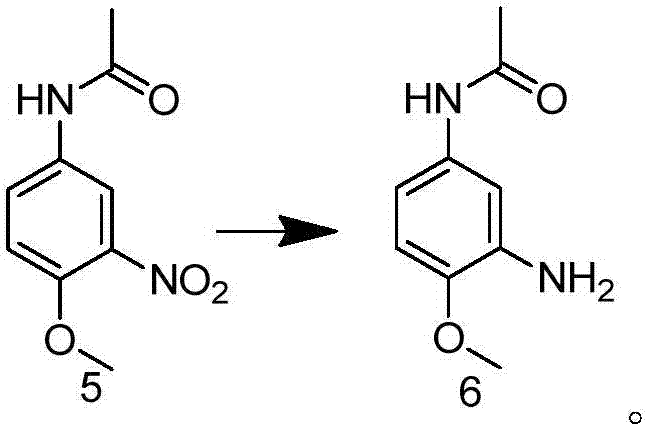

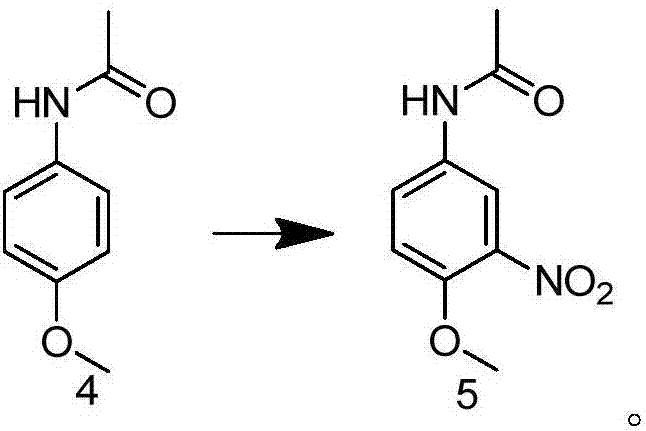

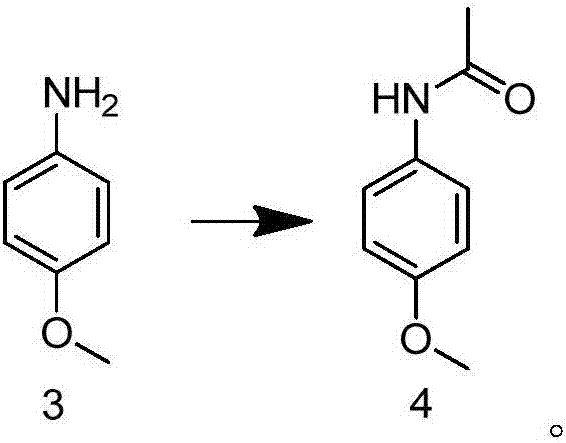

Preparation method of 2-methoxy-5-acetamidoaniline

InactiveCN107286043AEasy to recycleReduce pollutionOrganic compound preparationCarboxylic acid amides preparationHydrogenReaction temperature

The invention discloses a preparation method of 2-methoxy-5-acetamidoaniline. The preparation method comprises the following step: in a solvent, under the action of a catalyst Pd / C, performing a reduction reaction as shown below on a compound as shown in a formula 5 and hydrogen to obtain a compound as shown in a formula 6. The preparation method is low in pollution, high in yield rate, low in cost, convenient in catalyst or solvent recycling, short in reaction time, low in reaction temperature, high in safety and mild in reaction condition.

Owner:SHANGHAI ANOKY GRP +1

Method for preparing polymeric aluminum iron flocculating agent from wire rope acid sludge

ActiveCN105174405AHigh recovery rateReduce mass concentrationSludge treatmentWaste water treatment from metallurgical processSludgeIon exchange

The invention discloses a method for preparing a polymeric aluminum iron flocculating agent from wire rope pickling sludge (acid sludge). According to the method, hydrochloric acid and sulfuric acid are used as extracting agents to extract metal iron ions and aluminum ions from calcium sludge and sodium sludge respectively, lead ions are removed by ion exchange resin, and the extraction liquid is further processed to obtain the polymeric aluminum iron flocculating agent, so that resource utilization of the calcium sludge and the sodium sludge is realized; cement is added to calcium sludge residues and sodium sludge residues for solidifying, so that stabilization and harmlessness of heavy metals in the residues are realized; and deionized water is used for regenerating saturated ion exchange resin, and a sodium hydroxide solution is used for treating wastewater generated in the regeneration process to realize standard discharge of the wastewater. The method has recovery rate of more than 90% for iron and aluminum in the acid sludge; and the flocculating agent has excellent purification performance for domestic wastewater.

Owner:刘阳生

Continuous crystallization process for preparing nitroguanidine through nitric acid method

InactiveCN104860849AEmission reductionNo importOrganic chemistryOrganic compound preparationNitroguanidineFiltration

The invention relates to a continuous crystallization process for preparing nitroguanidine through a nitric acid method. The process is applied to continuous crystallization for preparing single-compound explosive nitroguanidine and belongs to the technical field of preparation processes of explosives and powder. According to the process disclosed by the invention, the nitroguanidine is dissolved in a nitric acid solution, the synthetic process is optimized by virtue of a micro-tube reactor, the requirement of the reaction system on the nitric acid concentration is reduced, and the product yield is improved. A continuous crystallizer and a filter are arranged behind the micro-tube reactor, the continuous crystallization and filtration process is established, the manual operation is reduced, and the production efficiency of the product is improved; and moreover, with the adoption of ultrasonic oscillating and washing, the washing frequency is reduced, and wastewater emission is reduced. The process disclosed by the invention has the advantages of simplicity, high continuity, high product yield, small wastewater emission amount and the like and is particularly suitable for continuous crystallization for preparing single-compound explosive nitroguanidine.

Owner:XIAN MODERN CHEM RES INST

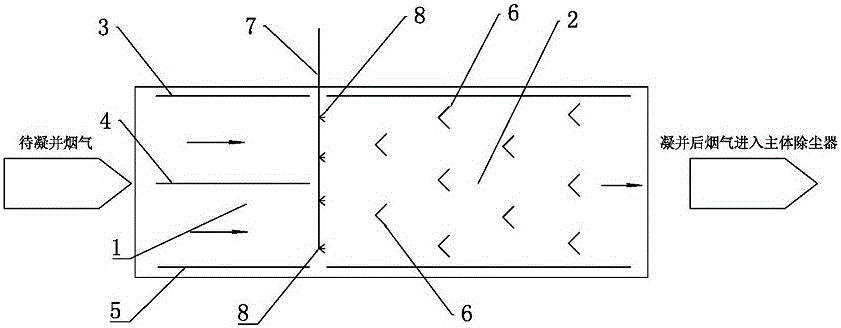

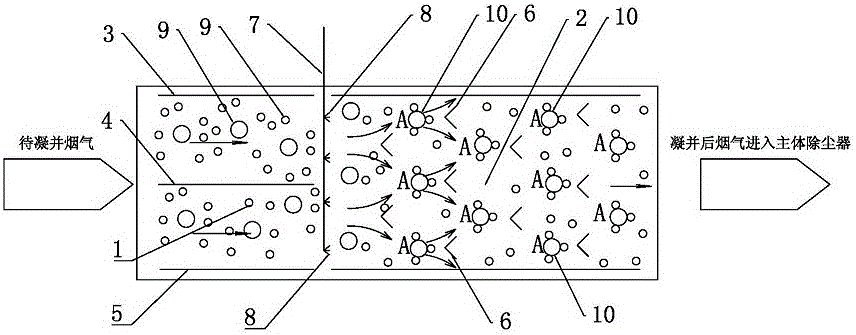

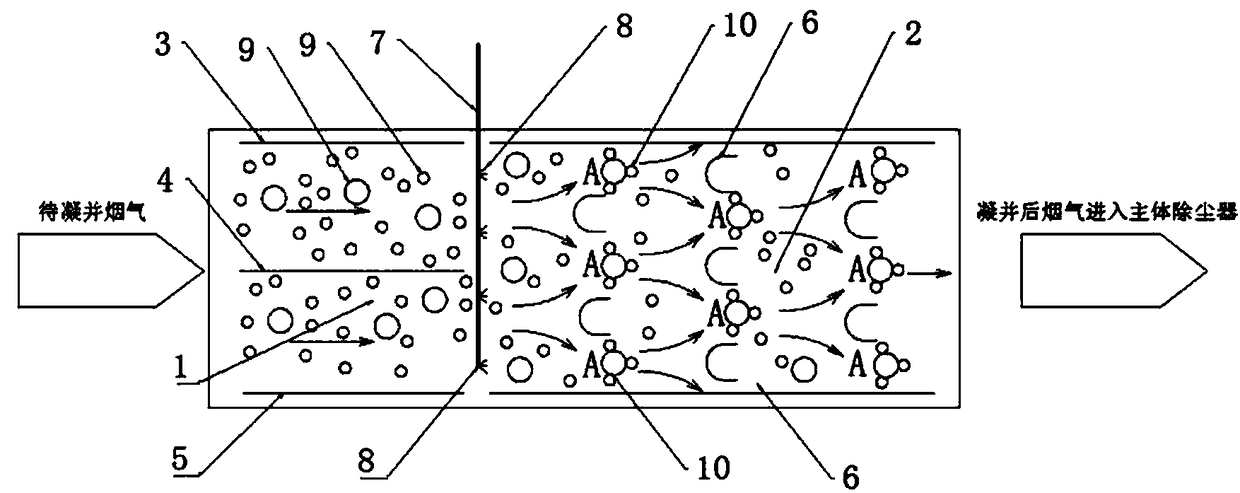

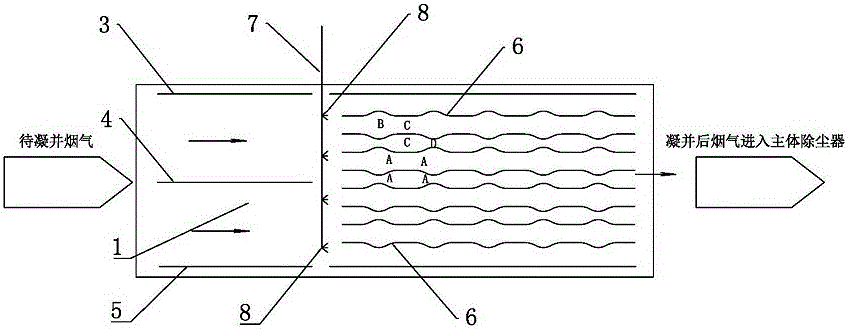

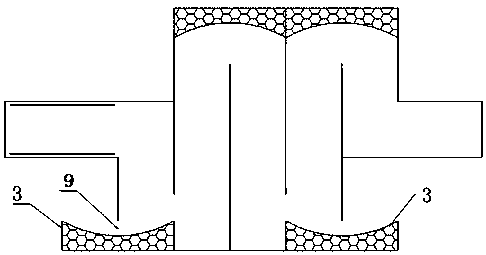

Angle-shaped pipeline type ultrafine particle coagulator

InactiveCN106731388AImprove condensation efficiencyDecrease in number concentrationCombination devicesElectrostatic separationElectricityEngineering

The invention relates to an angle-shaped pipeline type ultrafine particle coagulator. The angle-shaped pipeline type ultrafine particle coagulator is pipeline-shaped and is suitable for being mounted in an air inlet pipeline on the front side of a main dust remover. The coagulator is composed of a charge area and a coagulation area; a set of parallel channels with alternate anodes and cathodes are arranged in the charge area; a cathode plate, an anode plate and an insulating plate used for separating are arranged in the charge area; dust particles in exhaust gas pass by the charge area and then enter into the coagulation area; 2-4 sets of cross bars are arranged in the coagulation area; the cross bars are horizontally arranged in the coagulation area; the cross sections of the cross bars are of angle shape; and the exhaust gas after being coagulated enters into a main dust remover and then is treated. The angle-shaped pipeline type ultrafine particle coagulator has the advantages of high specificity, wide adaptable scope, simple structure and high reliability.

