Patents

Literature

110results about How to "Improve draining effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

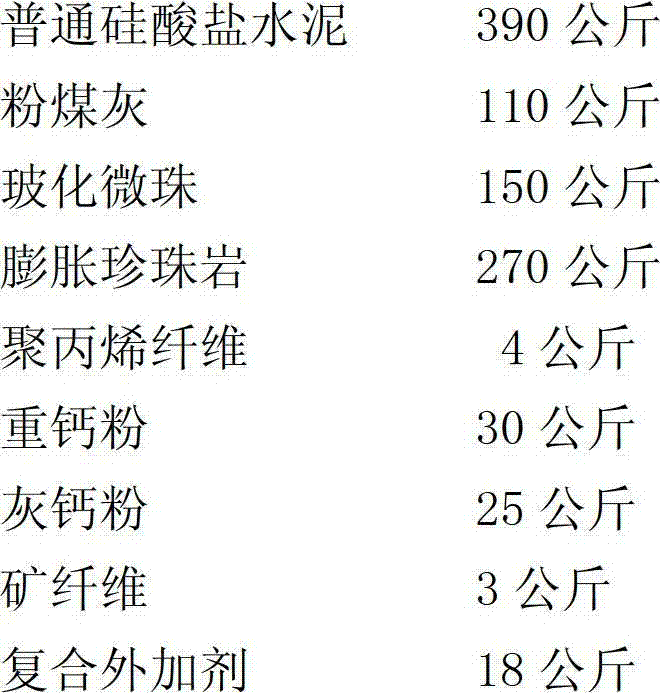

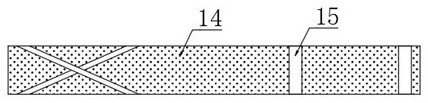

Inorganic composite thermal mortar

InactiveCN102924009AReduce energy consumptionRemarkable effect of thermal insulation and energy savingRebarPerlite

The invention discloses inorganic composite thermal mortar, which comprises ordinary Portland cement, coal ash, glass beads, expanded perlite, polypropylene fibers, heavy calcium powder, ash calcium powder, mineral fibers and a composite additive. By adopting the invention, fireproof insulation layers are constructed on the wall space and the top surface of the building effectively, the heat insulation property of the building is greatly improved, energy consumption for heating in winter and cooling in summer is reduced, and the inorganic composite thermal mortar has the advantages of light density, small heat conductivity coefficient, high temperature resistance, fire resistance, safety use, environmental friendliness and durability. The inorganic composite thermal mortar is suitable for thermal insulation construction of wall spaces and roofs, such as reinforced concrete, concrete, aerated concrete blocks, clay bricks, steel structures and the like, and is also suitable for construction of fireproof insulation layers, such as underground garage, elevator wells, tube wells, cold storages and the like.

