Film-coated sand thermal regeneration equipment and its regeneration method

A technology of thermal regeneration and coated sand, applied in foundry molding equipment, metal processing equipment, machinery for cleaning/processing of casting materials, etc. High smoke temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

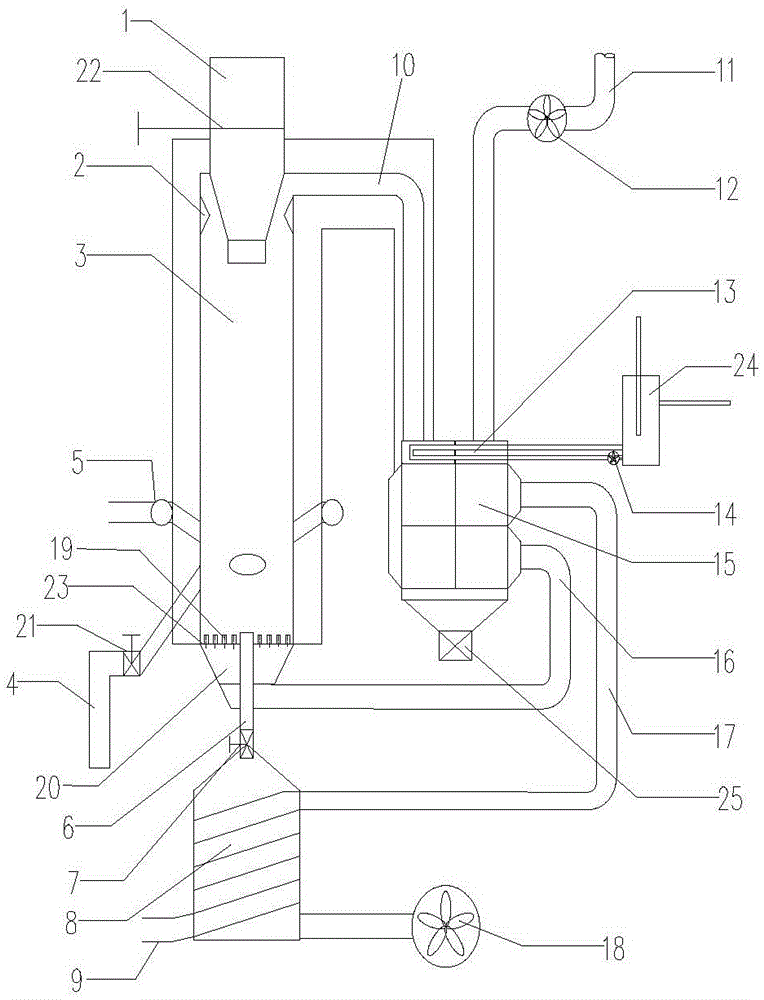

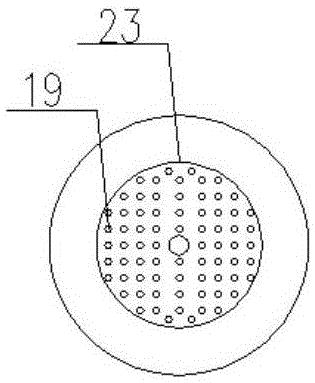

[0025] The film-coated sand thermal regeneration equipment of this embodiment includes a vertical fluidized bed furnace 3, a hopper 1, a counter-spray gas nozzle 5, a flue 10, a smoke exhaust pipe 11, a partition cooler 8 and an air preheater 15 , the feeding hopper 1 is arranged on the top of the vertical fluidized bed furnace 3, and the opposite gas injection nozzle 5 is in the middle and lower part of the furnace cavity of the vertical fluidized bed furnace 3, and the furnace cavity of the vertical fluidized bed furnace 3 passes through the flue 10 It communicates with the smoke exhaust pipe 11, and the end of the smoke exhaust pipe 11 is provided with an induced draft fan 12; the partition cooler 8 is arranged below the vertical fluidized bed furnace 3, and the top of the partition cooler 8 passes through the shakeout pipe 6 It is connected with the vertical fluidized bed furnace 3; the bottom of the vertical fluidized bed furnace 3 is provided with an air distribution plat...

Embodiment 2

[0027] The film-coated sand thermal regeneration equipment of this embodiment is the same as that of Embodiment 1 except for the following differences:

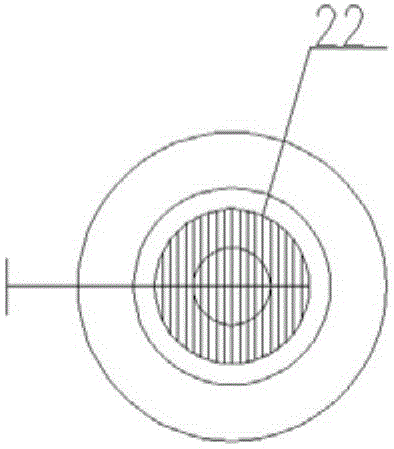

[0028]The joints of the flue 10, the smoke exhaust pipe 11 and the air preheater 15 are respectively provided with water-cooled coils 13, and the water-cooled coils 13 are connected to the water tank 24 through the circulating water pump 14, and the top of the vertical fluidized bed furnace 3 furnace chamber is provided with There is a triangular internal fixture 2, the bottom of the air preheater 15 is provided with an ash hopper 25 communicating with the cavity, the feeding hopper 1 is provided with a strip-shaped orifice plate 22, and the angle between the gas injection nozzle 5 and the furnace wall is 20° °, the cross section of the vertical fluidized bed furnace 3 is circular.

Embodiment 3

[0030] The film-coated sand thermal regeneration equipment of this embodiment is the same as that of Embodiment 1 except for the following differences:

[0031] The joints of the flue 10, the smoke exhaust pipe 11 and the air preheater 15 are respectively provided with water-cooled coils 13, and the water-cooled coils 13 are connected to the water tank 24 through the circulating water pump 14, and the top of the vertical fluidized bed furnace 3 furnace chamber is provided with There is a wedge-shaped inner piece 2; the bottom of the air preheater 15 is provided with an ash hopper 25 connected with the cavity; the side of the vertical fluidized bed furnace 3 is provided with a side discharge port 4, which is connected with the vertical fluidized bed furnace A valve 21 is provided between the chemical bed furnace 3; a strip-shaped orifice plate 22 is provided on the hopper 1; a flow regulating valve 7 is provided between the shakeout pipe 6 and the partition cooler 8; The includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com