Owner:YANCHENG INST OF TECH

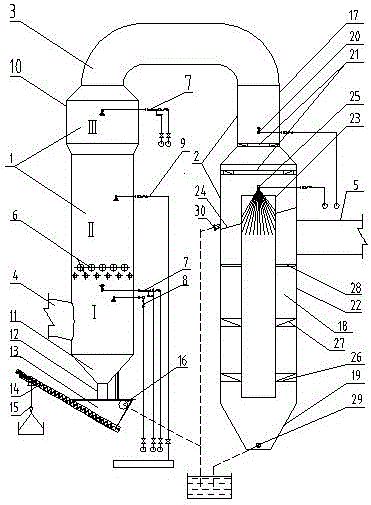

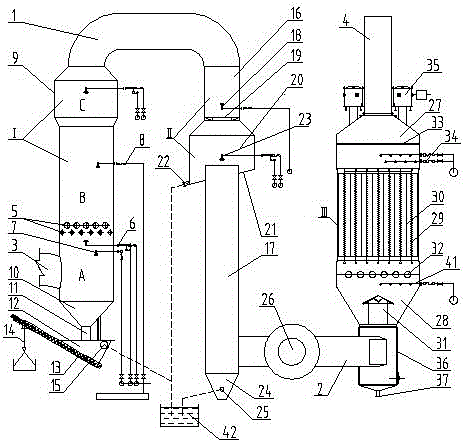

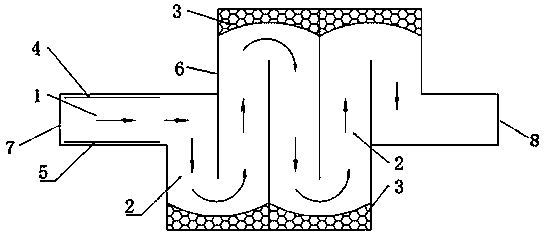

Dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in metallurgical slag treatment process

InactiveCN106731403AHigh efficiency of dust removal and purificationAchieve Energy Efficiency UpgradesCombination devicesGas treatmentEnvironmental resistanceMetallurgical slag

The invention relates to a dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in a metallurgical slag treatment process. The apparatus comprises a tower for spraying, sprinkling and washing and a downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow; an outlet at the upper end of the tower for spraying, sprinkling and washing and an inlet at the upper end of the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow are connected by a connection flue; a sidewall at the lower end of the tower for spraying, sprinkling and washing is provided with a flue gas inlet pipeline; a sidewall of the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow is provided with a flue gas outlet pipeline; the tower for spraying, sprinkling and washing employs a wet type multilayer gas-liquid countercurrent contact mode, and the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow employs a gas-liquid current contact mode. The dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in the metallurgical slag treatment process is adapted to characteristics of high temperature, high moisture and high viscosity flue gas, and realizes ultra-low flue dust emission concentration in a low energy consumption condition, in order to satisfy more strict environmental protection emission requirements of pollution treatment.

Owner:SHANGHAI BAOSTEEL ENERGY TECH +1

Wet type variable flow dedusting and wet type electrostatic deep purification system for metallurgical slag treatment flue gas

InactiveCN106731402AHigh efficiency of dust removal and purificationSeparation facilitates and speeds upCombination devicesMetallurgical slagFlue gas

The invention relates to a wet type variable flow dedusting and wet type electrostatic deep purification system for metallurgical slag treatment flue gas. The system comprises a tower for spraying, sprinkling and washing, a downstream type gas-liquid dehydration tower with foam suspension and pneumatic swirling flow, and an upstream type wet type electrostatic deep purification device. An outlet at the upper end of the tower for spraying, sprinkling and washing is connected to an inlet at the upper end of the downstream type gas-liquid dehydration tower with foam suspension and pneumatic swirling flow by a mist increasing type connection flue; an outlet at the lower end of the downstream type gas-liquid dehydration tower with foam suspension and pneumatic swirling flow is connected to an inlet at the lower end of the upstream type wet type electrostatic deep purification device by a connection flue; the tower for spraying, sprinkling and washing employs a wet type multilayer gas-liquid countercurrent contact mode, and the downstream type gas-liquid dehydration tower with foam suspension and pneumatic swirling flow employs a gas-liquid current contact mode; a sidewall at the lower end of the tower for spraying, sprinkling and washing is provided with a flue gas inlet pipeline, and the upper end of the upstream type wet type electrostatic deep purification device is provided with an exhaust pipe. The system can be used for effectively improving removal rate of the purifier for fine particles, so that ultra low flue dust emission concentration in a low energy consumption condition is stably realized, and more strict environmental protection emission requirements of pollution treatment is satisfied.

Owner:江苏博际环境工程科技有限公司 +1

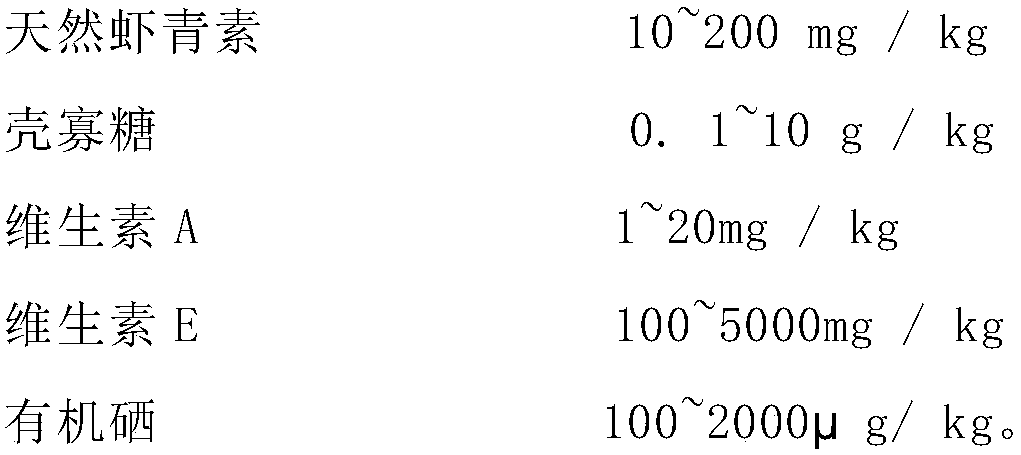

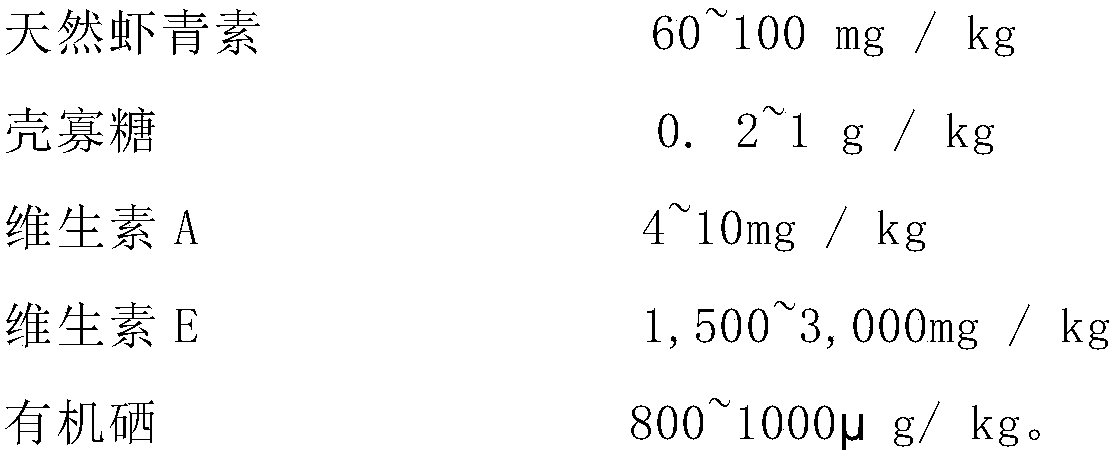

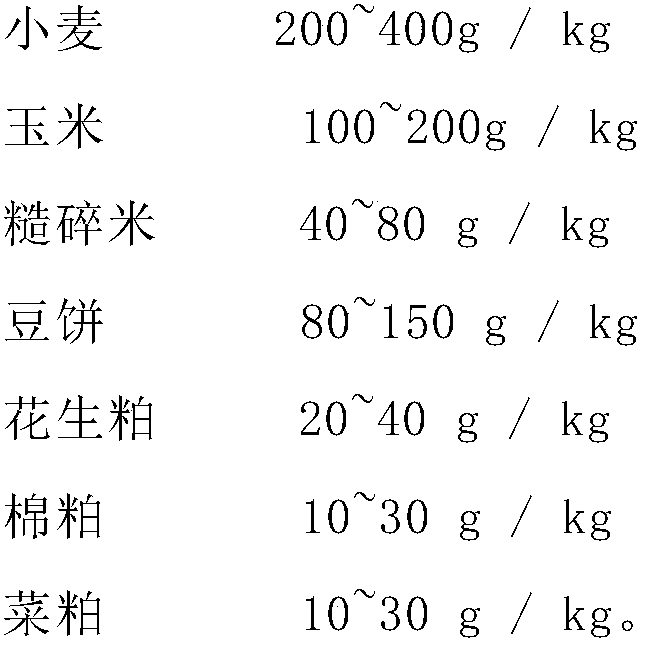

Poultry feed for producing poultry health-care eggs rich in natural astaxanthin and selenium and low in cholesterol and preparation method of poultry feed

InactiveCN108208313AImprove qualityLow in crude fatAnimal feeding stuffAccessory food factorsAnimal sciencePrawn

The invention relates to the field of feed for egg laying poultry, in particular to poultry feed for producing poultry health-care eggs rich in natural astaxanthin and selenium and low in cholesteroland a preparation method of the poultry feed. According to the poultry feed for producing the poultry health-care eggs rich in natural astaxanthin and selenium and low in cholesterol, fermentation isperformed by EM (effective microorganisms), and auxiliary materials containing the following components are added to fermented feed: 10-200 mg / kg of natural astaxanthin, 0.1-10 g / kg of chitosan oligosaccharide, 1-20 mg / kg of vitamin A, 100-5000 mug / kg of vitamin E and 100-2000 mu g / kg of organic selenium. Poultry eggs fed with the feed contain 3-4 mg / 100 g of natural astaxanthin, 30-60 mu g / 100 gof organic selenium and 200-250 mg / 100 g of cholesterol. The shelf life is 1.5 times longer than that of common eggs in 6-7 weeks (at room temperature).

