Patents

Literature

94results about How to "Drain evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

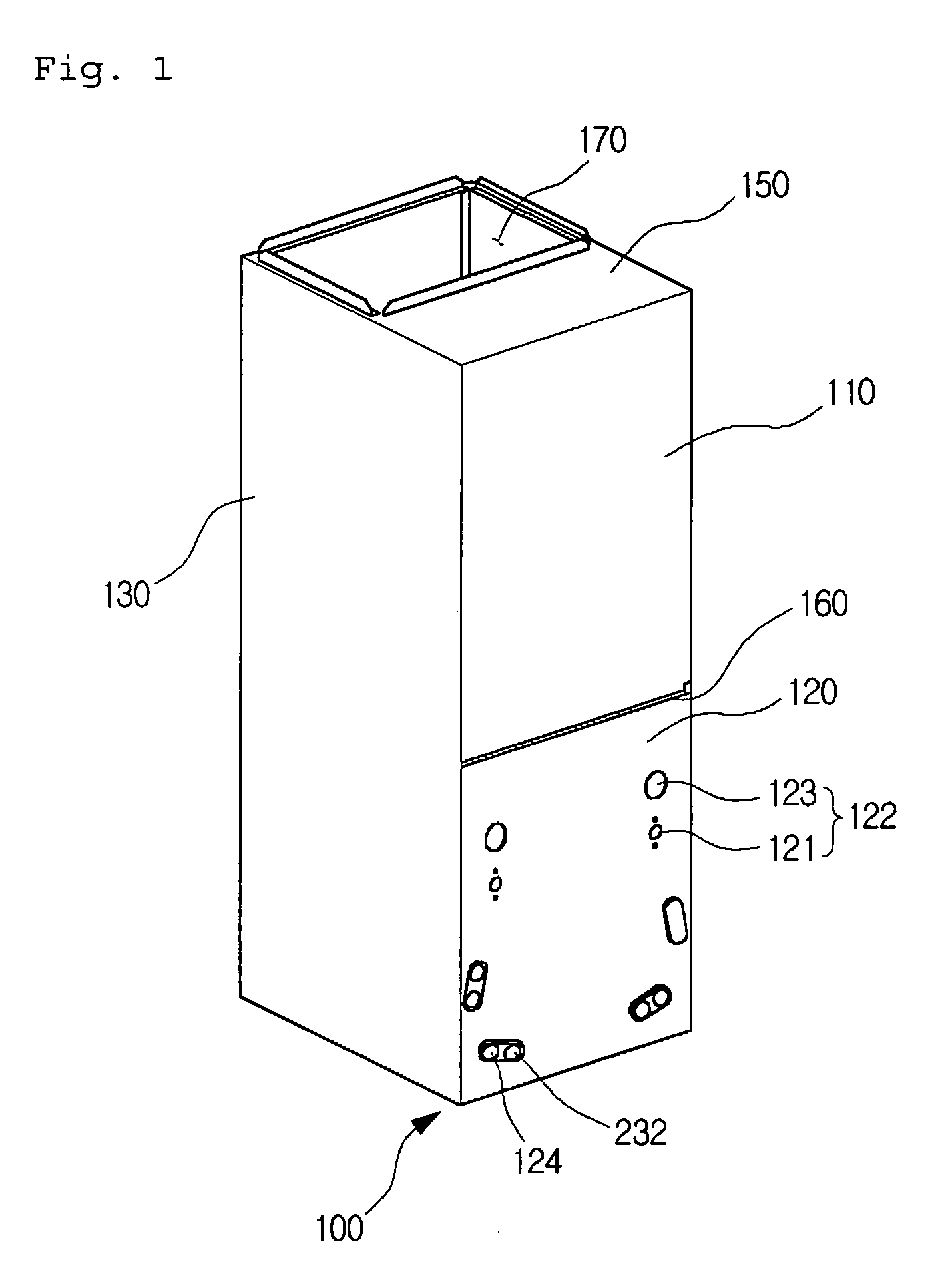

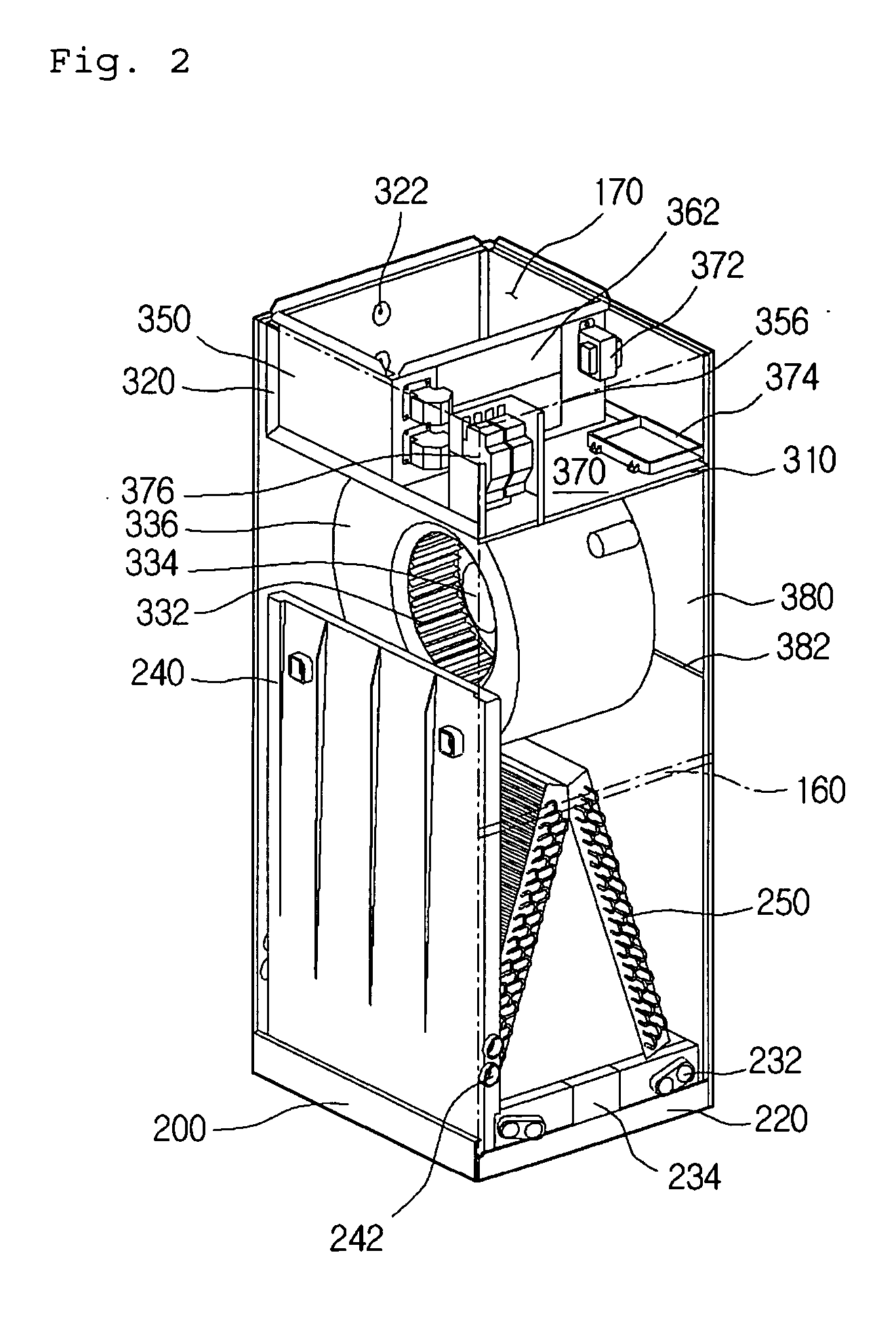

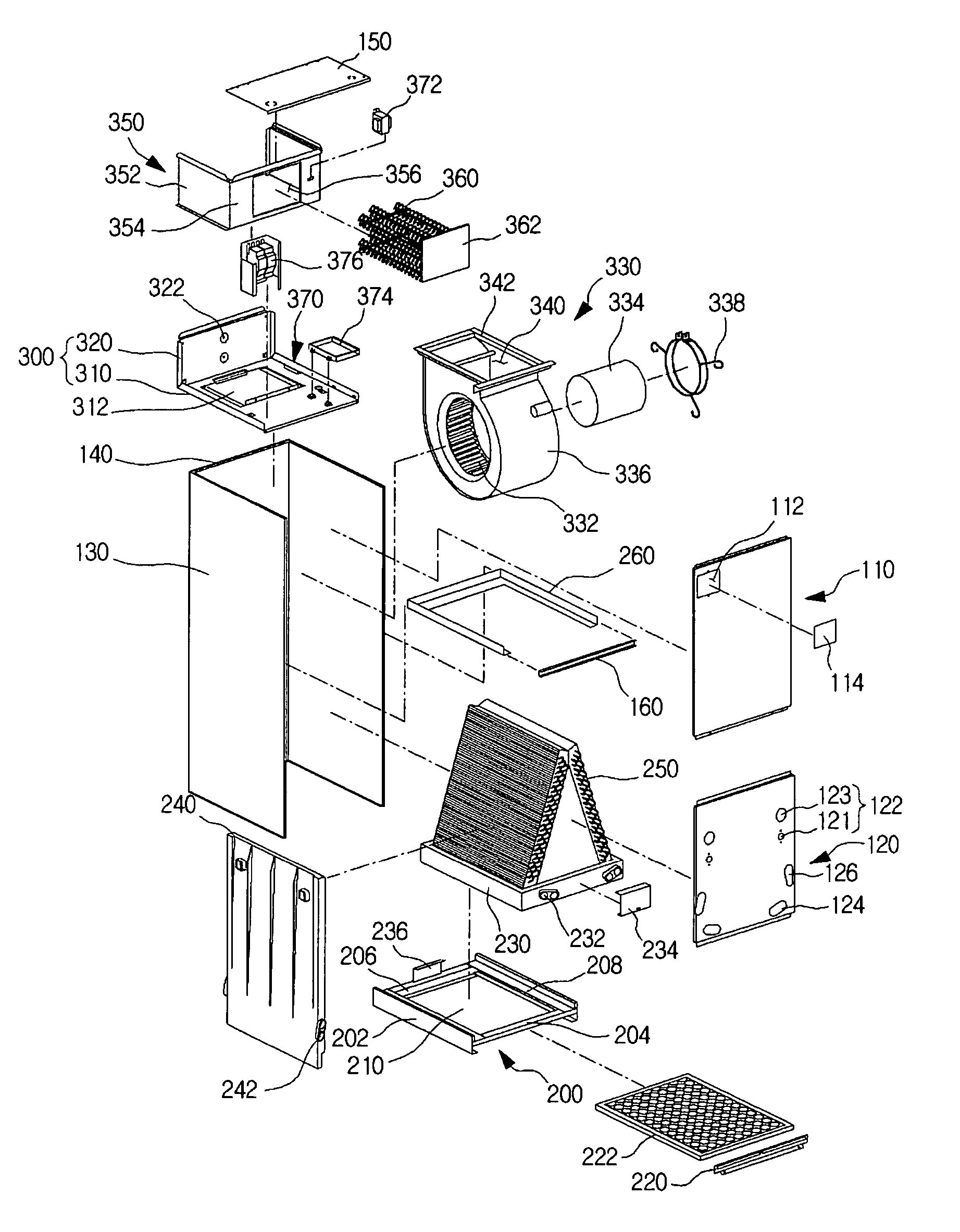

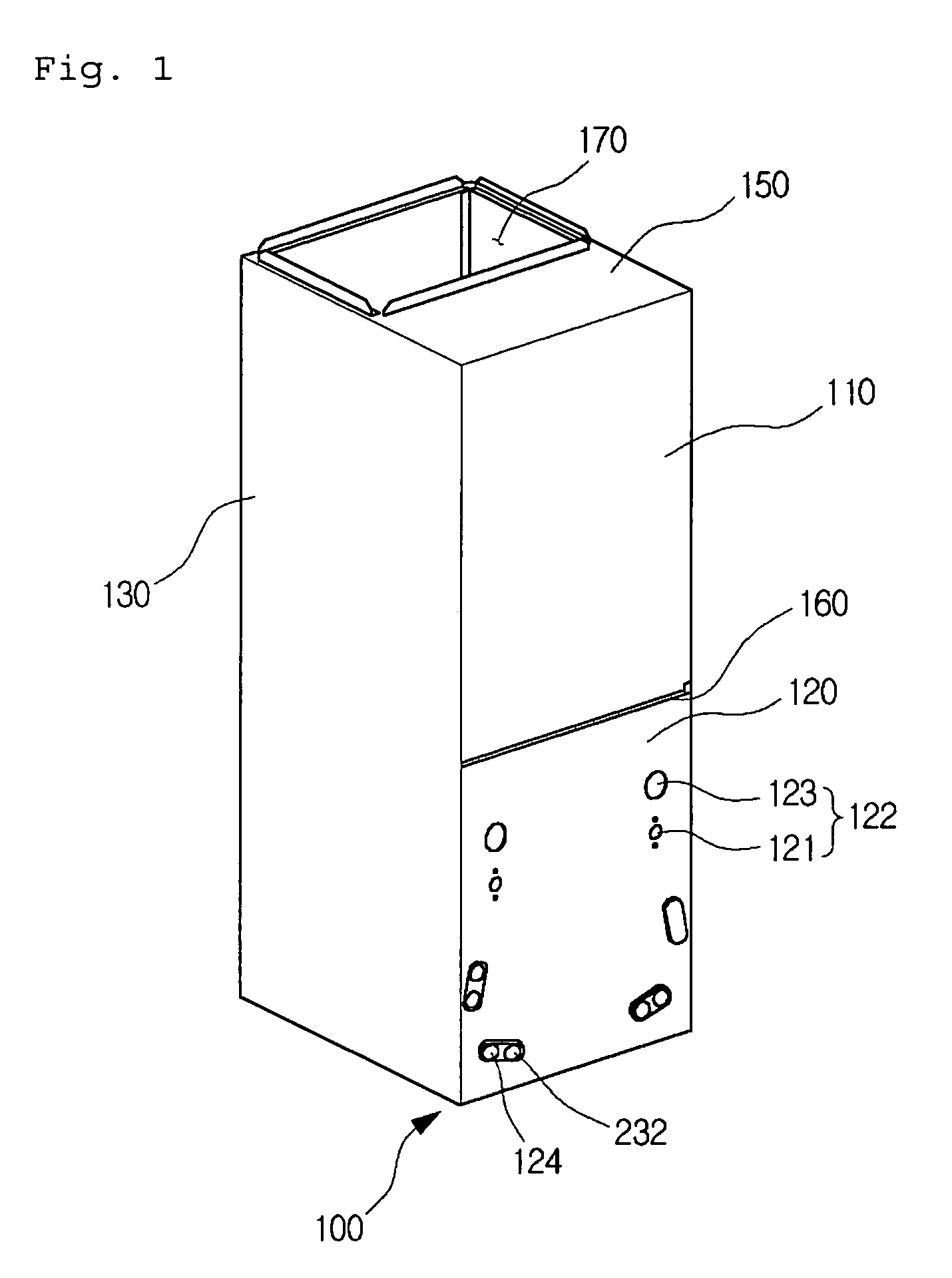

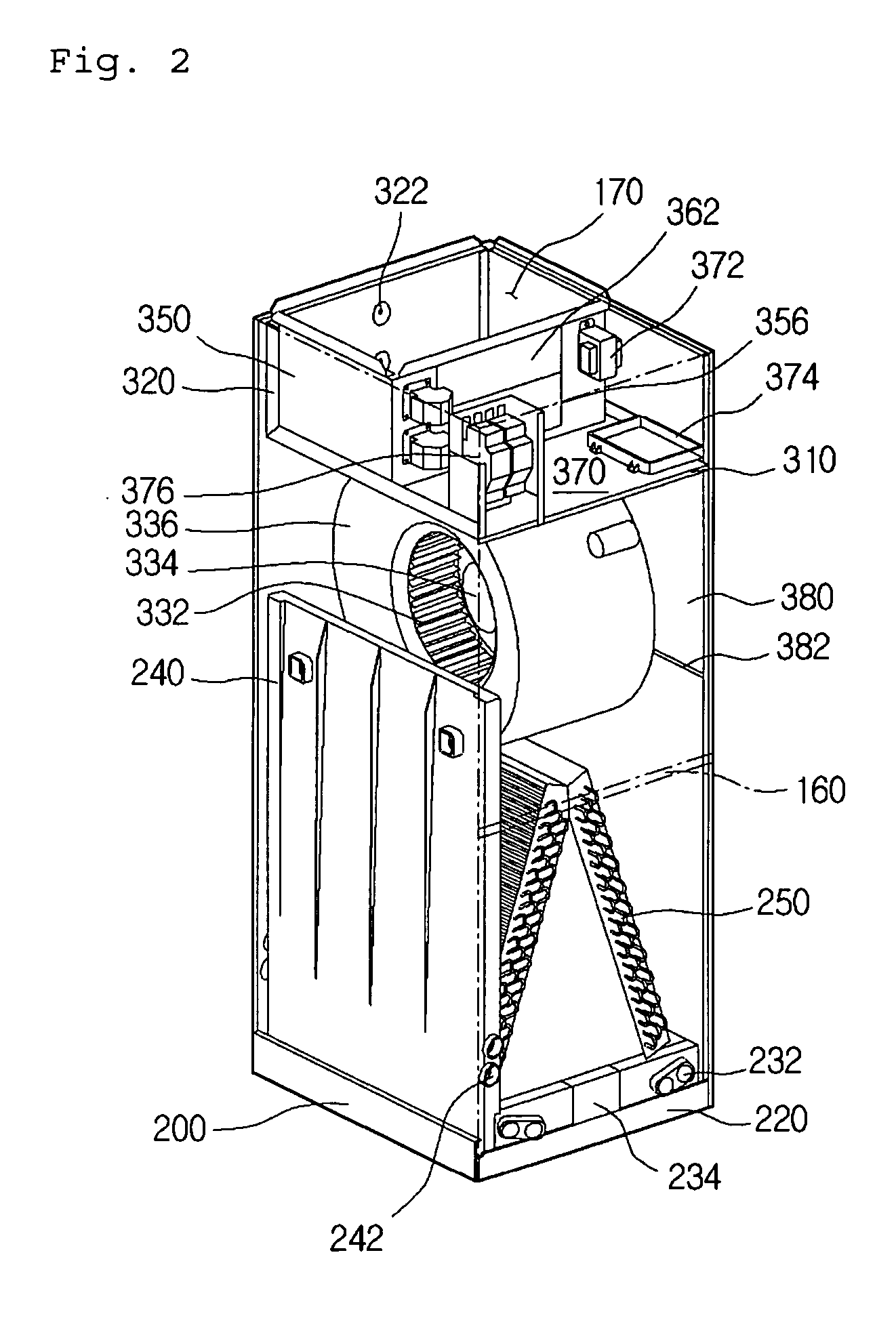

Indoor unit for air conditioner

ActiveUS20050109053A1Actively respondingDrain fastCondensate preventionLighting and heating apparatusWaste managementHeat exchanger

Disclosed is an indoor unit for an air conditioner to smoothly drain condensed water to the outside regardless of an installation state of the indoor unit. The indoor unit includes: a heat exchanger for performing heat exchange; a drain pan for collecting and draining condensed water generated in the heat exchanger; and two or more drain parts formed in the drain pan and through which the condensed water is drained.

