Medical dressing and preparation method thereof

A composite cross-linking agent and sodium alginate technology, which is applied in the field of medical materials, can solve problems affecting large-scale production of products, unsatisfactory product stability, and long production cycle, so as to achieve improved stability, shortened cross-linking time, and improved effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

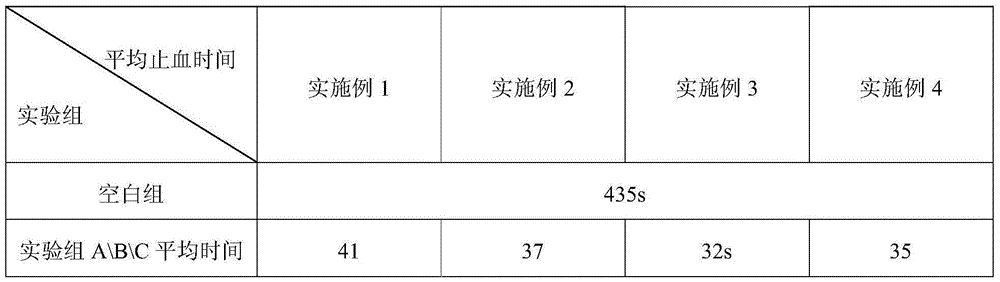

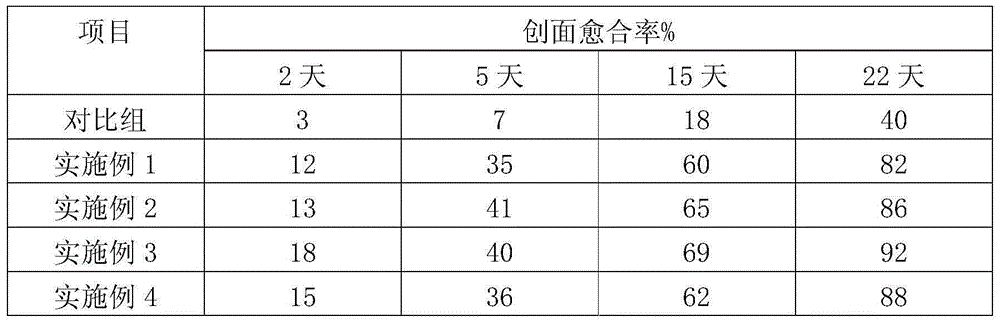

Examples

Embodiment 1

[0017] A kind of medical dressing, comprises bacterial cellulose film 200g, water-soluble chitosan 20g, sodium alginate 6g, polyhydroxyethyl methacrylate 2g and composite cross-linking agent 3g; Composite cross-linking agent is 25g methacrylic acid- 2-Hydroxyethyl ester and 10g of 2-ethyl-4-methylimidazole were heated to 50°C under the protection of ammonia gas, reacted for 40 minutes, cooled to room temperature, added 10g of lauroyl peroxide, and then heated at a pressure of 0.01MPa Heated to 60°C under negative pressure conditions, stirred and reacted for 20 minutes to obtain a composite crosslinking agent.

[0018] The preparation method of above-mentioned medical dressing, comprises the following steps:

[0019] Step 1: Add sodium alginate into 480g of deionized water, heat to 50°C, stir and mix evenly to obtain mixed solution 1;

[0020] Step 2: Add water-soluble chitosan and polyhydroxyethyl methacrylate to the mixed solution 1, stir to dissolve, add bacterial cellulose...

Embodiment 2

[0023] A medical dressing, comprising bacterial cellulose membrane 300g, water-soluble chitosan 40g, sodium alginate 12g, polyhydroxyethyl methacrylate 5g and composite crosslinking agent 6g; Composite crosslinking agent is the 15g methacrylic acid- 2-Hydroxyethyl ester and 12g of 2-ethyl-4-methylimidazole were heated to 53°C under the protection of ammonia gas, reacted for 46 minutes, cooled to room temperature, added 8g of lauroyl peroxide, and then heated at a pressure of 0.02MPa Heated to 63°C under negative pressure conditions, stirred and reacted for 25 minutes to obtain a composite crosslinking agent.

[0024] The preparation method of above-mentioned medical dressing, comprises the following steps:

[0025] Step 1: Add sodium alginate into 1000g of deionized water, heat to 55°C, stir and mix evenly to obtain mixed solution 1;

[0026] Step 2, adding water-soluble chitosan and polyhydroxyethyl methacrylate to the mixed solution 1, stirring to dissolve, adding bacterial...

Embodiment 3

[0029] A kind of medical dressing, comprises bacterial cellulose membrane 200g, water-soluble chitosan 40g, sodium alginate 12g, polyhydroxyethyl methacrylate 3g and composite cross-linking agent 4g; Composite cross-linking agent is 45g methacrylic acid- 2-Hydroxyethyl ester and 30g of 2-ethyl-4-methylimidazole were heated to 56°C under the protection of ammonia gas, reacted for 55 minutes, cooled to room temperature, added 15g of lauroyl peroxide, and then heated at a pressure of 0.03MPa Heated to 68°C under negative pressure conditions, stirred and reacted for 26 minutes to obtain a composite crosslinking agent.

[0030] The preparation method of above-mentioned medical dressing, comprises the following steps:

[0031] Step 1: Add sodium alginate into 1100g of deionized water, heat to 58°C, stir and mix evenly to obtain mixed solution 1;

[0032] Step 2, adding water-soluble chitosan and polyhydroxyethyl methacrylate to the mixed solution 1, stirring to dissolve, adding bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com