Dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in metallurgical slag treatment process

A technology of deep purification device and treatment process, which is applied in the field of purification and cooling system, high-efficiency and low-energy consumption dust removal and deep purification device for flue gas in metallurgical slag treatment process, and can solve the problems of low empty tower speed in the spraying section, poor reliability of system operation efficiency, Problems such as difficulty in uniformity of the cloth liquid in the tower can achieve the effect of improving the classification dust removal efficiency and gas dust removal and purification efficiency, high dust removal and purification efficiency, and speeding up dynamic and efficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

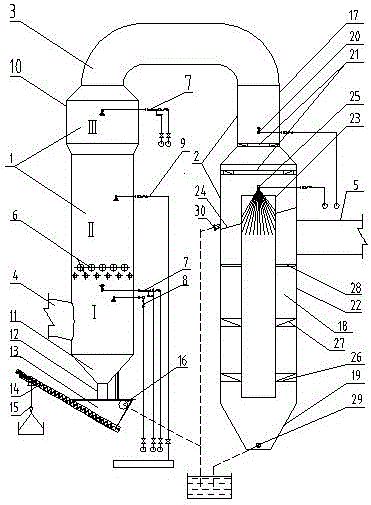

[0044] The high-efficiency, low-energy-consumption dust removal and deep purification device for flue gas in the metallurgical slag treatment process includes a spray spray scrubber 1 and a downward gas-liquid foam suspension pneumatic swirl deep purification dehydration and demist tower 2. The upper outlet of the spray spray scrubber 1 and the downward flow Gas-liquid foam suspension, pneumatic swirl deep purification, dehydration and defogging tower 2, the upper entrance is connected through connecting flue 3;

[0045] The spray spray washing tower 1 is a wet multi-layer gas-liquid countercurrent contact method, and the downward gas-liquid foam suspension pneumatic swirl deep purification dehydration demisting tower 2 is a gas-liquid downstream contact method;

[0046] Above the smoke inlet pipe 4 in the spray spray washing tower 1, there are fog condensation and trapping area I, spray spray washing area II, and primary gas-liquid separation and aerosol preconditioner area II...

Embodiment 2

[0068] The slag treatment comprehensive transformation project of a large iron and steel company adopts the drum method slag treatment process, and the dust-laden steam stream from the slag treatment device has a high moisture content: 13%-15%, and the dust carried is ultra-fine steel slag. Powder, with hydraulic and sticky (knot) properties. From the perspective of dust particle size distribution: volume percentage / %: particle size > 10 μm accounted for 56%, particle size 2--10 μm accounted for 32%, and the rest <2 μm accounted for 12%. Select the high-efficiency, low-energy dust removal and deep purification device and system for flue gas in the metallurgical slag treatment process.

[0069] Wet spray dust removal equipment is installed before the induced draft fan, and the purified gas is discharged to the atmosphere through the fan and exhaust pipe.

[0070] The relevant operating parameters of this embodiment are as follows

[0071] Flue gas volume 24×10 4 m 3 / h

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com