Supercritical water oxidization treatment system for high-salinity organic waste water

A technology for supercritical water oxidation and organic wastewater, which is applied in water/sewage treatment, oxidation treatment of sludge, degassed water/sewage treatment, etc., and can solve problems such as increased operating costs, reactor blockage, and complex feed characteristics. Achieve the effect of reducing operating costs, reducing removal rates, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

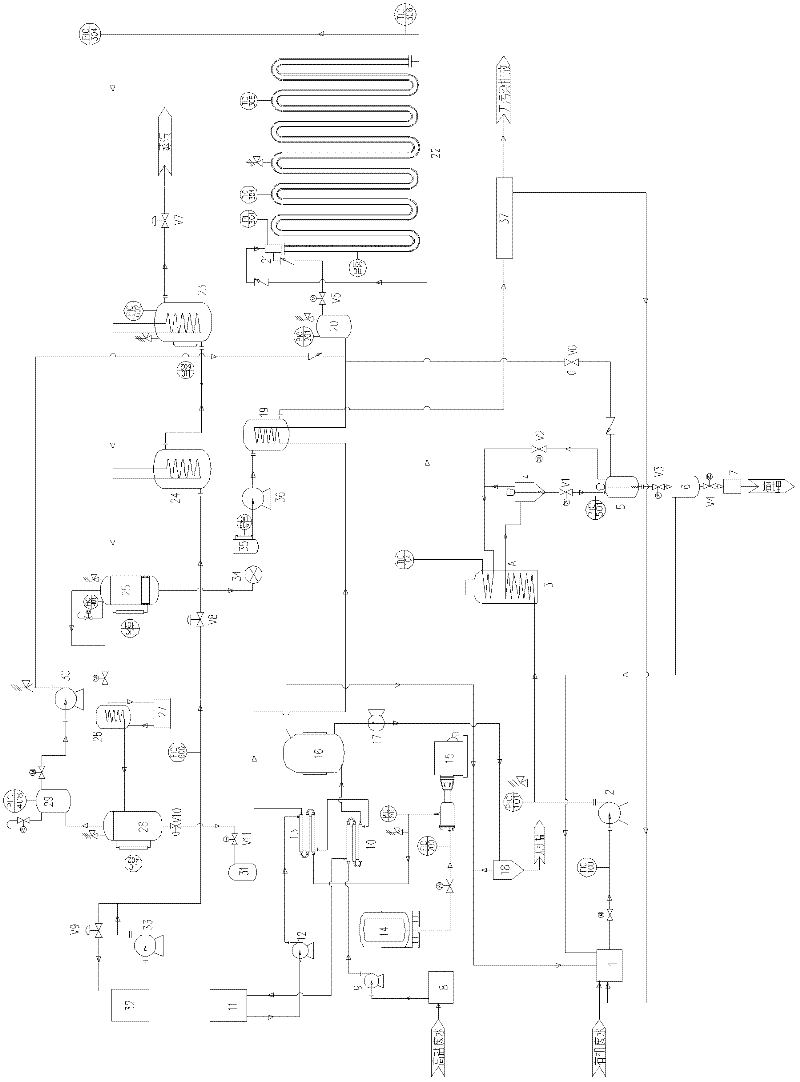

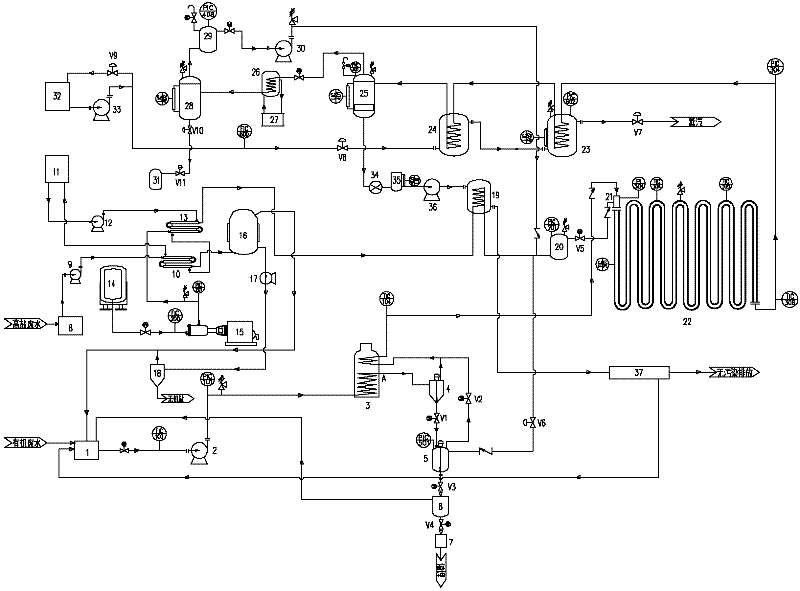

[0030] refer to figure 1 , the outlet of the storage tank 1 is connected to the inlet of the high-pressure plunger pump 2, the outlet of the high-pressure plunger pump 2 is connected to the inlet of the heating furnace 3, the middle outlet of the heating furnace 3 is connected to the inlet of the hydrocyclone 4, and the hydrocyclone The top outlet of the flow device 4 is connected to the middle inlet of the heating furnace 3, and the outlet of the heating furnace 3 is connected to the inlet of the mixer 21. The outlet end of the high-salt wastewater pool 8 is connected to the inlet end of the low-pressure pump 9, the outlet end of the low-pressure pump 9 is connected to the inlet port on the tube side of the first sleeve heat exchanger 10, and the outlet port on the tube side of the first sleeve heat exchanger 10 The outlet end of the cooling crystallizer 16 is connected to the inlet end of the cooling crystallizer 16, the outlet end of the top of the cooling crystallizer 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com