Owner:LG ELECTRONICS INC

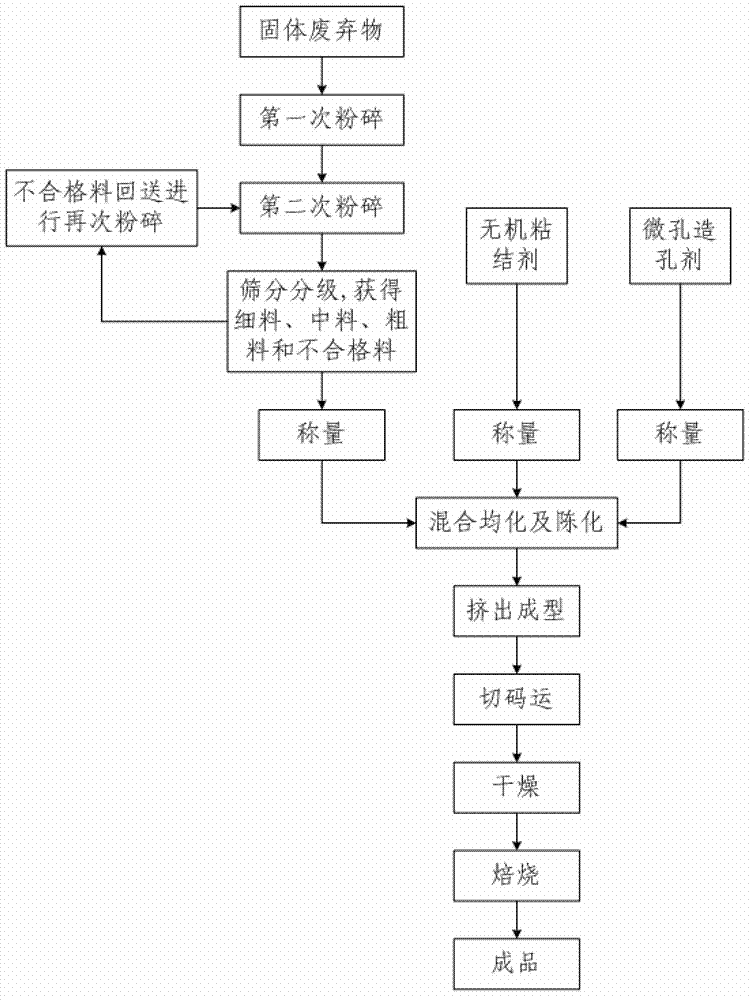

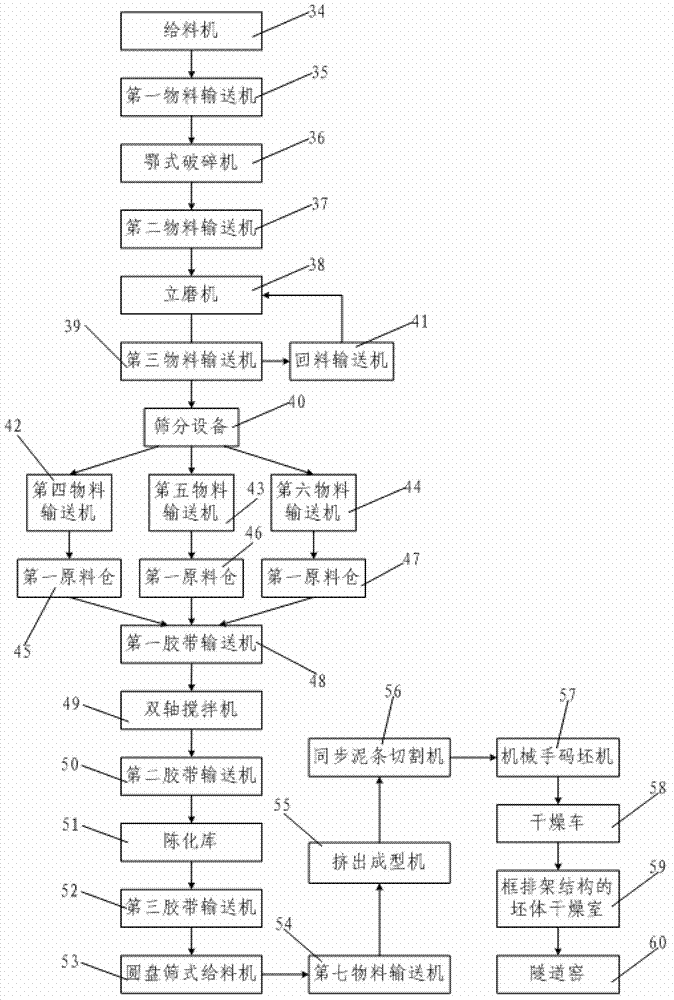

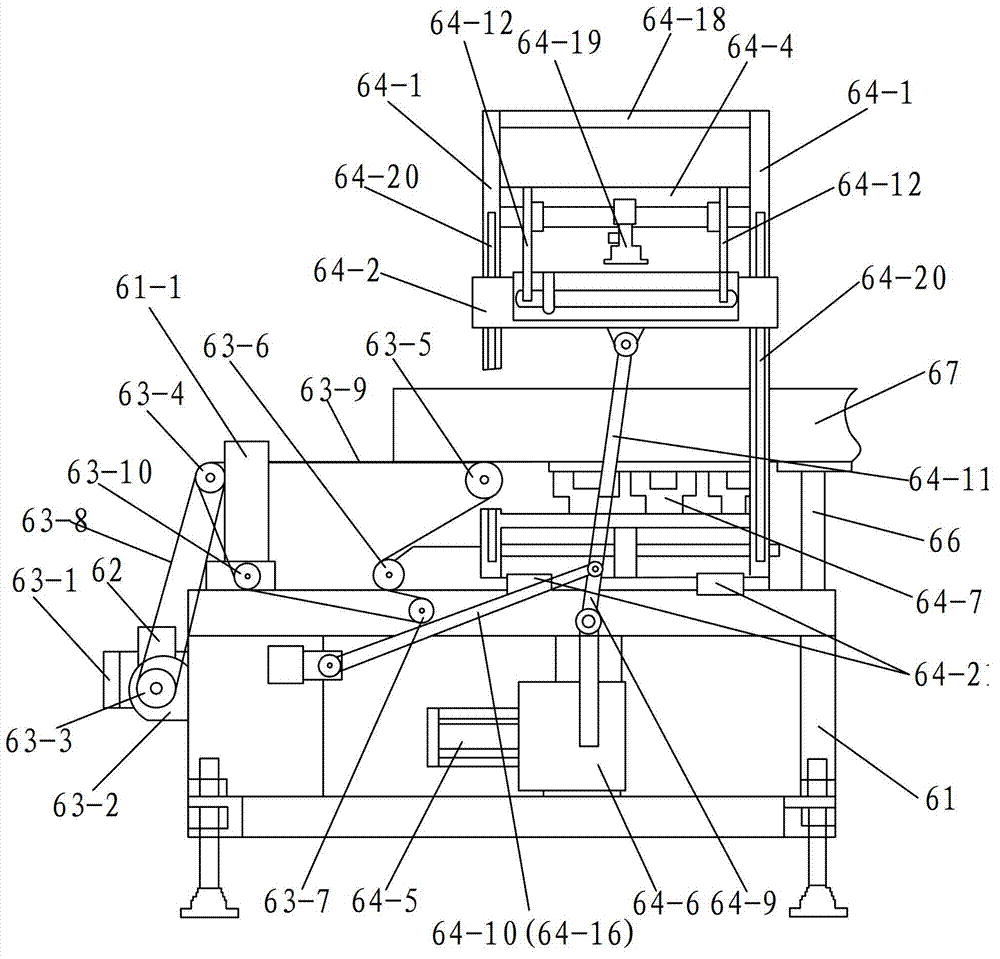

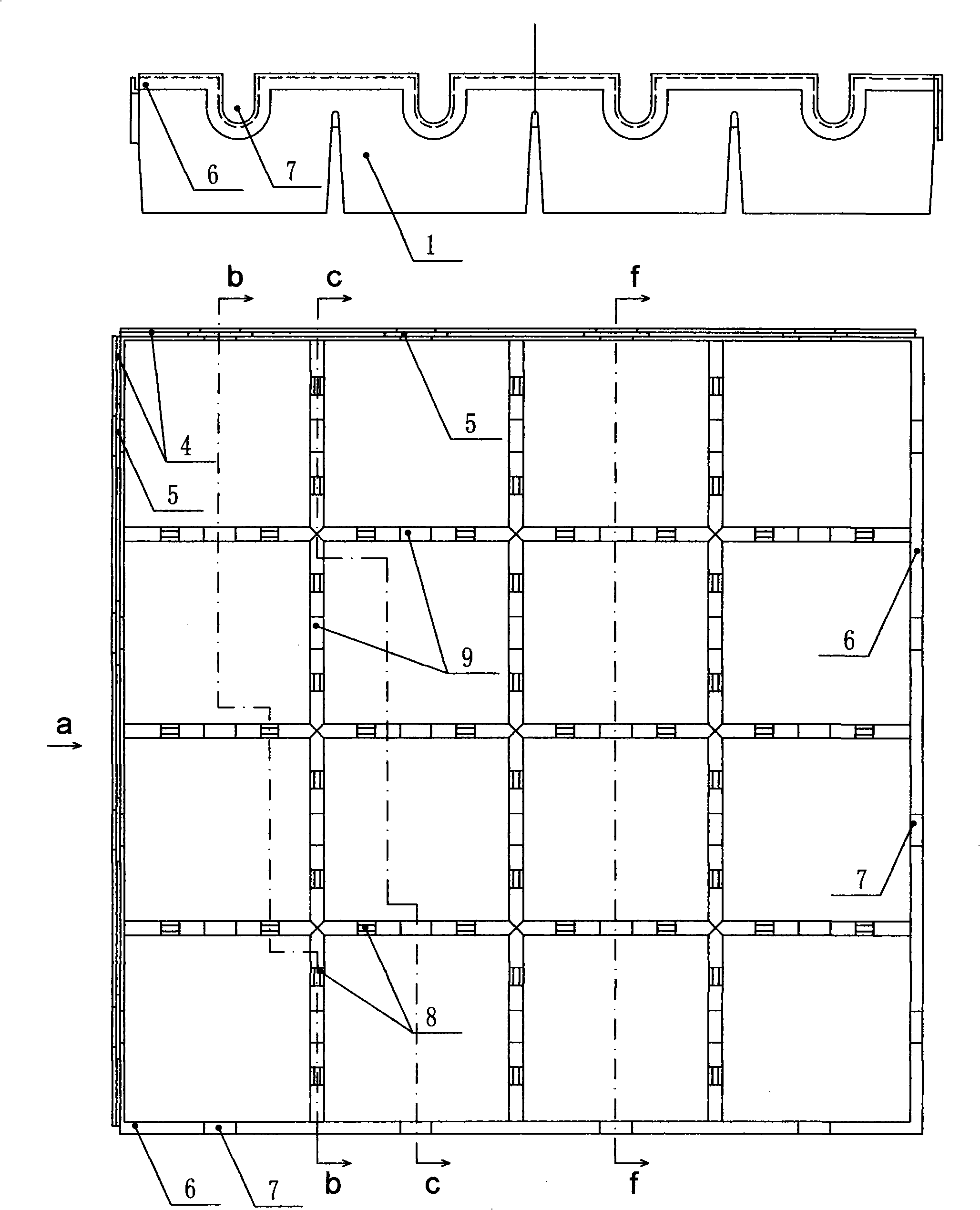

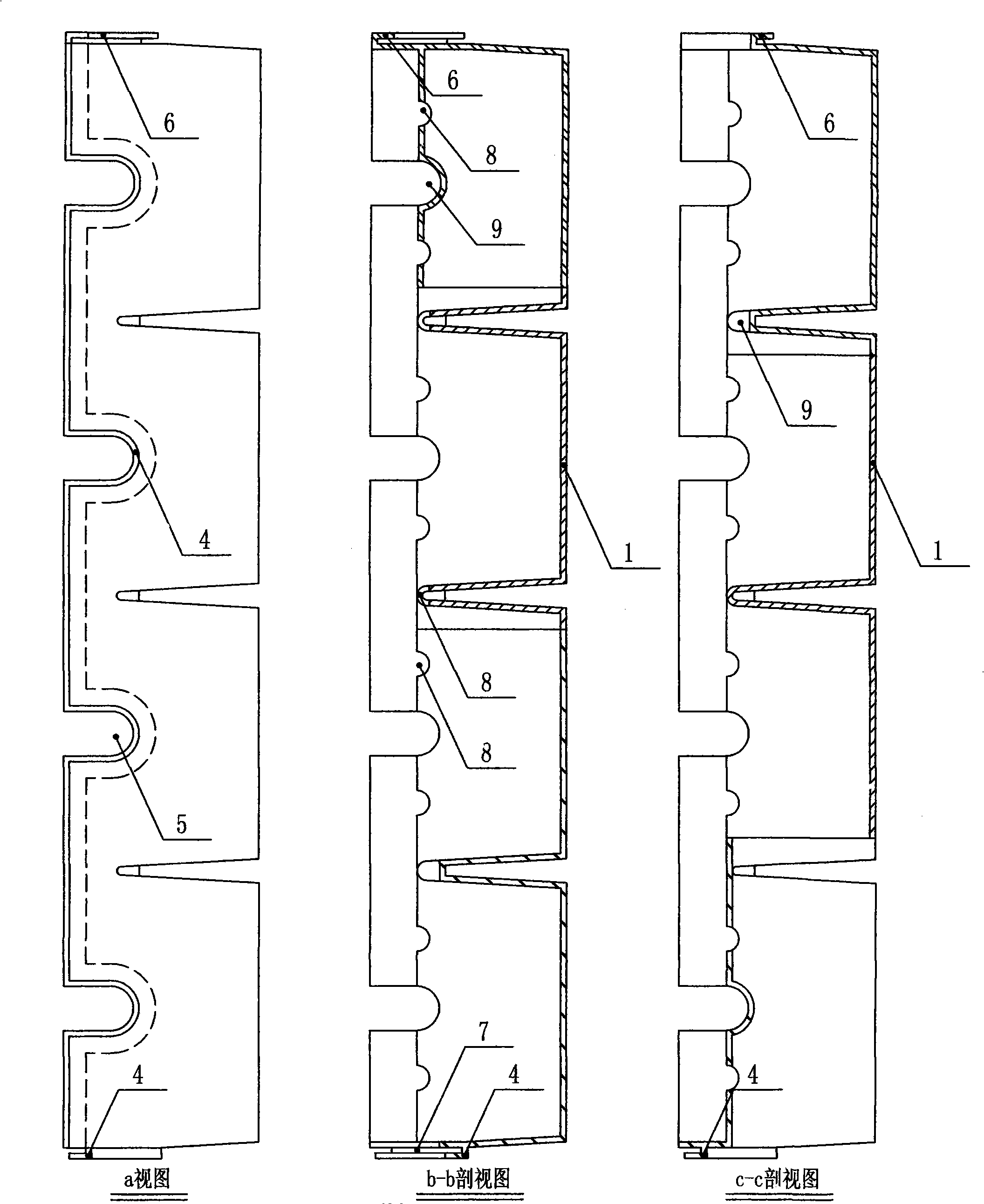

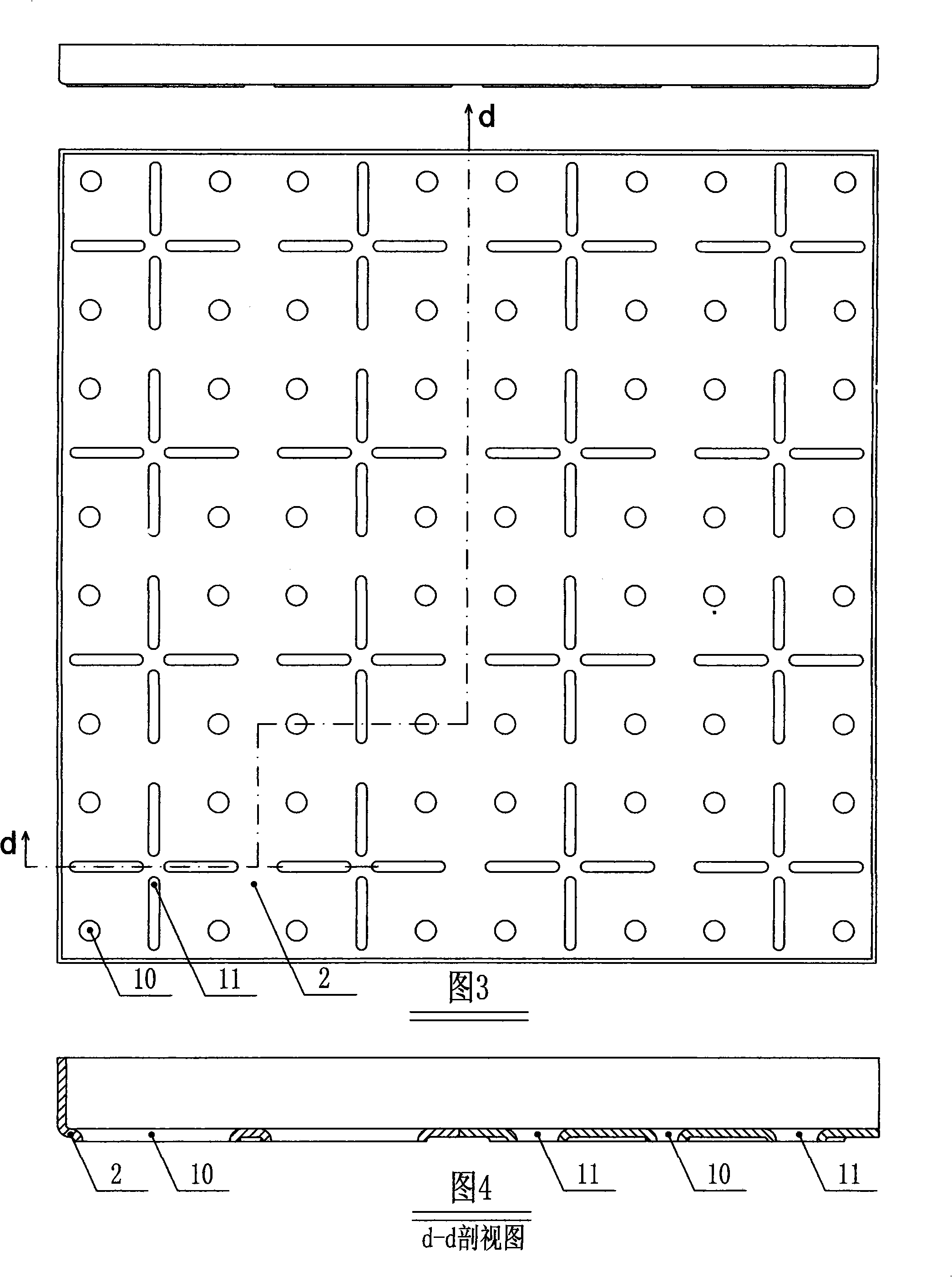

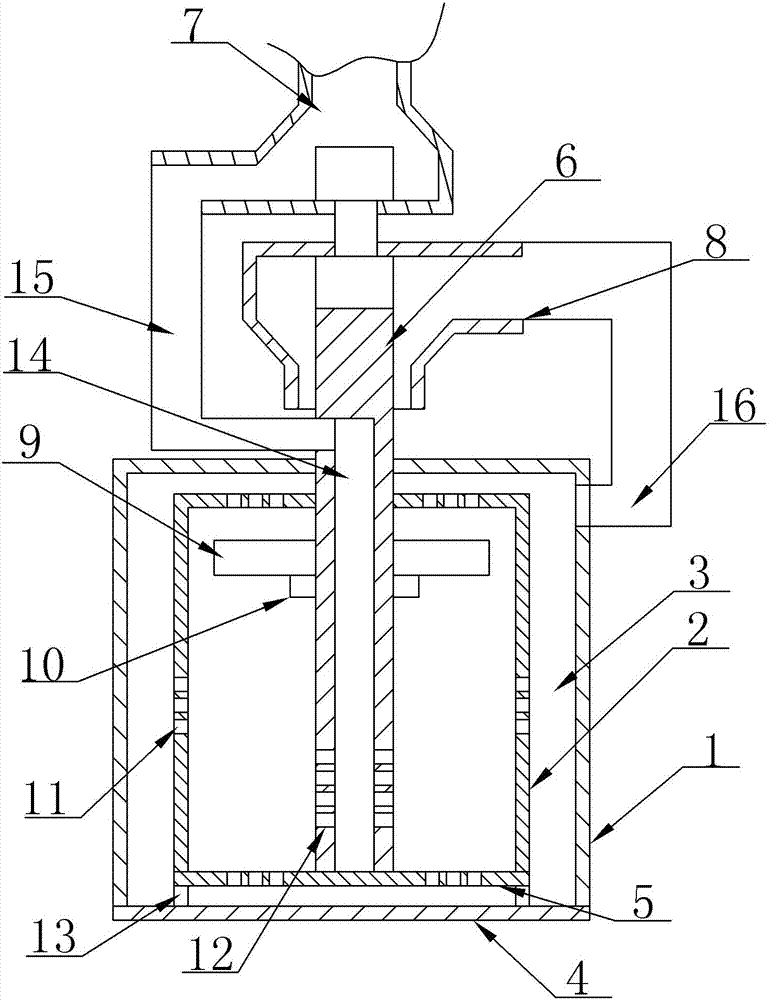

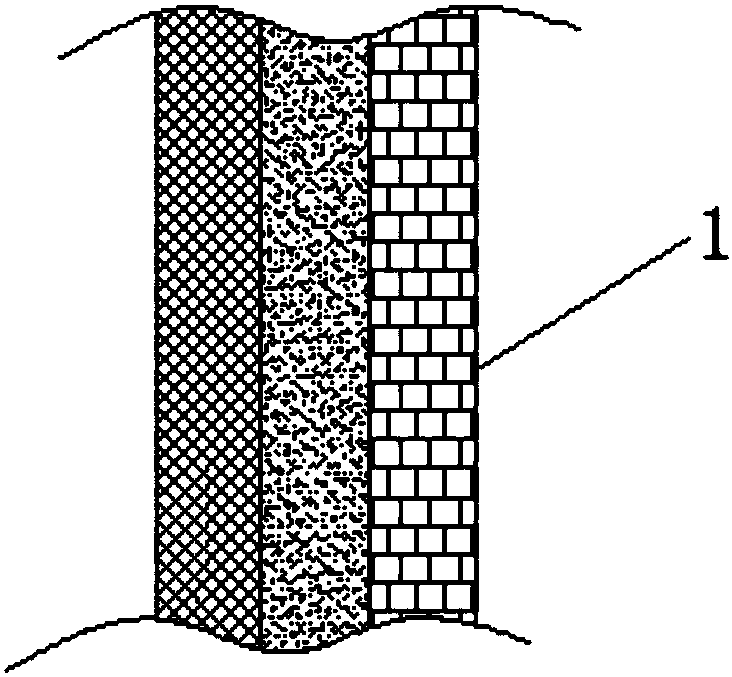

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

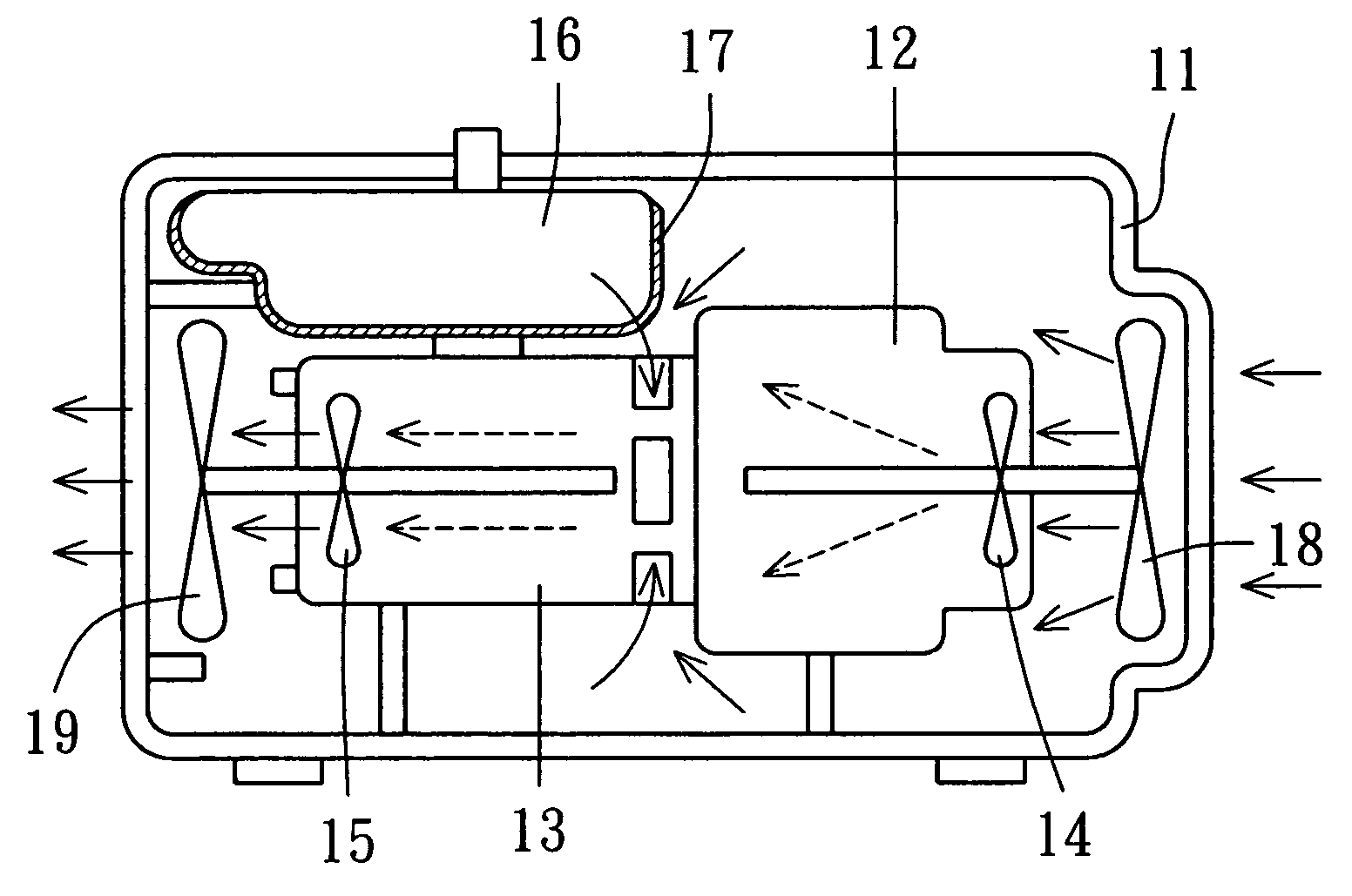

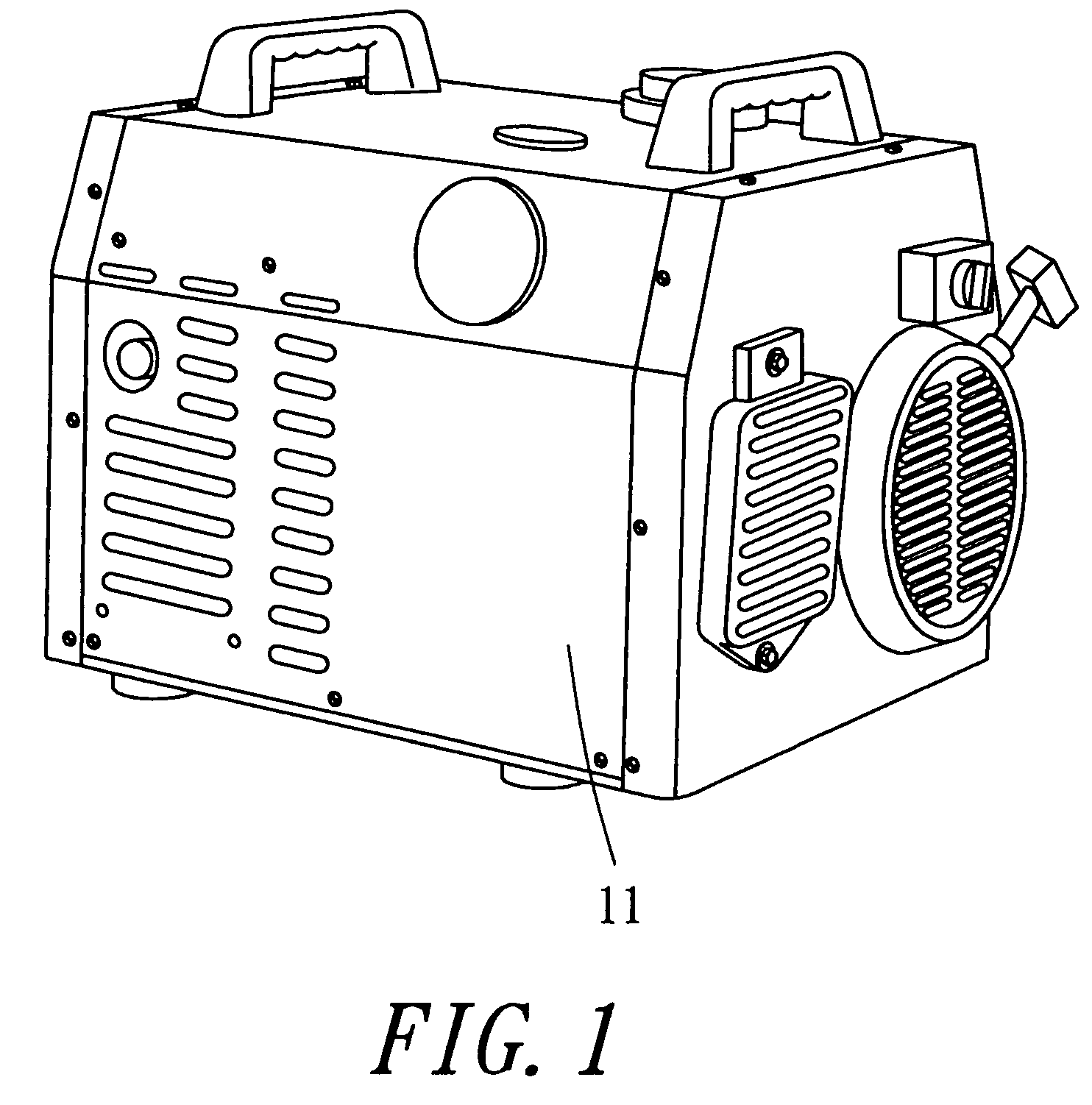

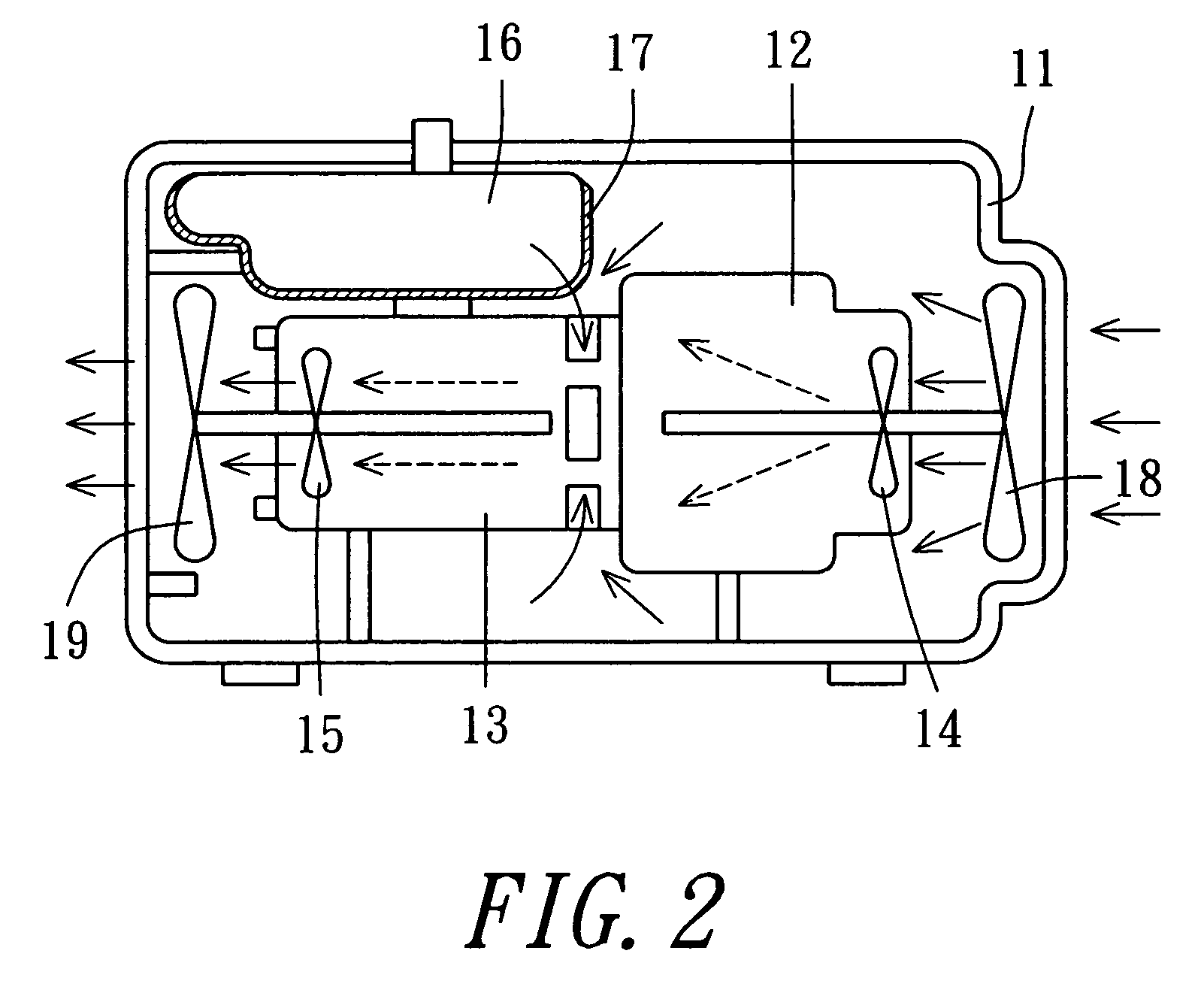

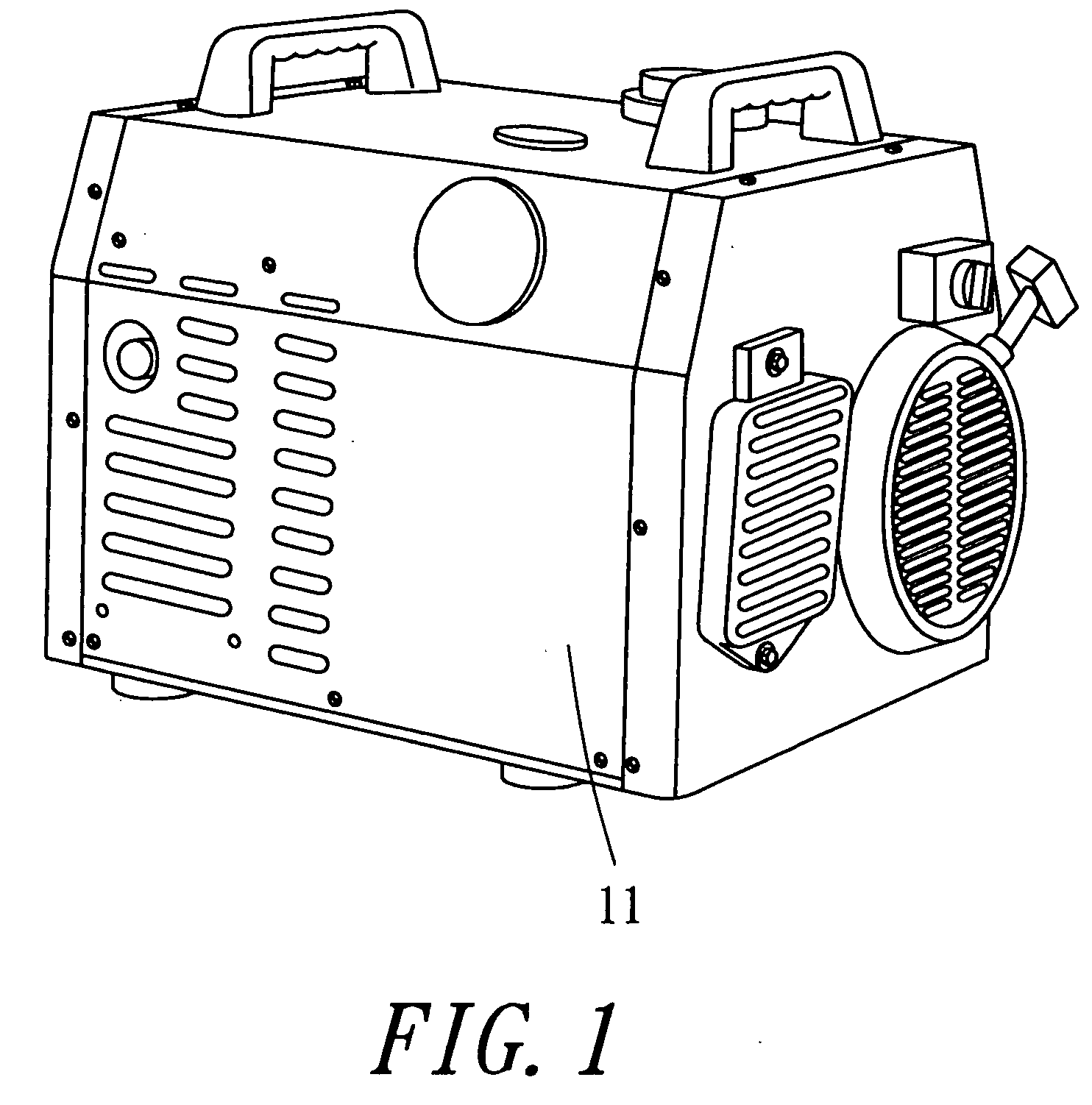

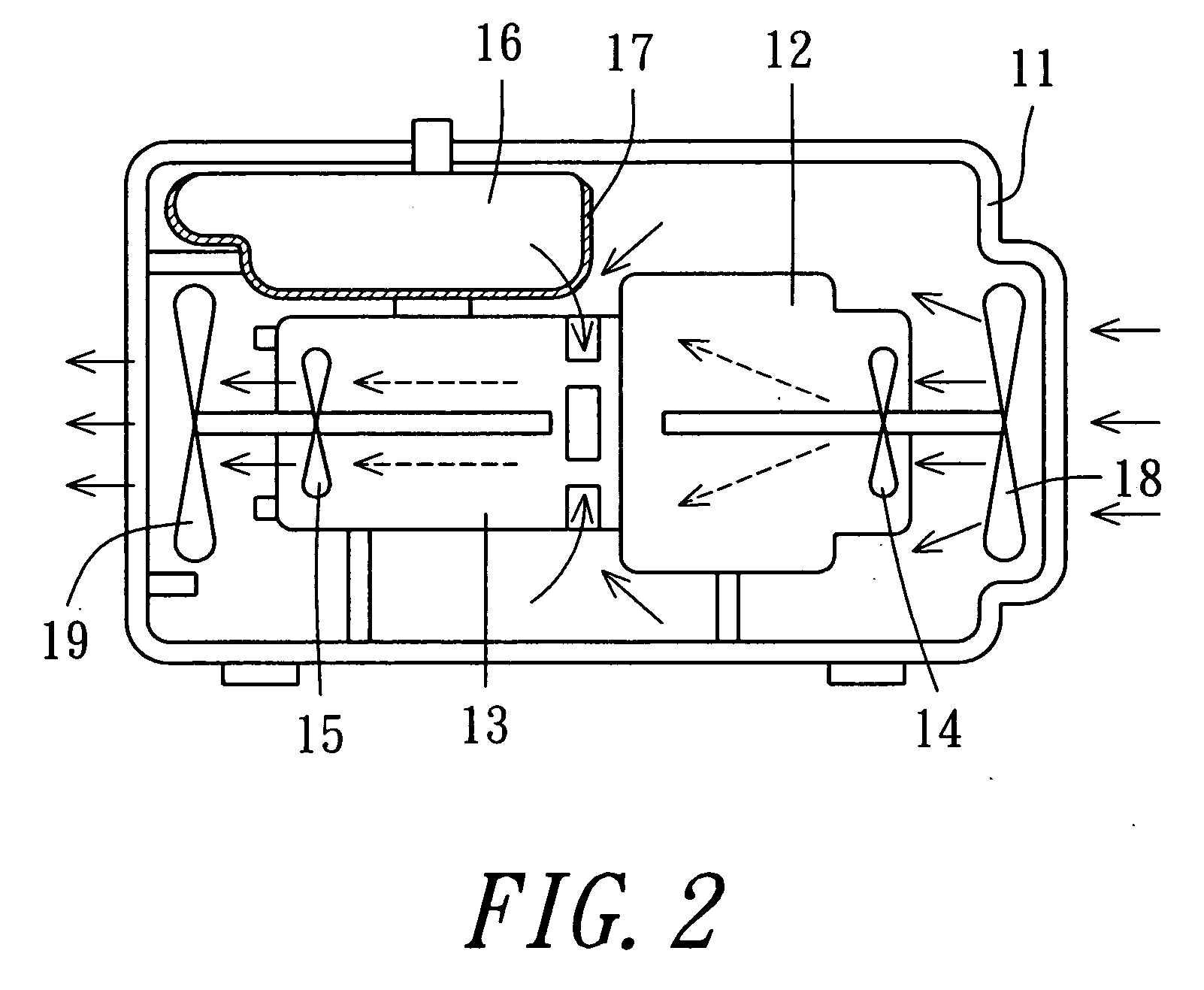

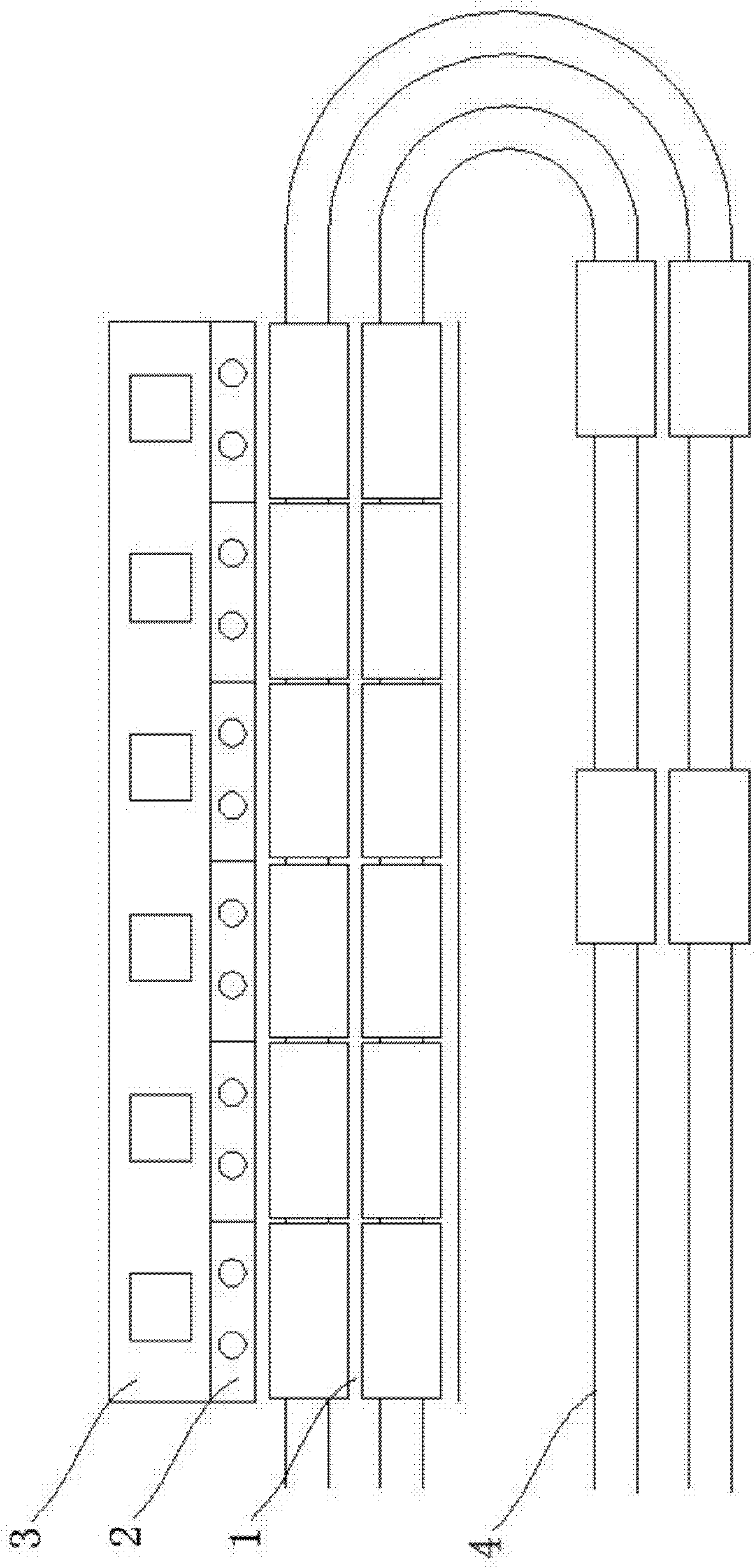

Air cooling generator

InactiveUS7023101B2Improve cooling effectLittle noiseAir coolingPropulsion using engine-driven generatorsImpellerElectric generator

A generator includes a housing, an engine, a first main impeller rotatably mounted in the engine, a first secondary impeller rotatably mounted in the housing and located outside of the engine, a generating body, a second main impeller rotatably mounted in the generating body, and a second secondary impeller rotatably mounted in the housing and located outside of the generating body. Thus, the first secondary impeller and the second secondary impeller can dissipate the heat produced from the engine and the generating body, thereby enhancing the heat dissipation effect of the generator, and thereby increasing the lifetime of the generator.

Owner:WANG WEN CHANG

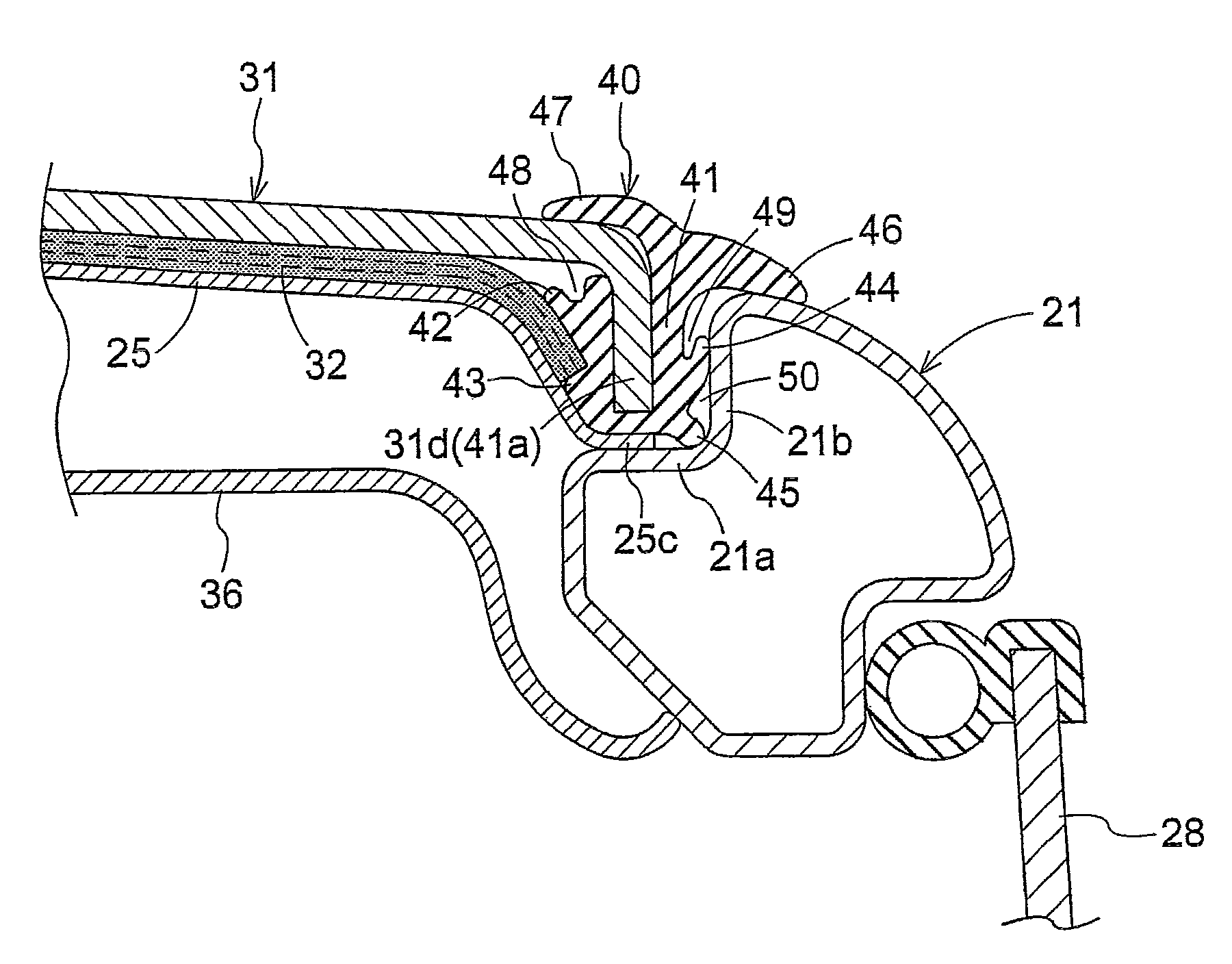

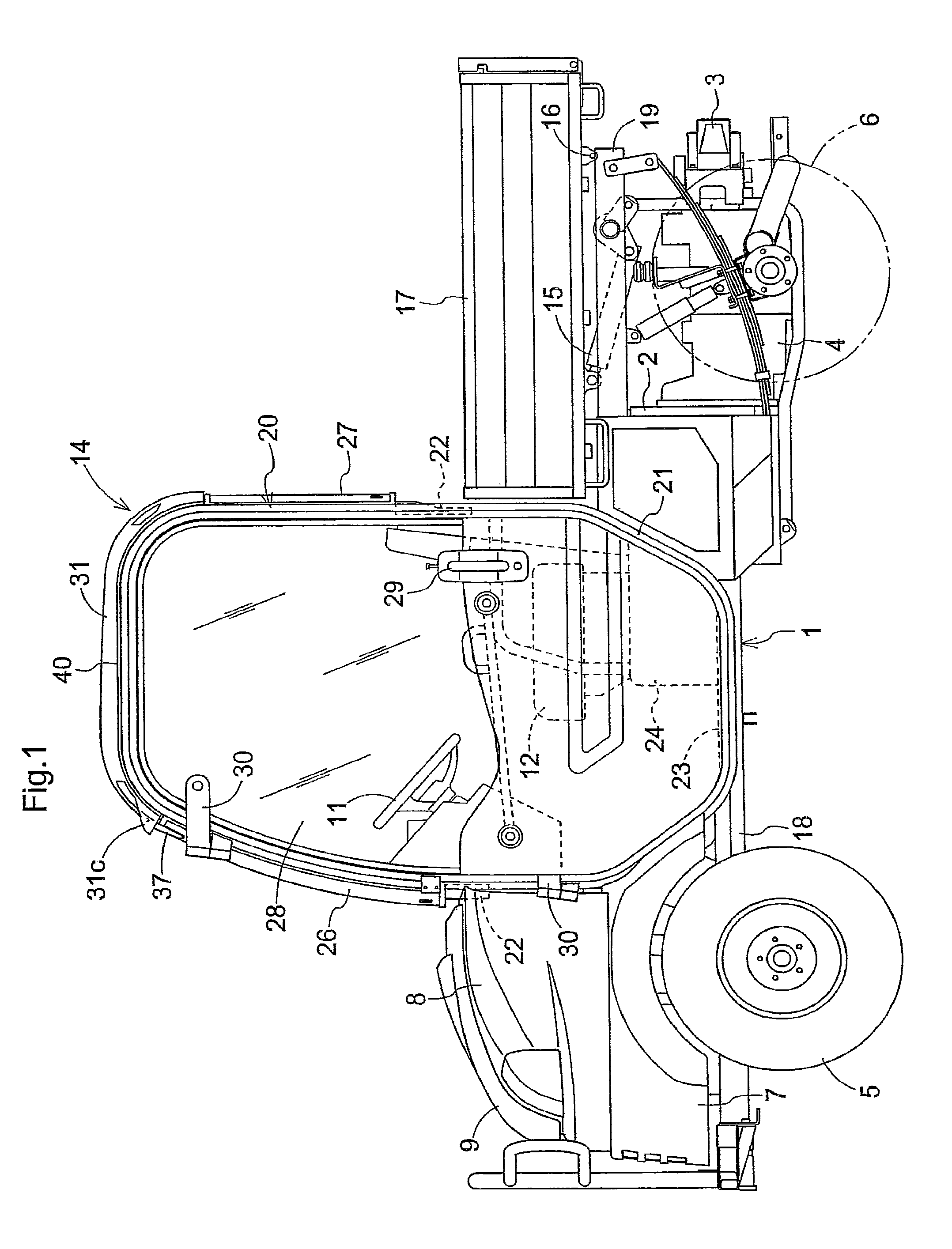

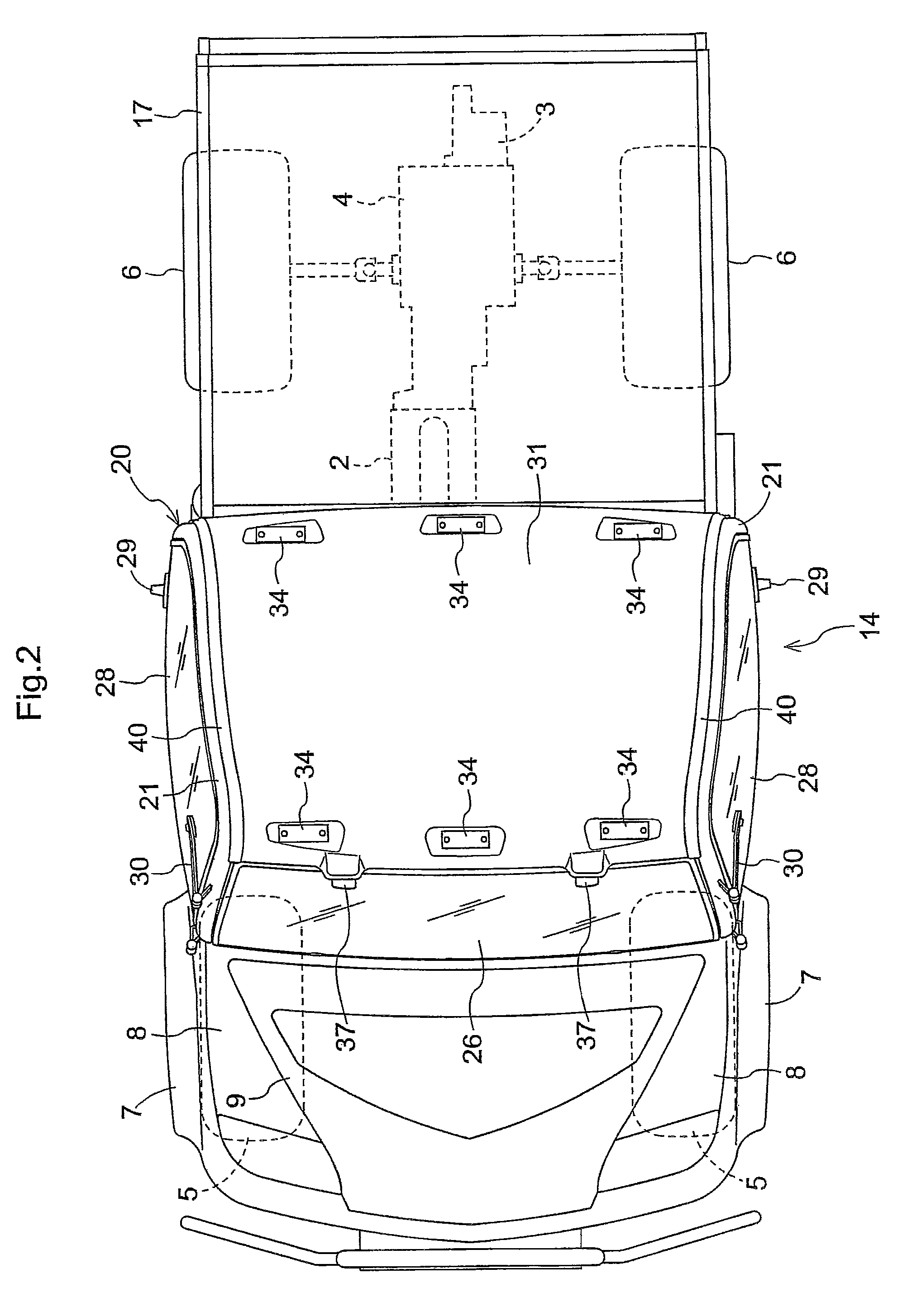

Sealing structure for cabin

ActiveUS7815246B2Improve sealingWater is prevented from stagnatingVehicle seatsSuperstructure subunitsNacelleEngineering

A cab includes a cab frame forming the cab, an outer roof configured to cover the cab frame from above and to be fastened to the cab frame from above, a seal mount protruding downwardly from an edge of the outer roof, and a seal material including a body portion having a recess for receiving the seal mount. The periphery of the body portion of the seal material has a seal lip for contacting the cab frame for sealing, and a drain groove for draining water entering between the seal material and the cab frame.