Owner:林大昌

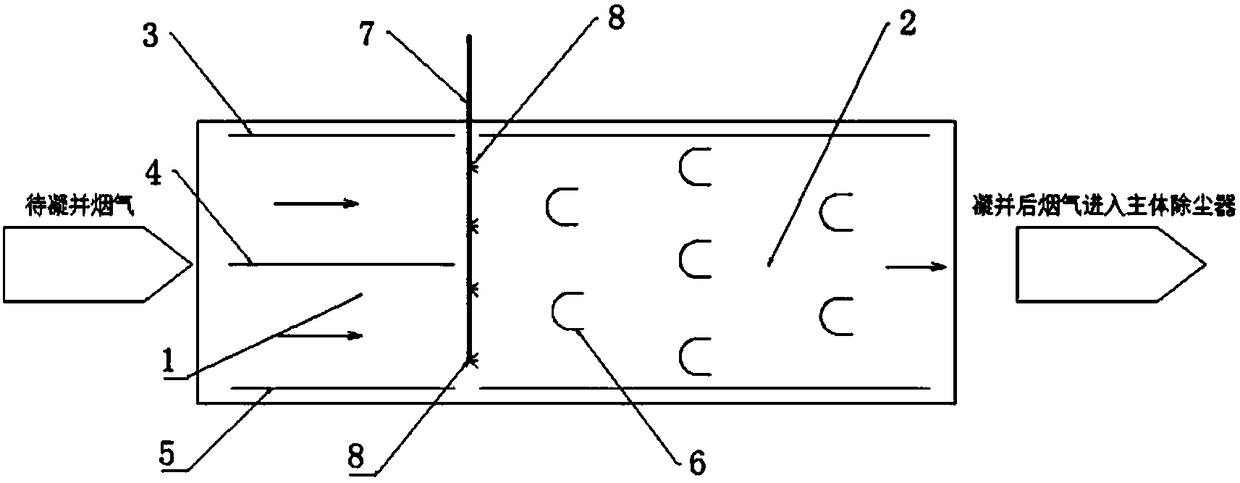

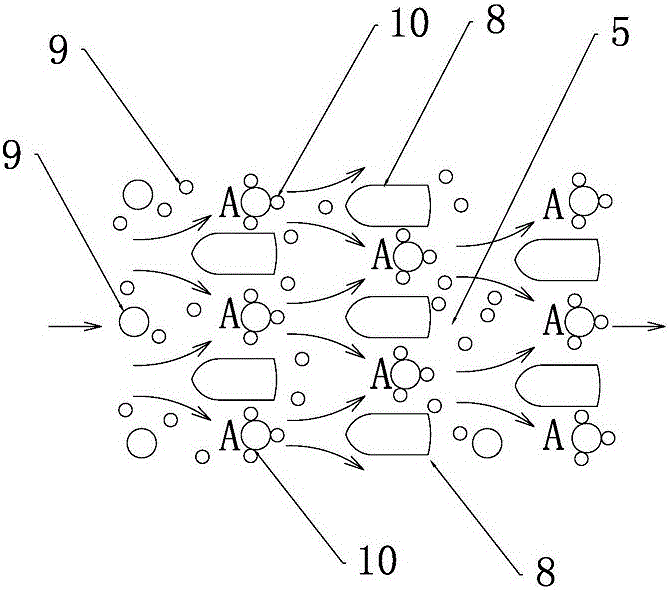

Improved superfine particle pipeline type coalescer

InactiveCN108479285AImprove condensation efficiencyImprove removal efficiencyAuxillary pretreatmentElectrostatic separationParallel channelHorizontal diameter

The invention provides an improved superfine particle pipeline type coalescer. The improved superfine particle pipeline type coalescer is in a pipeline form, is suitable for being mounted on a gas inlet pipeline before a main body dust collector and consists of a charging region and a coagulation region; the charging region is provided with one group of positive and negative alternated parallel channels and is internally provided with a negative electrode plate, a positive electrode plate and an insulating plate for separating; dust particles in flue gas enter the coagulation region by charging; 2 to 4 groups of horizontal bars are arranged in the coagulation region and are horizontally arranged in the coagulation region; the section shape of the horizontal bars is in a C-shaped semicircular shape; the condensed flue gas enters the main body dust collector for treating. The improved superfine particle pipeline type coalescer provided by the invention has the advantages of high pertinence, wide application range, simple structure and good reliability.

