Preparation method of polycarbosilane

A technology of polycarbosilane and chloromethylchlorosilane, which is applied in the field of polycarbosilane preparation, can solve the problems of unfavorable industrial production, high production cost, and difficult post-operation, and achieve easy recycling, convenient operation, and cross-linking The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

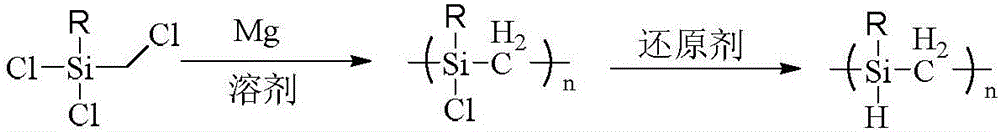

Method used

Image

Examples

Embodiment 1

[0023] Place (96g, 4mol) metal magnesium powder, iodine particle 0.22mol in a three-necked round-bottomed flask of 1000mL that is equipped with a magnetic stirrer, a constant pressure dropping funnel, a reflux condenser, and an air guide device, under a nitrogen atmosphere, Inject 300 mL of benzotrifluoride, and add (chloromethyl)methyldichlorosilane (250 mL, 2.2 mol) dropwise into the reaction flask under nitrogen protection. After the dropwise addition, react at room temperature for 3 hours, then add sodium hydride (52.8 g, 2.2 mol) and react at room temperature for 5 hours. Then add 100mL dilute hydrochloric acid to quench the reaction, separate the layers, filter, wash the organic phase twice with distilled water and saturated brine, and dry over anhydrous sodium sulfate. After removing the solvent, a light yellow oil is obtained, which is heated at 150°C for 5 hours to obtain Milky white rubber-like solid polysiloxane 1.

[0024] The yield is 70% (M w / M n =1.3, M n =...

Embodiment 2

[0026] Place (96g, 4.4mol) metal magnesium powder and 0.11mol of iodine particles in a 1000mL three-necked round bottom flask equipped with a magnetic stirrer, a constant pressure dropping funnel, a reflux condenser, and a gas guide device, under a nitrogen atmosphere , inject 1000mL trifluorotoluene, under the protection of nitrogen, add (chloromethyl)methyldichlorosilane (250mL, 2.2mol) dropwise into the reaction flask. After the dropwise addition, react at room temperature for 3 hours, then add potassium hydride (88 g, 6.6 mol) and react at room temperature for 3 hours. Then add 100mL dilute hydrochloric acid to quench the reaction, separate the layers, filter, wash the organic phase twice with distilled water and saturated brine, and dry over anhydrous sodium sulfate. After removing the solvent, a light yellow oil is obtained, which is heated at 200°C for 3 hours to obtain Milky white rubber-like solid polysiloxane 2.

[0027] reducing agent. The yield is 72% (M w / M n...

Embodiment 3

[0029] Place (96g, 5mol) metal magnesium powder, iodine particle 0.33mol in a three-necked round-bottomed flask of 1000mL that is equipped with a magnetic stirrer, a constant pressure dropping funnel, a reflux condenser, and an air guide device, under a nitrogen atmosphere, Inject 2000 mL of benzotrifluoride, and add (chloromethyl)trichlorosilane (248 mL, 2.2 mol) dropwise into the reaction flask under nitrogen protection. After the dropwise addition, react at room temperature for 2 hours, then add sodium hydride (176 g, 4.4 mol) and react at room temperature for 5 hours. Then add 1000mL dilute hydrochloric acid to quench the reaction, separate the liquids, filter, wash the organic phase twice with distilled water and saturated brine, and dry over anhydrous sodium sulfate. After removing the solvent, a light yellow oil is obtained, which is heated at 250°C for 2 hours to obtain Milky white rubber-like solid polysiloxane 3.

[0030] The yield is 85% (M w / M n =1.4, M n =22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com