Owner:KUBOTA LTD

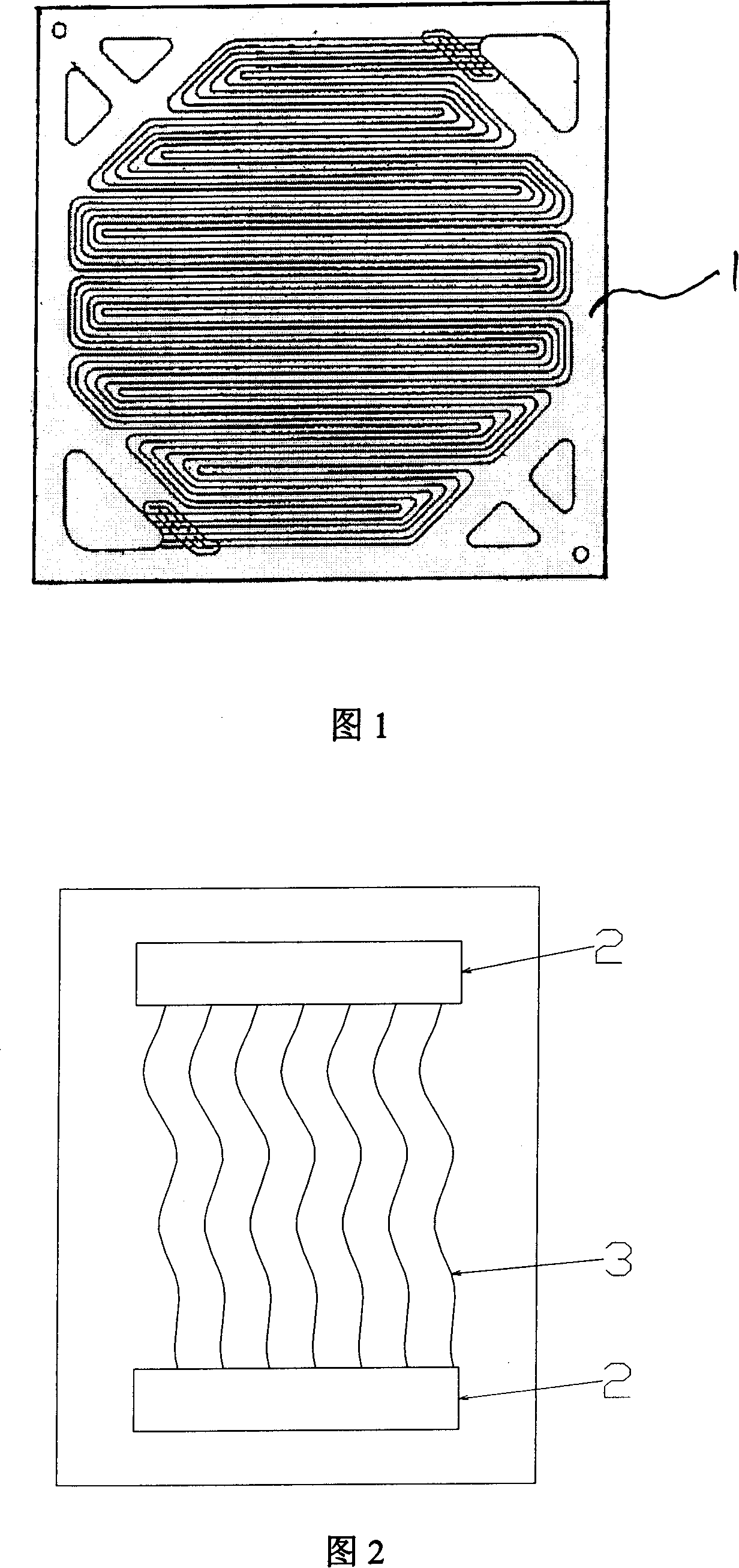

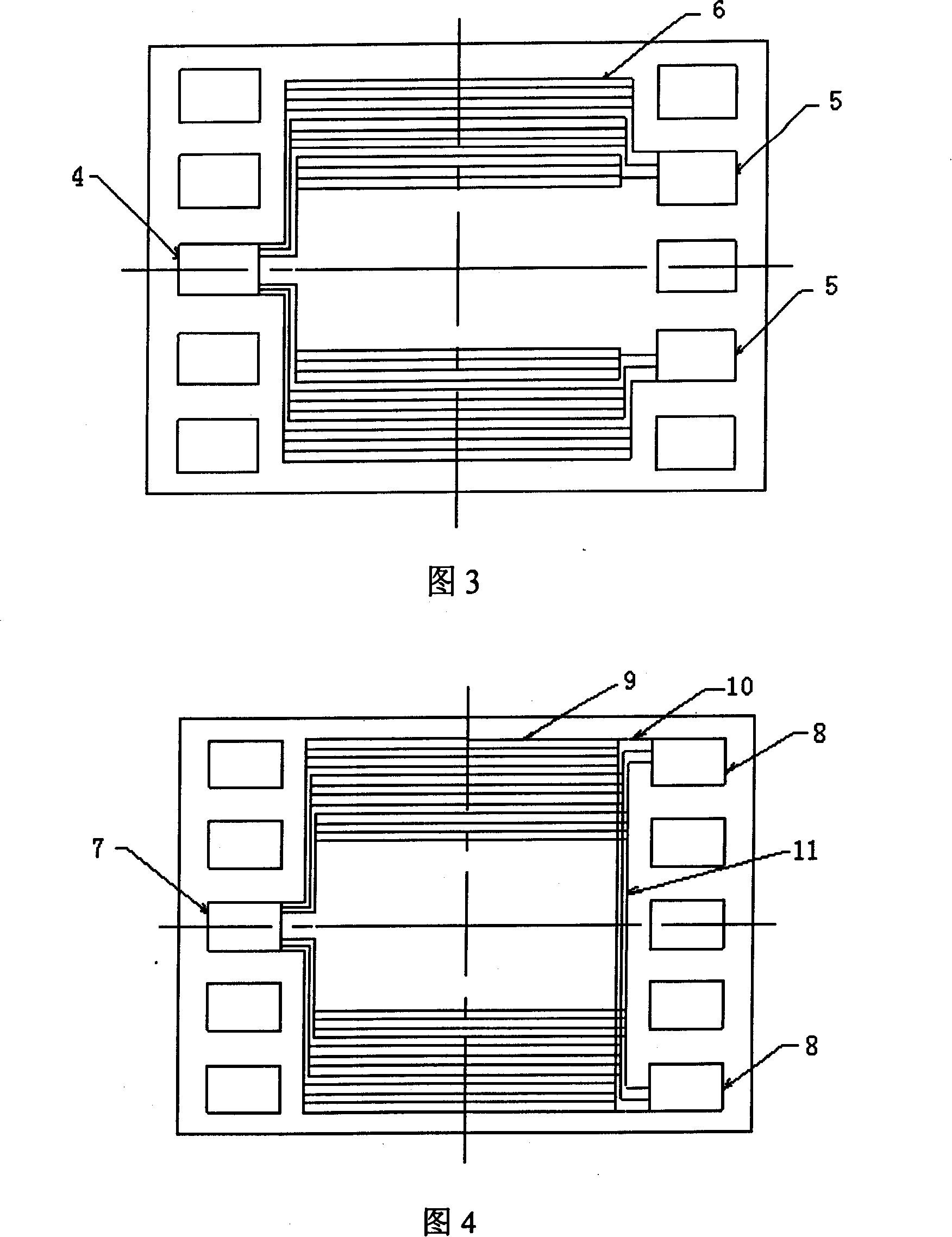

A fuel battery flow guiding polarized plate without water blockage

The invention relates to fuel battery guiding board which is not easy to stop water, the guiding board is guiding two-way board, said guiding two-way board comprises positive air guiding groove, negative hydrogen guiding groove, middle cooling flow interlayer, said flow hole which air or hydrogen in and out is single hole for in, two or more hole for out, guiding groove and connecting groove which connects guiding groove are set between flow hole for air or hydrogen, the guiding groove and connecting groove are all designed to direct flow groove or nearly direct flow groove; said flow hole for cooling liquid is single hole or double holes or more holes for in, two holes or more holes for out, guiding groove and connecting groove which connects guiding groove are set between flow hole for cooling liquid, the guiding groove and connecting groove are all designed to direct flow groove or nearly direct flow groove. Comparing with current technique, the invention can make liquid flow on liquid field evenly, freely; jam of guiding groove can be avoided.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Irrigation-free maintenance-free combined grow module of roof top garden

InactiveCN101313654ACountless benefitsCountless wealthCovering/liningsGeneral water supply conservationPlant rootsSurvival ratio

The invention provides a roof garden combination planting module which does not need water, electricity, artificial watering and maintenance and is energy saving and environment friendly. The module consists of five parts of a rain water collecting box, a drainage plate, a planting box, edge sealing strips and angle sealing strips. The module is particularly applied to the greening of old houses and light steel roofs, which is low in cost requirement, small in bearing and difficult in watering and maintenance. The combination planting module depends on the structural advantages and has the characteristics of plant root resistance and water storage intercommunication; on the one hand, the module can be directly arranged on roofs to be used without needing the cooperation of root resistance waterproof coiled materials of other plants, on the other hand, the module does not need a large number of water supply pipes and adaptors, thereby greatly reducing cost of a roof garden system. Depending on the advantages of the standardized function design, the combination planting module has the characteristics of high commonality of products, strong adaptability of the system, high survival ratio of plants, short construction cycle, no construction rubbish, quick and convenient arrangement, low labor intensity, low product cost and convenient large-scale flow line production, etc.

Owner:上海银鼎工程技术有限公司 +1

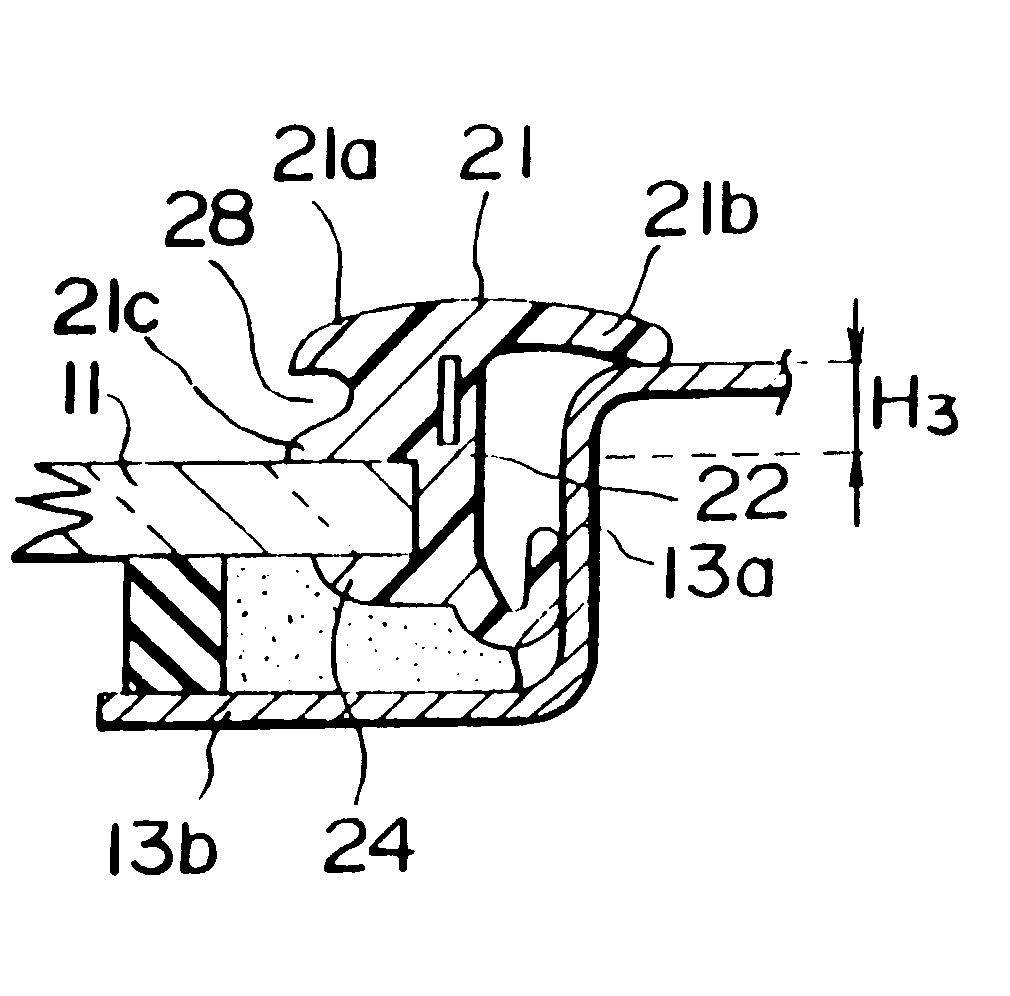

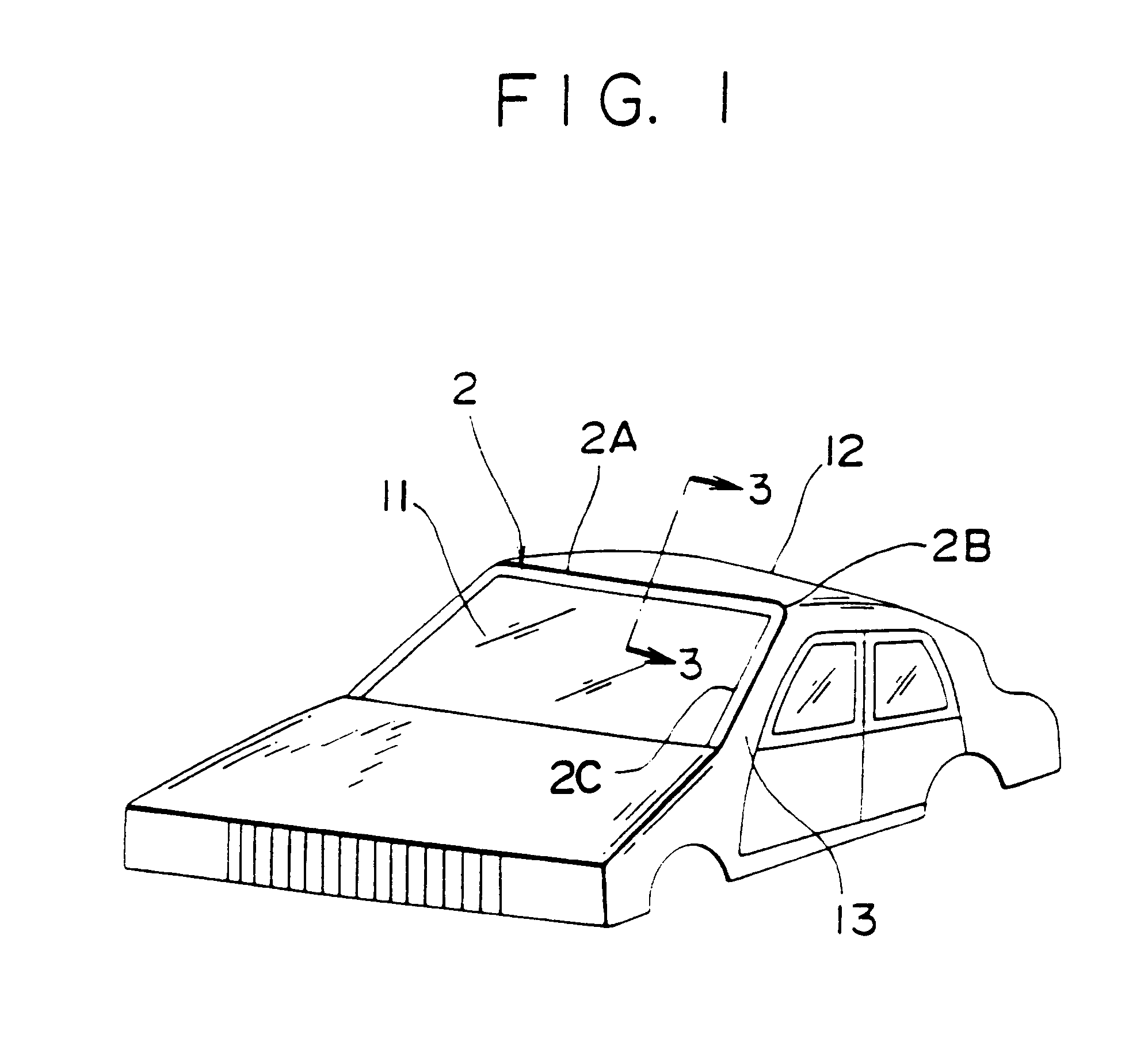

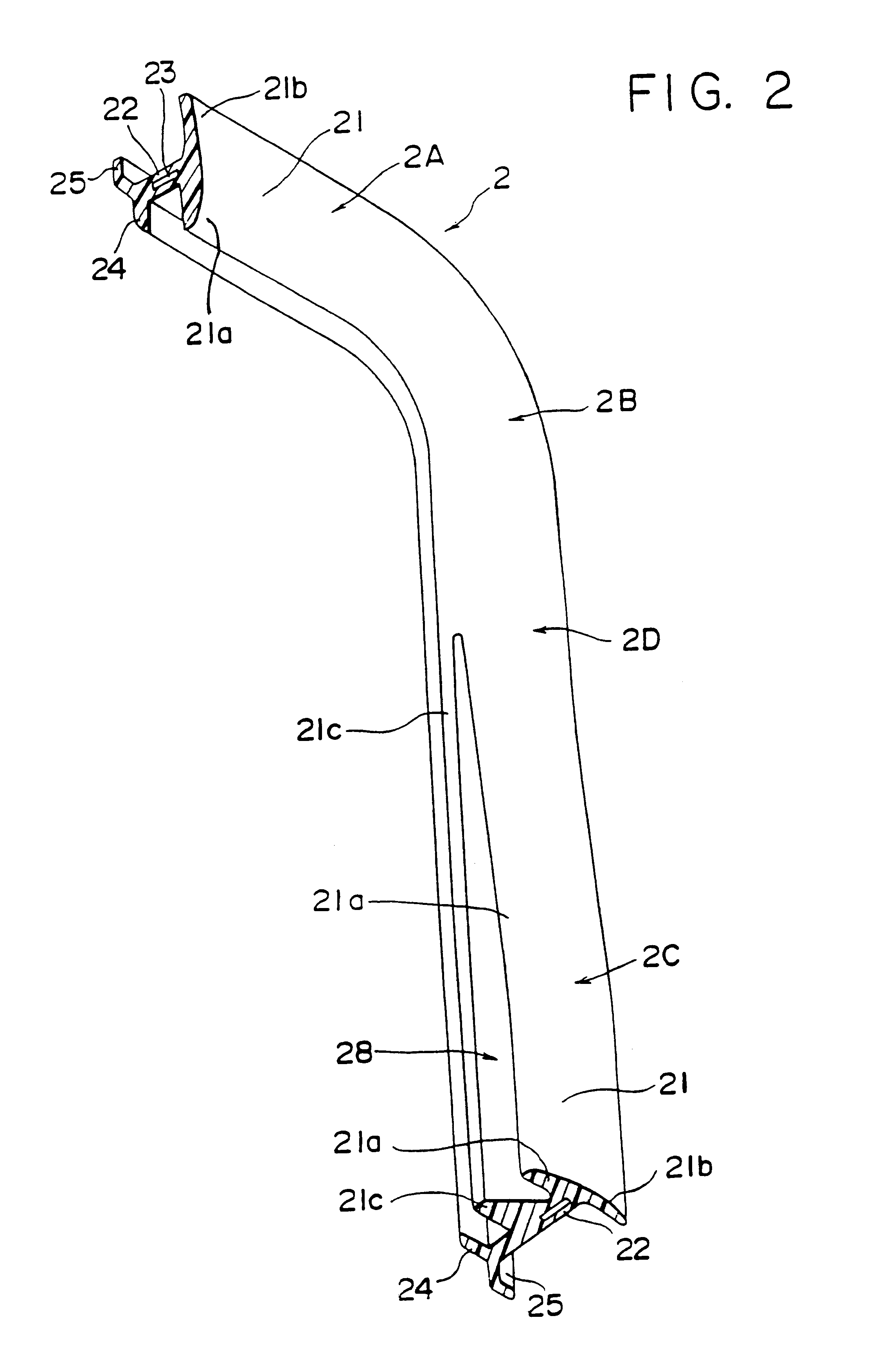

Automobile windshield molding and the method of producing the same

A windshield molding which is installable in the space between a windshield and a periphery of a window opening of a vehicle body panel. The windshield molding includes a pair of extruded side molding parts, a pair of extruded corner molding parts, and an extruded upper molding part integral with and extending between the side and corner molding parts. Each of the side molding parts associated with each side edge of the windshield is greater in thickness as compared with the upper end corner molding parts, where a water drain channel is formed. A windshield molding is also provided which drains rainwater smoothly through the rainwater groove provided at necessary sections and having a different depth in the longitudinal direction for better drainage which can be produced simply and continuously as a single molding without the addition of cutting or other processes.

Owner:TOKAI KOGYO CO LTD

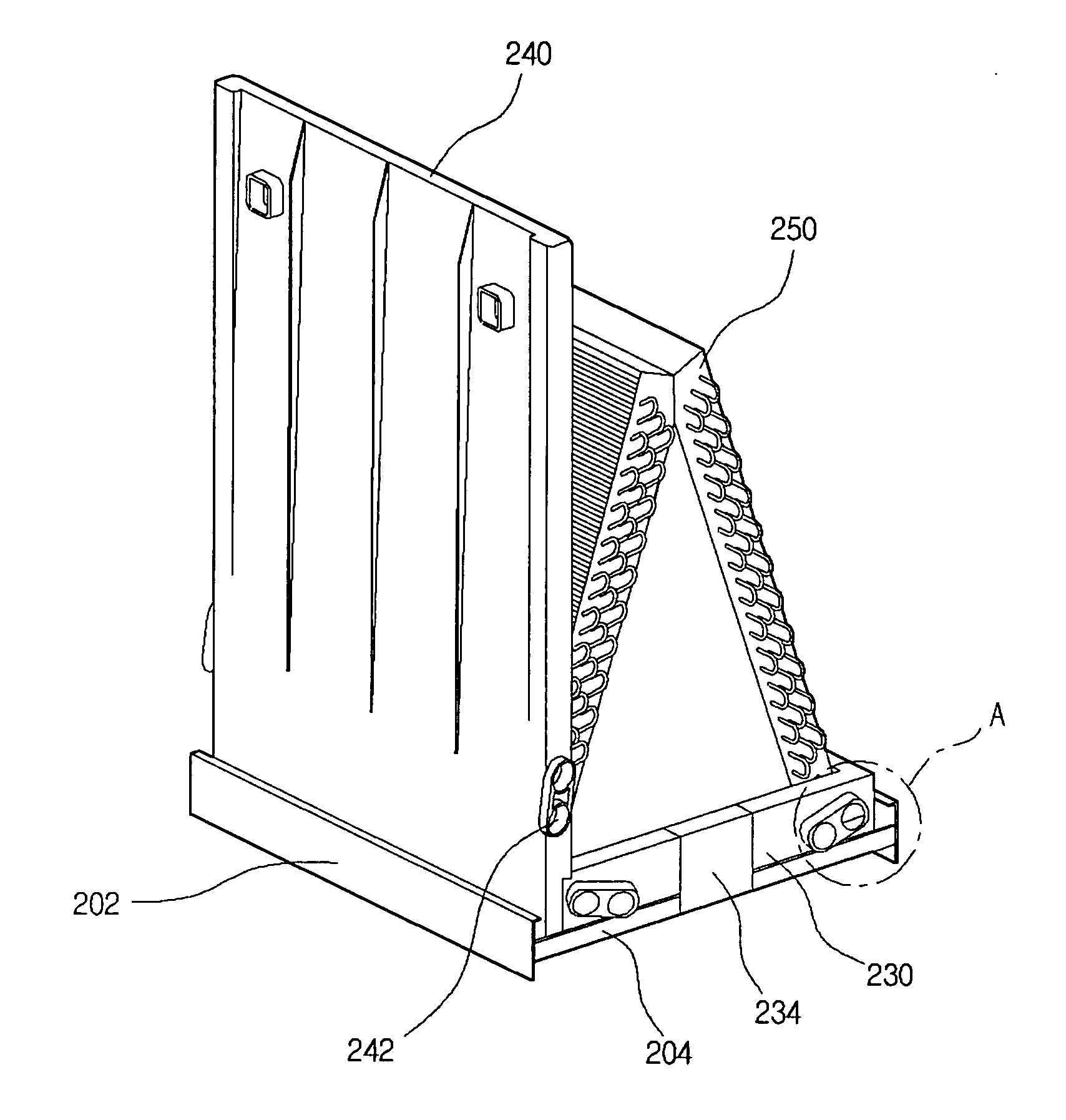

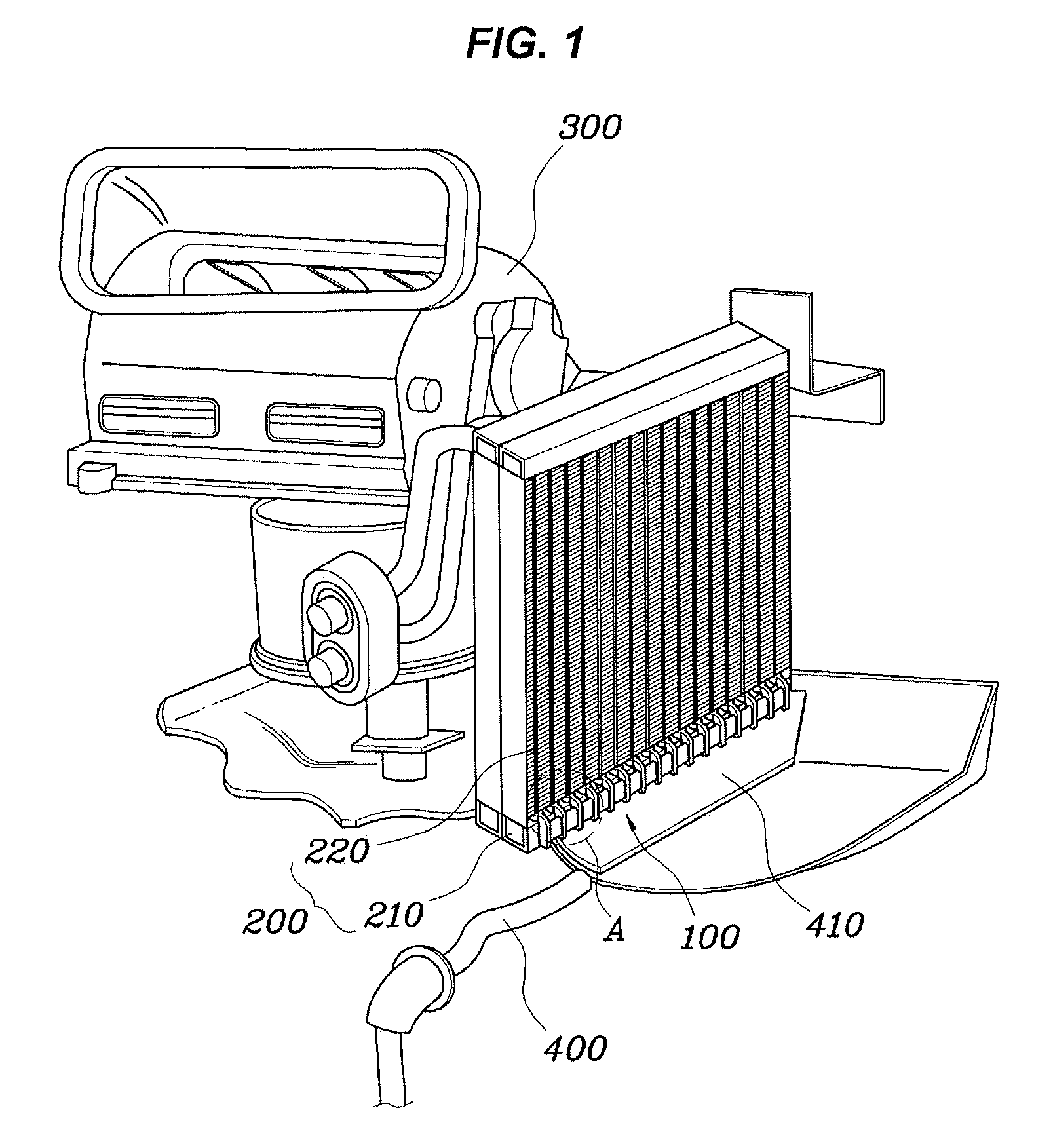

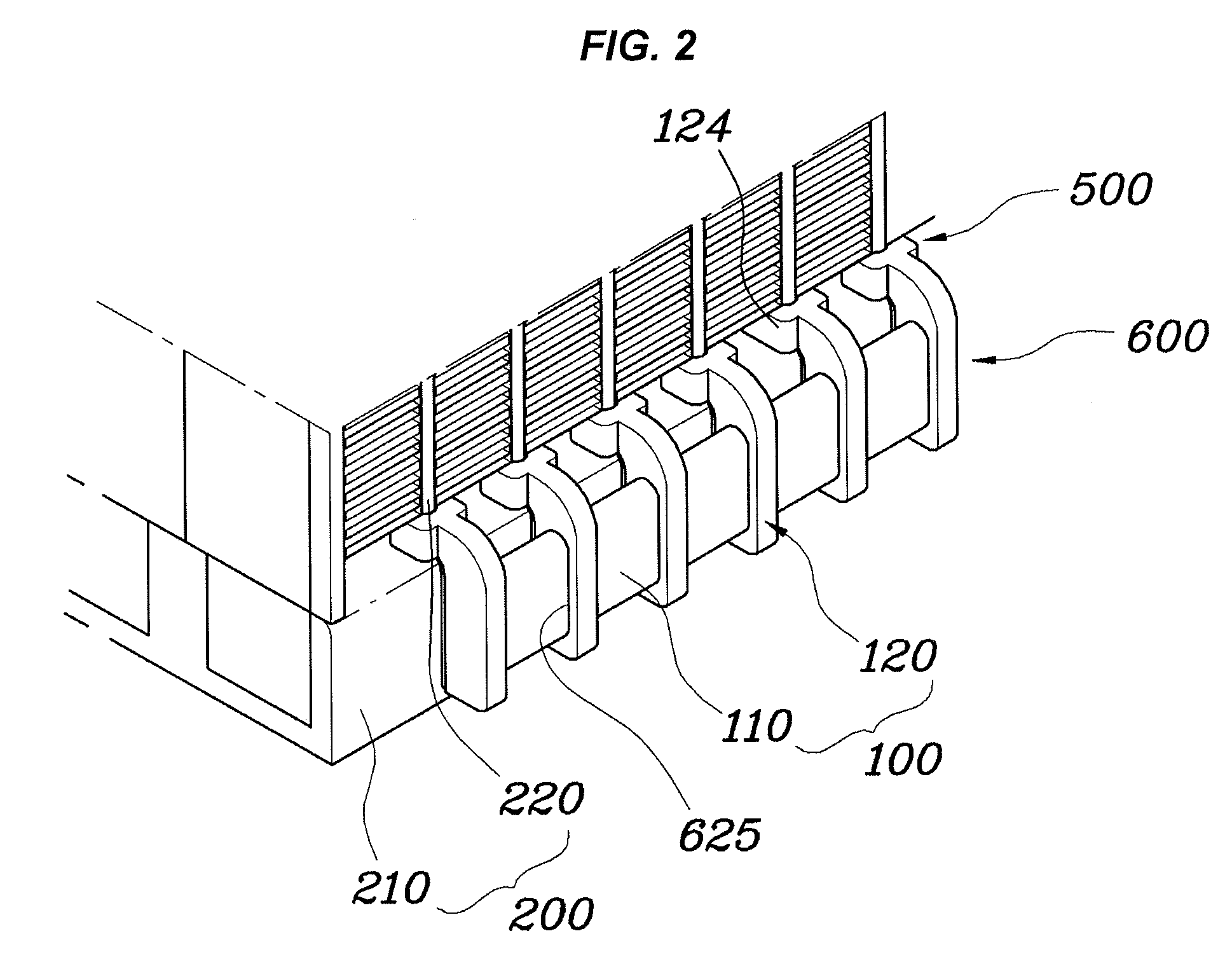

Indoor unit for air conditioner

ActiveUS7003972B2Actively respondingDrain fastCondensate preventionLighting and heating apparatusPlate heat exchangerWaste management

Disclosed is an indoor unit for an air conditioner to smoothly drain condensed water to the outside regardless of an installation state of the indoor unit. The indoor unit includes: a heat exchanger for performing heat exchange; a drain pan for collecting and draining condensed water generated in the heat exchanger; and two or more drain parts formed in the drain pan and through which the condensed water is drained.