Owner:YANCHENG INST OF TECH

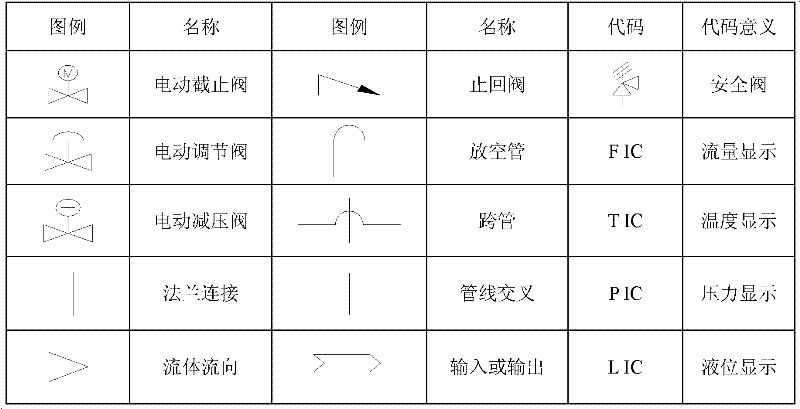

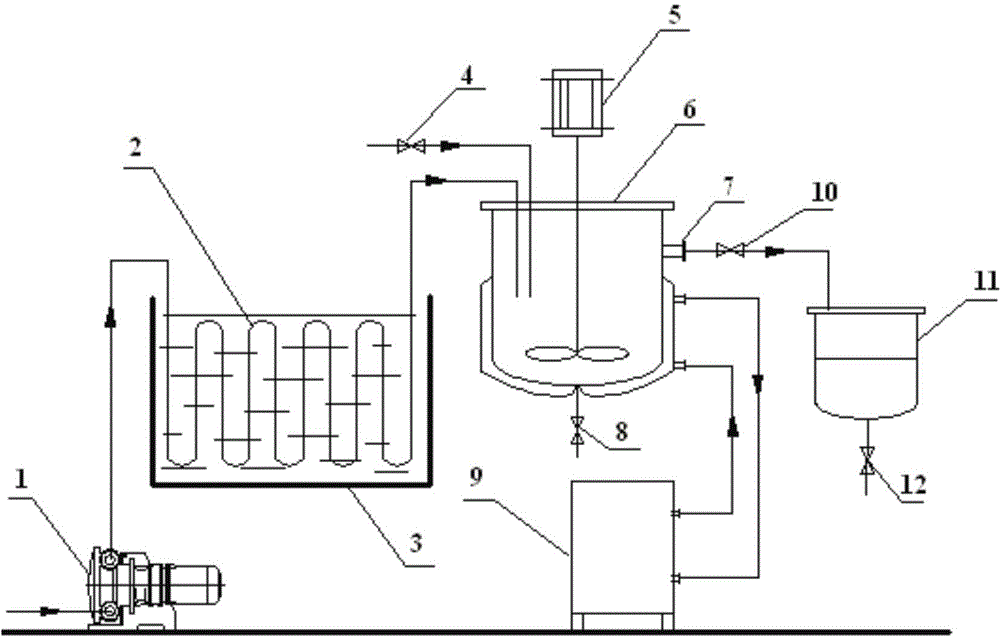

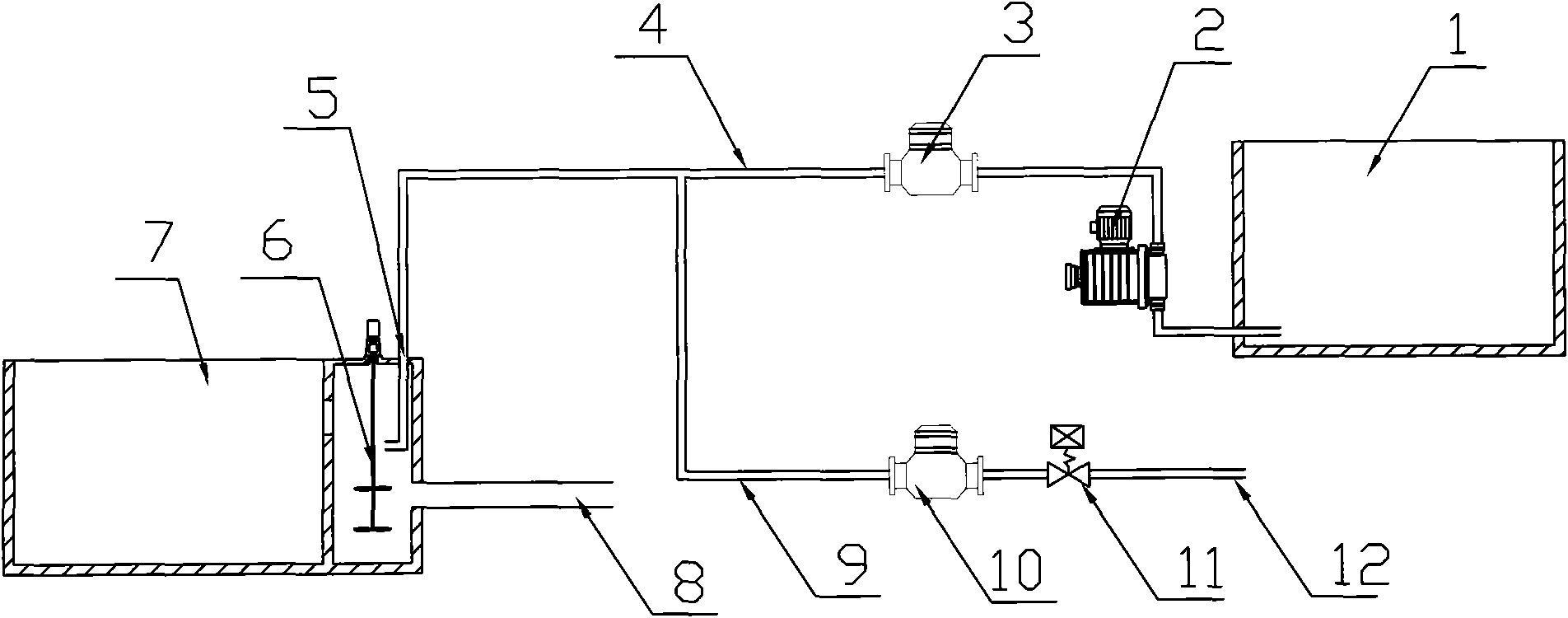

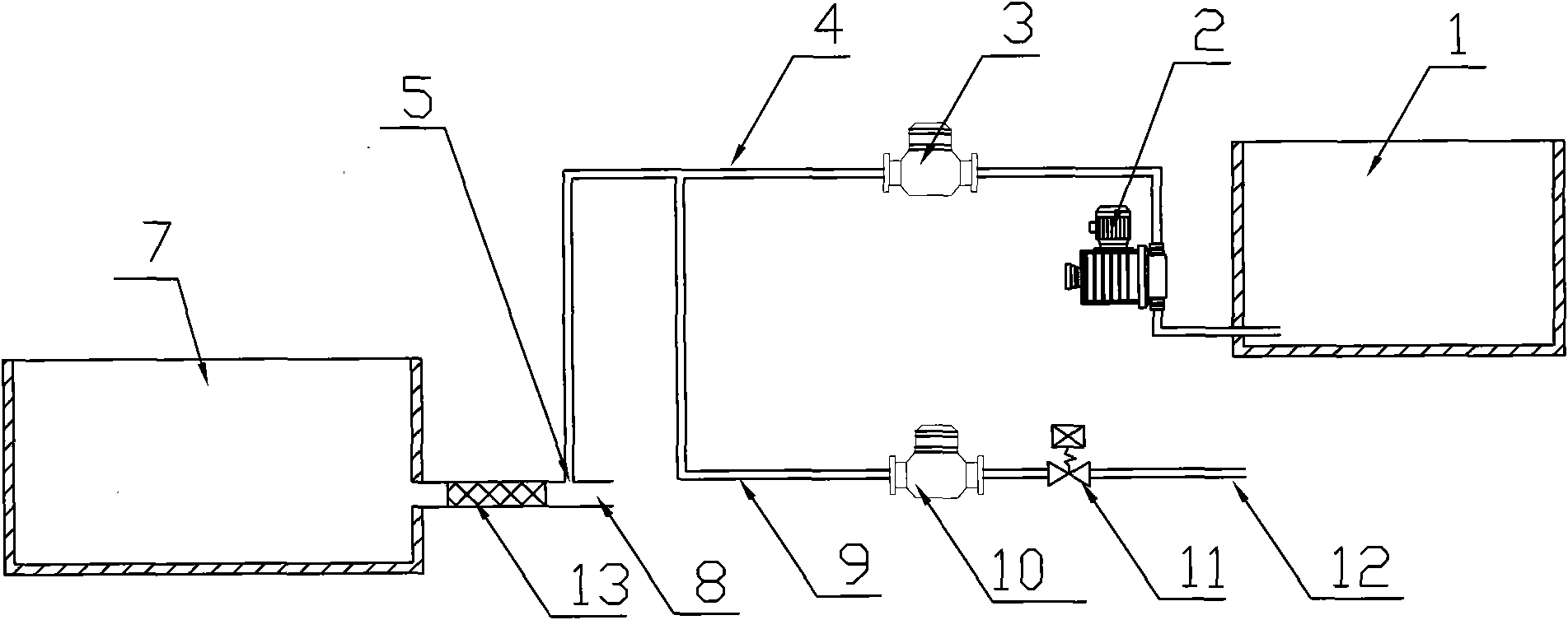

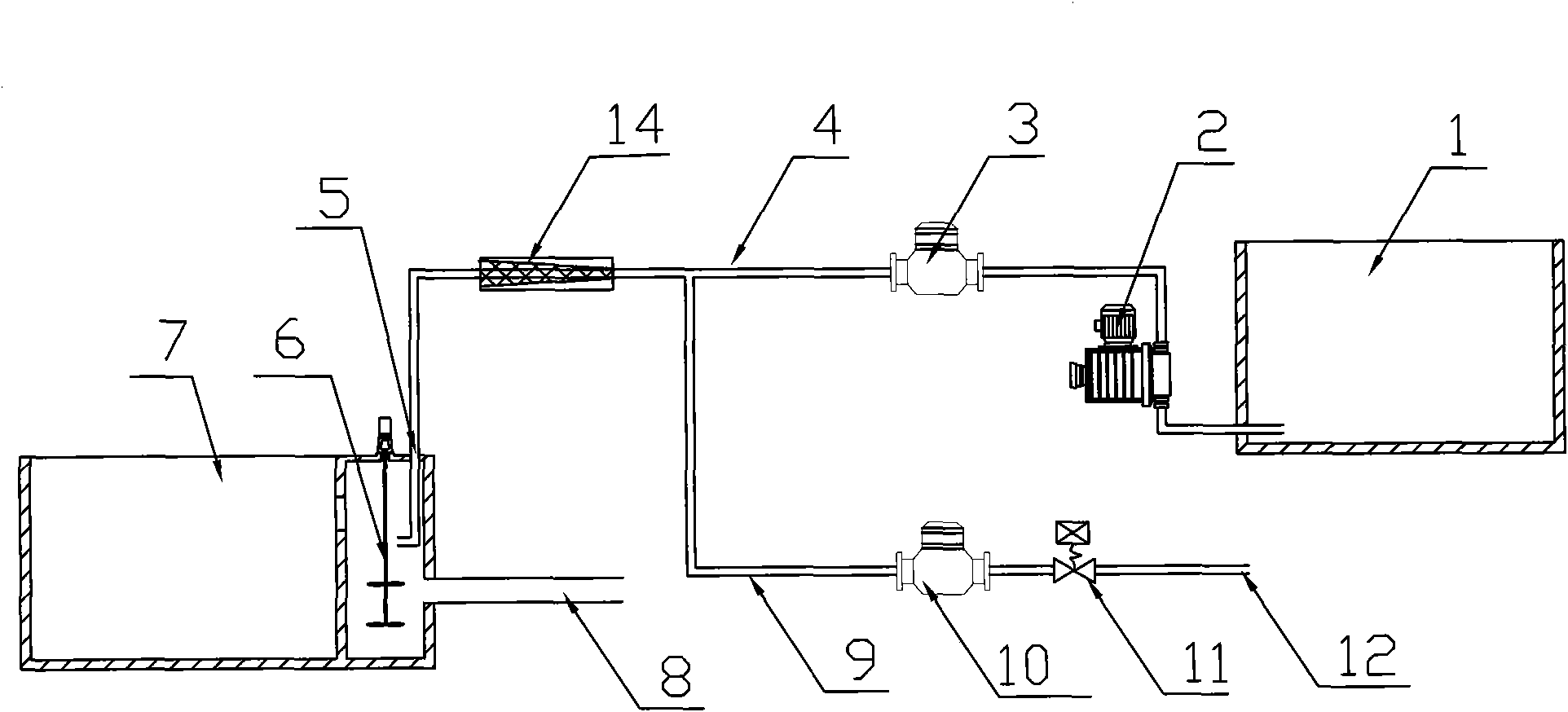

Method and device thereof for secondarily diluting and feeding coagulant

ActiveCN101602532ADilution achievedReduce mass concentrationWater/sewage treatment by flocculation/precipitationFlocculationDiluent

The invention relates to a method and a device thereof for secondarily diluting and feeding coagulant. The device comprises a diluting tank, a flocculation reaction tank, a mixing device, an infusion pipe, an infusion pump and a diluent flow meter, a water pipe, an adjusting valve and a water flow meter; the infusion pipe is connected to the flocculation reaction tank through the infusion pump and the diluent flow meter; and the water pipe is connected to the infusion pipe through the adjusting valve and the water flow meter. The primary dilution of the coagulant is finished in the diluting tank, and then the primary diluent is conveyed to a diluent feeding point by the infusion pump through the infusion pipe; simultaneously, the water for diluting is injected to the infusion pipe by the water pipe to realize secondary dilution of the coagulant; and the secondary diluent is fed to the water to be treated at the diluent feeding point, and undergoes a flocculation reaction in the flocculation reaction tank after full mixing so as to finish the purification treatment for the water. By implementing the method, the mass concentration of the coagulant is reduced to 0.5 to 2 percent through the secondary dilution, so that the utilization efficiency is improved, and the using amount is reduced.

