A device and method for heat treatment and dehydration of municipal sludge with low energy consumption

A dehydration device and sludge technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high sludge treatment cost and lower water content, and achieve The effect of compact structure, less waste gas treatment, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

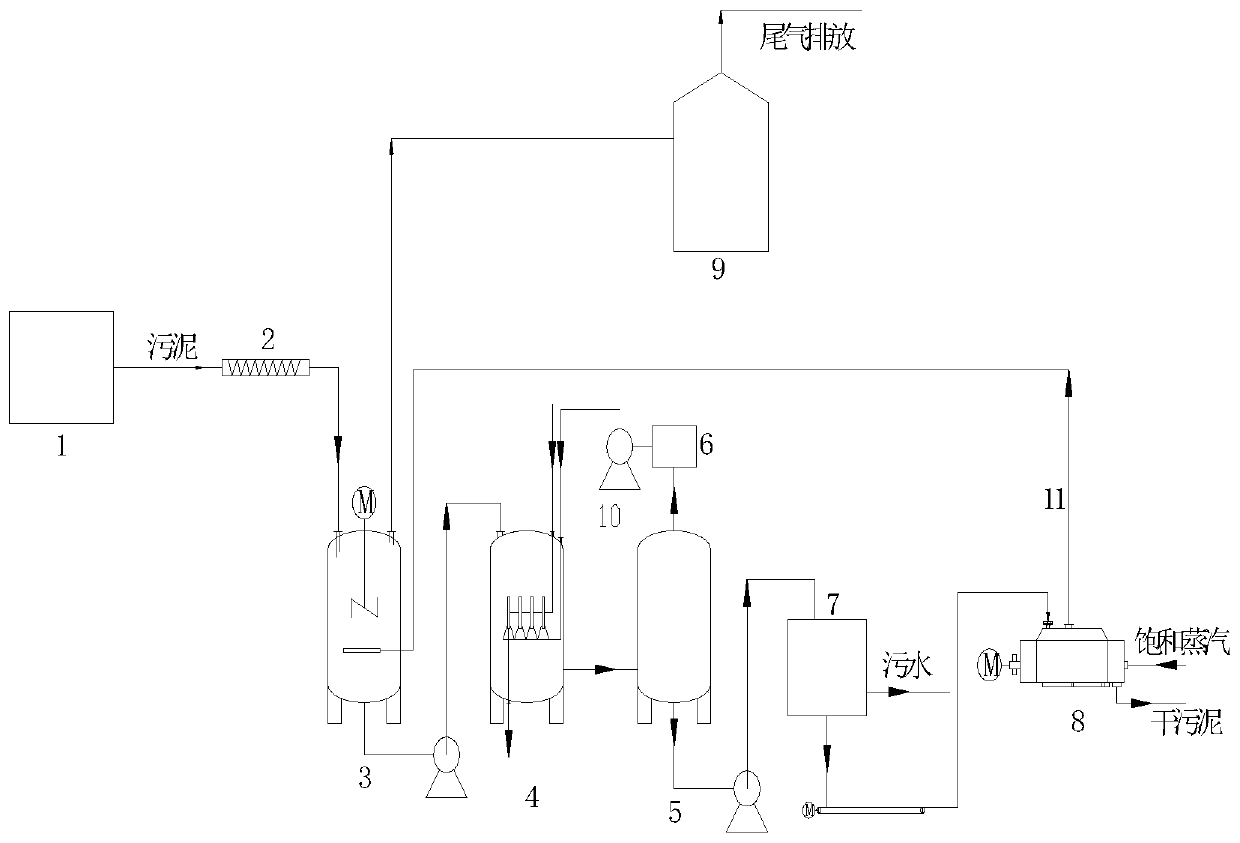

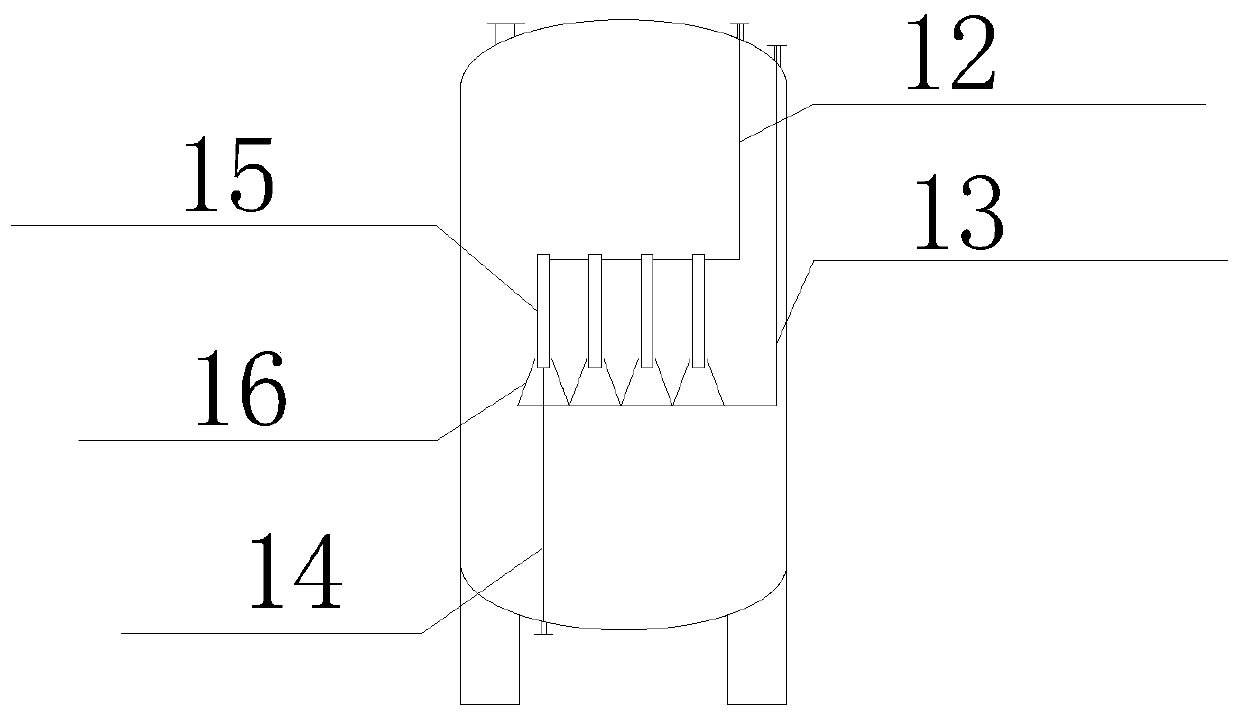

[0023] Such as figure 1 As shown, the sludge heat treatment and dehydration device includes: a preheater 3 , a reaction kettle 4 , a flash tank 5 , a storage tank 6 , a centrifuge 7 , a drying machine 8 , and a deodorizing device 9 . The sludge first enters the preheater 3 through the screw pump 2, and at the same time, the tail gas 11 produced by drying is passed into the preheater 3. The tail gas evenly enters the preheater 3 through the gas distribution device. After the direct heat exchange between the sludge and the tail gas, the temperature of the dried tail gas decreases, the water vapor releases latent heat, and the temperature of the sludge rises. The preheater 3 has a jacket, and inside the jacket is steam condensed water from the reactor. The preheater 3 is equipped with a stirring device, which makes the temperature of the sludge uniform and reduces the viscosity of the sludge at the same time. In the preheater 3, after 20-30 minutes of reaction, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com