Owner:LG ELECTRONICS INC

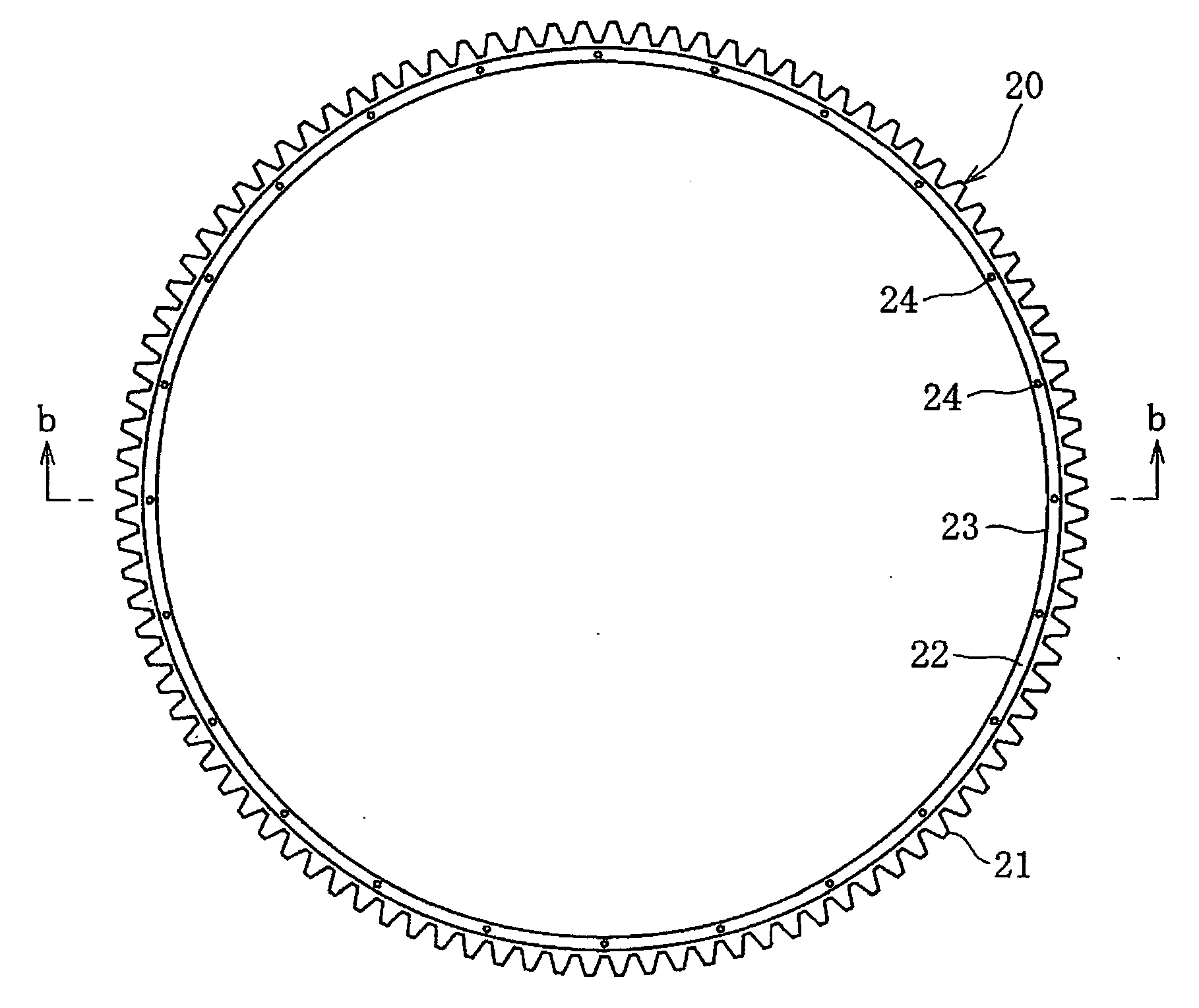

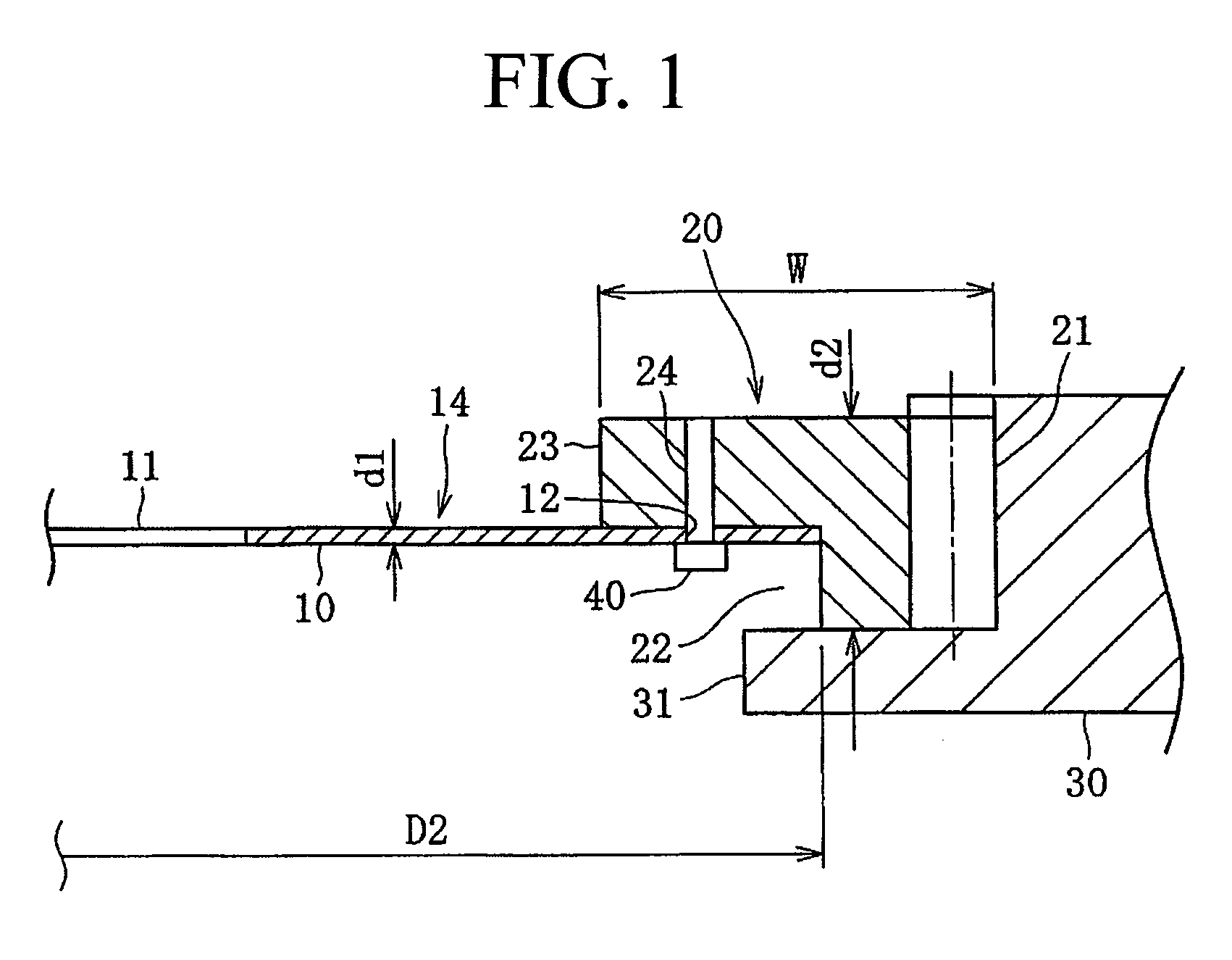

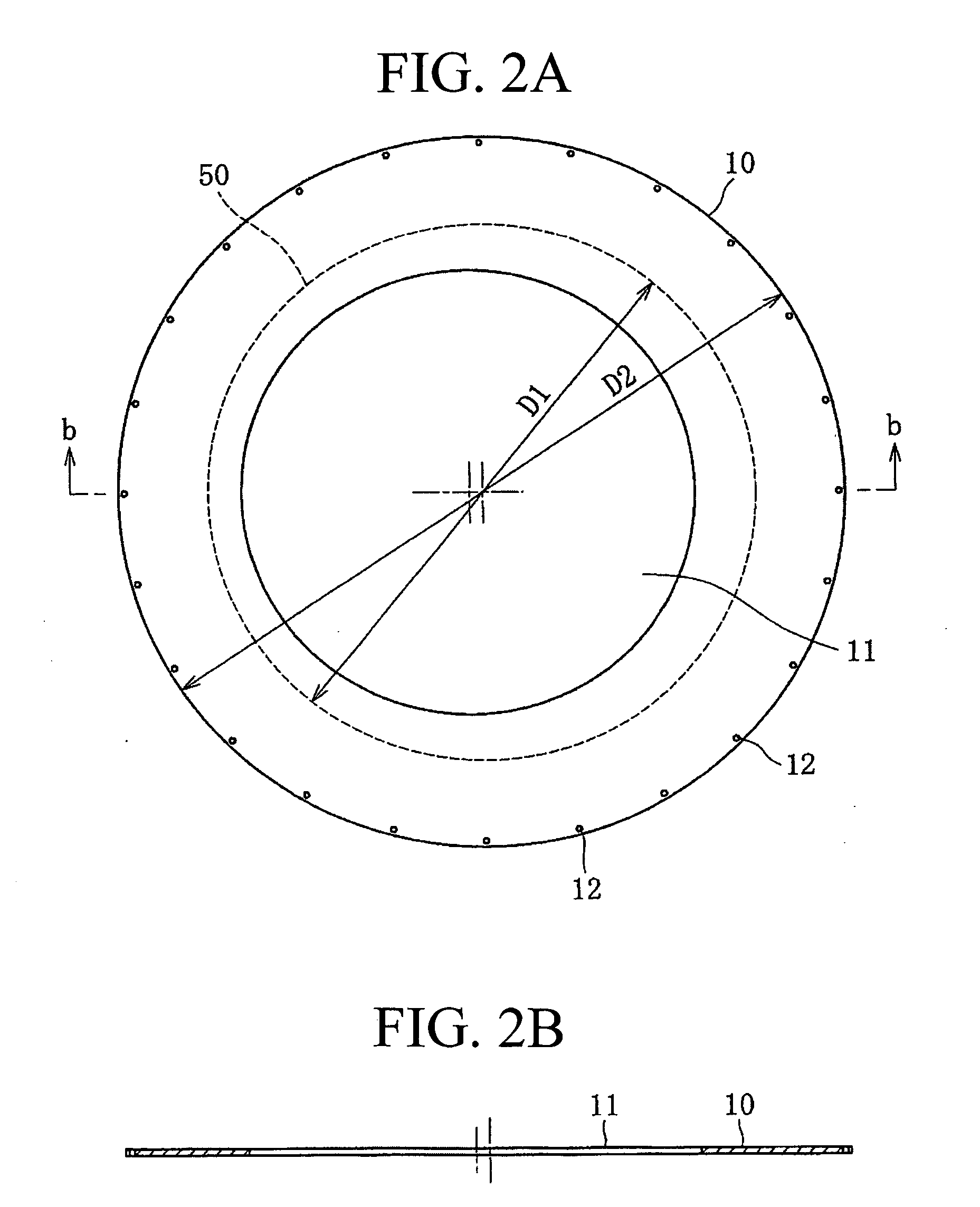

Carrier for double side polishing

InactiveUS20060128276A1Avoid deformationAvoid failurePolishing machinesRevolution surface grinding machinesMechanical engineeringEngineering

In a carrier of the invention, a thick ring-shaped support frame is provided at an outer periphery of a carrier body in which a workpiece housing hole for holding a workpiece is opened. An outer periphery of the support frame is provided with a teeth portion for engaging with driving gears for driving the carrier. The support frame is made of a different member from the carrier body. The carrier body is removably attached to the support frame by screws. The carrier body is made of a material suitable for holding a wafer. The support frame is made of a material suitable for engaging with driving gears for moving the carrier.

Owner:SUMCO CORP

Firing process of Nixing pottery products

The invention discloses a firing process of Nixing pottery products. The process comprises the steps that: (1) blank moisture eliminating is carried out, wherein blanks processed through a drying treatment are placed in a kiln, a temperature is gradually increased to 40-60 DEG C with a heating speed of 20-30 DEG C per hour, and continuous firing is carried out for 10-12h under the temperature; (2) after the moisture eliminating treatment, the temperature is increased to 1050-1100 DEG C with a heating speed of 50-100 DEG C per hour; and (3) heating is stopped, and the blanks are fetched from the kiln after cooling, such that blank firing is finished. According to the invention, moisture eliminating is carried out upon the blanks first, water content in the blanks are slowly discharged by firing under a low-temperature environment. Blank moisture eliminating is uniform, and blank cracking due to breakage caused by large amounts of bubbles produced in the blanks is avoided. With the process, a firing success rate is higher than 95%. Also, during the subsequent high-temperature firing process, blank shrinkage is reduced, and blank cracking rate is reduced, such that firing success rate is further improved.

Owner:钦州市奇圣古坭斋坭兴陶有限公司

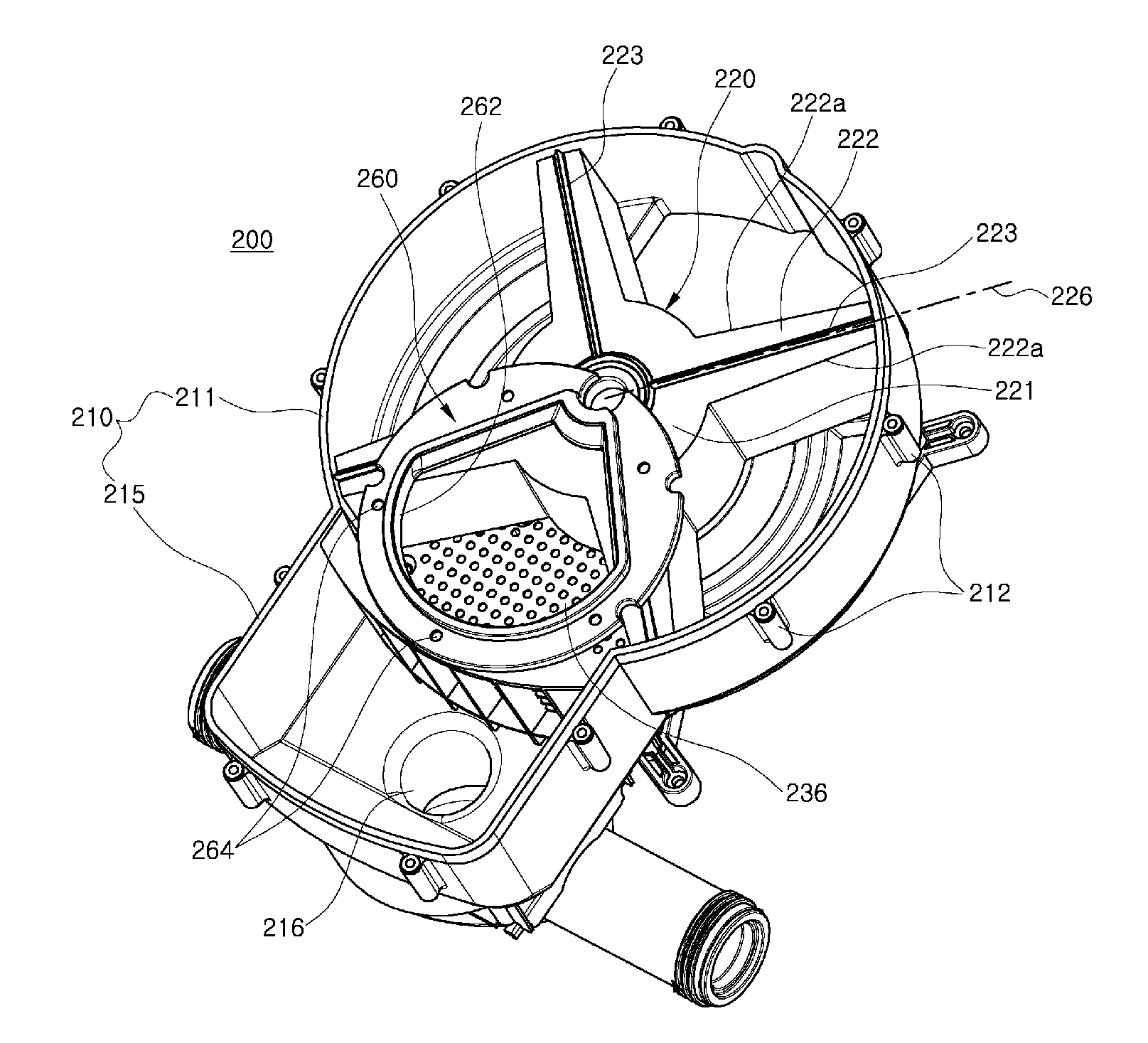

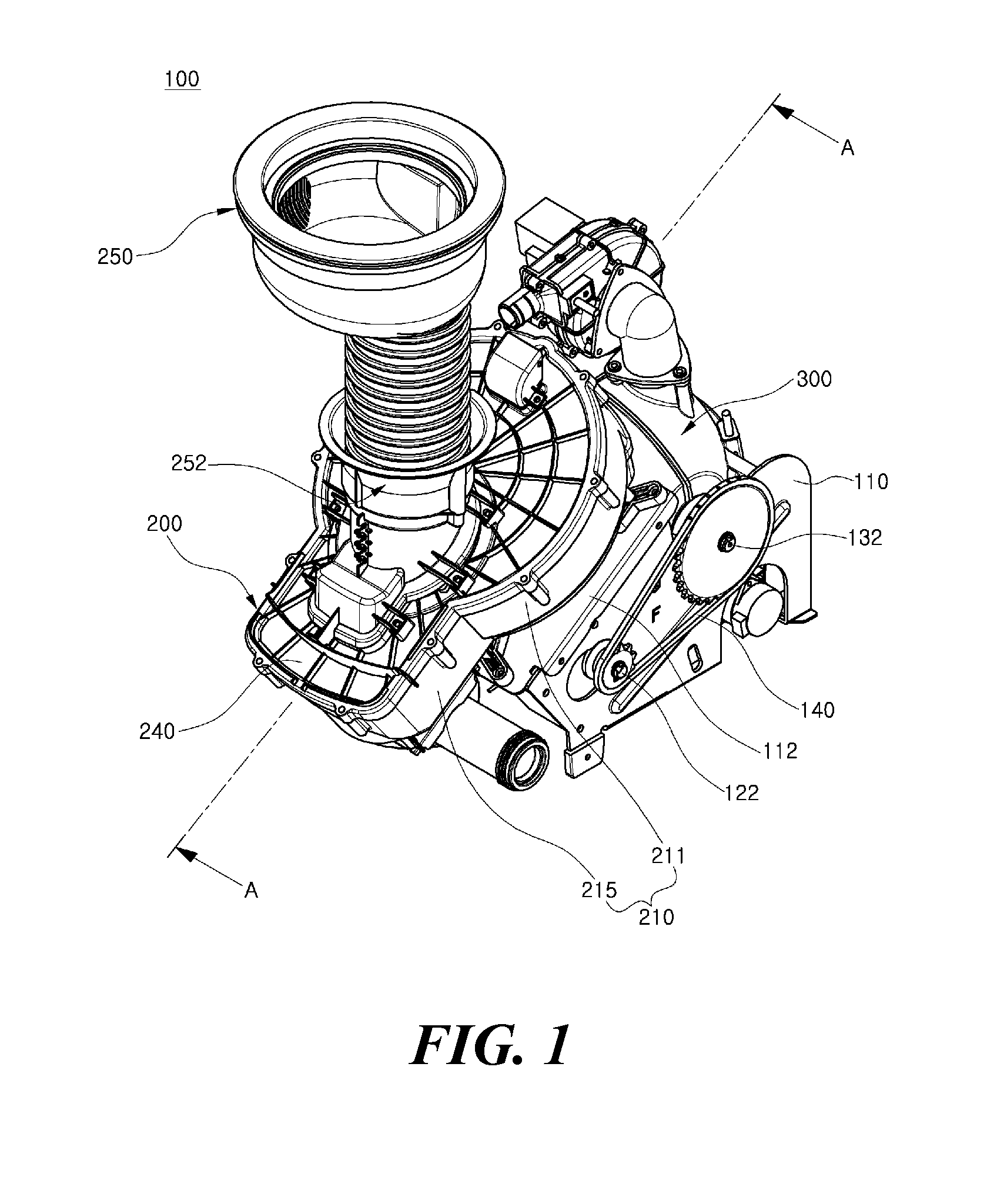

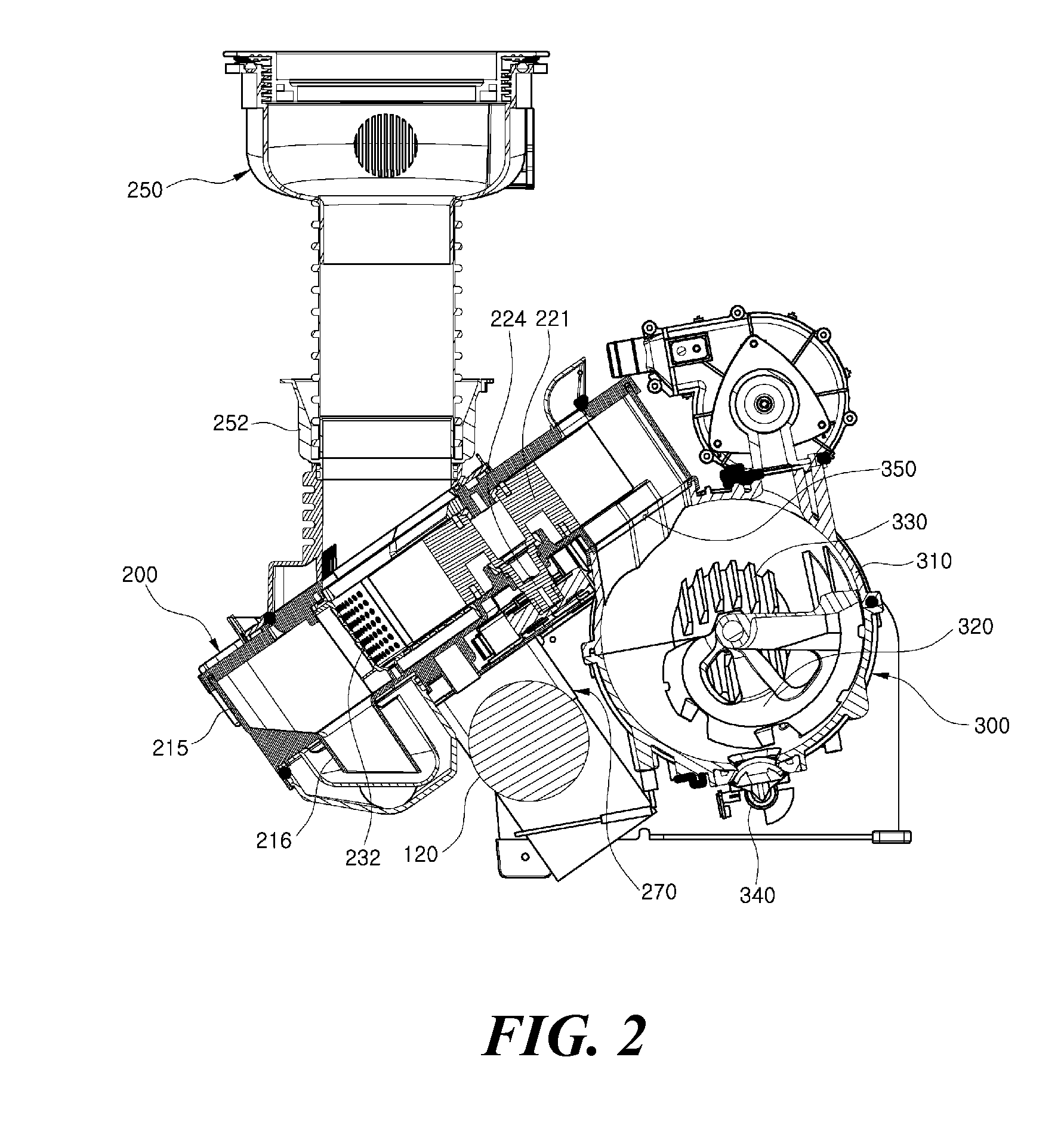

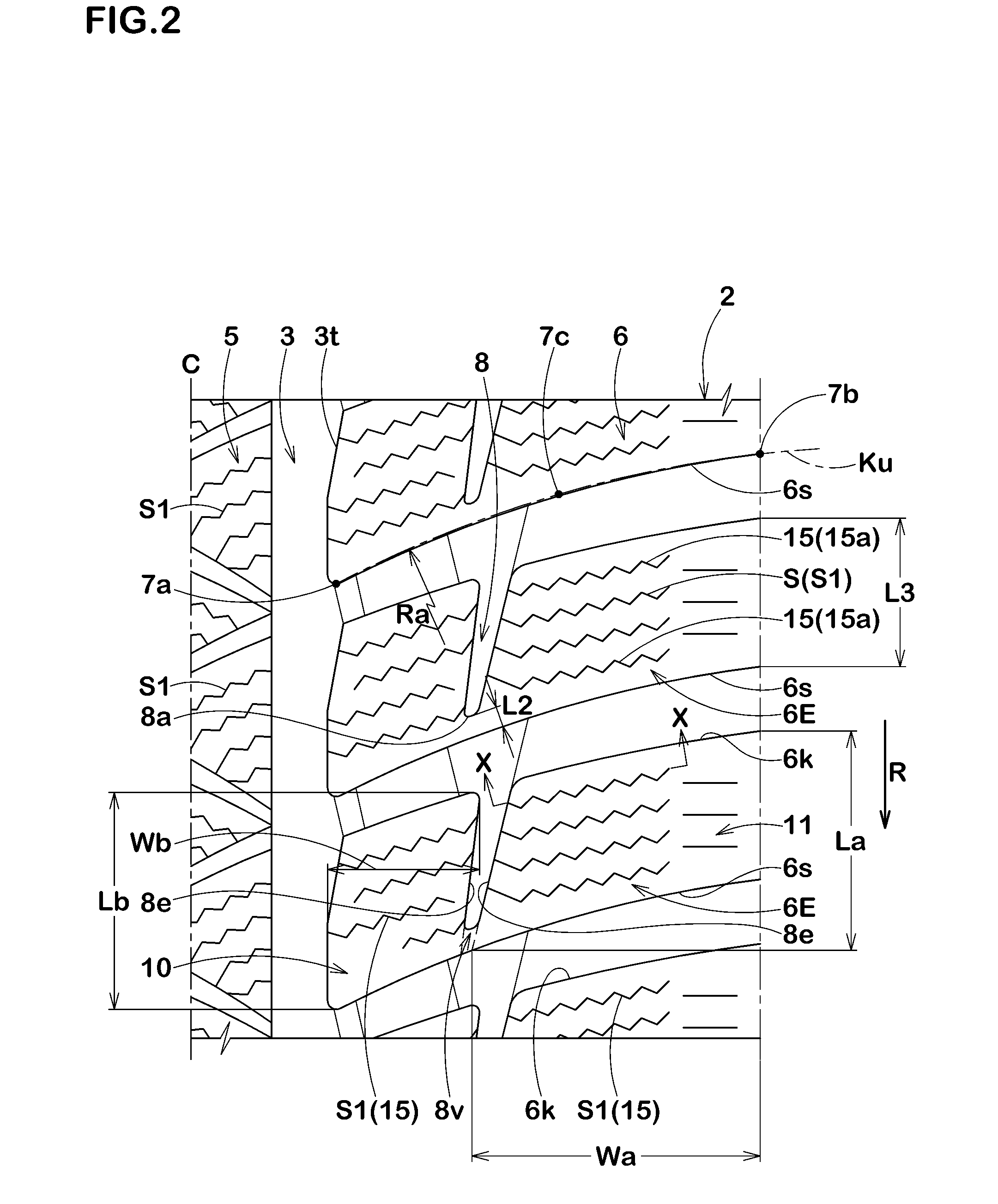

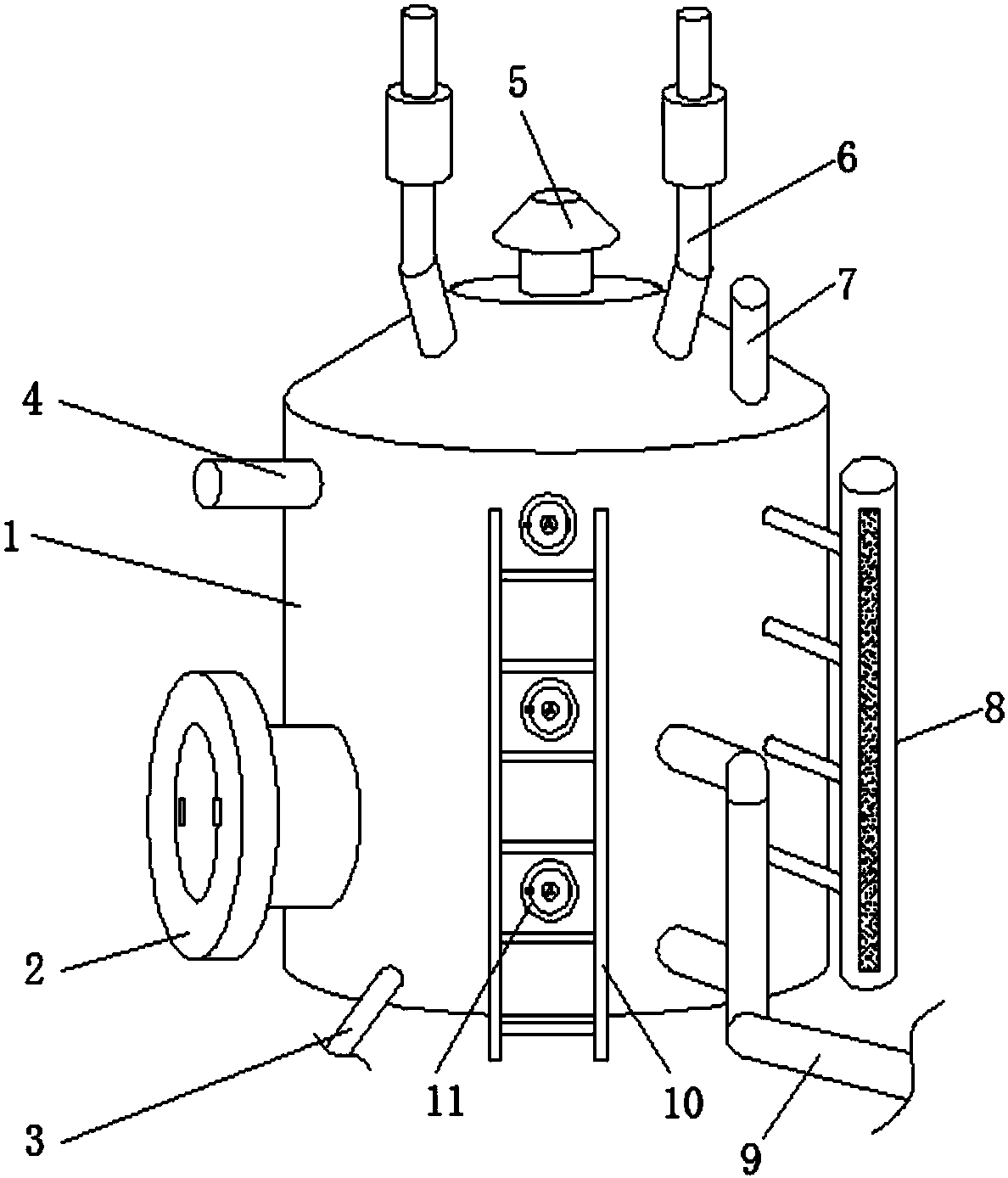

Transfer unit having transfer rotor and food waste treatment apparatus using the same

InactiveUS20100213298A1Drain evenlyAvoid sludgeSolid waste disposalRotary centrifugesSewageFood waste disposal equipment

The present invention provides a transfer unit having a transfer rotor and a food waste treatment apparatus using the transfer unit. The transfer unit includes the transfer rotor, a housing and a sieve. The transfer rotor includes a rotor body, and at least one blade provided on the circumferential outer surface of the rotor body. The housing has a hollow container shape and contains the transfer rotor therein such that the transfer rotor is rotatable without interference from the housing. The housing is inclined at a predetermined angle with respect to the horizontal plane. The sieve is provided in the housing to guide discharge of sewage from food waste. The sieve is disposed in the lower portion of the housing to drain the sewage generated from the food waste to the outside of the housing.

Owner:WOONGJIN COWAY

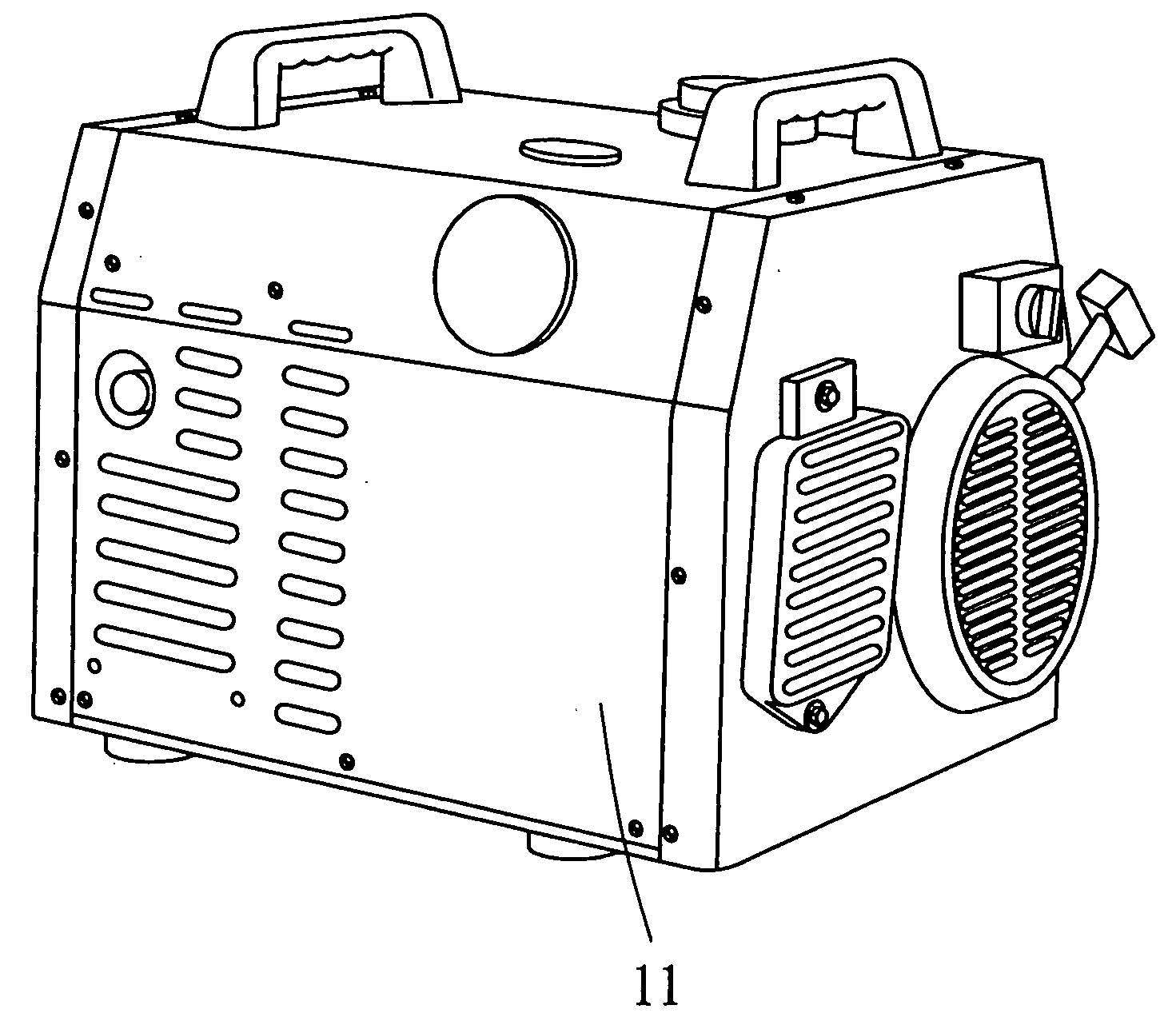

Air cooling generator

InactiveUS20050212299A1Improve cooling effectLittle noiseAir coolingPropulsion using engine-driven generatorsImpellerEngineering

A generator includes a housing, an engine, a first main impeller rotatably mounted in the engine, a first secondary impeller rotatably mounted in the housing and located outside of the engine, a generating body, a second main impeller rotatably mounted in the generating body, and a second secondary impeller rotatably mounted in the housing and located outside of the generating body. Thus, the first secondary impeller and the second secondary impeller can dissipate the heat produced from the engine and the generating body, thereby enhancing the heat dissipation effect of the generator, and thereby increasing the lifetime of the generator.