Owner:上海艾晟特环保科技股份有限公司

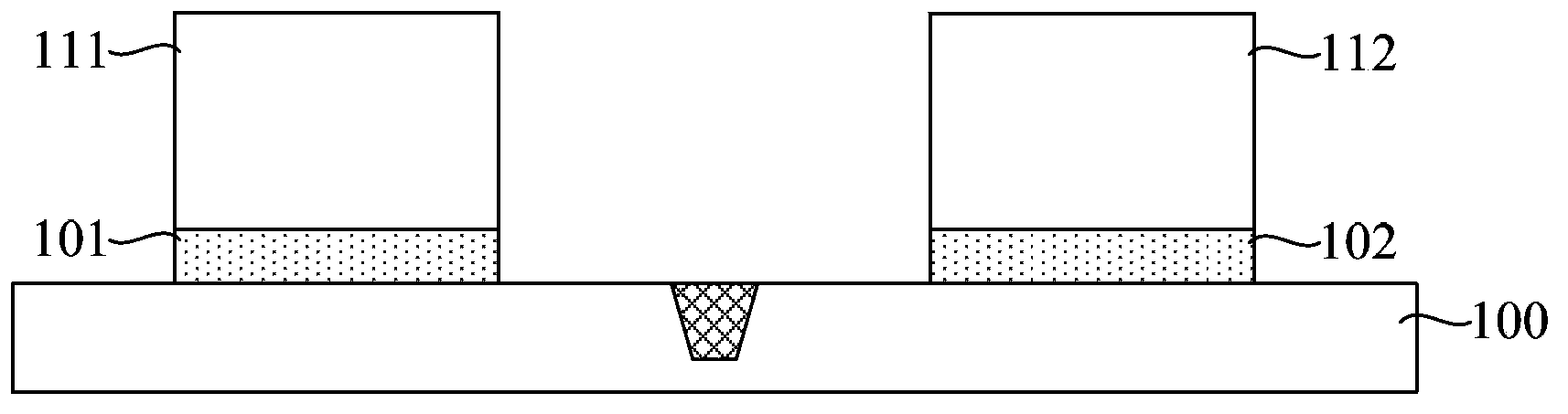

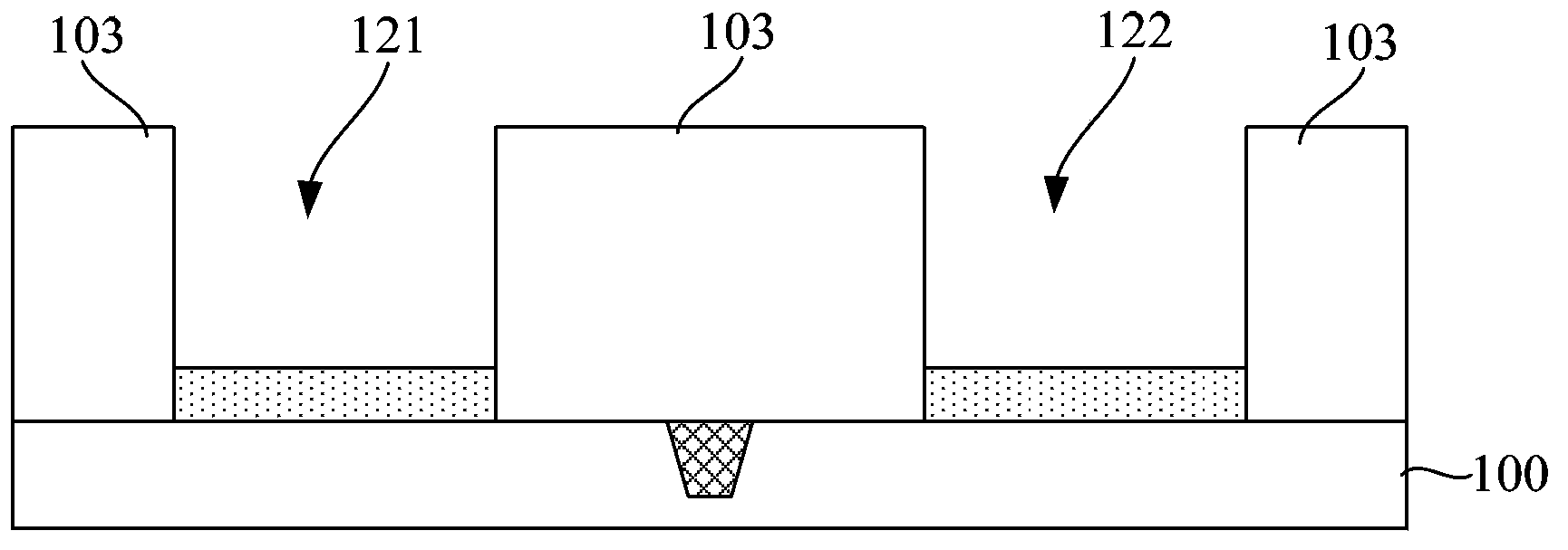

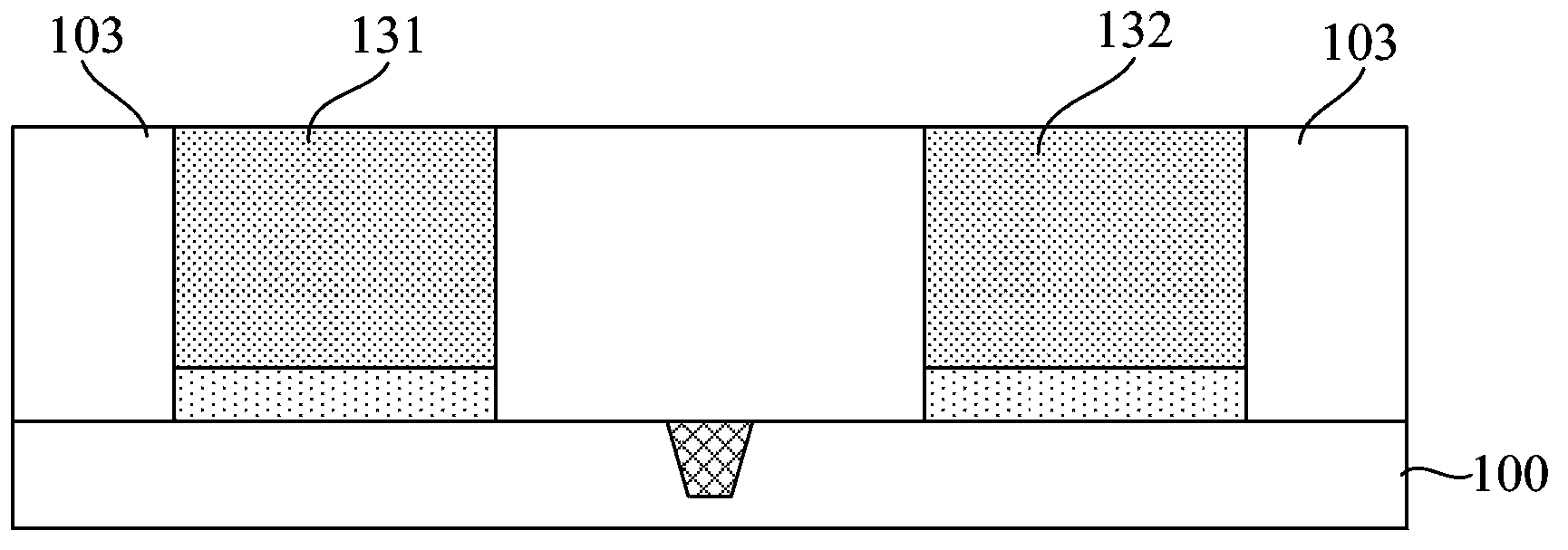

Semiconductor device formation method

ActiveCN104347507AImprove performanceIncrease mass concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesMedia layerDielectric layer

The invention relates to a semiconductor device formation method. The semiconductor device formation method comprises steps that a substrate is provided, the substrate has a first active region and a second active region, and the first active region and the second active region have opposite types; a first dummy grid electrode structure at the first active region and a second dummy grid electrode structure at the second active region are formed on the substrate, the first dummy grid electrode structure comprises a first grid medium layer and a first dummy grid electrode, and the second dummy grid electrode structure comprises a second grid medium layer and a second dummy grid electrode; an interlayer dielectric layer is formed on the substrate, and the upper surface of the interlayer dielectric layer is level with the upper surface of the first dummy grid electrode and the upper surface of the second dummy grid electrode; the first dummy grid electrode is removed to form a first dummy grid slot; the second dummy grid electrode is removed to form a second dummy grid slot; third grid dielectric layers are formed at the bottom portion and side walls of the second dummy grid slot. According to the semiconductor device formation method, parameters of material composition and thickness of the first grid dielectric layer and the third grid dielectric layers can be respectively adjusted, and thereby performance of transistors of the corresponding first grid dielectric layer and the third grid dielectric layers is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

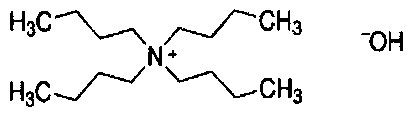

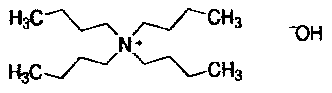

Method for improving enzymatic hydrolysis efficiency by adopting hydrothermal-microwave approach combined with ionic liquid for two-step pretreatment of lignocellulose raw material

The invention relates to the field of biomass pretreatment and provides a method for improving the enzymatic hydrolysis efficiency by adopting a hydrothermal-microwave approach combined with an ionicliquid for two-step pretreatment of a lignocellulose raw material. The method can effectively improve the enzymatic hydrolysis efficiency of the lignocellulose raw material. The pretreatment method aims to achieve the effects that the method is environmentally friendly, the material is recyclable and the energy consumption and the cost are low, and the use rate of the ionic liquid is increased. Byadopting the hydrothermal-microwave approach combined with the ionic liquid tetrabutylammonium hydroxide [TBA][OH] for carrying out pretreatment sequentially on the lignocellulose raw material, the lignocellulose raw material is effectively destructed, the wetting effect of tetrabutylammonium hydroxide [TBA][OH] on lignocellulose is enhanced, more tetrabutylammonium hydroxide [TBA][OH] enters thelignocellulose through destroyed gaps in the surface of the lignocellulose, structures of hemicellulose and lignin are broken, depolymerization among the hemicellulose, the lignin and cellulose occurs, and correspondingly the solubility degree of tetrabutylammonium hydroxide [TBA][OH] on the cellulose is increased.

Owner:SOUTH CHINA AGRI UNIV

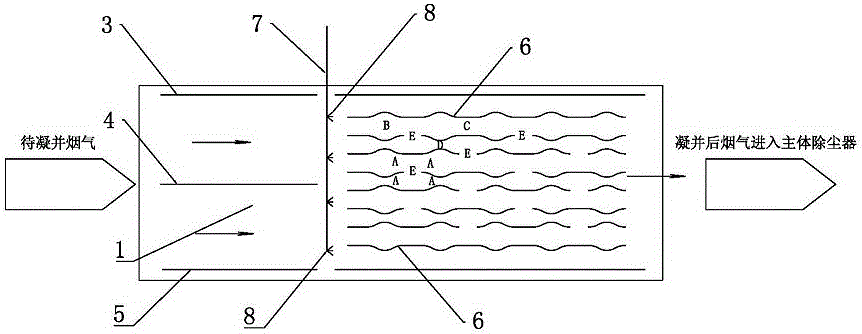

Intersection-type waveform speed change pipeline coalescer

ActiveCN106622661AImprove condensation efficiencyDecrease in number concentrationCombination devicesAuxillary pretreatmentElectricityFlue gas

The invention discloses an intersection-type waveform speed change pipeline coalescer. The intersection-type waveform speed change pipeline coalescer shapes like a tube, and is suitable to be arranged in an air-intake pipeline before a main body deduster; the intersection-type waveform speed change pipeline coalesce is composed of an electrically charged zone and a coagulation zone; the electrically charged zone comprises a channel which is positively charged and negatively charged alternately in parallel; a negative plate, a positive plate, and an insulation plate are arranged in the channel, and the insulation plate is used for isolating the negative plate from the positive plate; dust particles in flue gas enter into the coagulation zone after electrically charged; wave-shaped insolating plates are arranged in the coagulation zone; intersection-type strengthened coagulation of dust particles is realized among the wave-shaped insolating plates; after coagulation, flue gas enters into the main body deduster for treatment. The intersection-type waveform speed change pipeline coalesce is high in pertinence, wide in application range, and high in reliability; and structure optimization is realized.

Owner:江苏鑫泉环保材料有限公司

Selection and breeding method of special wild pigs

The invention relates to a selection and breeding method of special wild pigs. The selection and breeding method of the special wild pigs includes following steps: (1) selecting breeding pigs according to a blood standard: selecting individuals which have 62.5% of wild pig blood and 37.5% of lean type pig blood as the breeding pigs to be screened according to blood content; (2) performing primary selection: performing the primary election according to hair color, appearance, growth and physique conditions of piglets after the piglets are weaned and experience a nursery transition period; (3) performing secondary selection: performing the secondary selection when the selected piglets are four months old, selecting pigs which are high in feed utilization rate, quick in growth and development, normal in development of reproductive organs, powerful in female parent lactation performance, healthy and free of disease, and strong in physique, and individually have more than 6 pairs of effective teats as breeding pigs; (4) performing third selection: performing the third selection when the breeding pigs selected in the step 3 are 6 months old, and selecting pigs which are high in feed utilization rate, quick in growth and development, and normal in development of reproductive organs as final breeding pigs. By using the selection and breeding method of the special wild pigs, the special wild pigs which are selected and bred are stable in heredity, a sow of the special wild pigs can bear more than two litters one year, the average number born alive is larger than 20, and the special wild pigs are strong in disease resistance, and rarely sick after the weight of the special wild pigs reaches 20kg.

Owner:四川惠远农牧科技有限公司

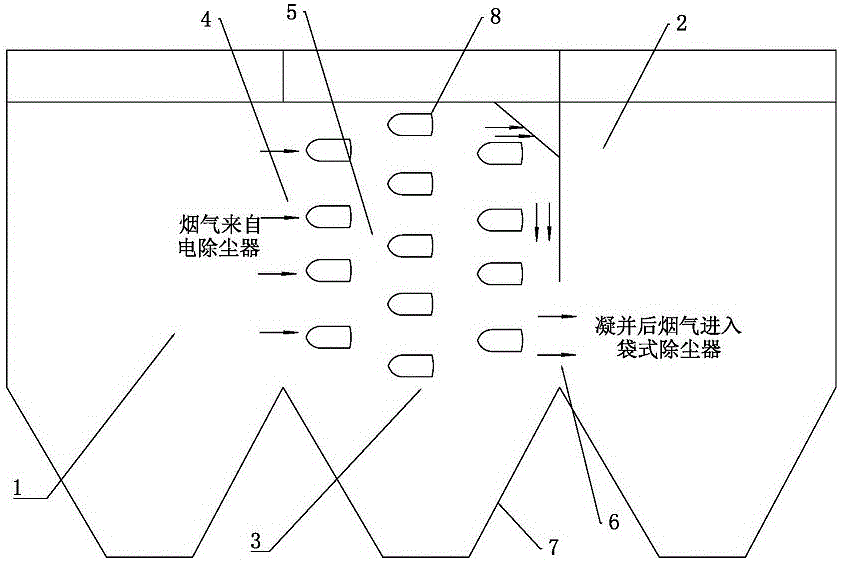

Streamline ultrafine particle coagulation box

InactiveCN106512634AImprove condensation efficiencyDecrease in number concentrationAuxillary pretreatmentEngineeringHead shape

Provided is a streamline ultrafine particle coagulation box. The whole coagulation box is in a box type and is suitable for being mounted between an electric dust remover and a bag dust remover; a coagulation box body is composed of a gas inlet, a gas outlet, a coagulation area and an ash bucket; the gas inlet is a channel behind the electric dust remover, and smoke is from the electric dust remover; 2-4 sets of cross bars are arranged in the coagulation area, the cross bars are transversely arranged in the coagulation area, and the sections of the cross bars are in streamline guided missile head shapes. The gas outlet is formed in the position, above the ash bucket, of the lower portion of the coagulation area and arranged into a flowing channel, and coagulated smoke enters the bag dust remover to be treated. The streamline ultrafine particle coagulation box is high in pertinency, wide in application range, optimized in structure and good in reliability.

