Water drainage wall adopting brick structure and used in cut-and-fill stoping method

A backfill mining method and brick structure technology, which is applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of high construction quality requirements, leakage of slurry, and high cost, which is beneficial to environmental protection and improves the pressure bearing capacity. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

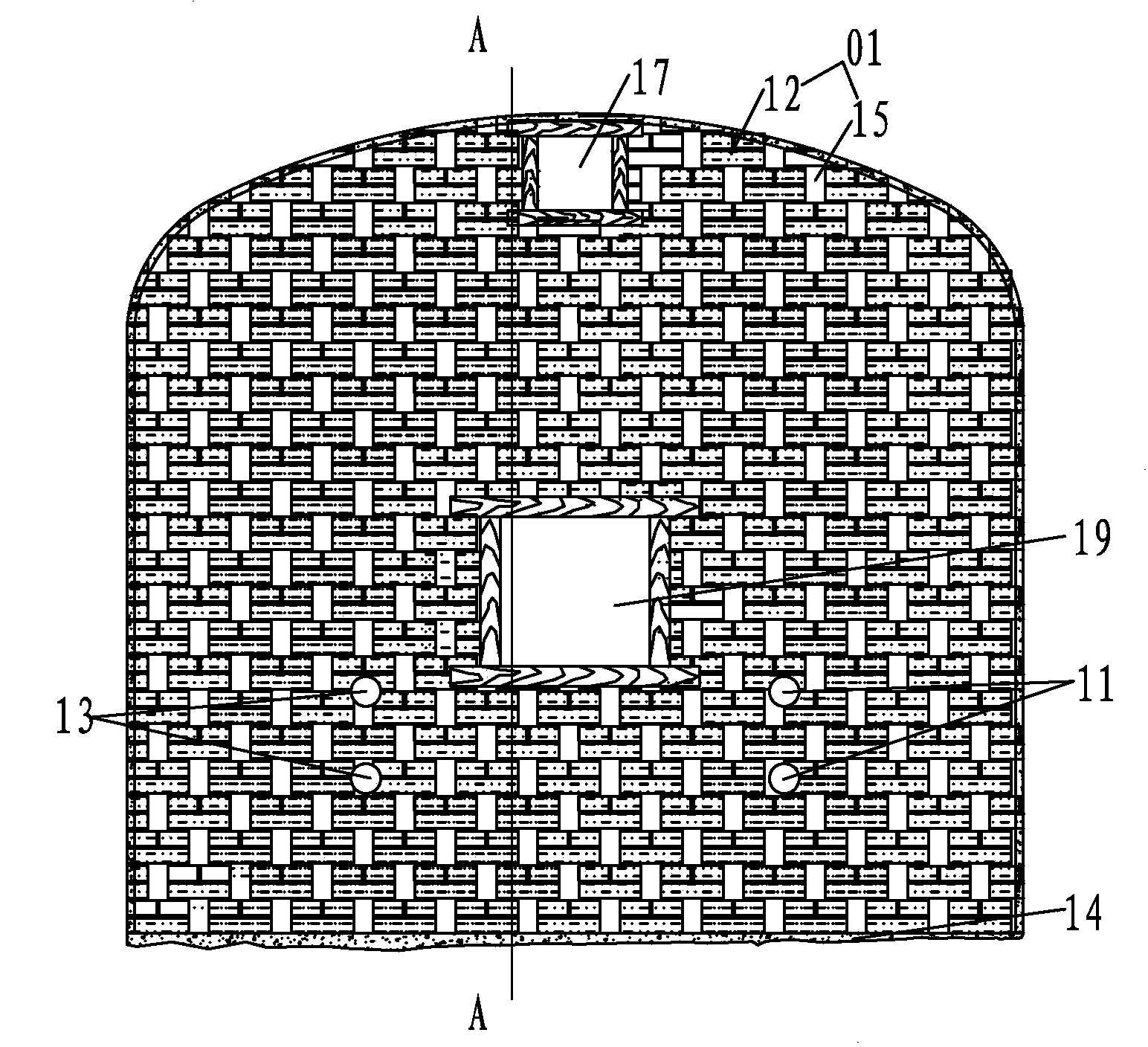

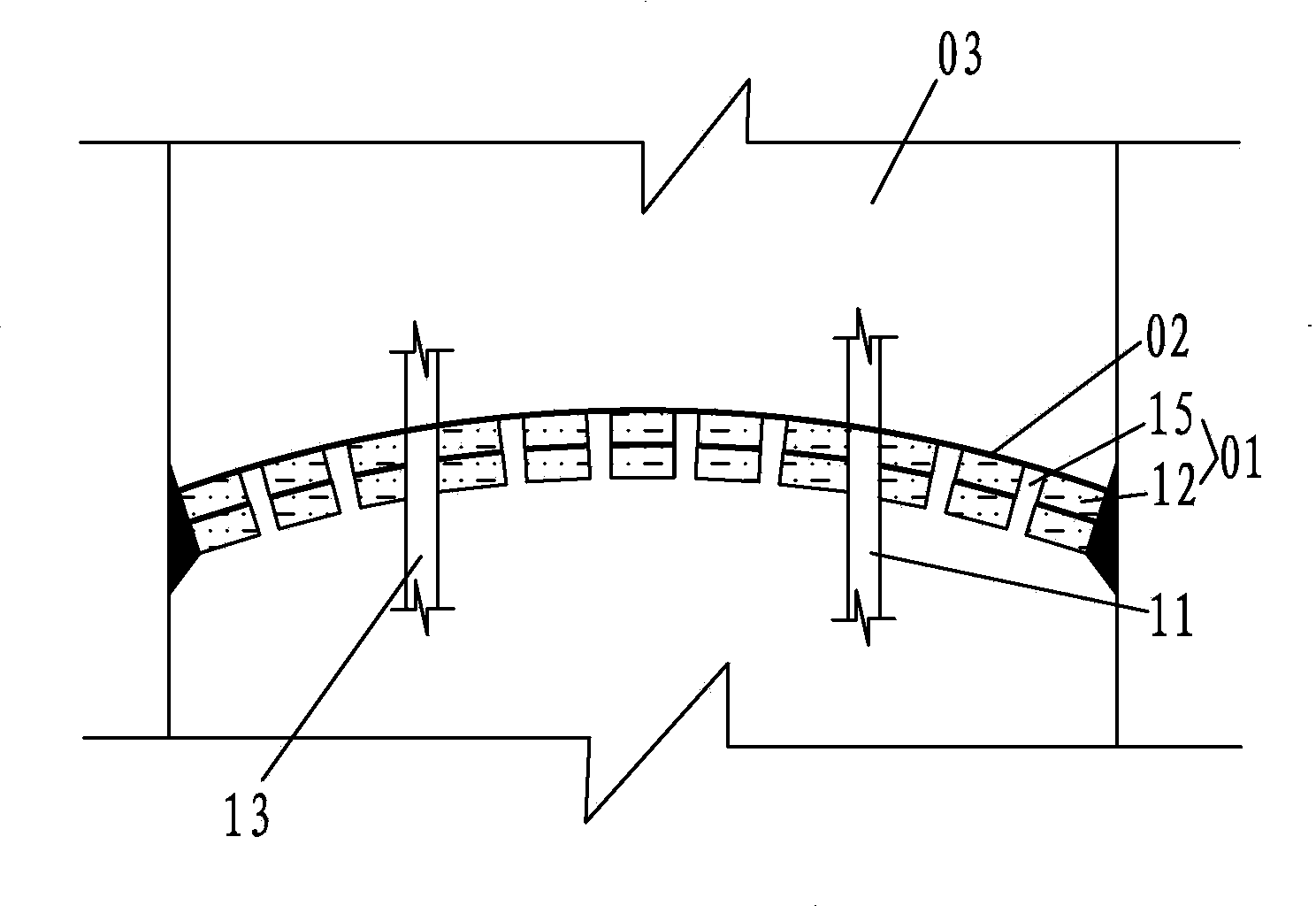