Owner:WANG WEN CHANG

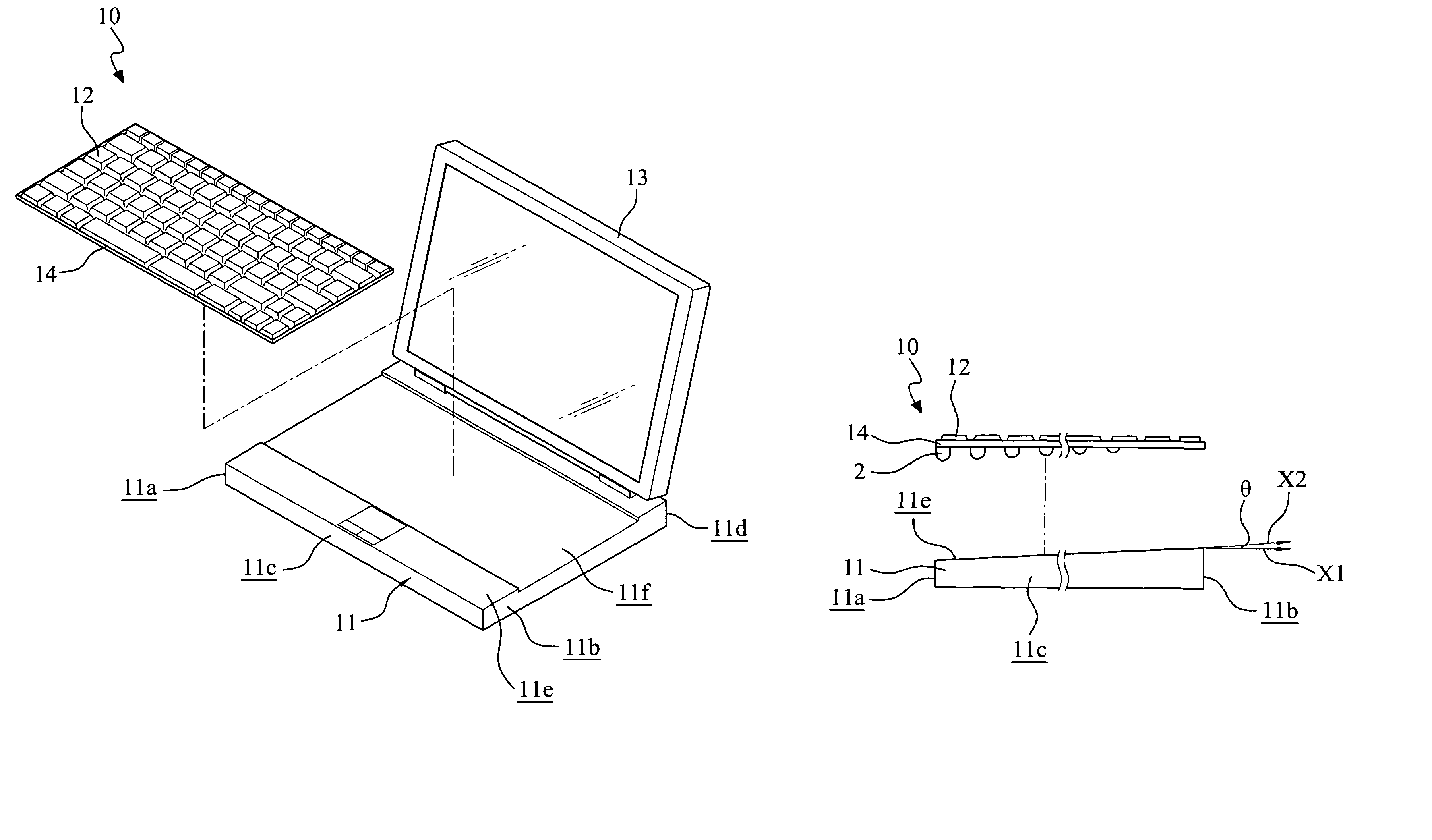

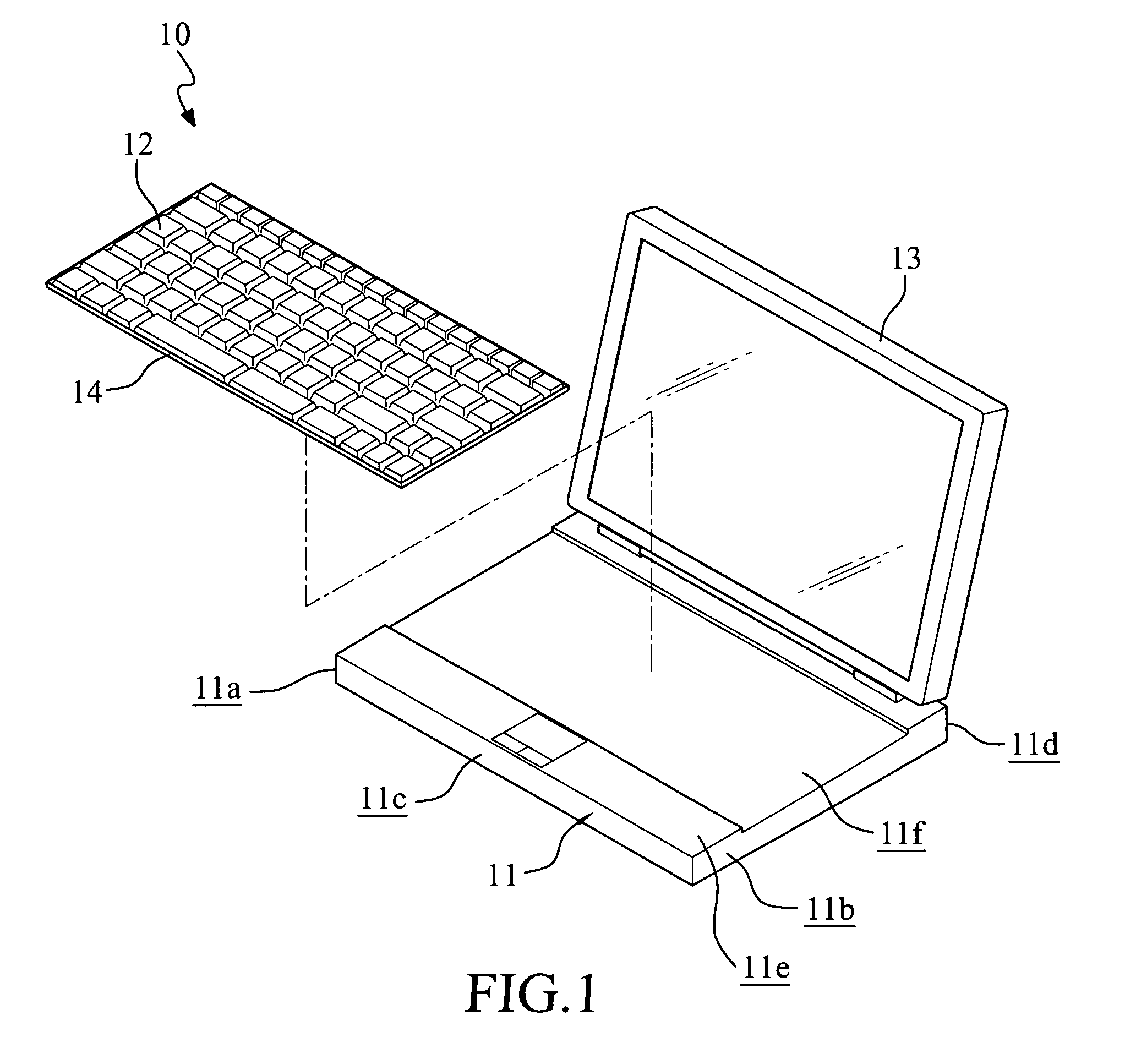

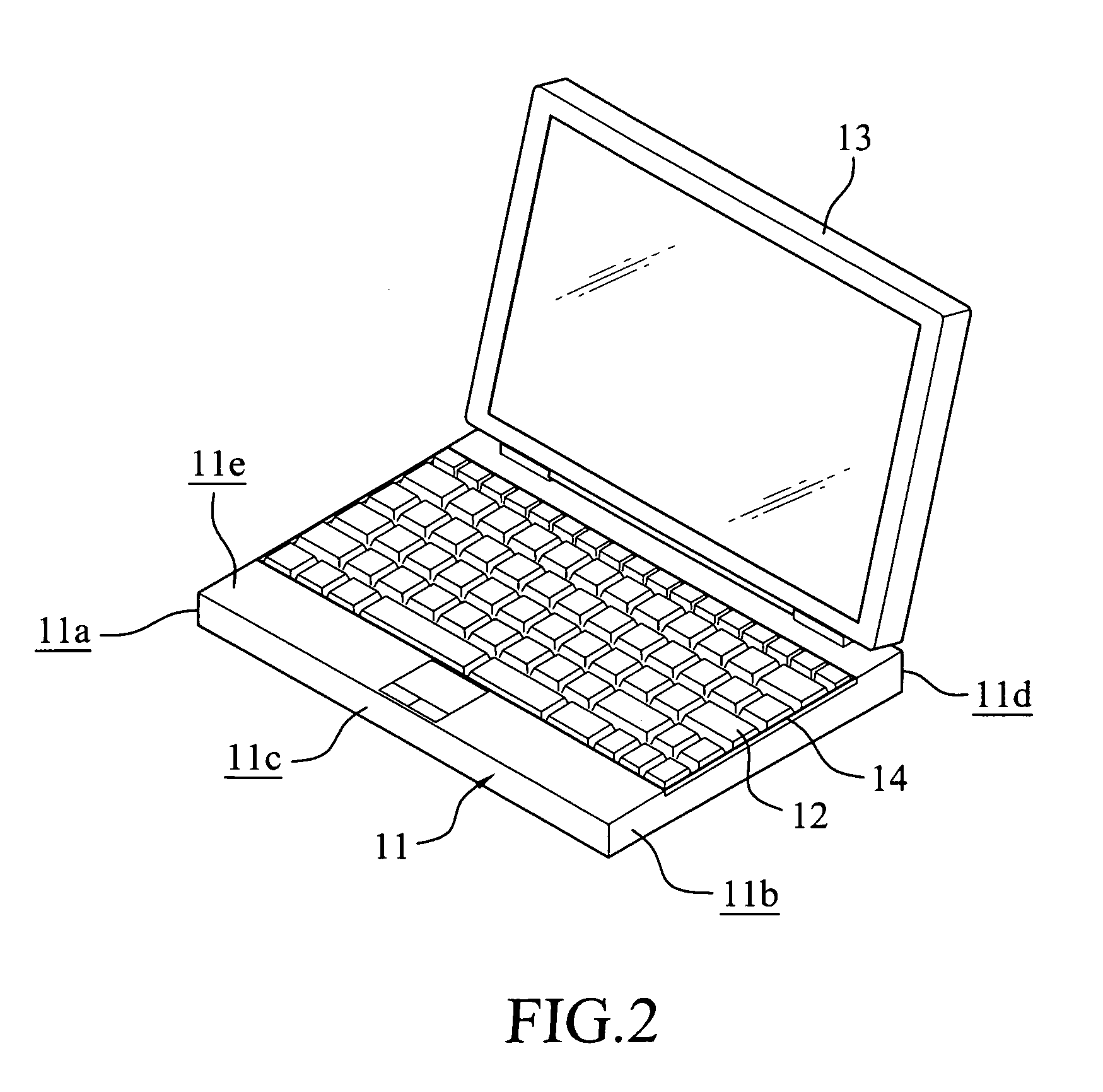

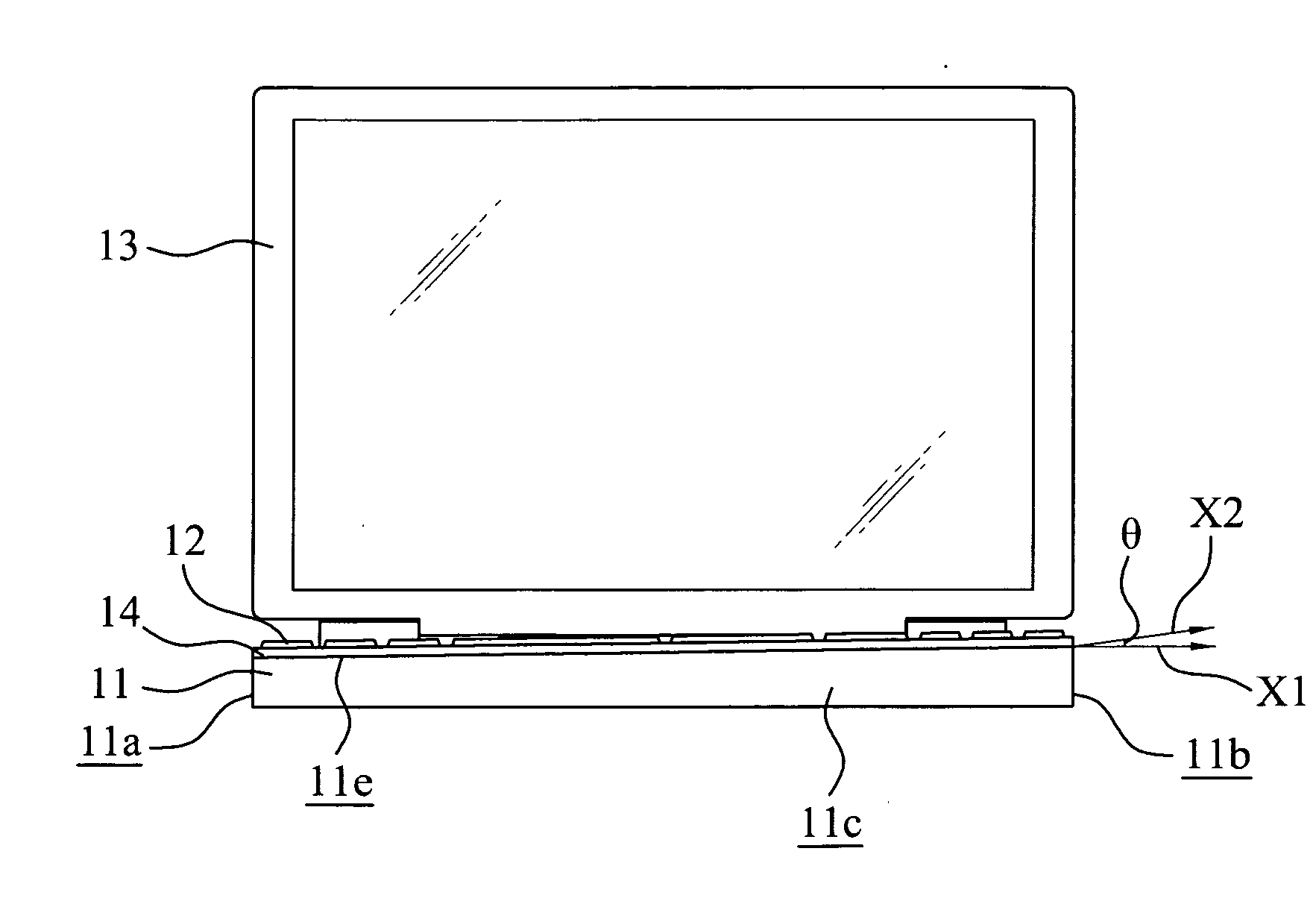

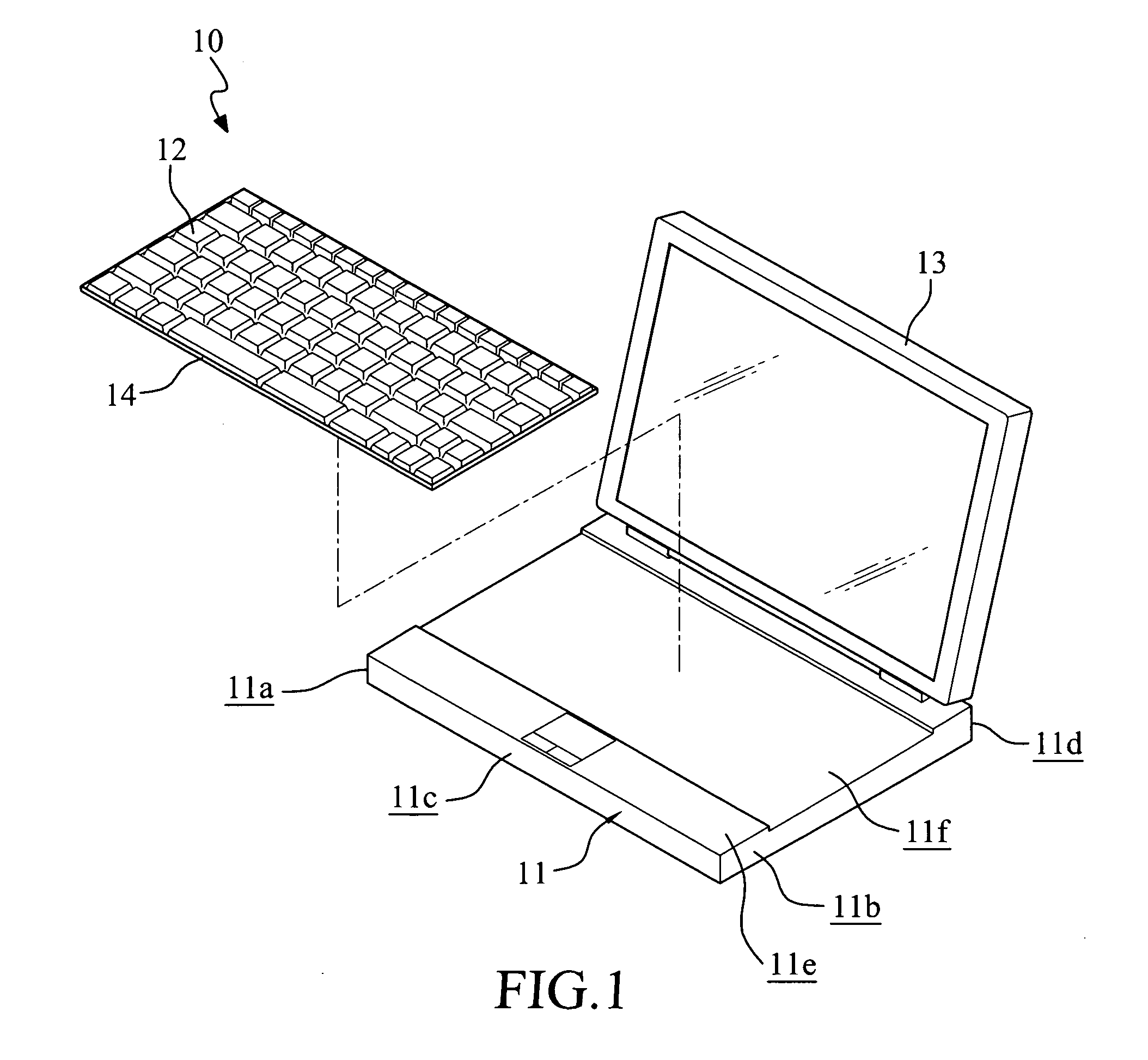

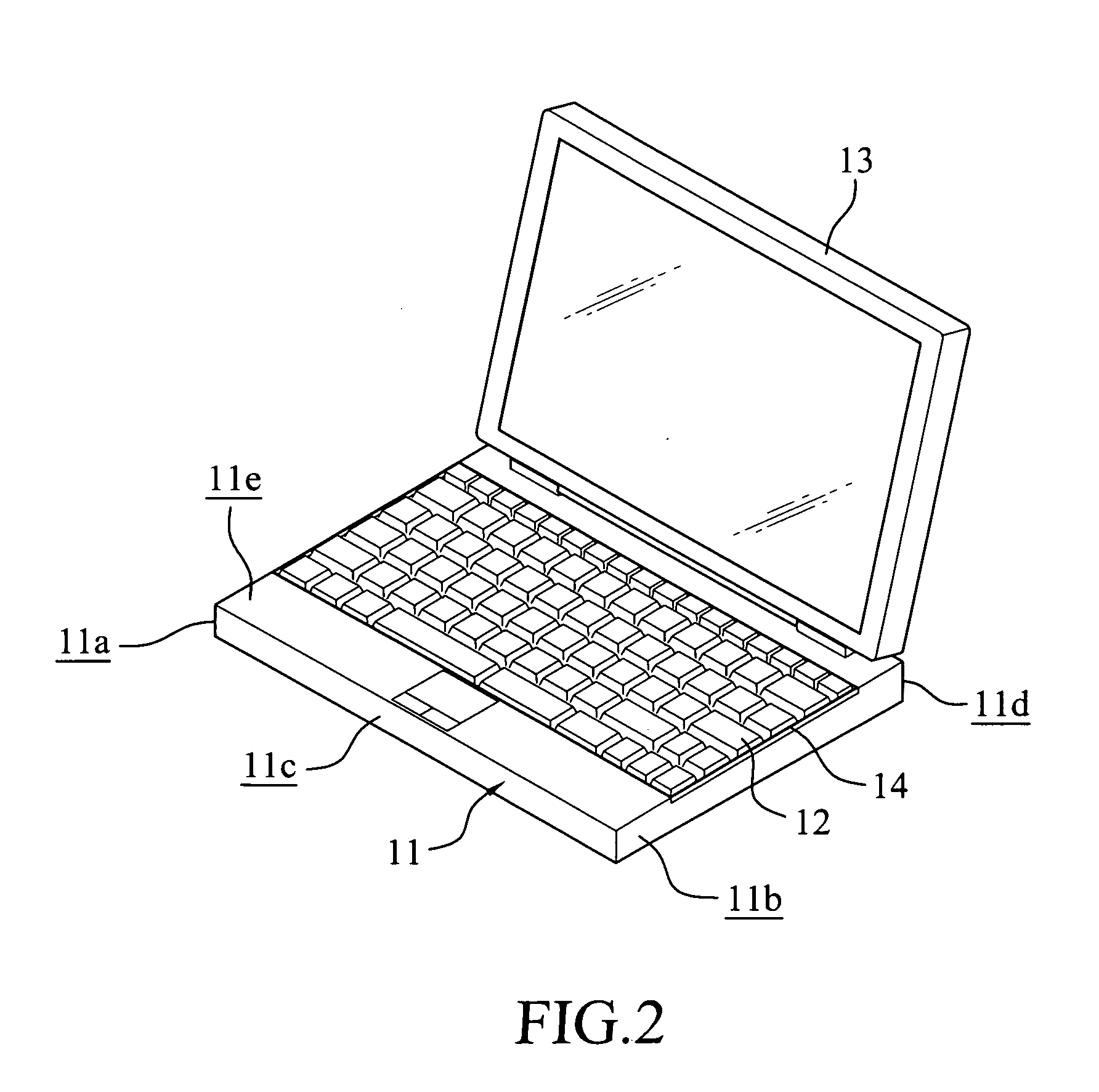

Portable electronic device with drainage structure

ActiveUS7619880B2Drain evenlySimple structureTypewritersDetails for portable computersEngineeringElectrical and Electronics engineering

A drainage structure is provided for a portable electronic device, such as a portable computer. The drainage structure includes an inclination formed on a top surface of a body of the portable electronic device to support a keyboard device in an inclined manner so that water spilled on the keyboard device or the top surface can be expelled out of the electronic device by gravity. If desired, height adjusting units can be arranged between the keyboard device and the top surface of the body to selectively maintain the keyboard in a horizontal condition. A drain hole or groove can be selectively formed in the body of the electronic device to facilitate drainage of water.

Owner:GETAC TECH CORP

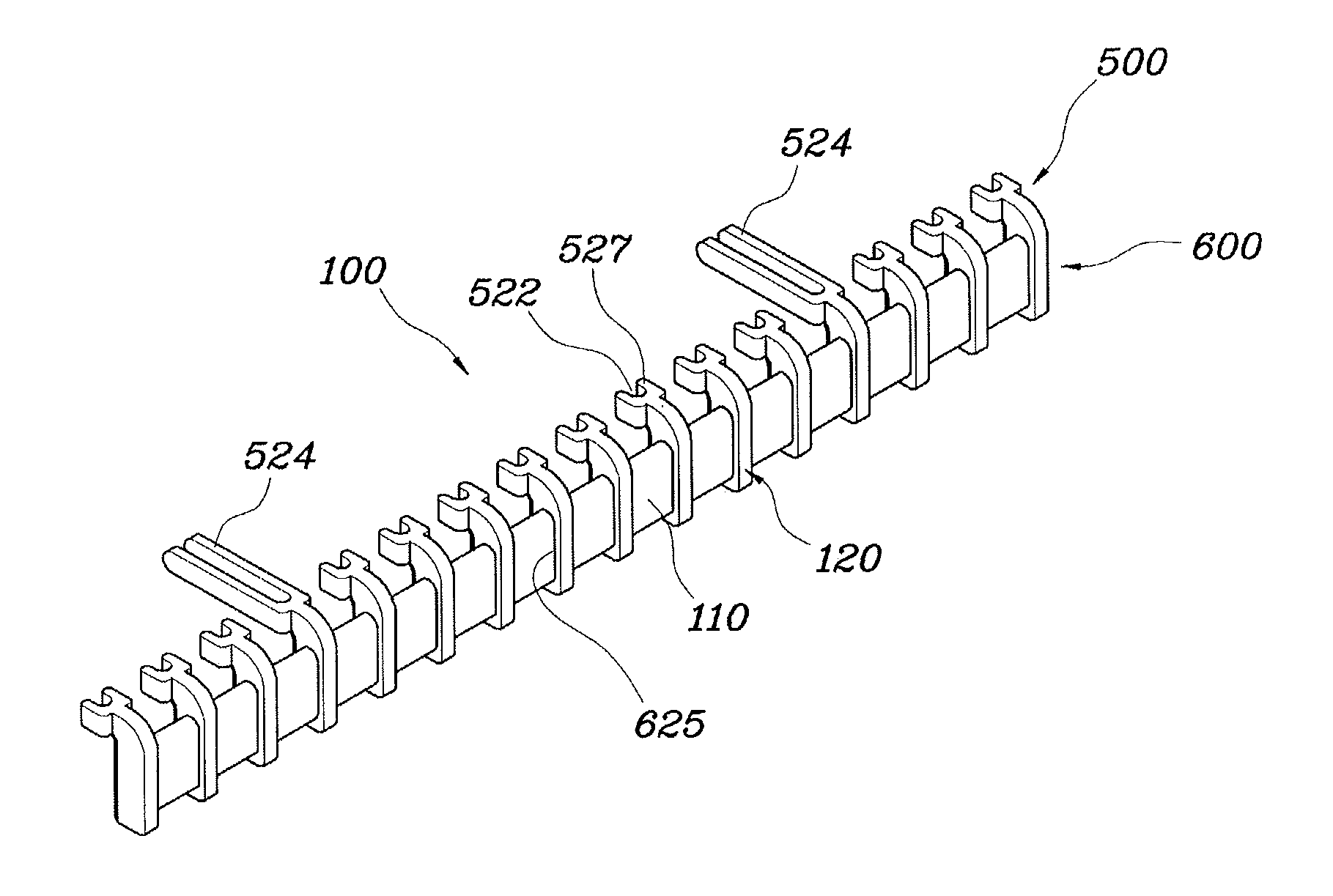

Condensate water guide unit of air conditioner for vehicles

ActiveUS8555668B2Drain evenlyCorrosion preventionVehicle heating/cooling devicesEngineeringClose contact

A condensate water guide unit of an air conditioner for vehicles which collects and drains condensate water, generated on the evaporator, outside the air conditioner is disclosed. The condensate water guide unit includes a plurality of guide pieces for draining condensate water outside the air conditioner, and a support bar, which connects the guide pieces to each other. The guide pieces are in close contact with the lower end of an evaporator. Each guide piece has a guide slot for drawing condensate water formed on the surface of the evaporator, and a water moving passage for draining the drawn condensate water outside the air conditioner.

Owner:HYUNDAI MOTOR CO LTD

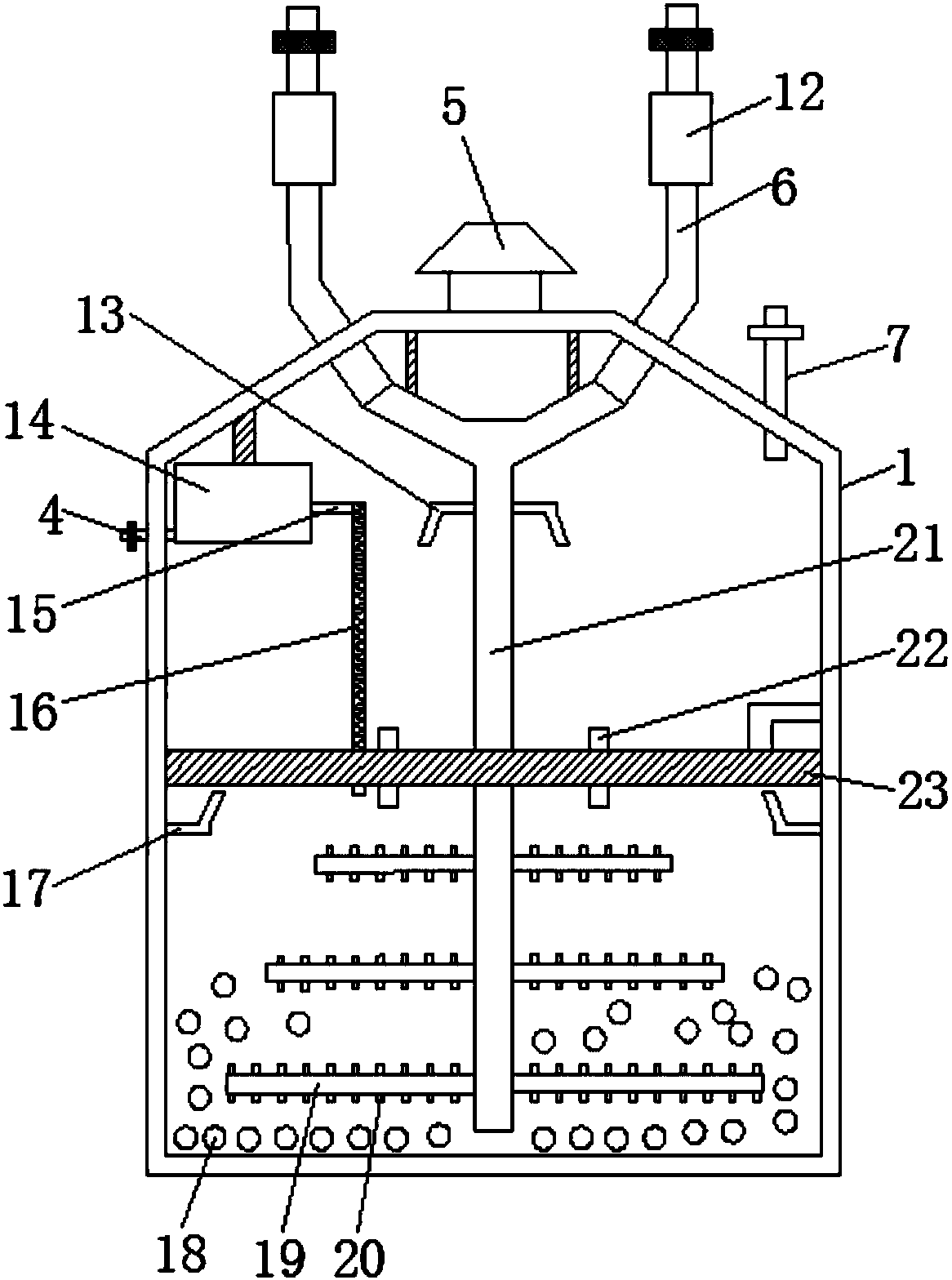

Furnace burden drying device

ActiveCN107576172AImprove the effectIncrease contact areaDrying gas arrangementsDrying solid materialsMoistureMetallurgy

The invention relates to the technical field of metallurgical furnace burden, and discloses a furnace burden drying device. The furnace burden drying device comprises a rack, an inner furnace body, anouter furnace body, an air blower and a turbocharger. The outer furnace body is fixedly mounted on the rack, the outer furnace body is arranged on the outer side of the inner furnace body in a sleeving mode, and a flowing cavity is formed between the inner furnace body and the outer furnace body. The inner furnace body is fixedly mounted on the outer furnace body, air vents communicating with theflowing cavity are formed in the side wall and the upper portion of the inner furnace body, a rotary shaft fixedly connected with a turbine of the turbocharger is arranged in the inner furnace body,and the rotary shaft is rotatably connected with the inner furnace body. A spiral electric coil for heating is fixed to the interior of the side wall of each of the inner furnace body and the rotary shaft, an air inlet of a compression wheel of the turbocharger communicates with an air outlet of the air blower, and a turbine air suction port of the turbocharger communicates with the flowing cavity. The furnace burden drying device can dry furnace burden evenly, and can rapidly treat the moisture generated in the drying process of the furnace burden, the working efficiency is improved, and thequality of the furnace burden is improved.

Owner:重庆琅博宛冶金材料有限公司

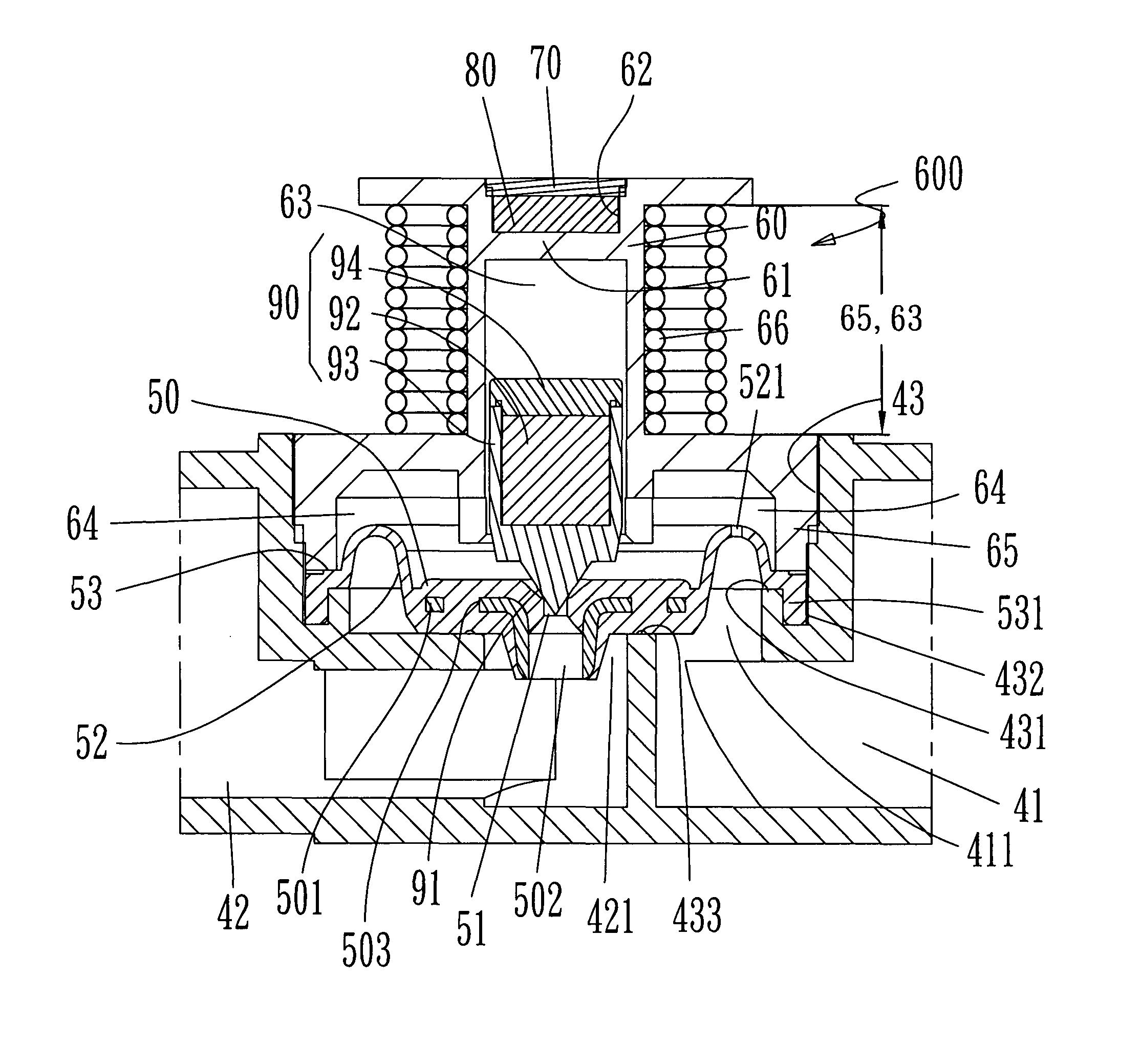

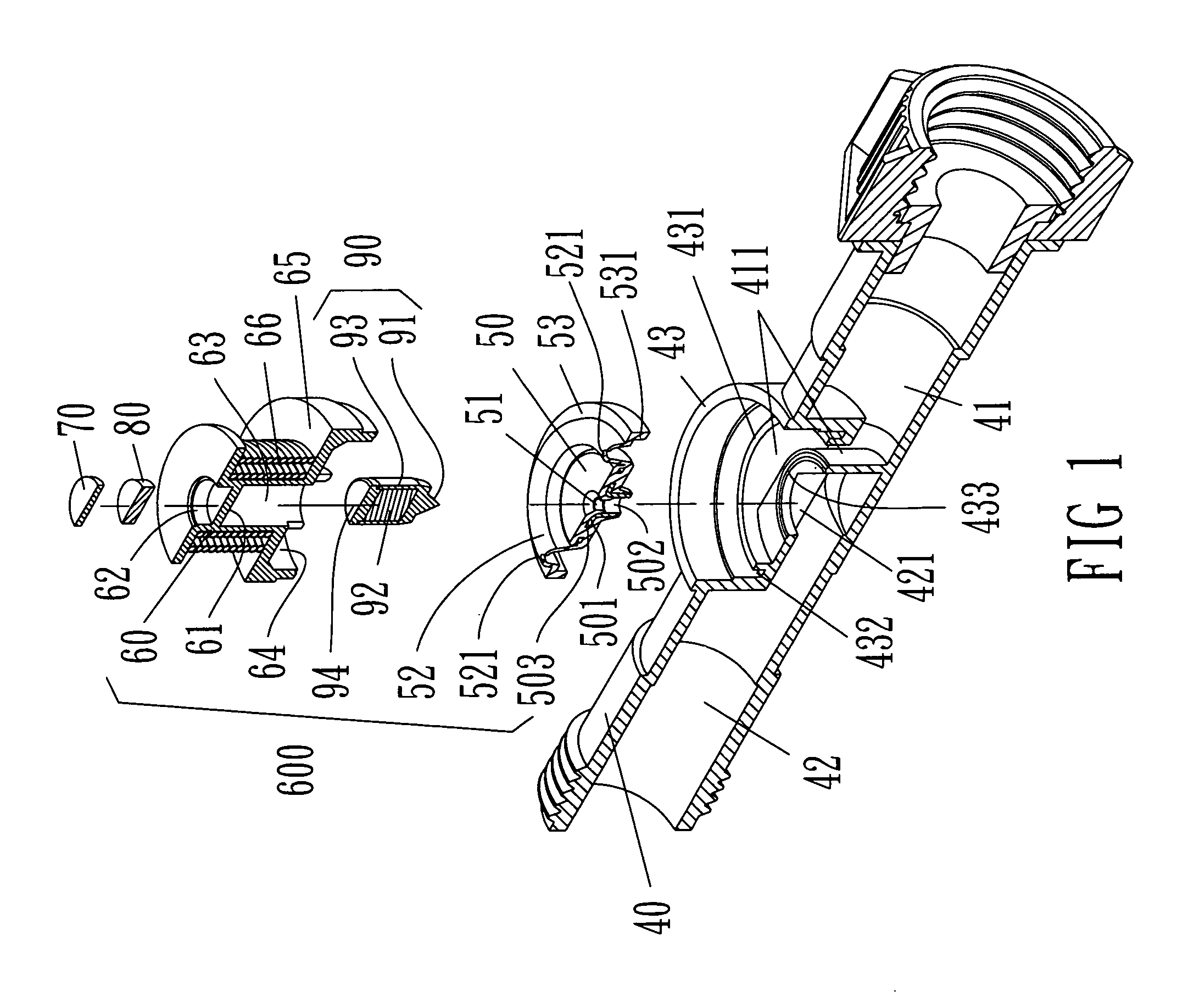

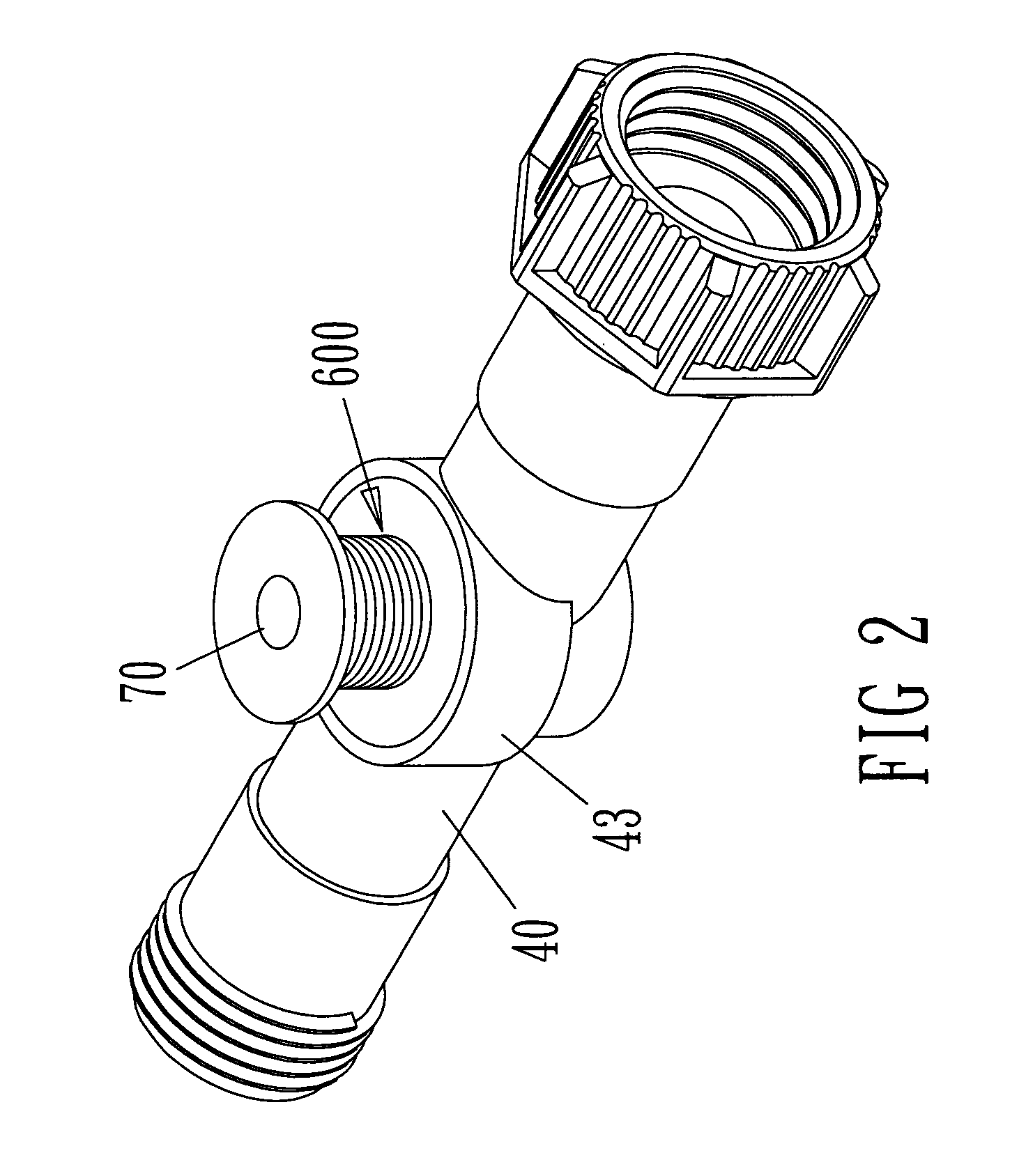

Magnetic control valve

ActiveUS8500087B2Few partsReduce manufacturing costOperating means/releasing devices for valvesMagnetic tension forceRubber ring

A magnetic control valve is to block an outlet end of a water inflow passage and an inlet end of a water outflow passage of a connection pipe by using a rubber ring. A valve of the rubber ring is opened or closed by a magnetic control switch. The magnetic control switch mainly takes a valve rod carrying permanent magnetic force that completely controls direction of electromagnetic pole as a power source for moving. When a valve plug at an end of the valve rod seals the valve, a metal plate capable of being sucked by magnetic force is combined with the rubber ring to allow both to generate magnetic sucking effect, thereby firmly closing.