Owner:YANCHENG INST OF TECH

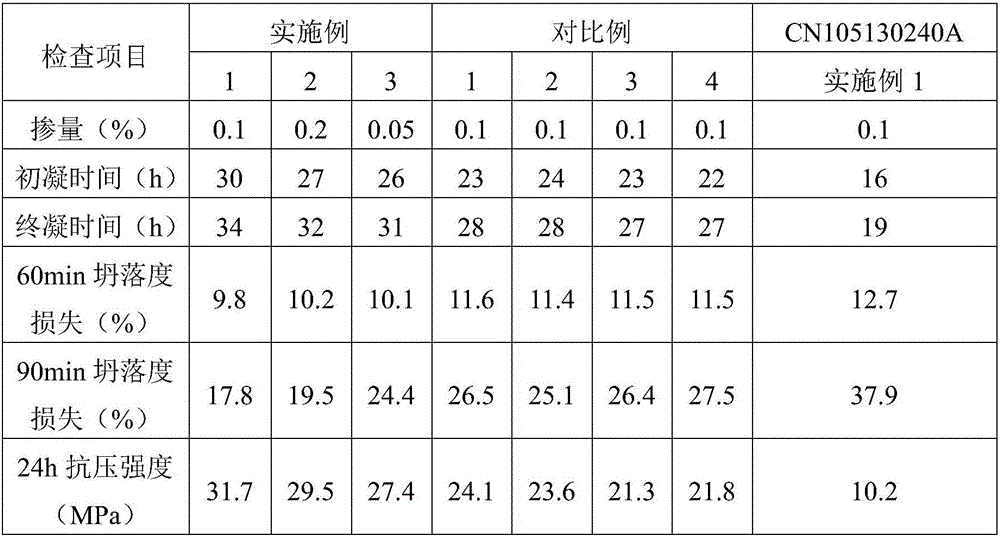

Composite concrete retarder

The invention discloses a composite concrete retarder, made from, by weight, 2-6 parts of sodium fluorosilicate, 3-9 parts of sodium dihydrogen phosphate, 4-8 parts of ammonium bicarbonate, 4-6 parts of ammonium persulfate, 7-9 parts of glycine, 2-6 parts of sodium carboxymethyl cellulose, 2-4 parts of shell-lac, 1-3 parts of ammonium oxalate, 10-15 parts of halloysite, 15-20 parts of Al2O3-ZrO2 porous ceramic powder, 2-5 parts of a water-reducing agent, 1-3 parts of a dispersant, and 0.3-0.6 part of a surfactant. The composite concrete retarder has the advantages of good retarding effect, high strength, zero pollution and the like, and is a concrete admixture that is promising.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Waveform variable speed pipeline coalescer

InactiveCN106693591AImprove condensation efficiencyDecrease in number concentrationCombination devicesGas treatmentElectricityFlue gas

A waveform variable speed pipeline coalescer is in a pipeline form, is suitable for being mounted in a gas inlet pipeline in front of a main body deduster, and comprises a charged area and a coagulation area, a group of positive and negative alternate parallel channels is arranged in the charged area, a negative electrode plate, a positive electrode plate and an insulating plate for separating the negative electrode plate and the positive electrode plate are arranged in the parallel channels, and dust particles in flue gas are charged and then enter the coagulation area; a waveform separator plates are arranged in the coagulation area, and the dust particles undergo enhanced coagulation in the channel between the waveform separator plates; and the coagulated flue gas enters the main body deduster and is processed. The waveform variable speed pipeline coalescer has the advantages of high pertinence, wide adaption, optimized construction and good reliability.

Owner:YANCHENG INST OF TECH

Carbon-attached enhanced ultrafine particle agglomerator

InactiveCN109926207AImprove condensation efficiencyReasonable partitionExternal electric electrostatic seperatorElectrode constructionsActivated carbonAirflow

The invention discloses a carbon-attached enhanced ultrafine particle agglomerator, which comprises an S-shaped airflow passage. An agglomeration zone is in the airflow passage; one end of the airflowpassage is provided with a flue gas inlet and the other end is provided with an interface for a main dust collector; the position, close to the flue gas inlet, in the airflow passage is provided witha positive electrode plate and a negative electrode plate; a zone near the positive electrode plate and the negative electrode plate is a charging zone; and the turning portion of the S-shaped structure of the airflow passage is internally provided with a carbon box. Compared with the prior art, according to the carbon-attached enhanced ultrafine particle agglomerator, through the agglomeration zone with the S-shaped structure, the efficiency of agglomerating ultrafine particles with positive and negative charges to large particles can be improved, the large particles are more easily absorbedby activated carbon, and the quantity concentration and the mass concentration of particles in dust can be reduced obviously.