Owner:天津哈澳德建筑材料研究院有限公司

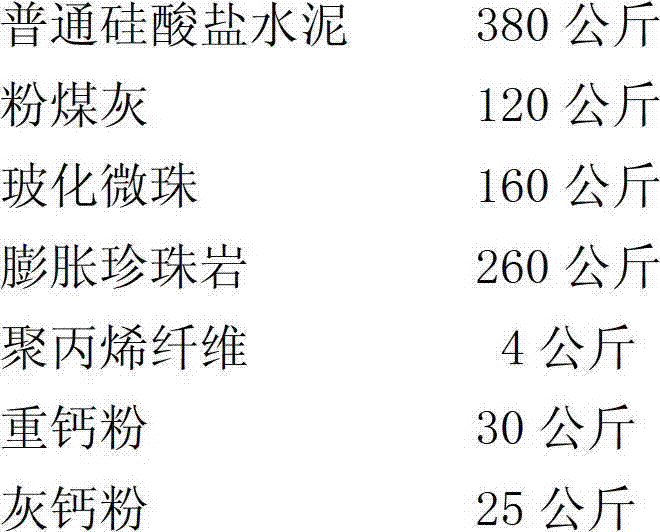

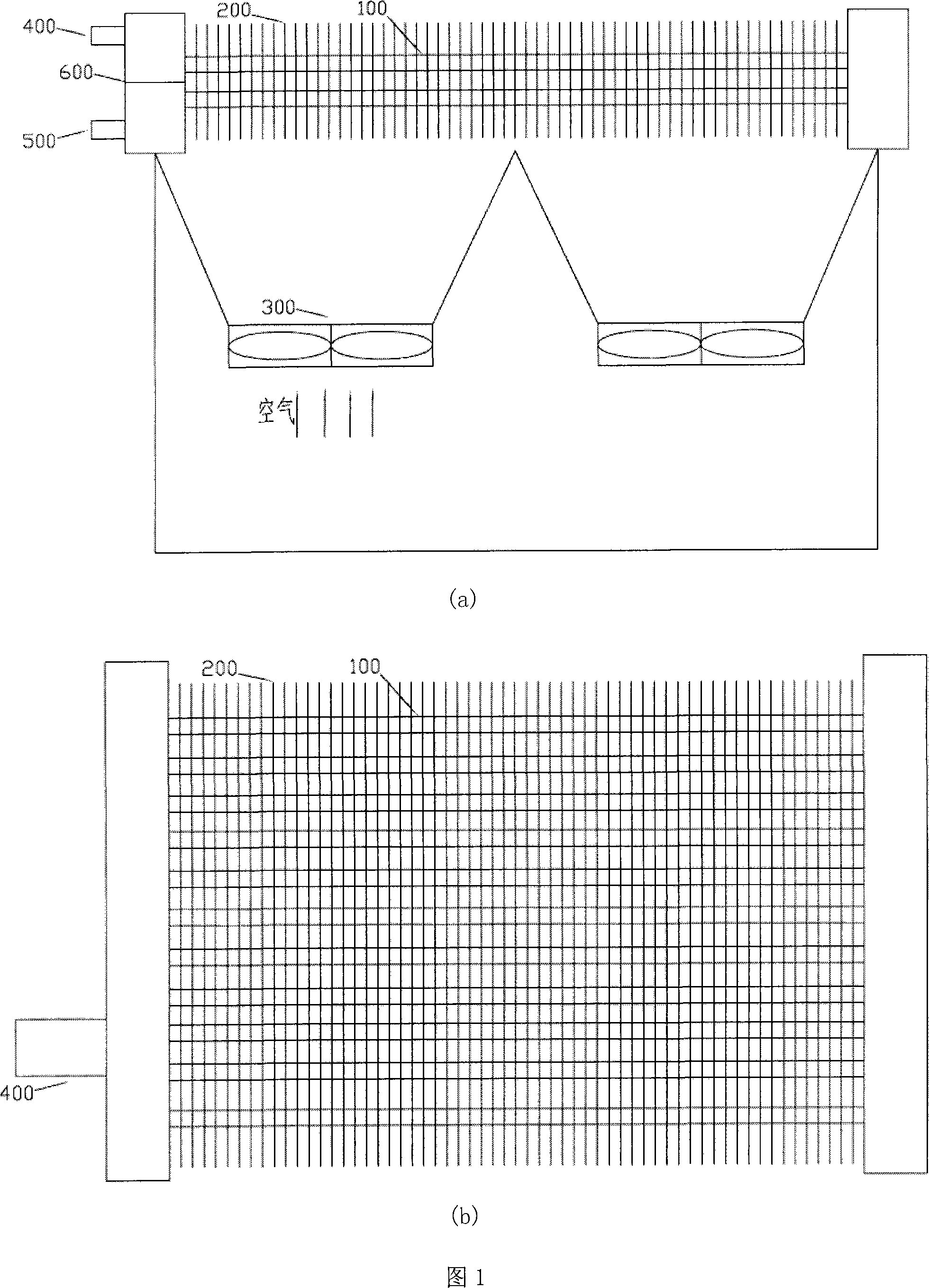