Owner:YUAN MEI CORP

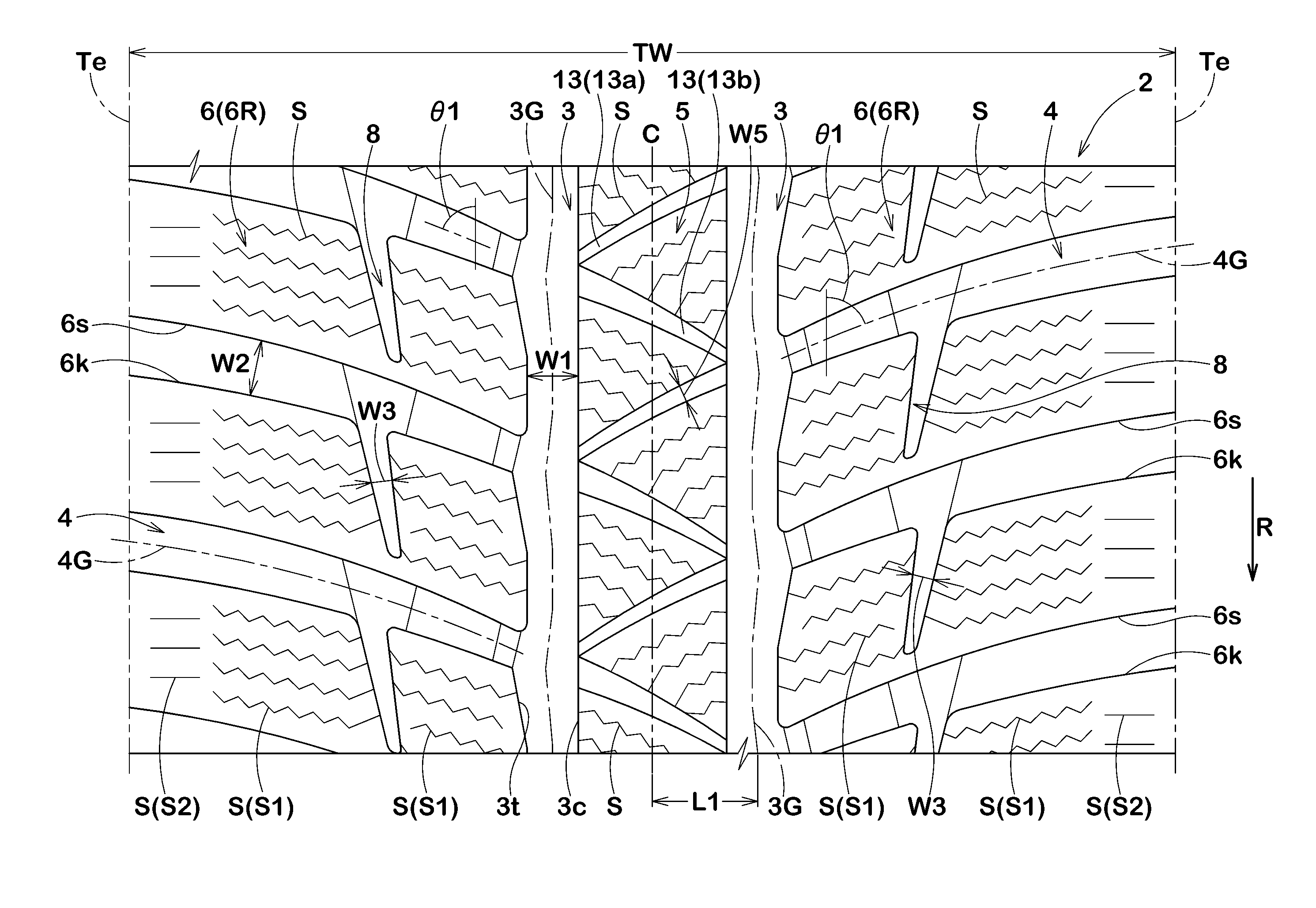

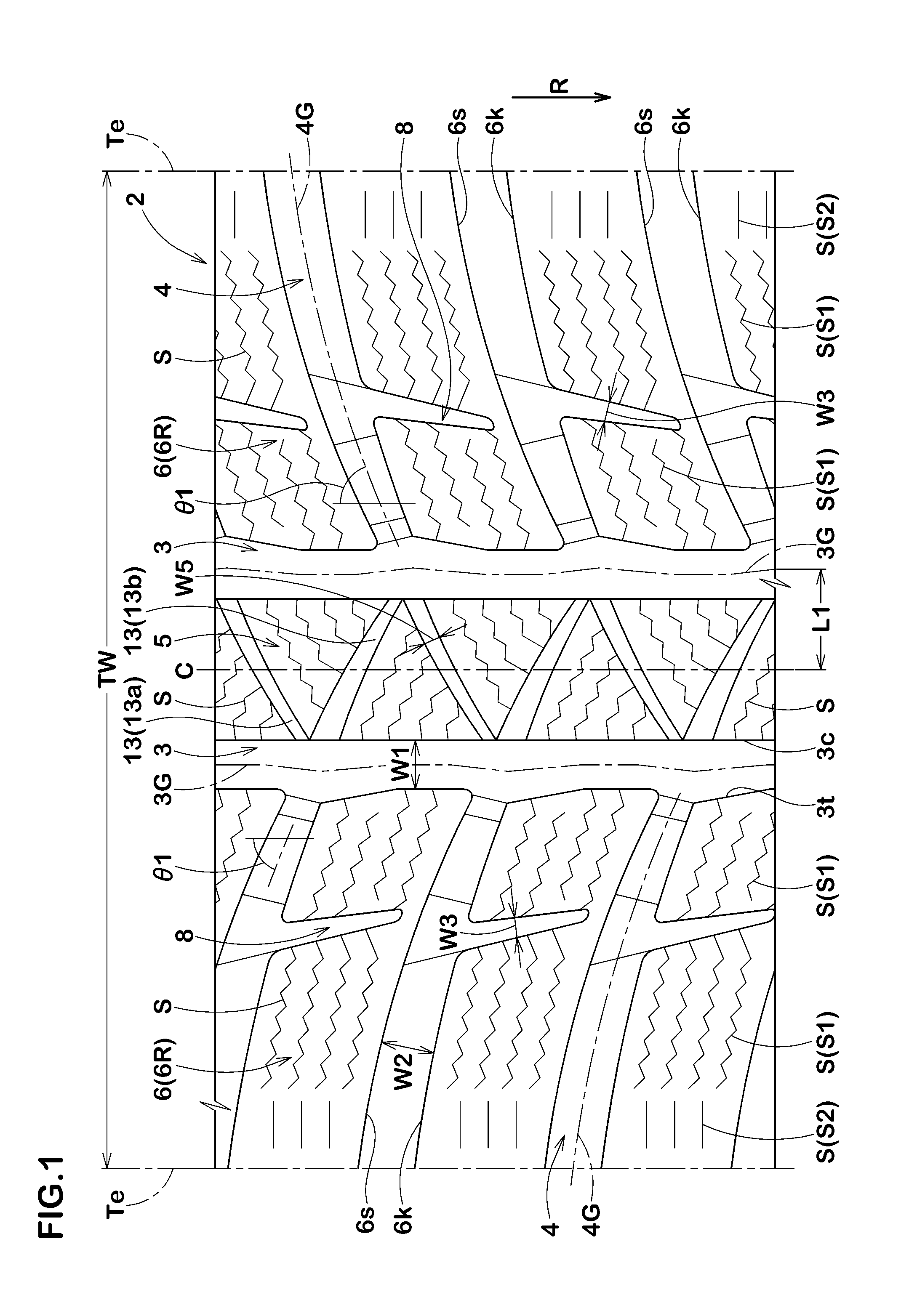

Pneumatic tire

ActiveUS20130105051A1Stretch smoothlyIncrease lateral stiffnessTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

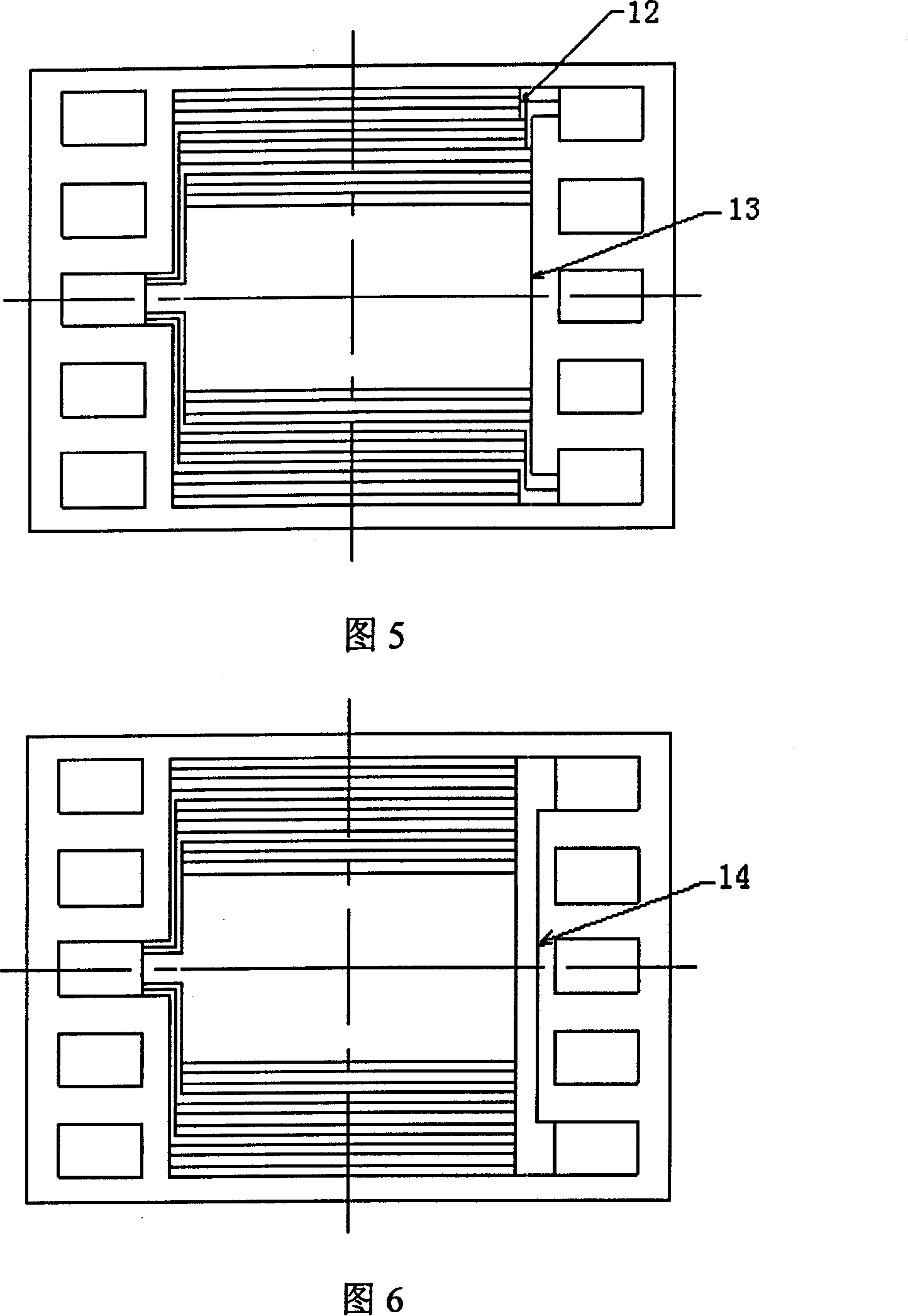

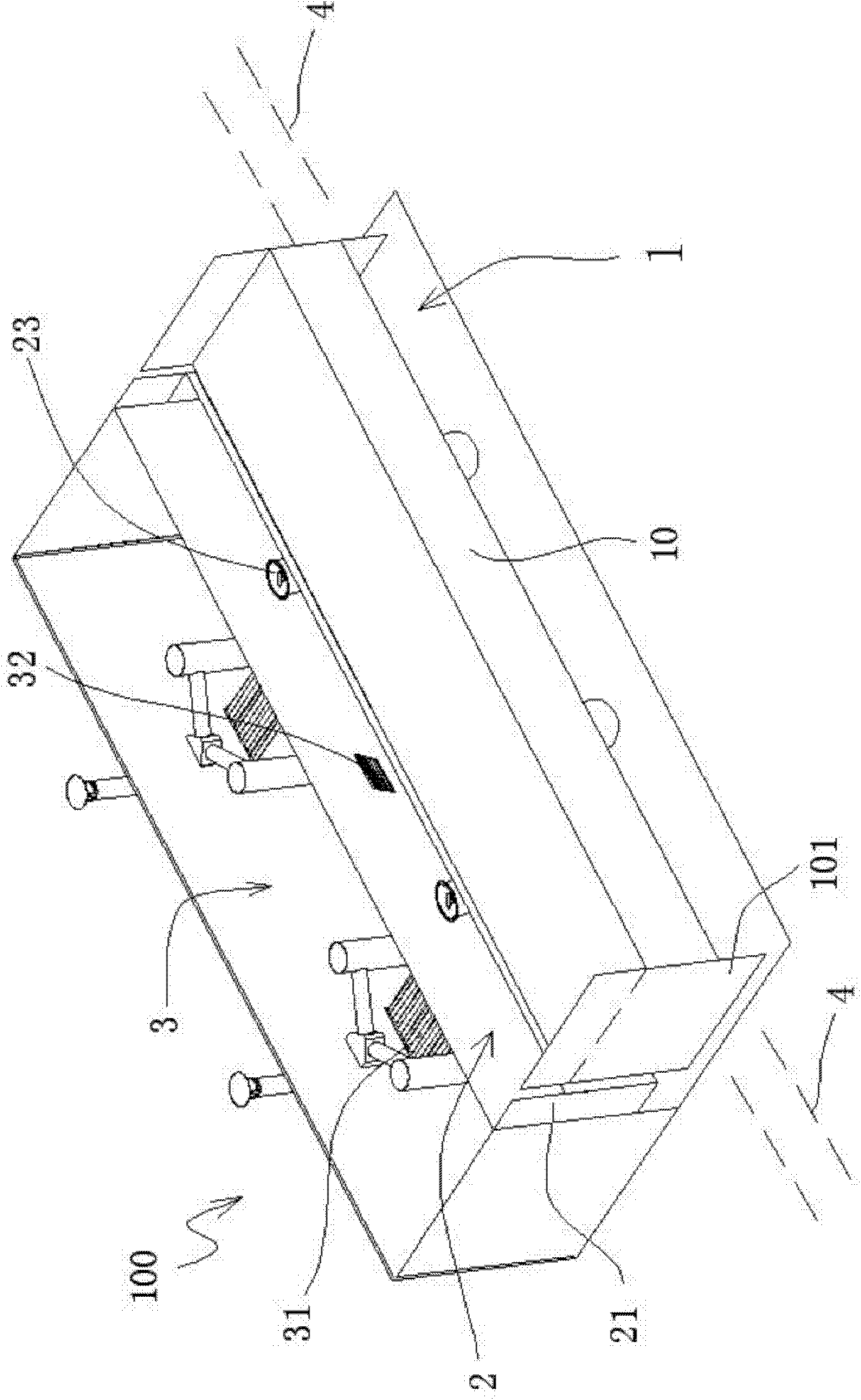

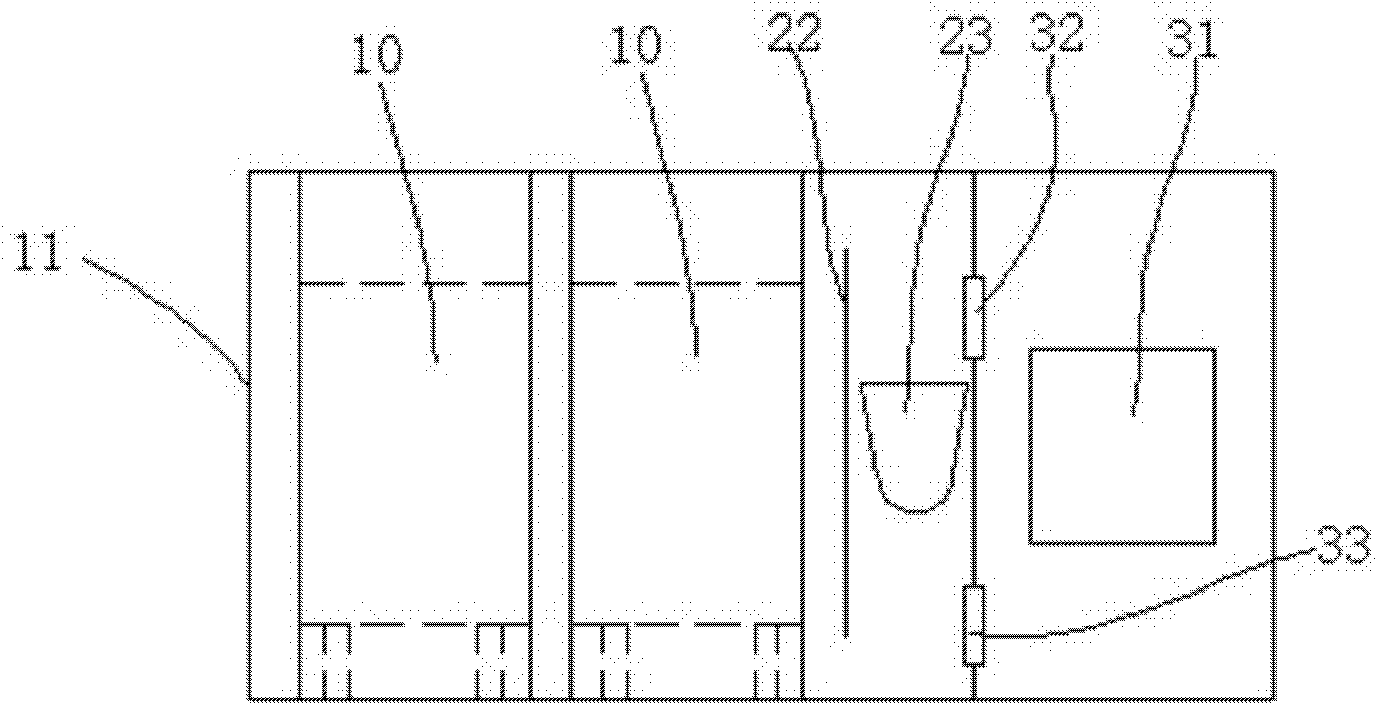

Tunnel curing barn adopting humiture subdivision control of alternate wind direction

ActiveCN102735035AEvenly heatedDrain evenlyDrying gas arrangementsDrying machines with progressive movementsAir cellOne-hot

Disclosed is a tunnel curing barn adopting humiture subdivision control of alternate wind direction, and the tunnel curing barn is formed by a plurality of work cells, which are penetrated through and connected by a track. Each work cell comprises a baking cell, an air-mixing layer and a hot air cell. Each work cell is provided with one hot air cell or the plurality of work cells share at least one hot air cell. The air-mixing layer is located between the baking cell and the hot air cell. Material trolleys which pass through the baking cells respectively move a distance of one baking cell every time, and the material trolleys are used for being filled with materials to be baked. A circulating fan is installed in the air-mixing layer to produce an ascending airflow or a descending airflow. A heating or heat exchanging device is disposed in the hot air cell. The whole tunnel curing barn is separated into a plurality of independent work cells by separating plates which are provided at the front end and the rear end of the material trolleys in the baking cells, and each work cell forms an independent hot air self-circulating system. The material trolleys on the track move forward at intervals and are capable of moving at fixed time and fixed quantity and staying in different work cells for drying according to temperature and humidity required by materials at different times.

Owner:北京华珍烘烤系统设备工程有限公司

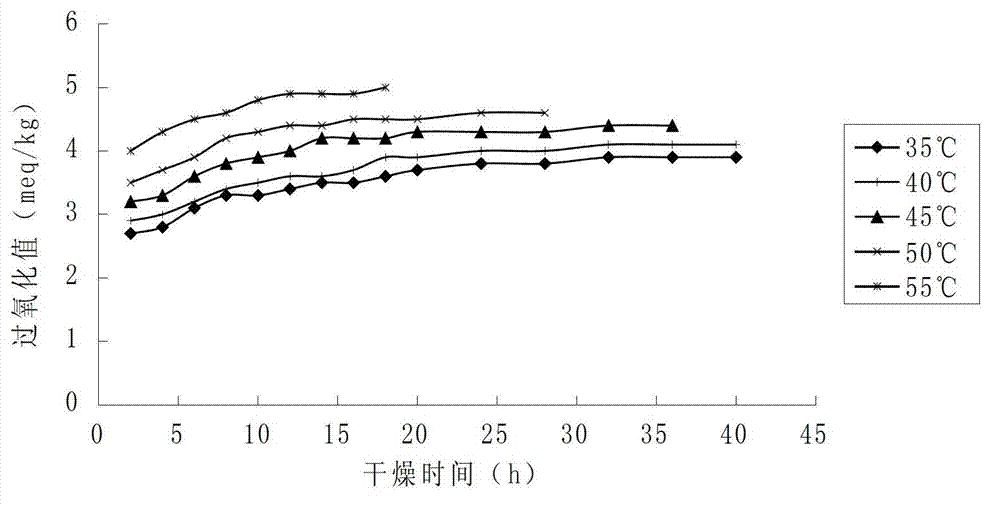

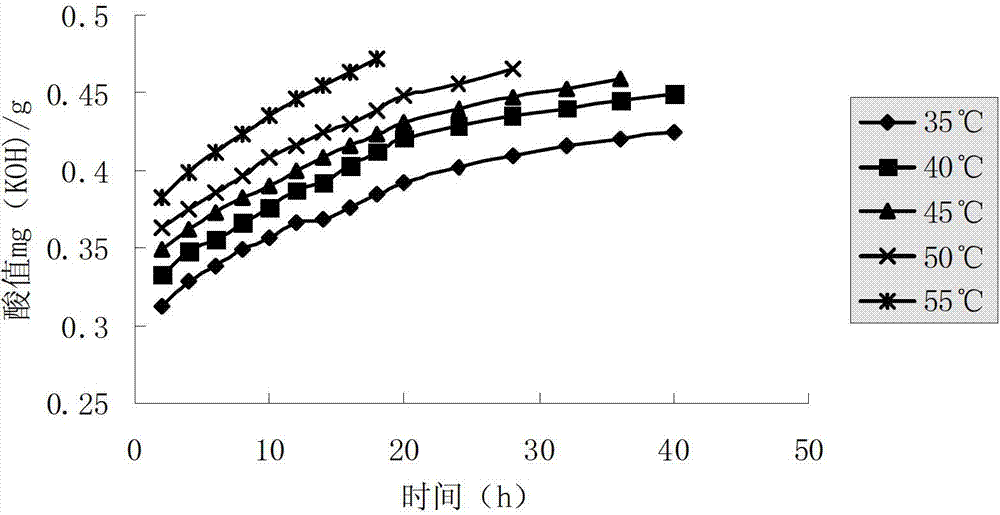

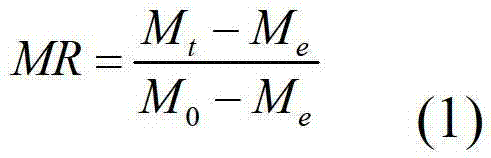

Method for drying walnuts with hot air based on parabolic temperature rise method

InactiveCN103110147AEvenly heatedDrain evenlyDrying solid materials with heatFood preparationFlavorProcess engineering

The invention relates to a method for drying walnuts with hot air based on a parabolic temperature rise method, wherein the relative humidity of the environment is controlled and the drying temperature is controlled by the parabolic temperature rise method, so that even heating of walnut roasting and even moisture removal are realized; as a result, the walnut drying time is effectively shortened and the interior quality and flavor of the dry walnuts are guaranteed; and the air-drying process is simple.