Owner:YANCHENG INST OF TECH

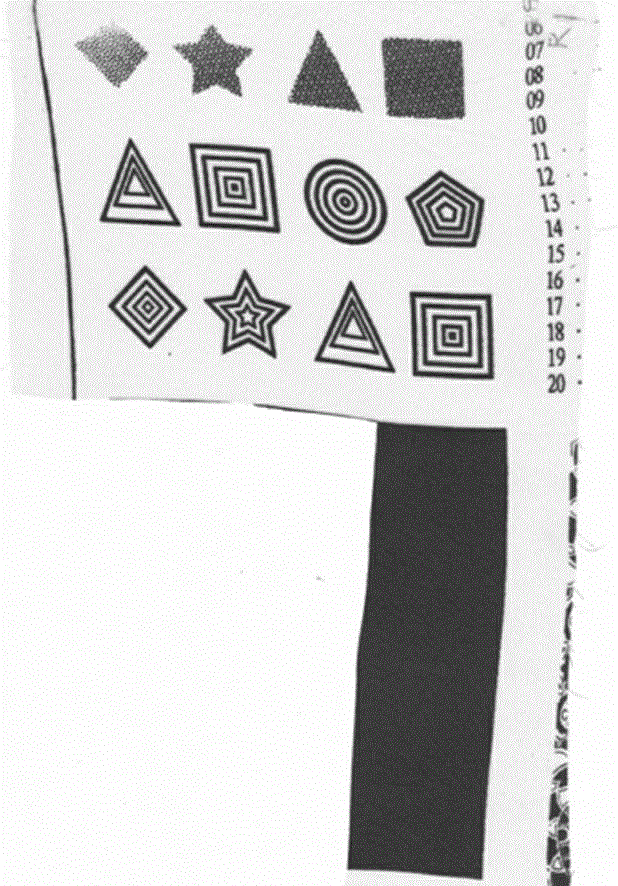

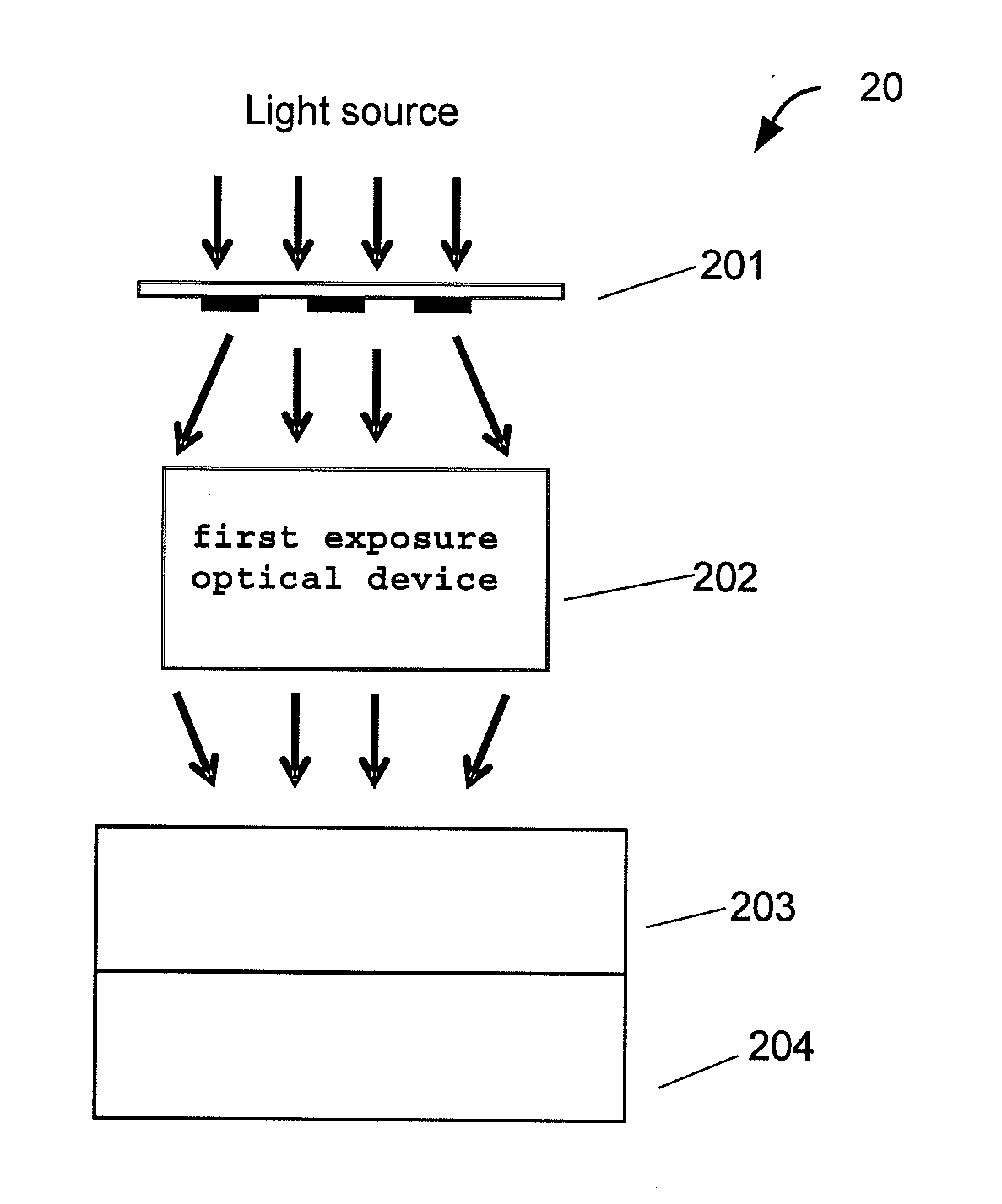

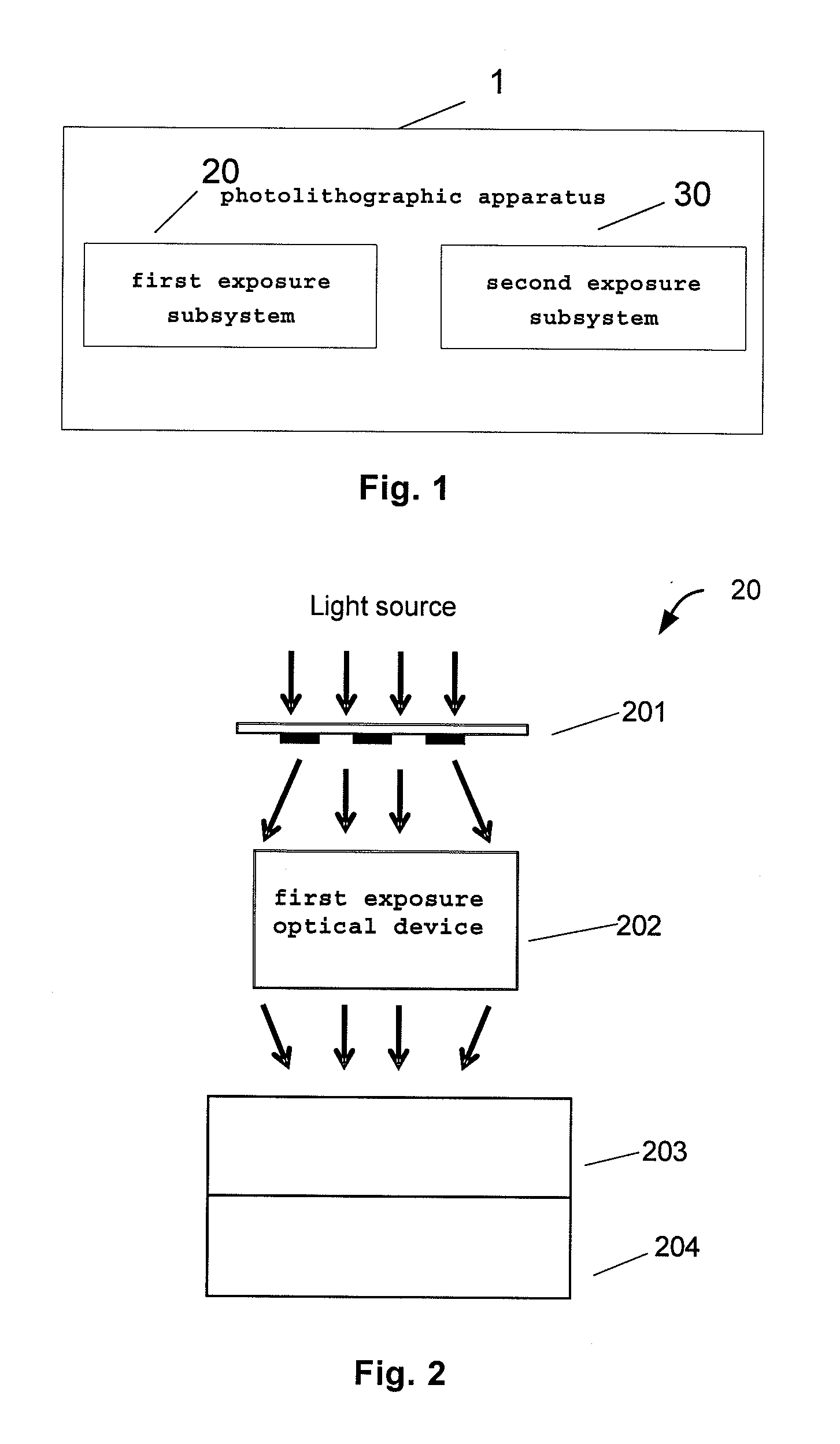

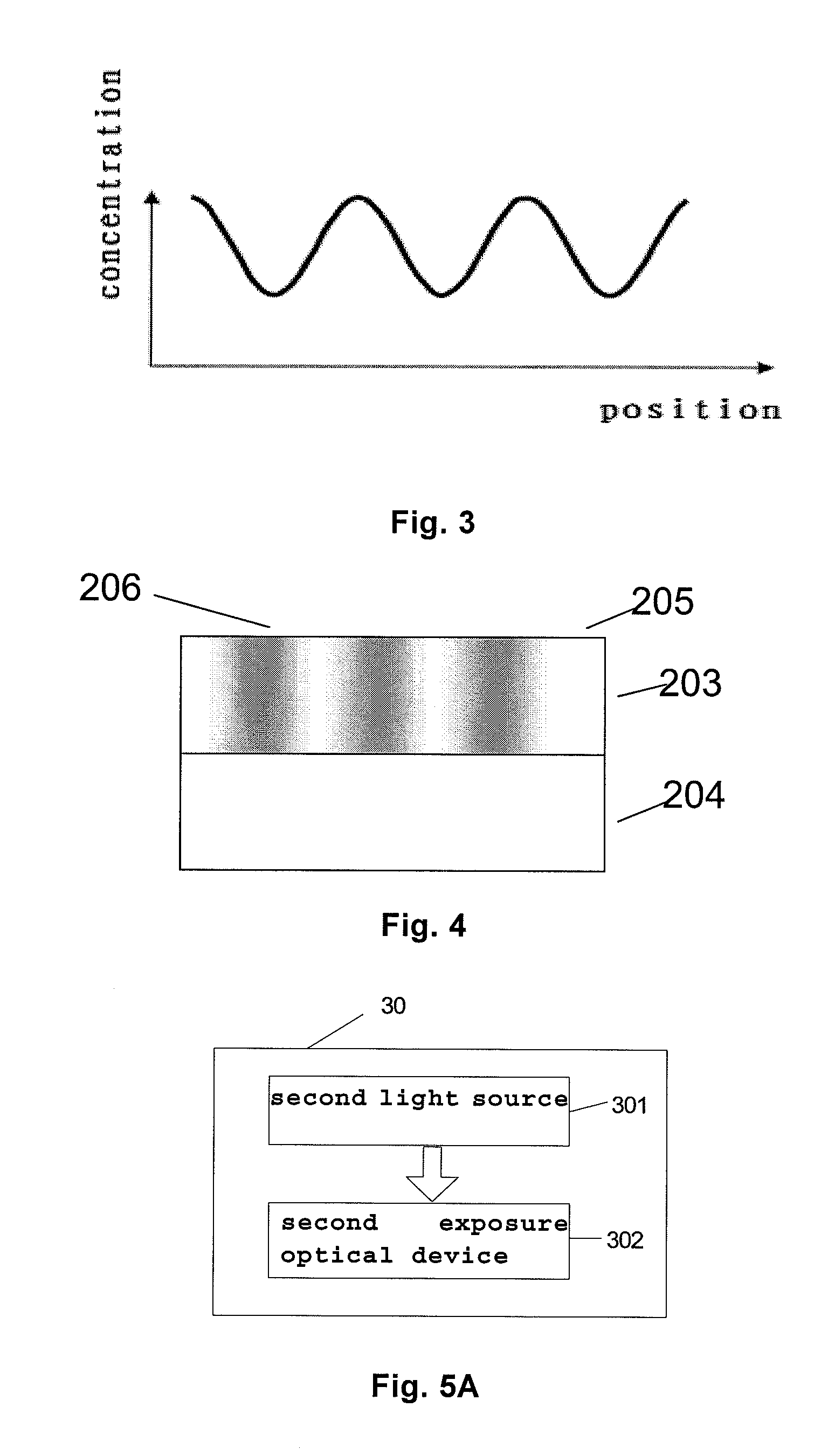

Photolithographic apparatus

ActiveUS20130083302A1Increase contrastReduce edge roughnessPhotomechanical apparatusPhotographic printingResistLatent image

A photolithographic apparatus for use with a photo-resist comprises a first component that generates a first chemical substance and produces a chemical amplification action and a second component that generates a second chemical substance. The photolithographic apparatus comprises a first exposure subsystem for selectively illuminating a surface of the photo-resist using a light of a first wavelength band such that the first component generates the first chemical substance and a second exposure subsystem for uniformly illuminating the surface using a light of a second wavelength band such that the second component generates the second chemical substance. The second chemical substance reacts with the first chemical substance to reduce the mass concentration of the first chemical substance in the photo-resist and improves the contrast of a latent image of the first chemical substance formed in the photo-resist.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