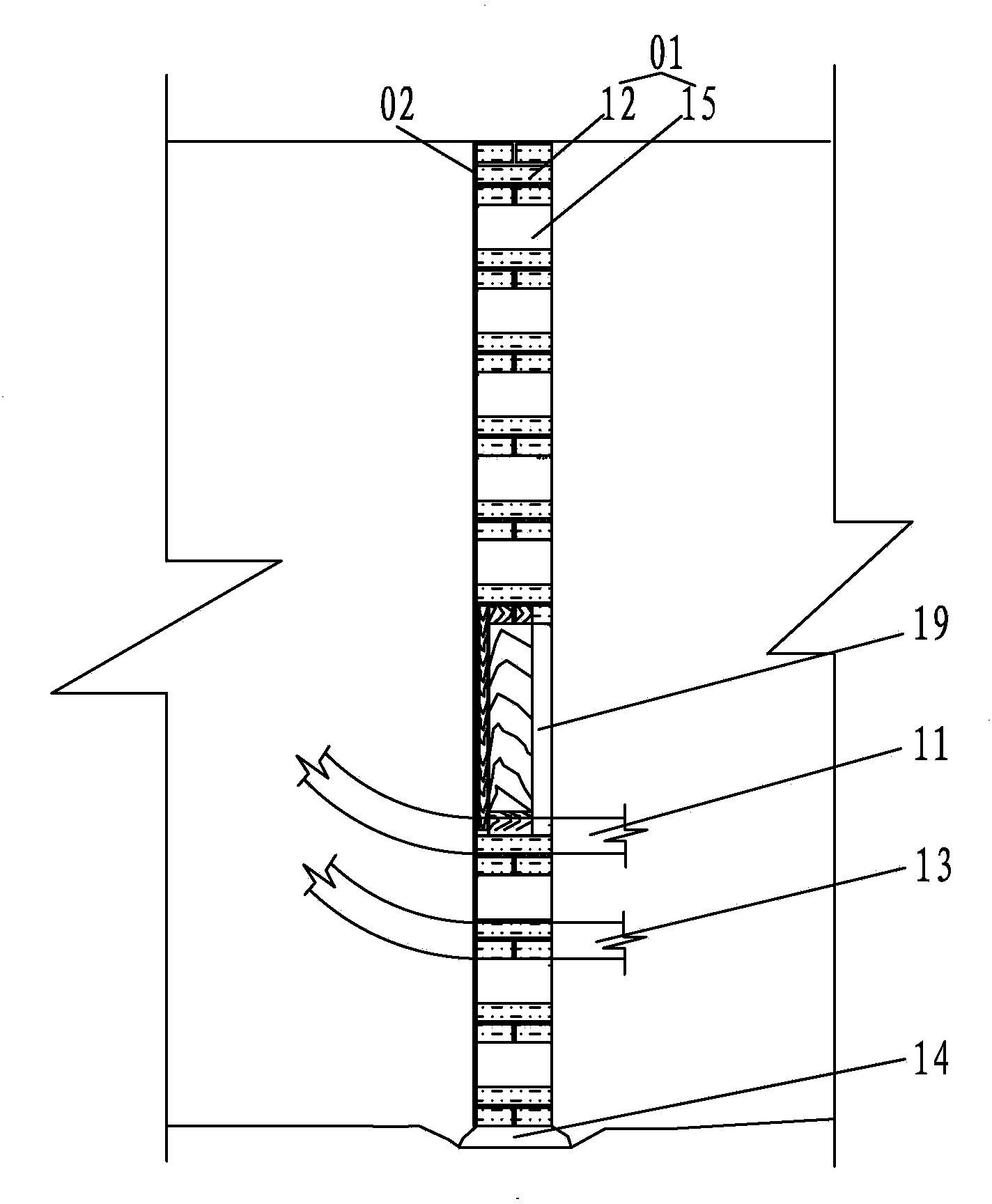

[0015] Such as figure 1 , 2 As shown, the brick structure drainage wall used in the filling mining method of the present invention includes a wall 01, a geotextile 02 arranged on the inner side of the wall 01, and a filling pipe 11, a filling return air return pipe 13, and a wall 01 are provided on the wall 01. The body 01 is made of bricks 12, and the bricks 12 are jointed by high-grade cement mortar, and there is a space between the bricks 12, which forms a weep hole 15, and the weep hole 15 is on the wall 01 Distributed in rows, every two adjacent rows of drainage holes 15 are staggered with each other, observation holes 17 are provided near the top of the wall body 01, pedestrian holes 19 are arranged in the middle of the wall body, and geotextile 02 is nailed to the wall body 01 by steel nails .

[0016] A wall base cement mortar cushion 14 is provided between the wall 01 and the roadway bottom plate, and the wall 01 and the roadway roof are smeared with high-grade ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com