Owner:SHAANXI ZHIDAO AGRI SCI & TECH DEV CO LTD

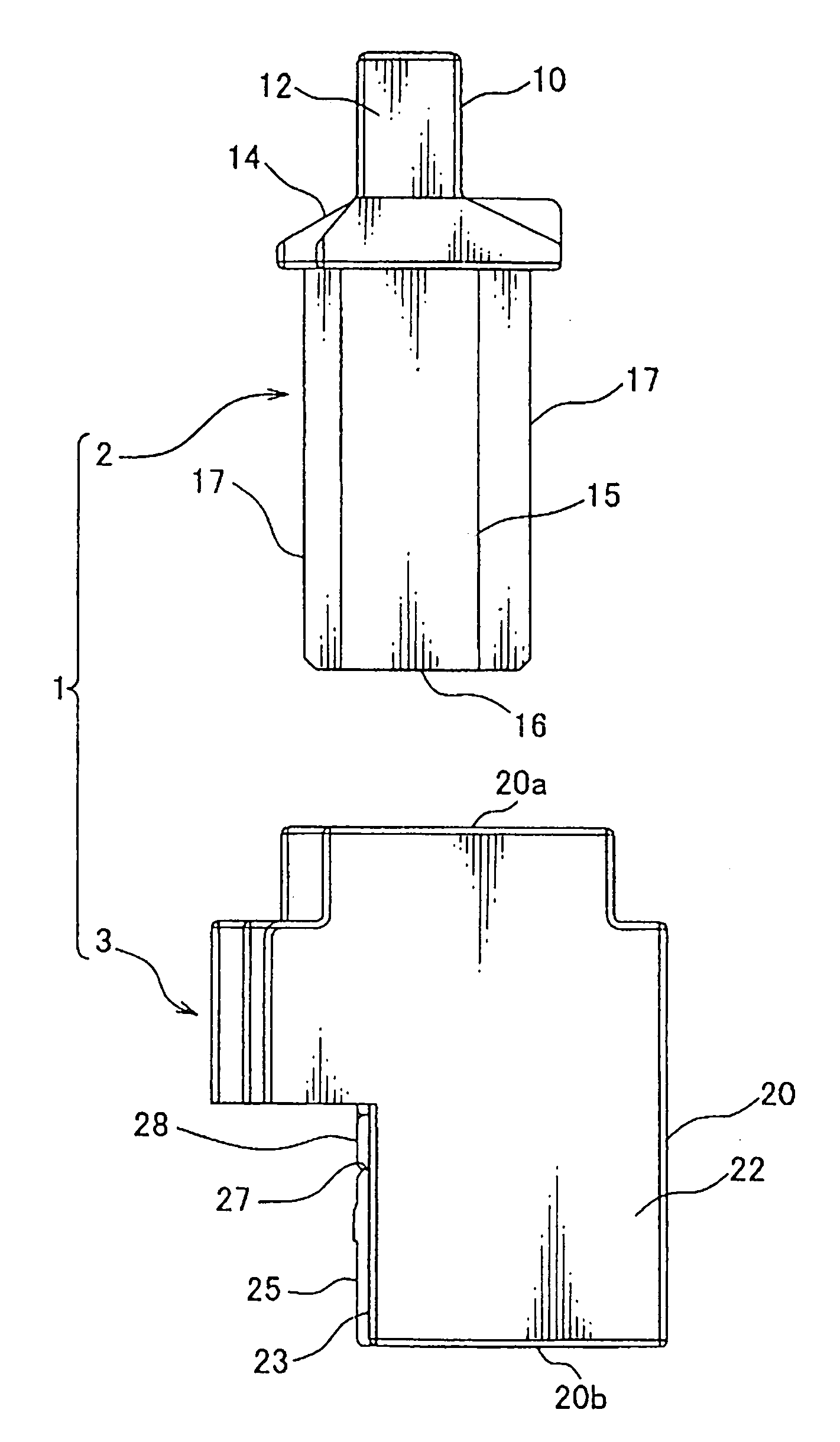

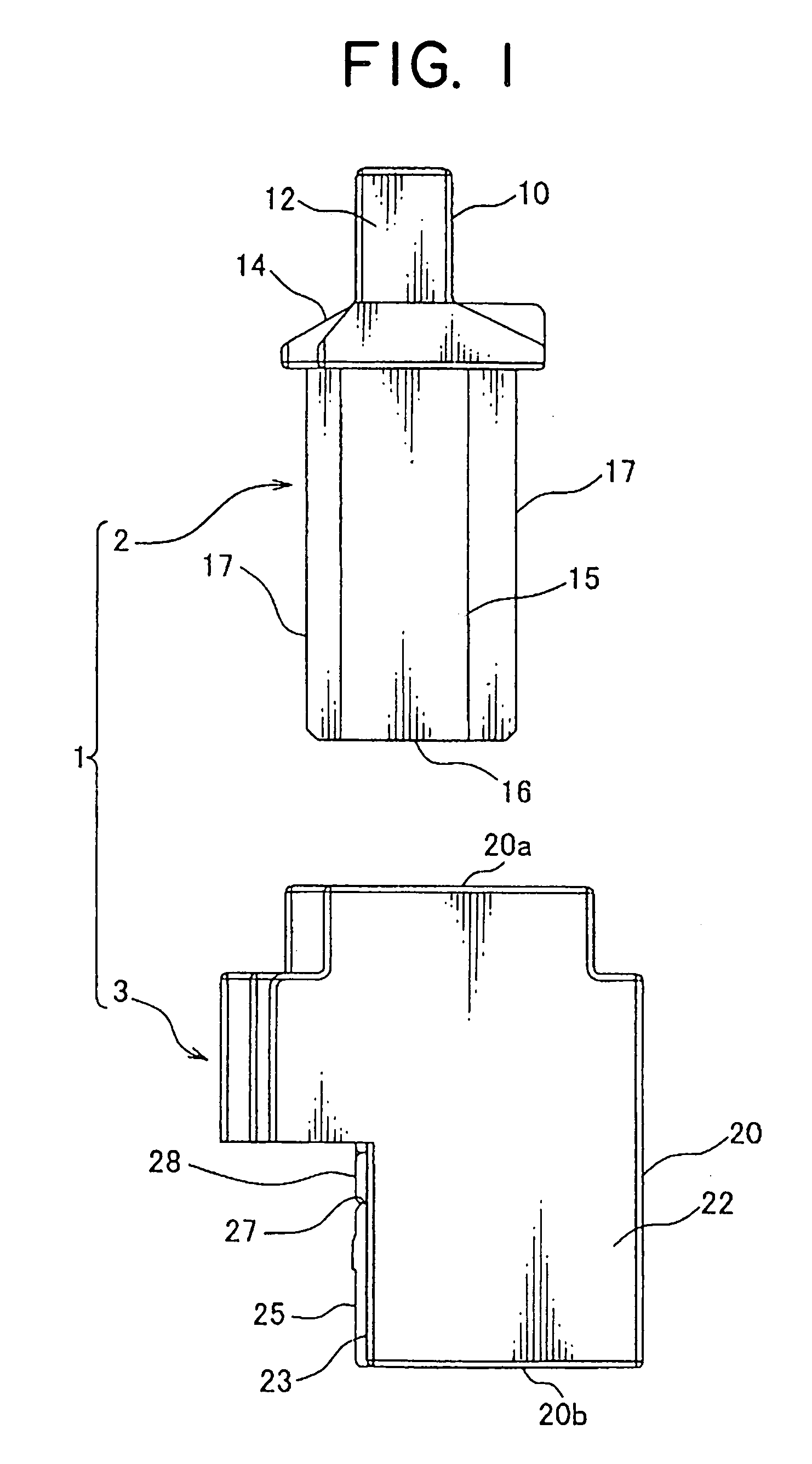

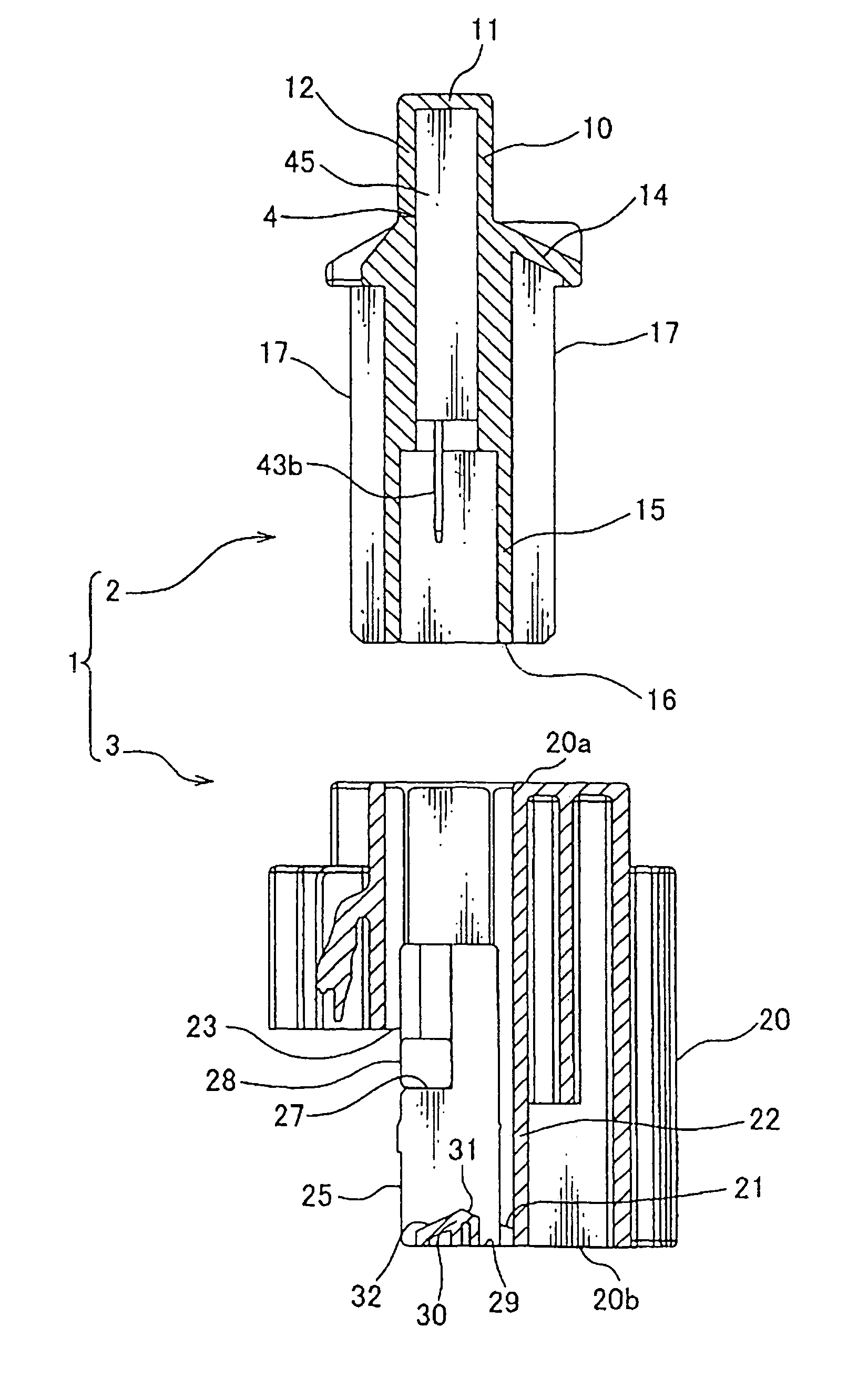

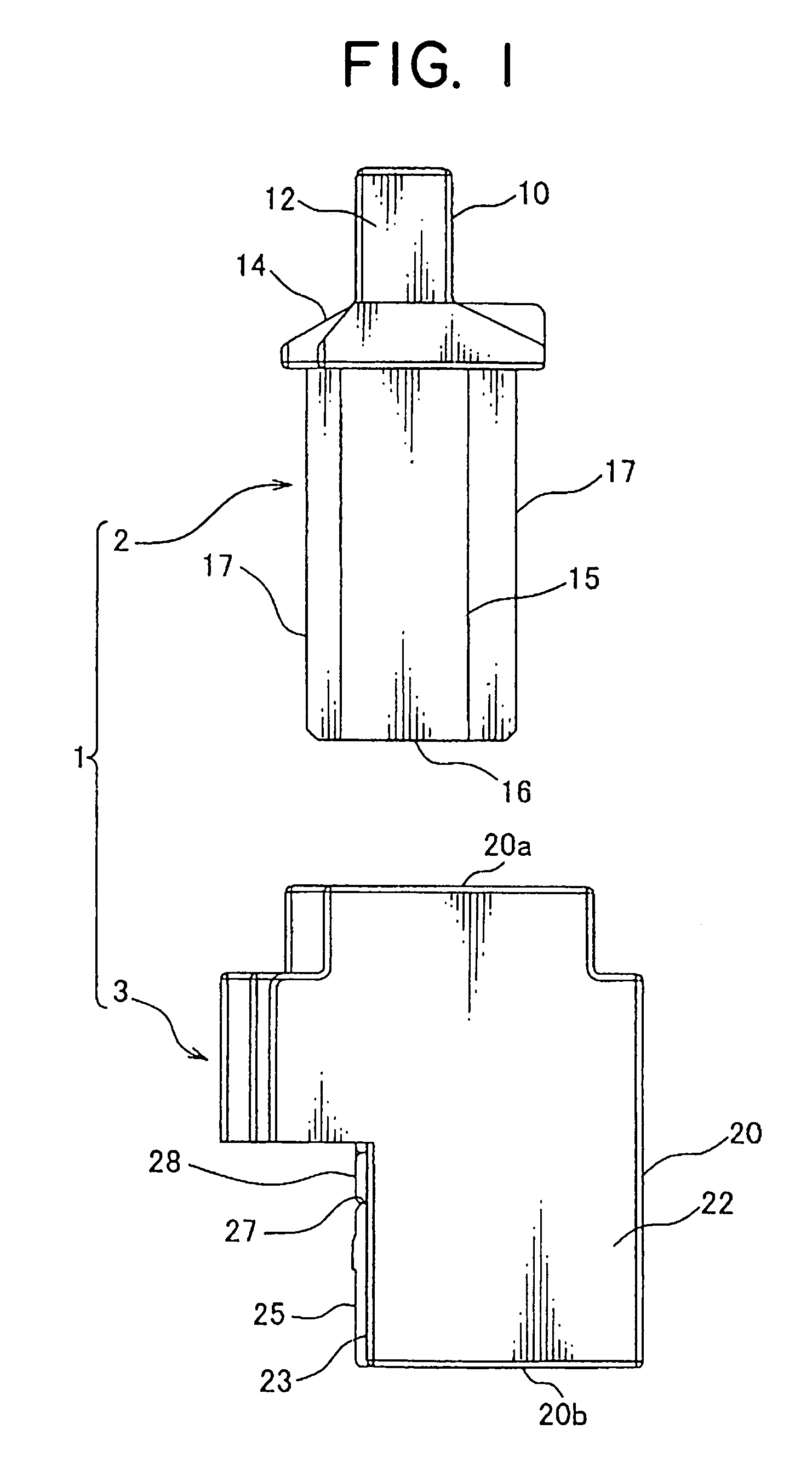

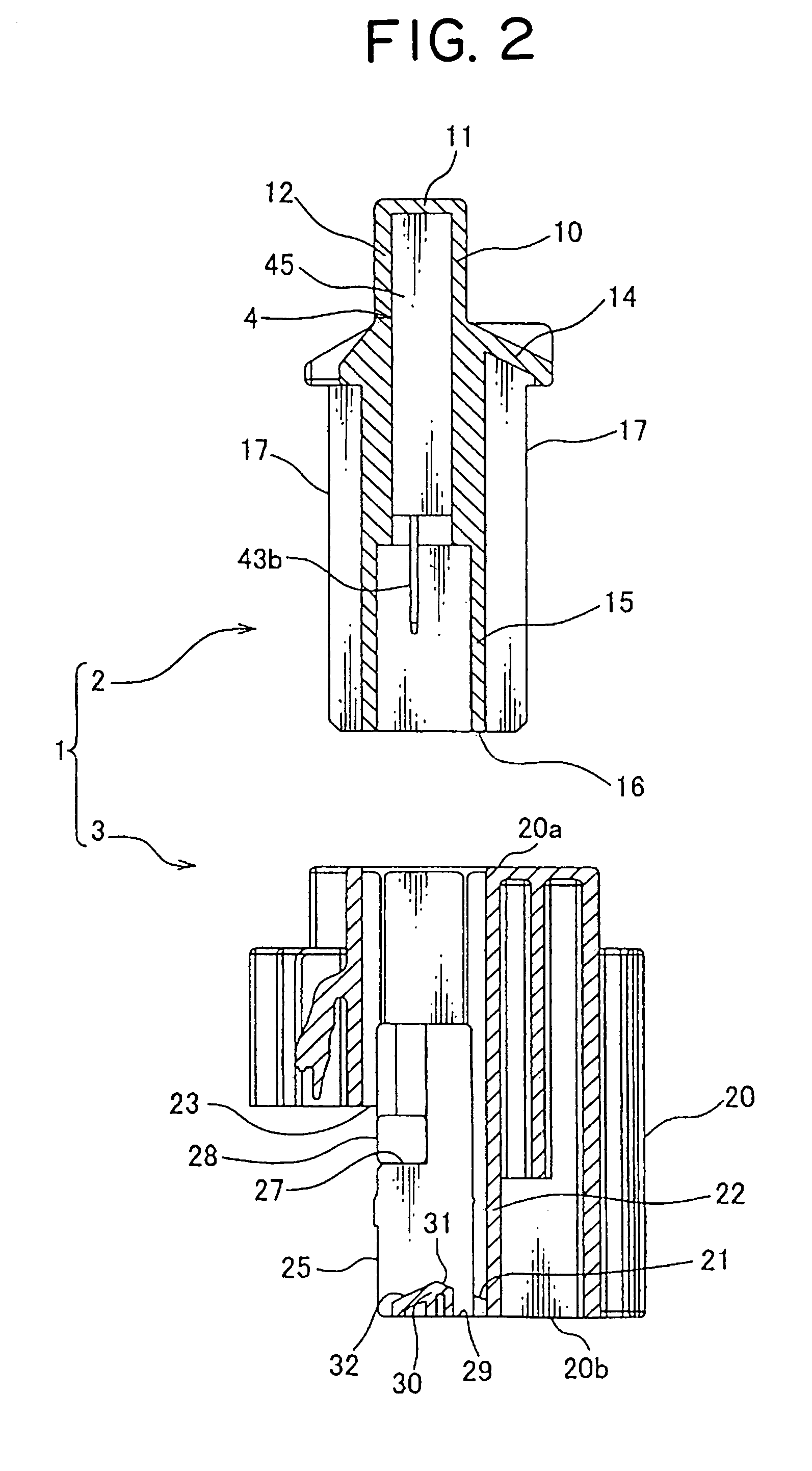

Connector

ActiveUS20090149052A1Drain evenlyAvoid enteringEngagement/disengagement of coupling partsCouplings bases/casesMechanical engineering

The connector including the first and second connector housings is provided with means for draining water entered inside. At an end part of the second connector housing, situated at the front of an insertion direction of the first connector housing into the second connector housing, the second connector housing includes: a connecting part which connects a tube part and a body part of the second connector housing to each other; and a through hole which is adjacent to the connecting part and penetrates through the tube part to communicate a first space, which is outside the body part and inside the tube part, and the outside of the tube part to each other, wherein a facing surface of the connecting part facing the first connector housing is provided with an inclined surface gradually inclining toward the insertion direction as the facing surface approaches the through hole.

Owner:YAZAKI CORP

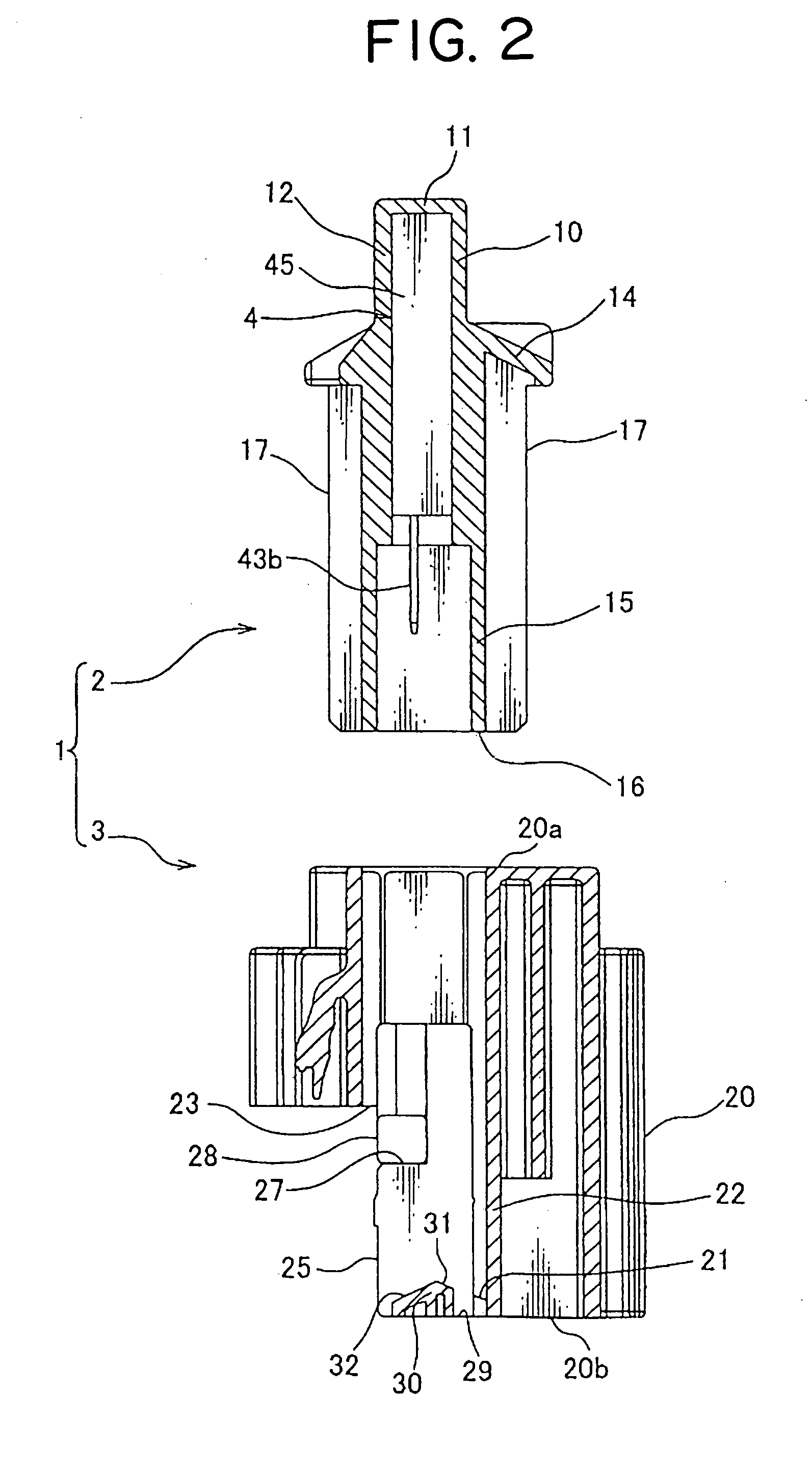

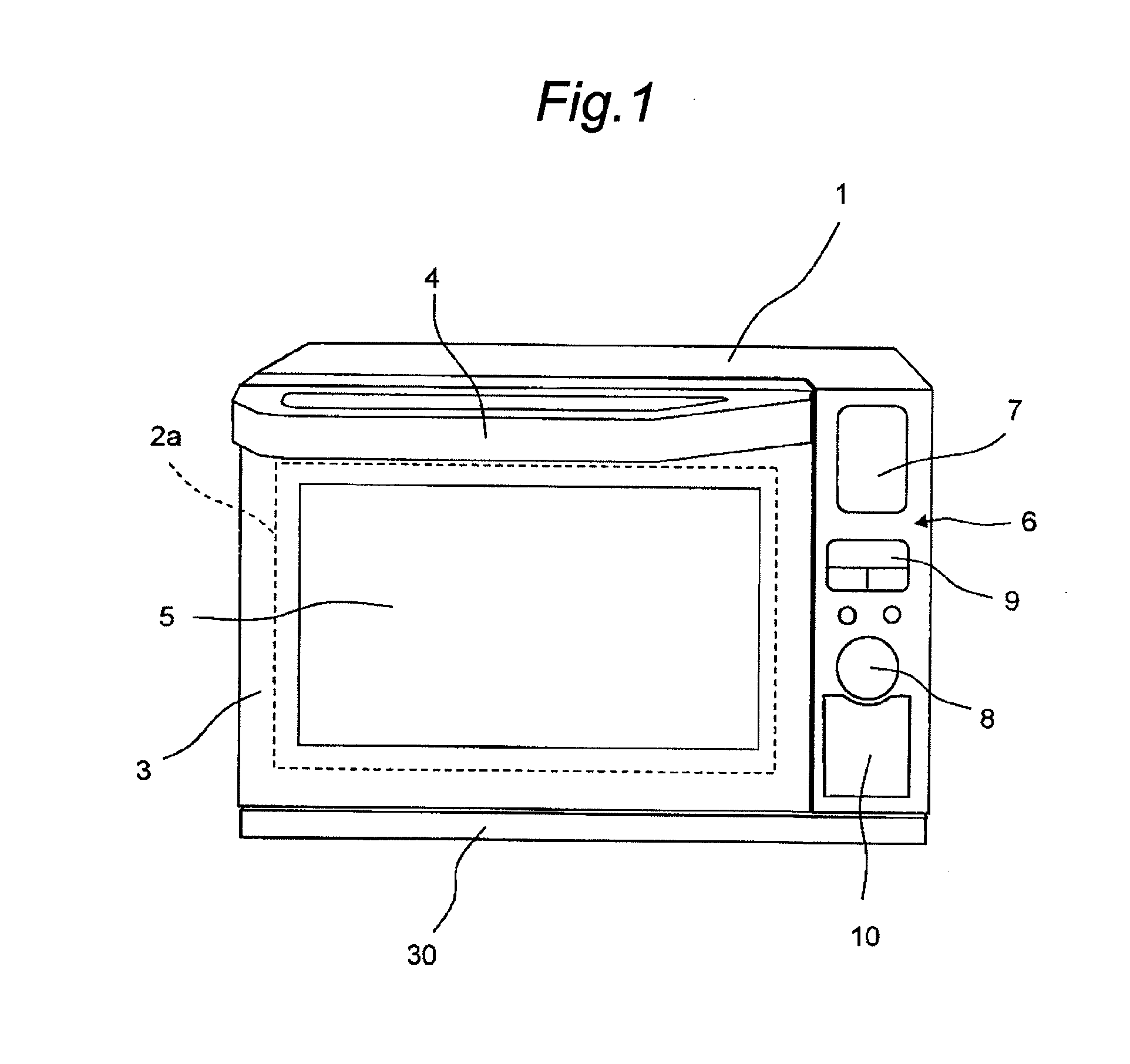

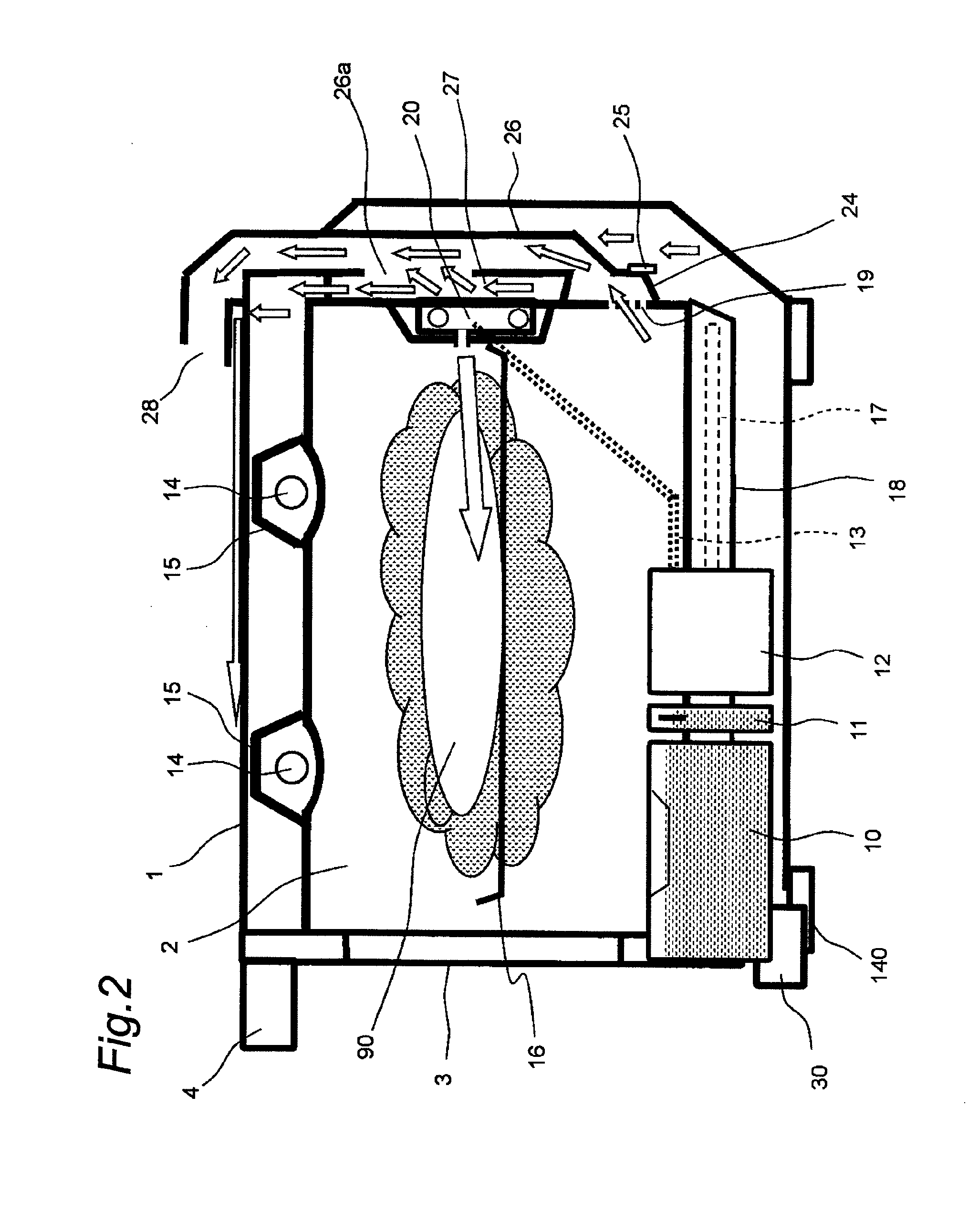

Cooking device

InactiveUS20120006207A1Drain evenlyDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

A cooking device includes a dew receiving container (30) which is removably attached to a main body casing (1) on a lower side and a front surface side of the main body casing (1); and a retention member (40) provided in the main body casing (1) on the lower side and the front surface side of the main body casing (1), to hold the dew receiving container (30). The retention member (40) includes a drainage channel which is positioned above a dew receiving recessed portion of the dew receiving container and receives water droplets dropping along the front surface of the main body casing, and a drainage hole through which the water droplets received by the drainage channel is introduced to the dew receiving recessed portion. A downwardly tapered rib (56) is provided in vicinity of an edge of the opening of the drainage hole (53) of the retention member.

Owner:SHARP KK

Firing process of Nixing pottery products

Owner:钦州市奇圣古坭斋坭兴陶有限公司

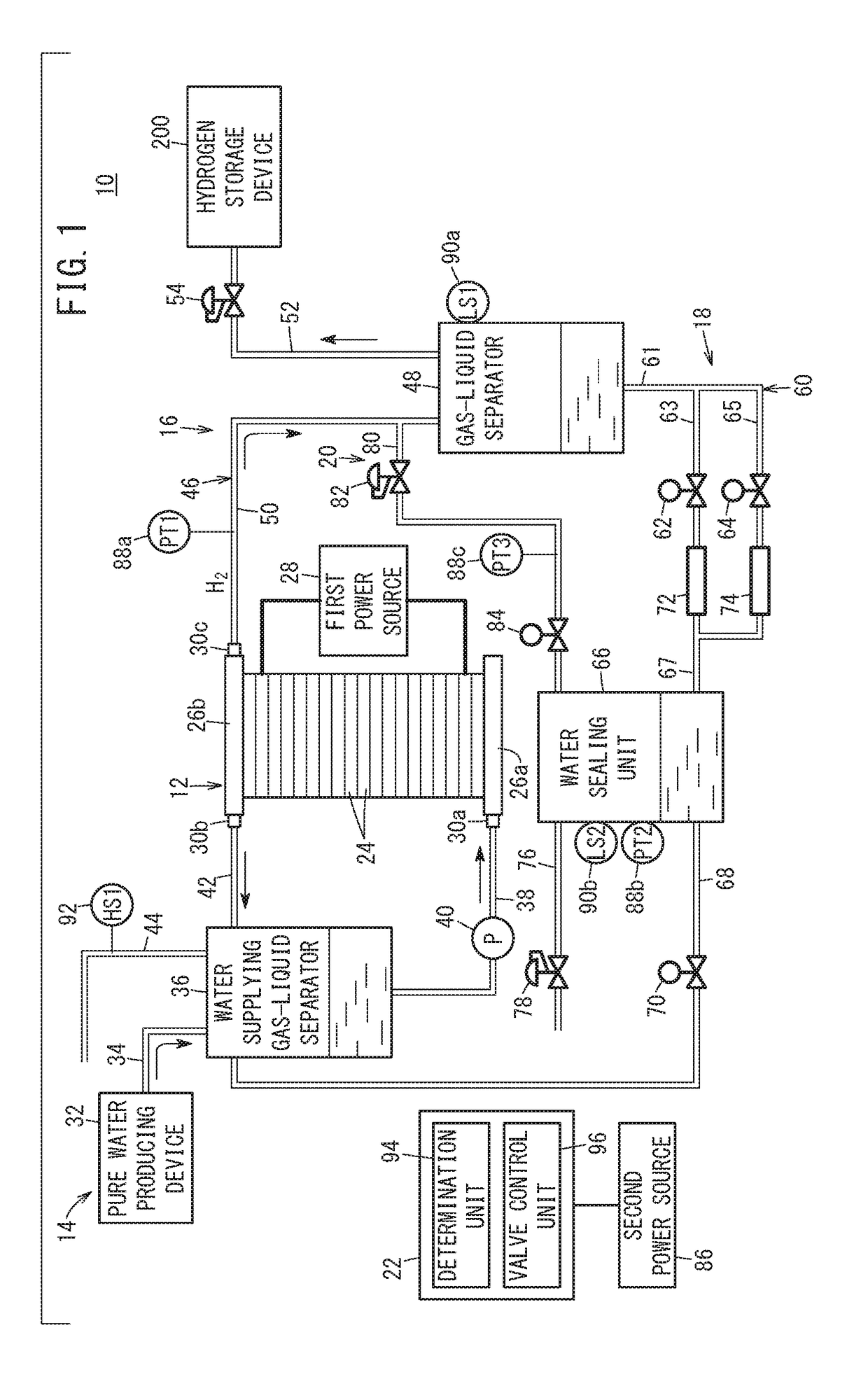

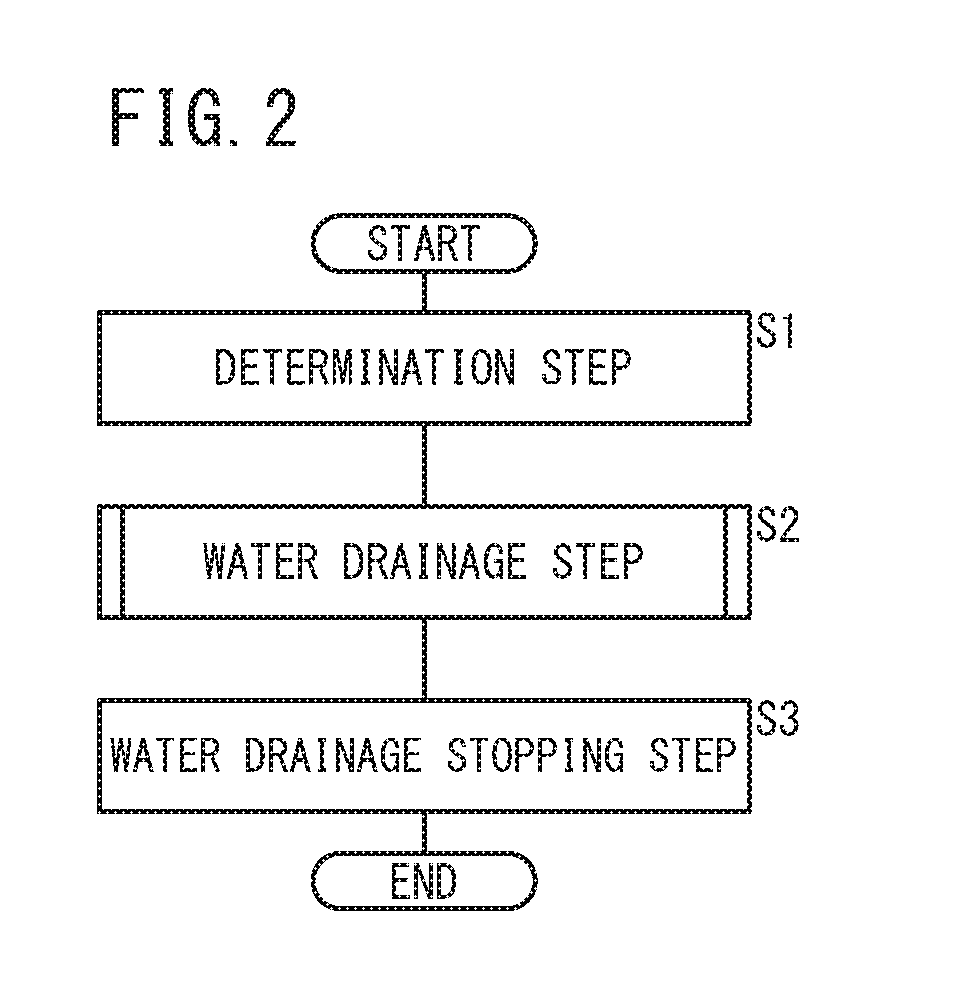

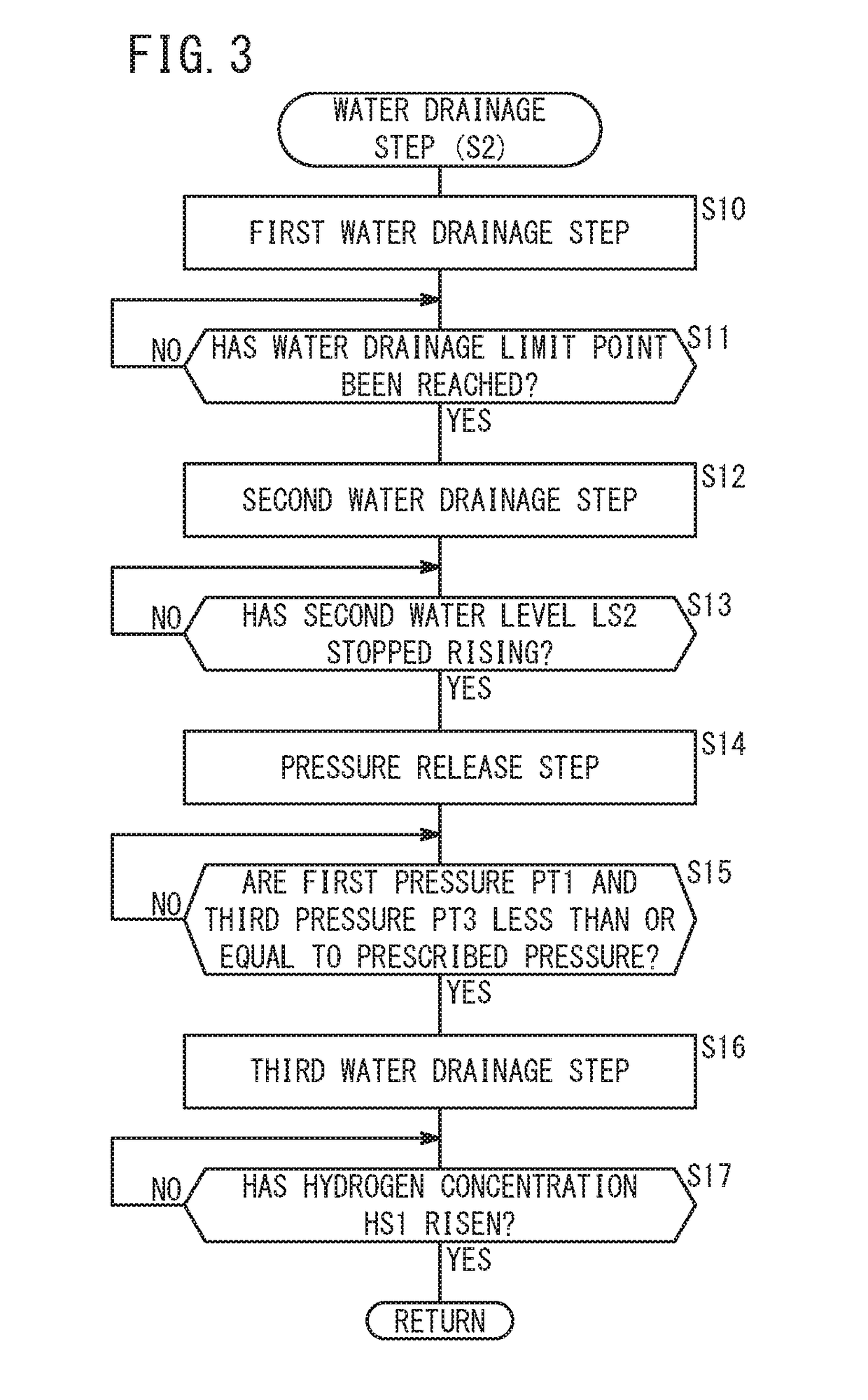

Water electrolysis system and method of stopping operation thereof

A water electrolysis system is equipped with a water electrolysis device, a water supply passage, a hydrogen supply passage, a gas-liquid separator, a first water drainage passage, a first water drainage valve, a second water drainage valve, a determination unit, and a valve control unit. In a method of stopping operation of the water electrolysis system, in a water drainage step, in the case that the determination unit determines that operation of the water electrolysis device has been stopped, the first water drainage valve is controlled to be placed in a valve open state, thereby draining liquid water from the gas-liquid separator into the first water drainage passage.