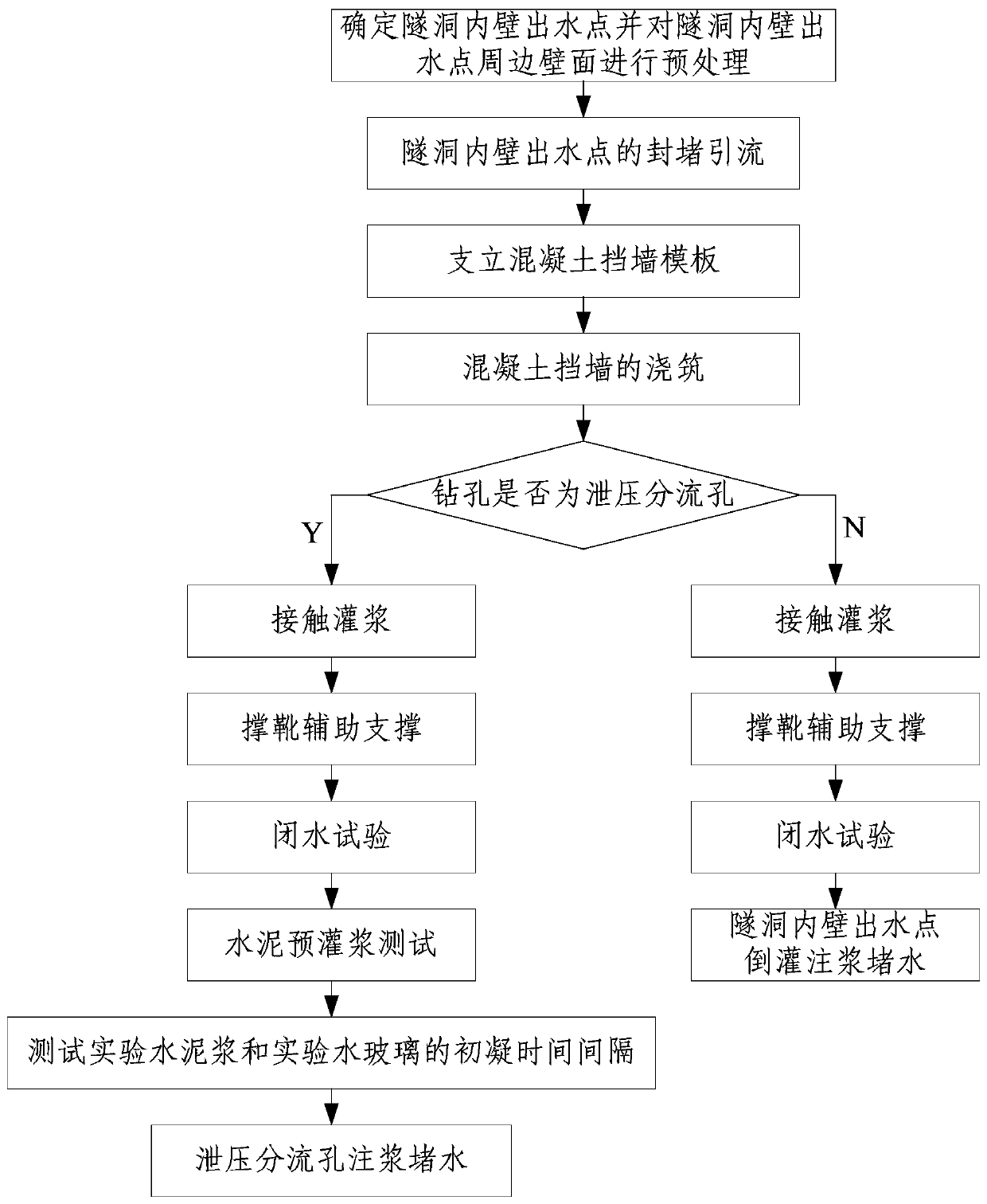

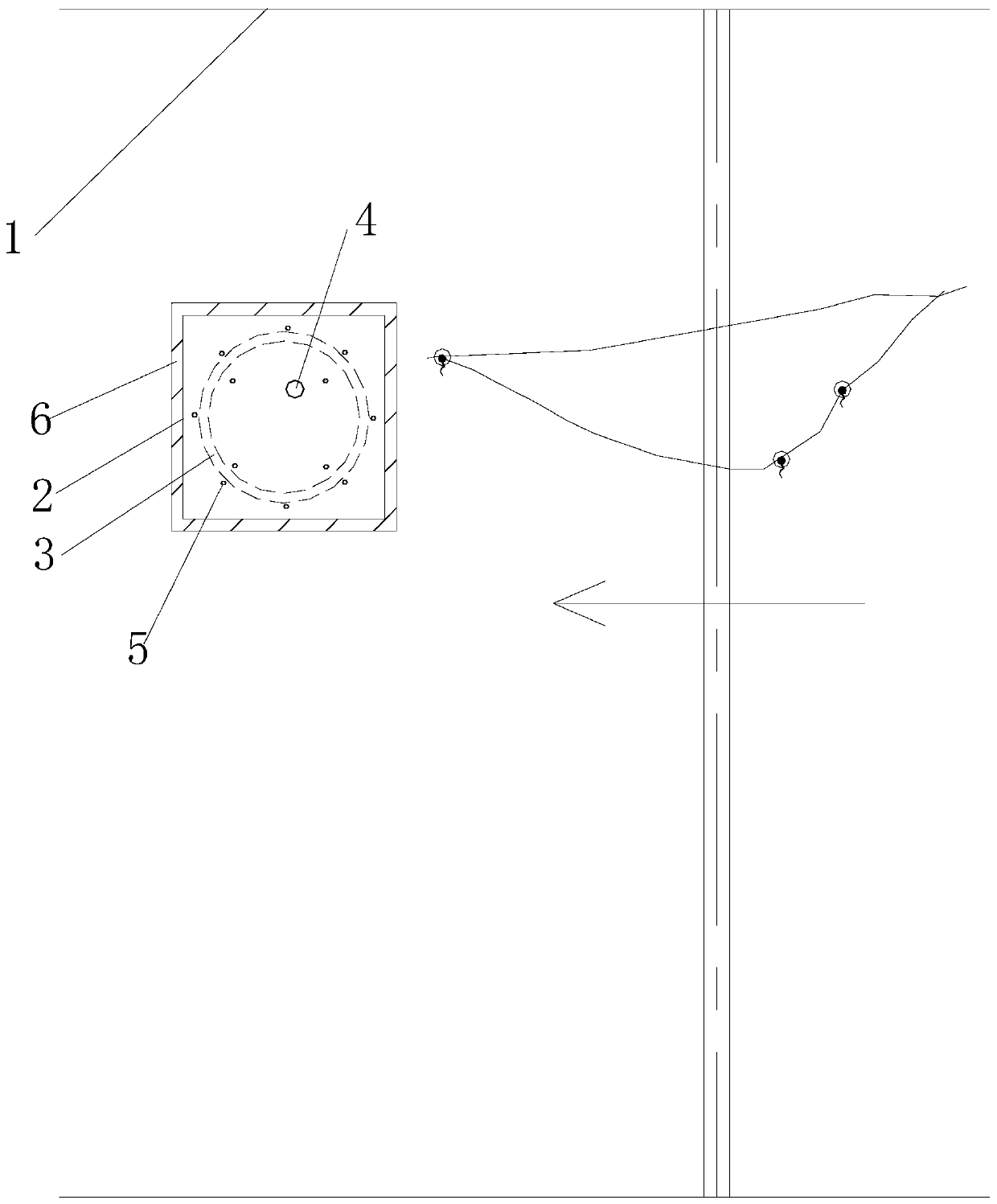

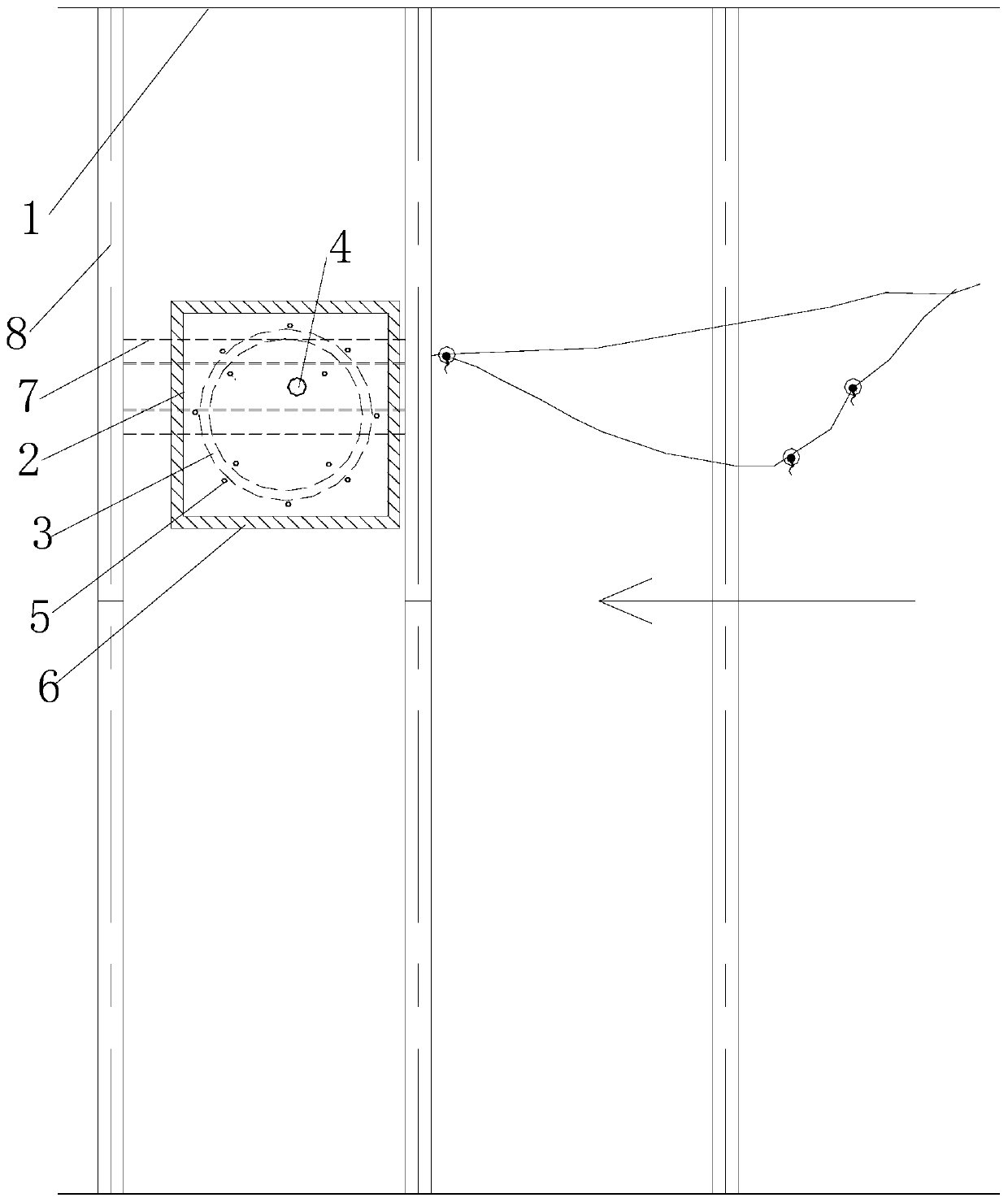

Open type TBM supporting shoe assisting jacking flow reduction tunnel water plugging method

The invention discloses an open type TBM supporting shoe assisting jacking flow reduction tunnel water plugging method. The method comprises the steps that 1, determining a water outlet point of the inner wall of a tunnel, and pretreating the peripheral wall face of the water outlet point of the inner wall of the tunnel; 2, plugging and drainage of the water outlet point on the inner wall of the tunnel; 3, erecting a concrete retaining wall template; 4, pouring a concrete retaining wall; 5, drilling a pressure relief shunting hole; 6, conducting grouting and water plugging on the pressure relief flow distribution hole; and 7, backward grouting and water plugging of the water outlet point of the inner wall of the tunnel. An open type TBM supporting shoe steel structure is utilized, the concrete retaining wall is jacked for flow reduction in an assisted mode, the efficient construction of a 'cement paste and water glass' method is adopted, the plugging is successful and thorough once without leaving the problem, the problem that the tunnel is difficult to construct due to narrow space and limited geographic position of the TBM tunnel is solved, a large amount of labor and material cost is saved, the construction period is shortened, and the efficiency is high.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

A kind of preparation method of polycarbosilane

The invention relates to the technical field of organosilicon and provides a preparation method of polycarbosilane in order to solve the problems in polycarbosilane preparation at present. The preparation method is characterized by taking chloromethyl chlorosilane as a raw material, synthesizing a polycarbosilane intermediate in an organic solvent and then preparing the polycarbosilane by using a reducing agent. The preparation method provided by the invention has the advantages that the operation is convenient, and the time is shortened; meanwhile, the number-average molecular weight of the prepared polycarbosilane is higher, and the demands of preparing an organic functional material can be met.

Owner:湖南昌威新材料科技有限公司

Process for recovering 1,4-butanediol

InactiveCN102161615BAchieve recyclingAvoid wastingOrganic compound preparationPreparation by hydrolysis1,4-ButanediolDepolymerization

The invention discloses a process for recovering 1,4-butanediol, and belongs to the technical field of the recycling of organic waste in the industrial production. A 1,4-butanediol product in distillation waste is circularly recovered by taking the distillation waste generated in the process of producing the 1,4-butanediol by a Reppe process as a raw material and dilute sulfuric acid as a catalyst through the simple process of depolymerization reaction, separation, distillation and condensation. The process has the characteristics that: the process is simple, and easy to operate; equipment issimple and has high performance-price ratio; secondary pollution is avoided, the process is favorable for environmental protection, and energy sources are saved; and resources can be circularly utilized, production cost can be reduced, the process is convenient for promotion and application and the like. The process can be widely applied to the recycling of the organic waste in the industrial production, and is particularly suitable for recycling the distillation waste generated in the process of producing the 1,4-butanediol by the Reppe process.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com