Method and device for counting the number of landings performed by an aircraft tyre

An aircraft and tire technology, applied in tire measurement, tire parts, instruments, etc., can solve problems such as weight increase and mass imbalance, and achieve the effect of weight reduction and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

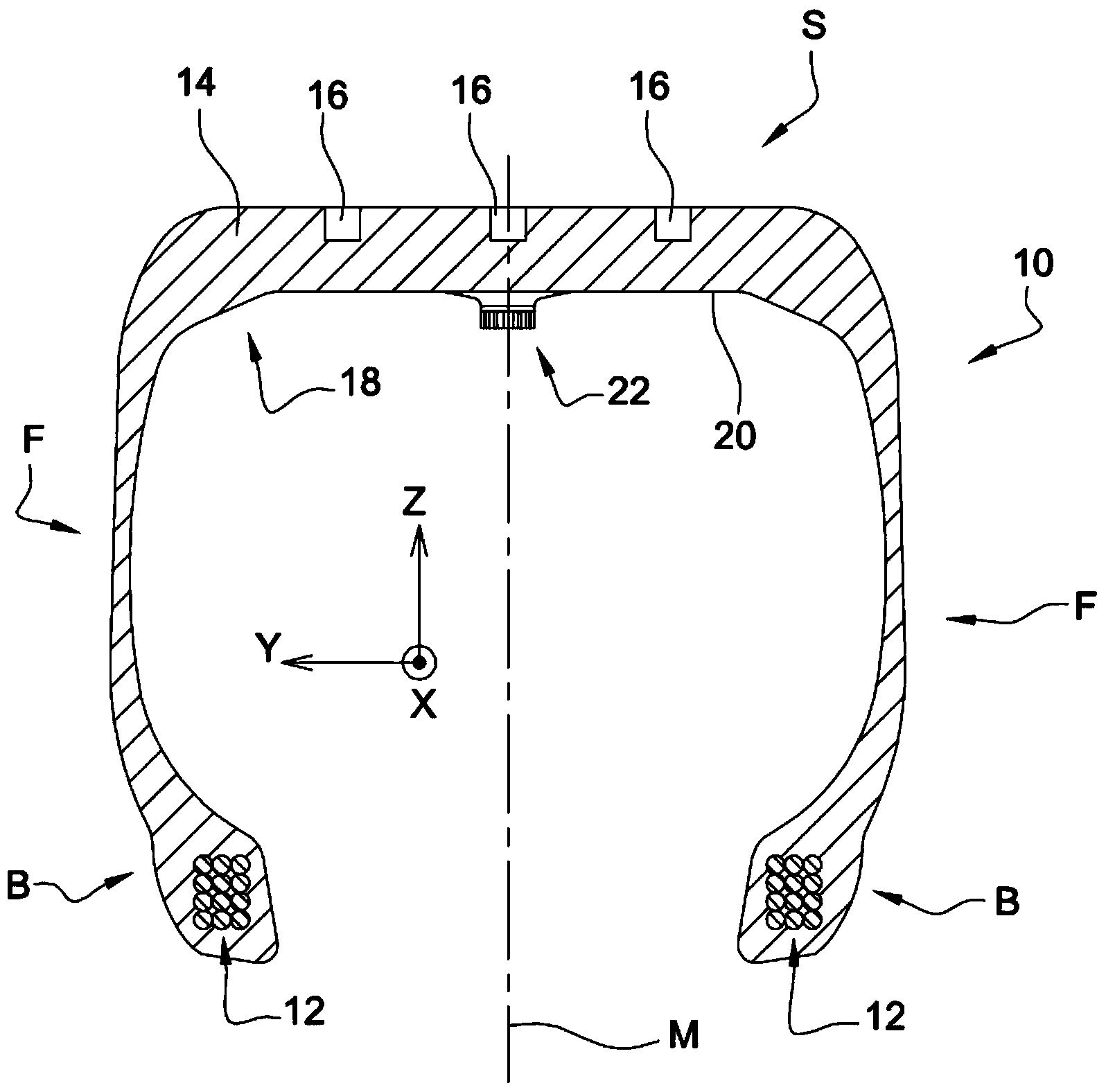

[0032] figure 1 A tire according to the invention is shown generally indicated at 10 . Tire 10 is designed to be mounted on aircraft wheels. figure 1 Mutually orthogonal axes X, Y, Z are shown, corresponding to the usual radial (Z), axial (Y) and circumferential (X) orientation of the tyre.

[0033] Conventionally, the tire 10 includes a crown S extending through two sidewalls F and two inner beads B. As shown in FIG. Two steel wire cores 12 are embedded in the inner bead B. The two wire cores 12 are arranged symmetrically with respect to the radial mid-plane M of the tyre. Each wire core 12 rotates about a reference axis. This axis of reference is substantially parallel to the direction Y and substantially coincides with the axis of rotation of the tyre. The crown S comprises a tread 14 equipped with sculptured features 16 . The tire 10 also includes an inner layer of leak-proof rubber 18 that runs across the crown S between the two annular wire cores 12 of the tire 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com