Owner:HONDA MOTOR CO LTD

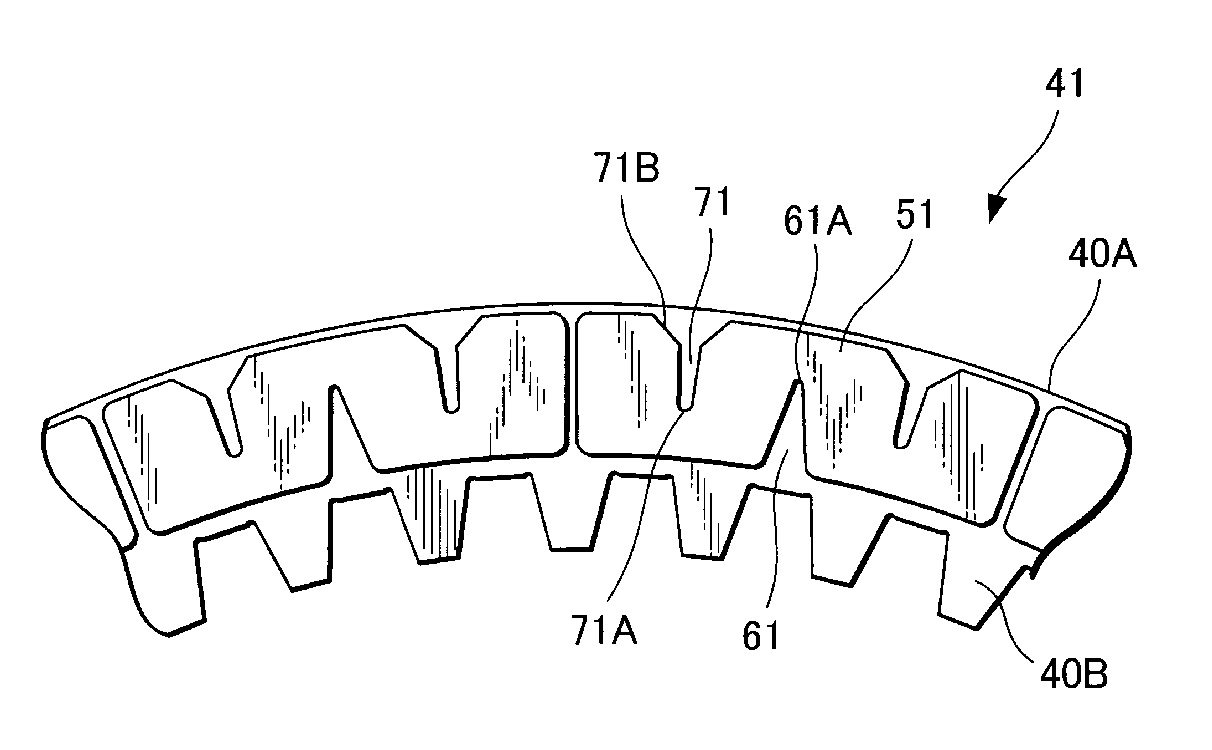

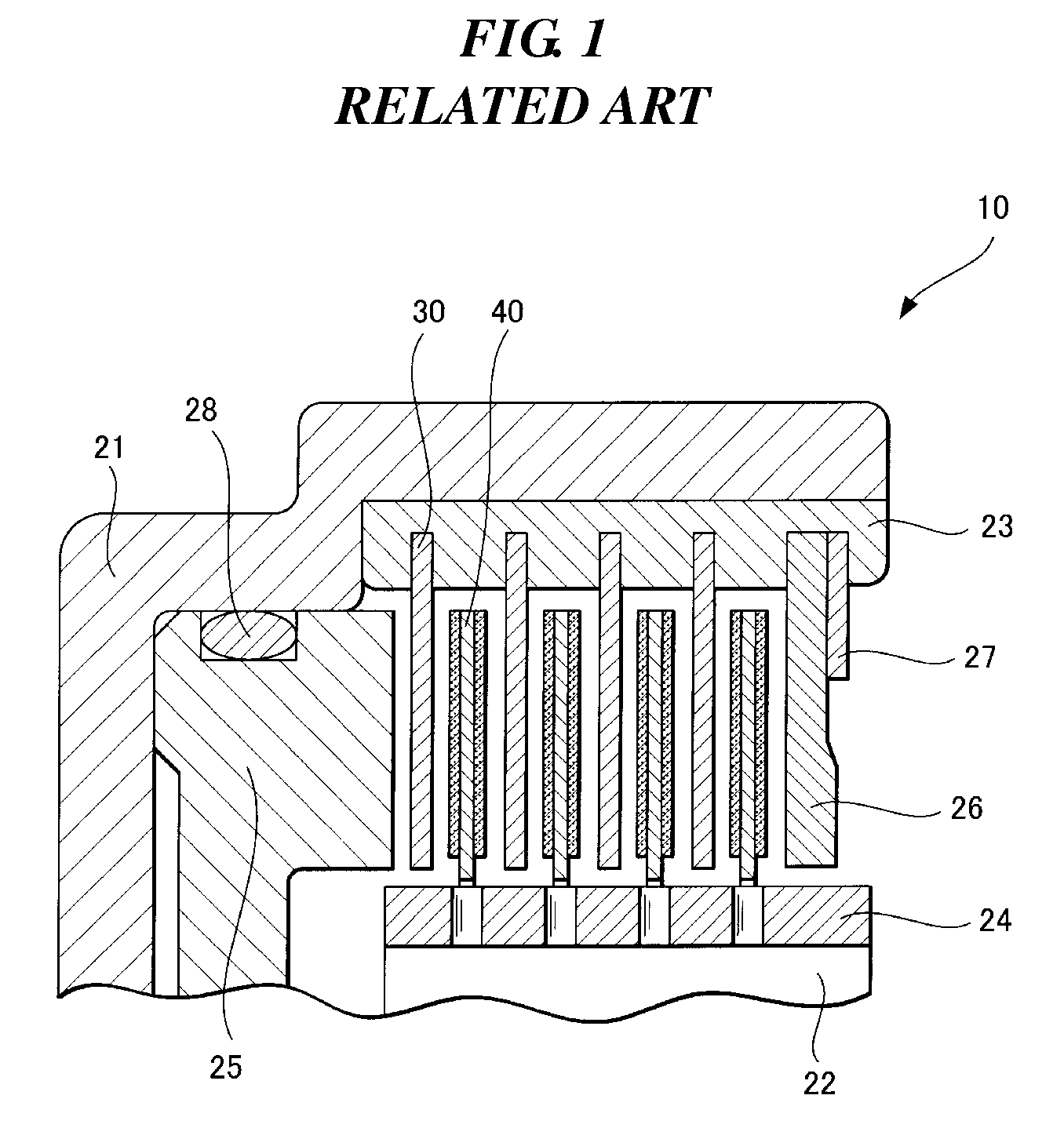

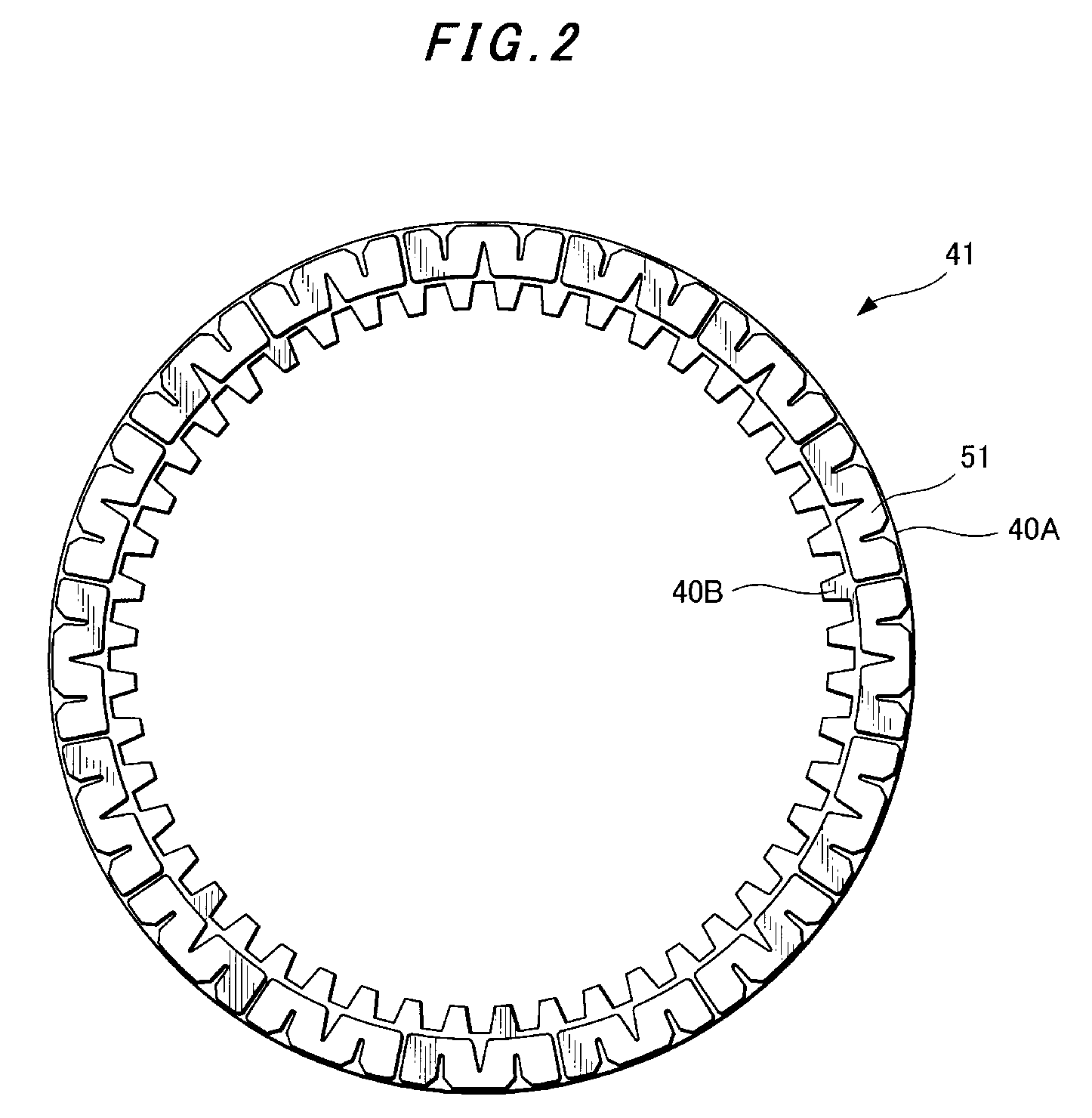

Friction plate for wet-type multiplate clutch

InactiveUS7980375B2Drag torque is reducedReduce a drag torqueFriction clutchesFriction liningEngineeringClutch

A friction plate for a wet-type multiplate clutch is provided with a core plate and friction linings bonded on opposite sides of the core plate, respectively. Each of the friction linings is composed of plural segment pieces each having at least one first oil groove and at least one second oil groove. The first oil groove opens to a radially-inner side of the friction plate and has a closed end portion located in a radially-intermediate part of the friction lining, and the second oil groove opens to a radially-outer side of the friction plate and has a closed end portion located in another radially-intermediate part of the friction lining. The second oil groove has an opening flared outwardly in a radial direction.

Owner:NSK WARNER

Connector

ActiveUS7785128B2Drain evenlyAvoid enteringCouplings bases/casesClamped/spring connectionsEngineeringMechanical engineering

The connector including the first and second connector housings is provided with means for draining water entered inside. At an end part of the second connector housing, situated at the front of an insertion direction of the first connector housing into the second connector housing, the second connector housing includes: a connecting part which connects a tube part and a body part of the second connector housing to each other; and a through hole which is adjacent to the connecting part and penetrates through the tube part to communicate a first space, which is outside the body part and inside the tube part, and the outside of the tube part to each other, wherein a facing surface of the connecting part facing the first connector housing is provided with an inclined surface gradually inclining toward the insertion direction as the facing surface approaches the through hole.

Owner:YAZAKI CORP

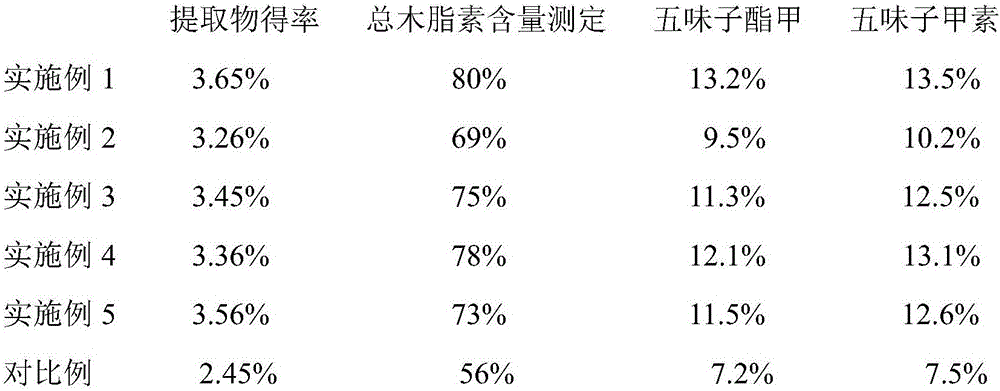

Preparation method of orange magnoliavine fruit lignan extract

InactiveCN106266168AImprove extraction efficiencyImprove production complianceNervous disorderMetabolism disorderReflux extractionLignan

The invention belongs to the technical field of traditional Chinese medicines and particularly relates to a preparation method of orange magnoliavine fruit lignan. According to the preparation method of the orange magnoliavine fruit lignan, reflux extraction is performed on an orange magnoliavine fruit medicinal material with an ethanol aqueous solution, a loading solution is prepared and passes a weakly polar macroporous resin adsorption column, elution for impurity removal is performed with 10%-30% of ethanol, then elution is performed with 70%-90% of ethanol, an ethanol eluent is collected and passes an alumina adsorption column with the weight 0.5-2 times that of the medicinal material, effluent is collected, a solvent is recovered under the reduced pressure or normal pressure, reduced pressure or normal pressure drying is performed at 60-100 DEG C, and the orange magnoliavine fruit lignan extract is obtained. The extraction efficiency is improved, liquid discharge is smooth, mass production compliance is substantially improved, the production time is substantially shortened, and the production cost is saved.

Owner:YANGTZE RIVER PHARM GRP NANJING HAILING PHARM CO LTD

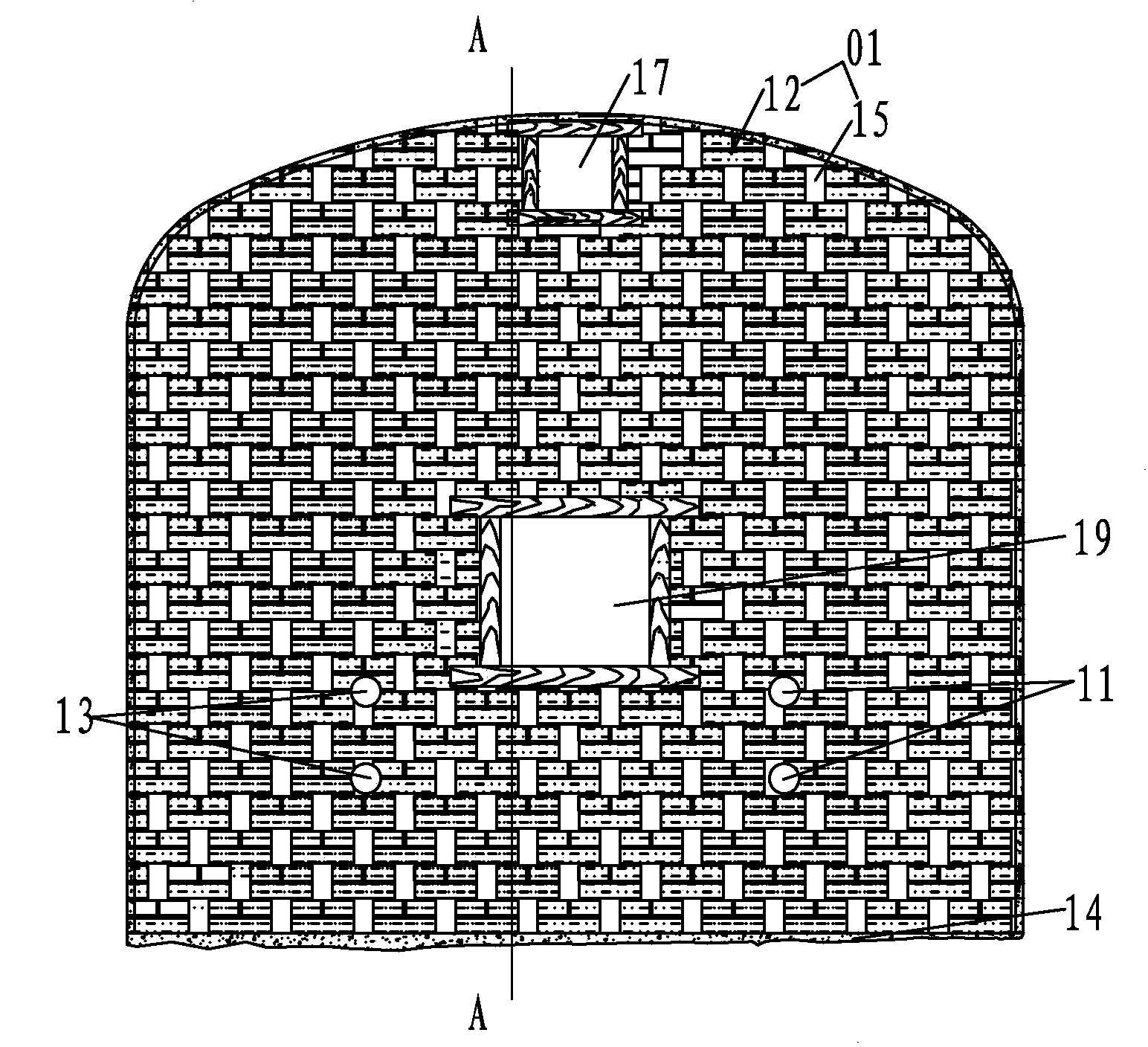

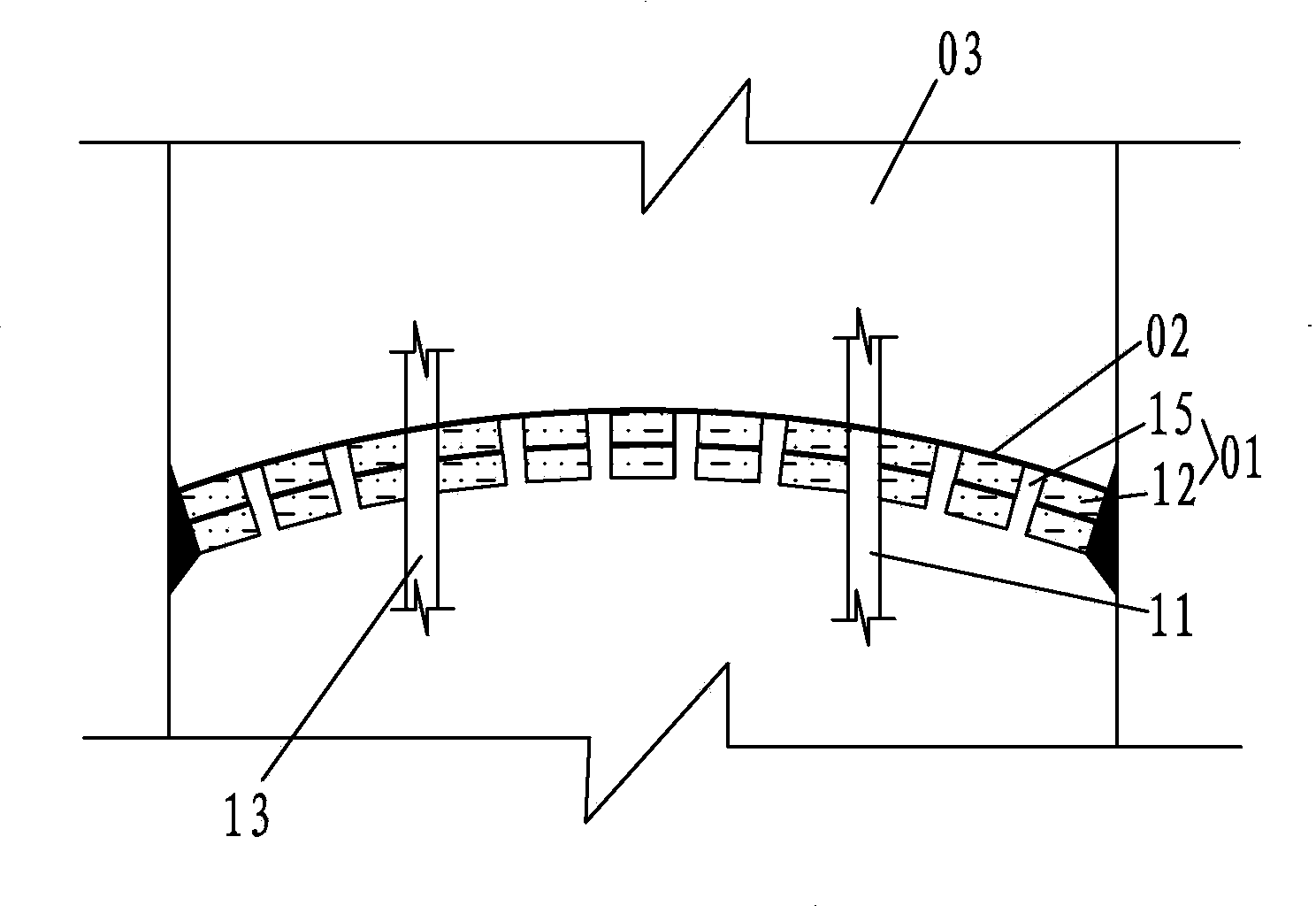

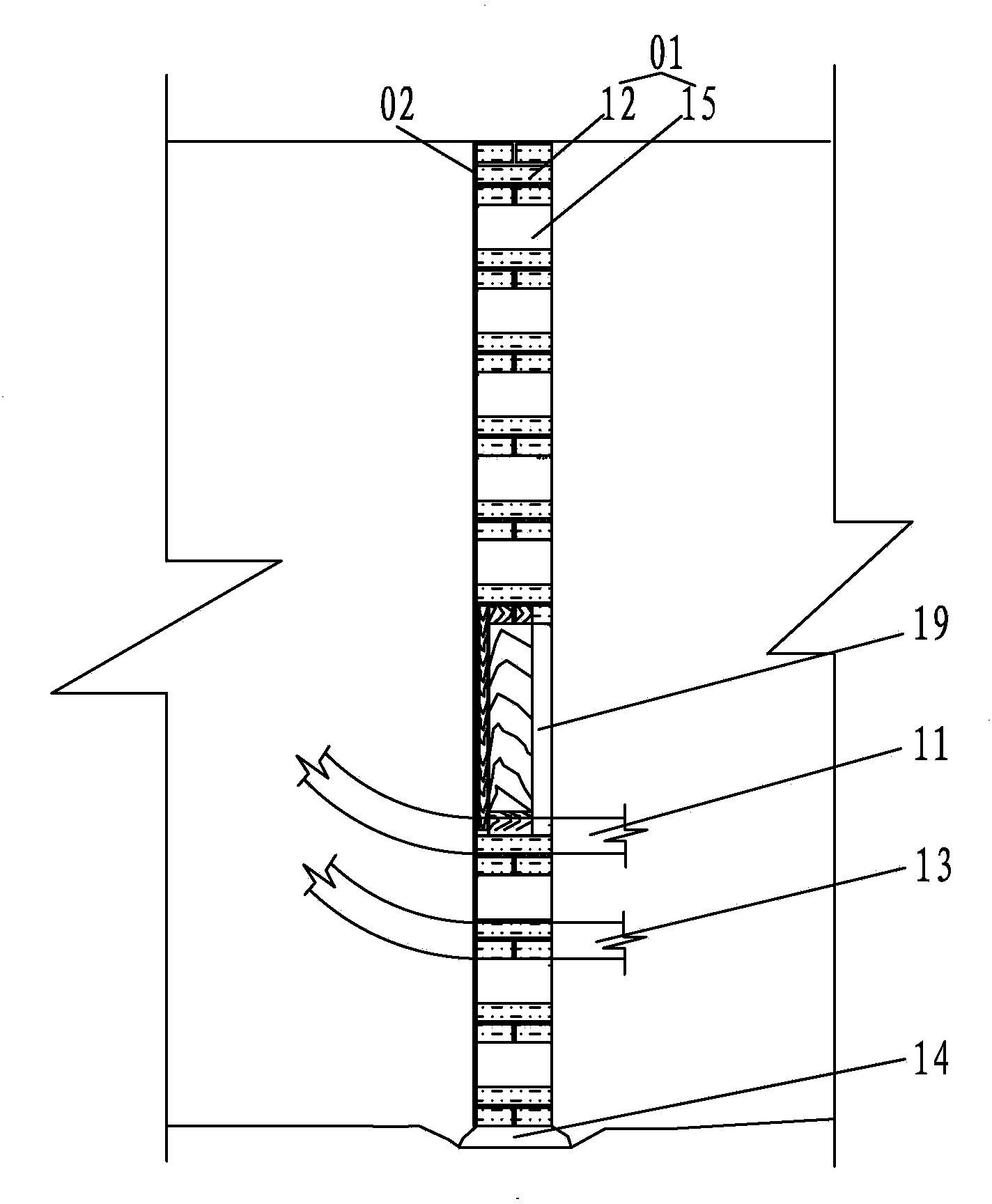

Water drainage wall adopting brick structure and used in cut-and-fill stoping method

A water drainage wall adopting a brick structure and used in a cut-and-fill stoping method comprises a wall body and geotechnical cloth arranged on the inner side of the wall body, wherein filling pipes and filling air-returning and water-returning pipes are arranged on the wall body; the wall body is built by bricks; intervals are reserved between the bricks and form water drainage holes; an observing hole is formed in the position close to the top of the wall body; and a man hole is formed in the middle of the wall body. The water drainage wall adopting the brick structure and used in the cut-and-fill stoping method is good in water drainage effect, not easy to block and low in cost, and has the firm wall body.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

Efficient and durable storage container

InactiveCN109928103AReduce static electricityImprove securityLarge containersUnderwater structuresEngineeringLiquid storage tank

The invention discloses an efficient and durable storage container. The efficient and durable storage container has high quality and comprises a container, wherein a ceiling is horizontally arranged inside the container; the upper end of the interior of the container is connected to a mixed liquid storage tank through a bracing frame; a mixed liquid passage is arranged at one side of the mixed liquid storage tank; a joining passage is arranged at one side, far away from the mixed liquid passage, of the mixed liquid storage tank; a soft channel is arranged at one end, far away from the mixed liquid storage tank, of the joining passage; a transparent cover is arranged on the top end of the container; two entering liquid passages are symmetrically arranged at the upper end of the container; agas exchanging device is also inserted in the upper end of the container; and a temperature reducing instrument is arranged on each entering liquid passage. The efficient and durable storage container is practicable, stable, simple and convenient to operate, safe, efficient, and durable in use, can also treat internal liquid and has a high promotion value.

Owner:陕西海嵘工程项目管理有限公司

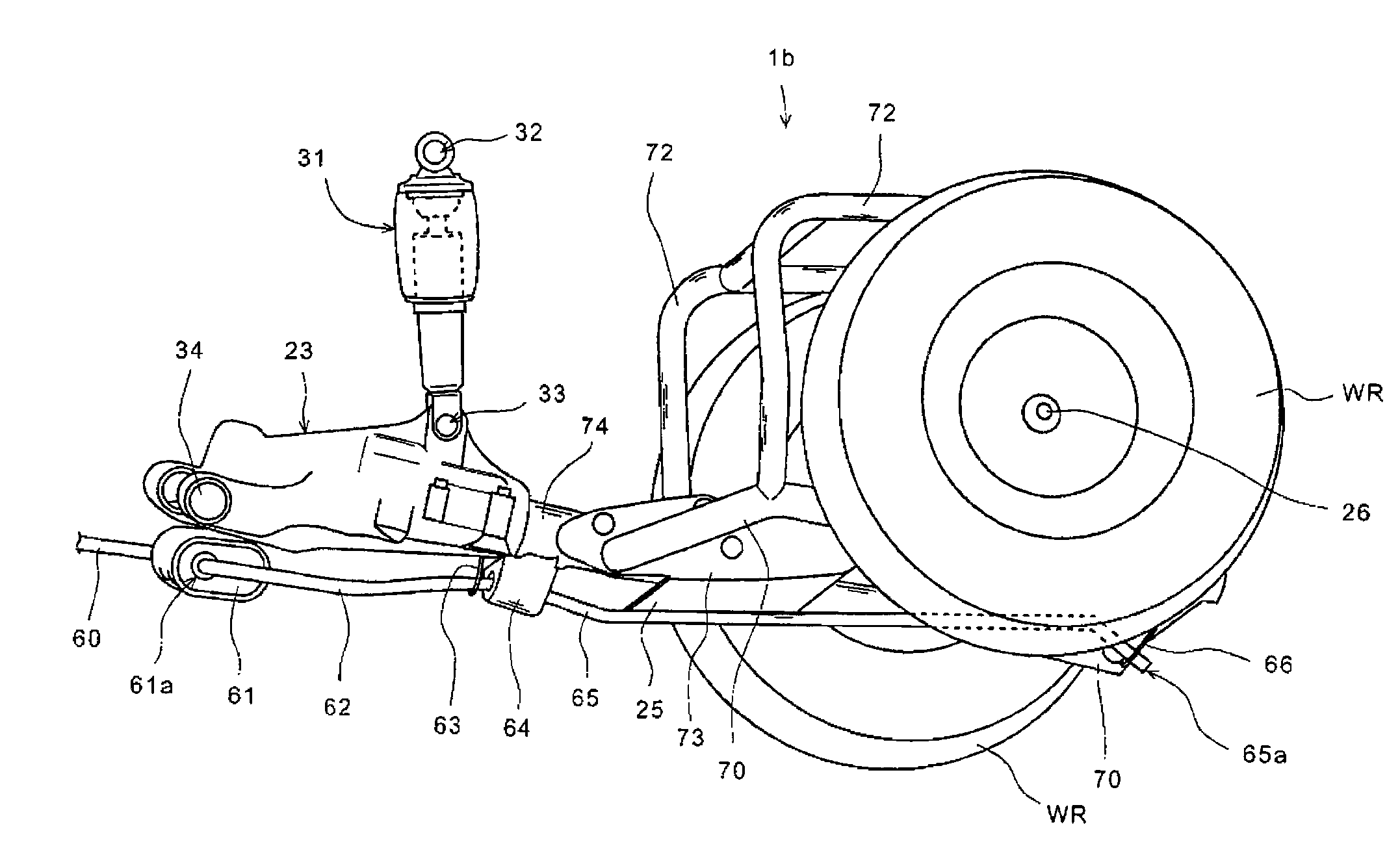

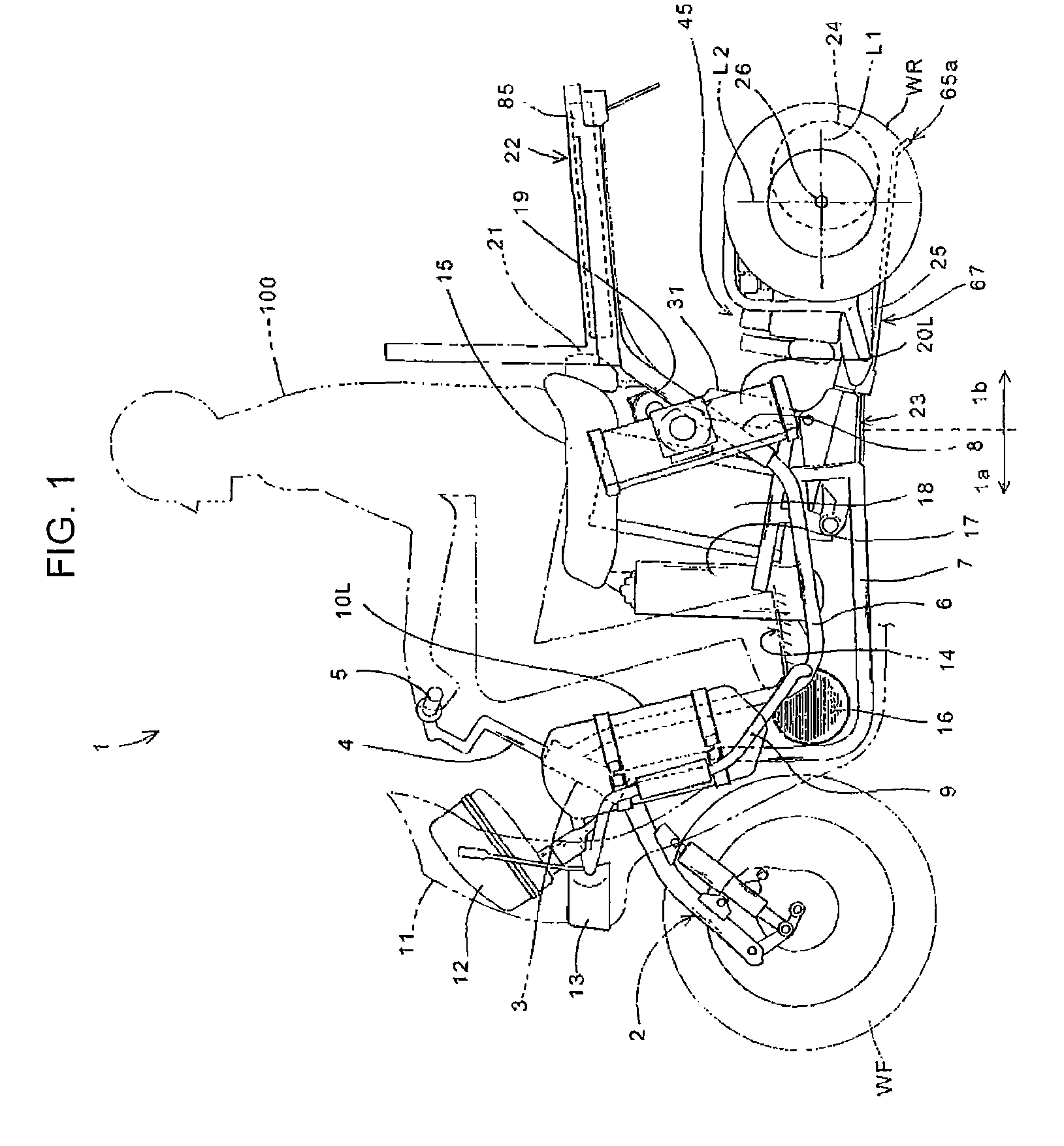

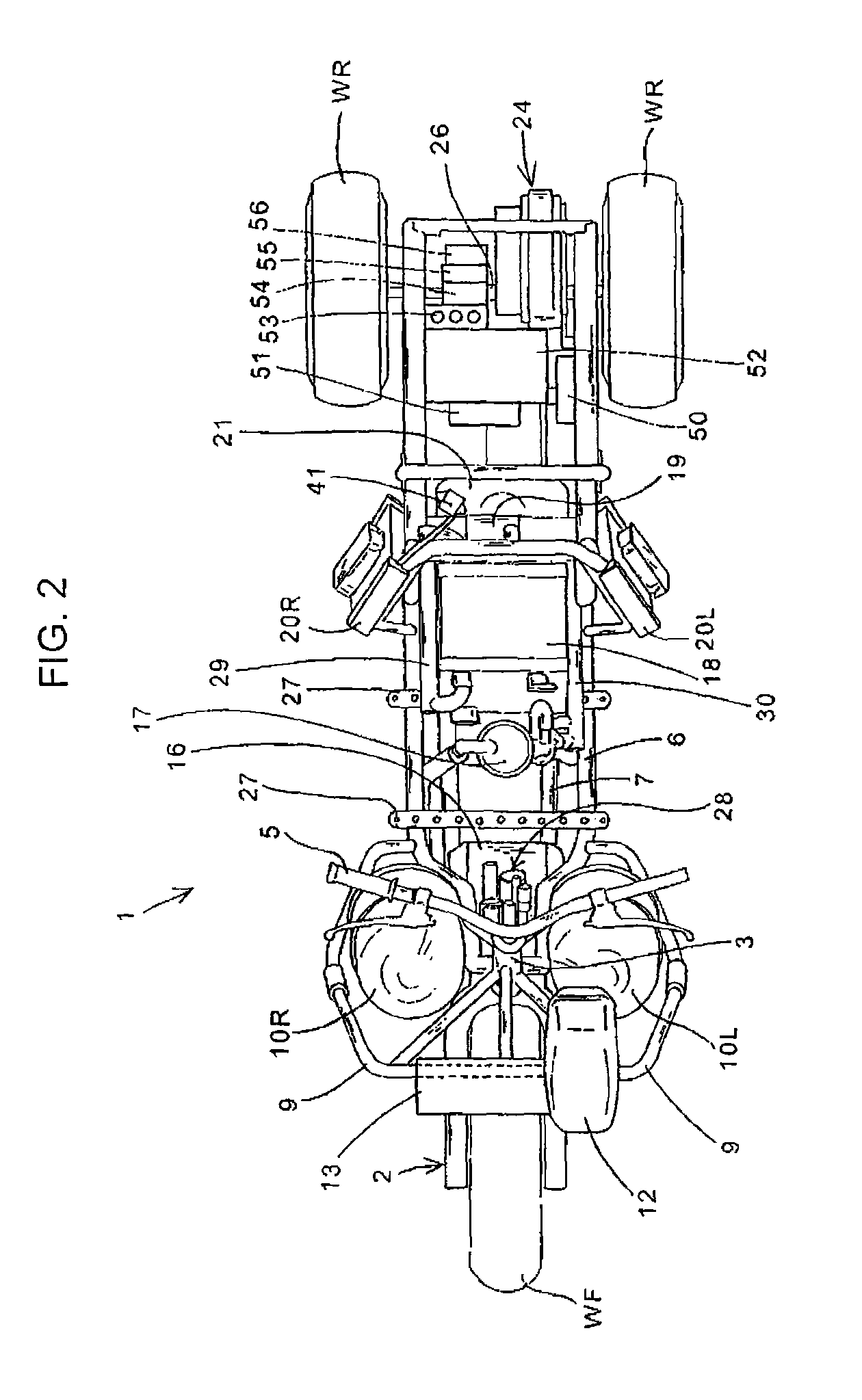

Saddle-ride type fuel cell three-wheeled vehicle

InactiveUS8177012B2Drain evenlyPreventing the water from being splashedMotorised scootersElectric propulsion mountingWater dischargeFuel cells

A saddle-ride three-wheeled vehicle has a fuel cell which generates an electric power by a chemical reaction between a fuel gas and a reaction gas. The three-wheeled vehicle includes a drain pipe which guides water discharged from the fuel cell out of a vehicle body; a rear body to which a pair of left and right rear wheels are journaled; and a linking mechanism which swingably links the rear body and a front body to allow the front body to sway left and right with respect to the rear body, wherein the drain pipe has a drain port between the pair of left and right rear wheels.

Owner:HONDA MOTOR CO LTD

Portable electronic device with drainage structure

ActiveUS20080266765A1Drain evenlySimple structureTypewritersDetails for portable computersEngineeringElectrical and Electronics engineering

A drainage structure is provided for a portable electronic device, such as a portable computer. The drainage structure includes an inclination formed on a top surface of a body of the portable electronic device to support a keyboard device in an inclined manner so that water spilled on the keyboard device or the top surface can be expelled out of the electronic device by gravity. If desired, height adjusting units can be arranged between the keyboard device and the top surface of the body to selectively maintain the keyboard in a horizontal condition. A drain hole or groove can be selectively formed in the body of the electronic device to facilitate drainage of water.

Owner:GETAC TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com