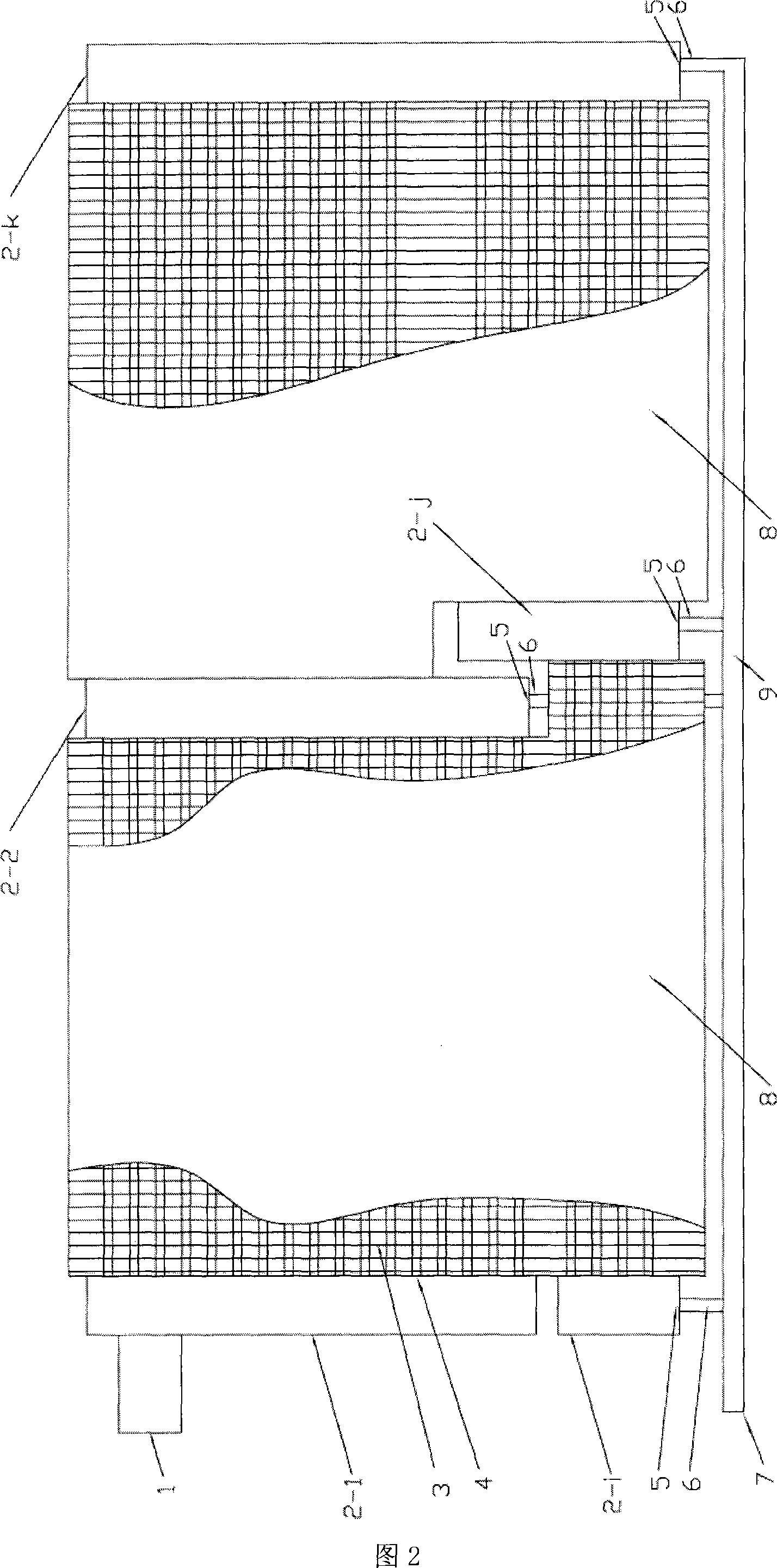

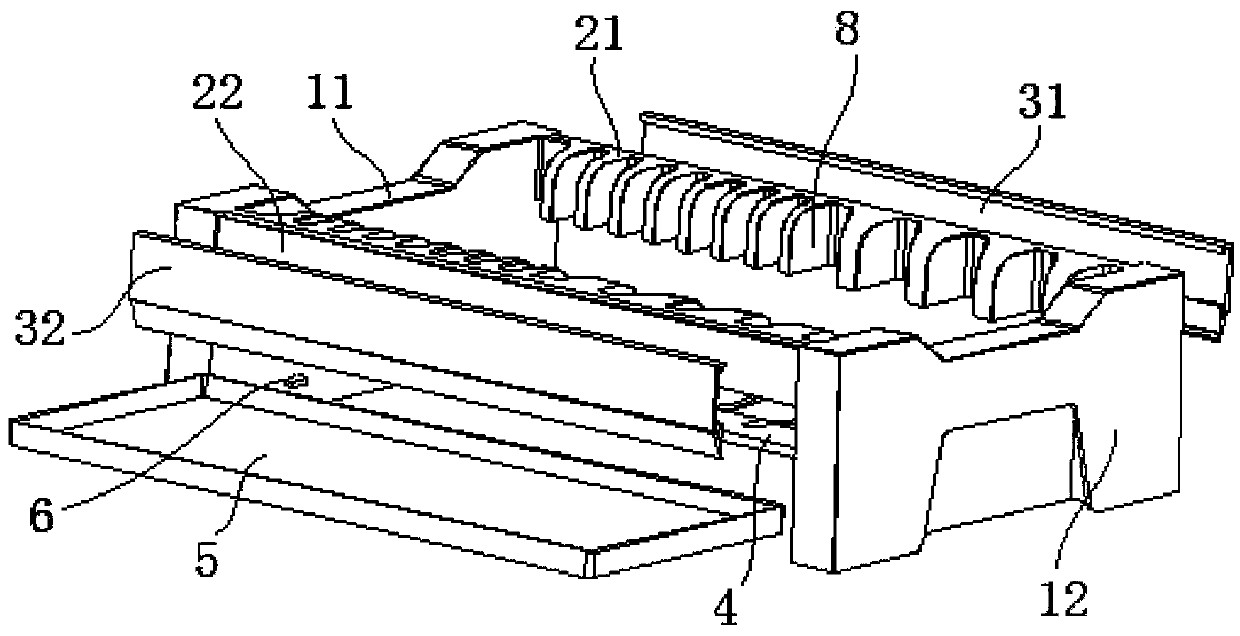

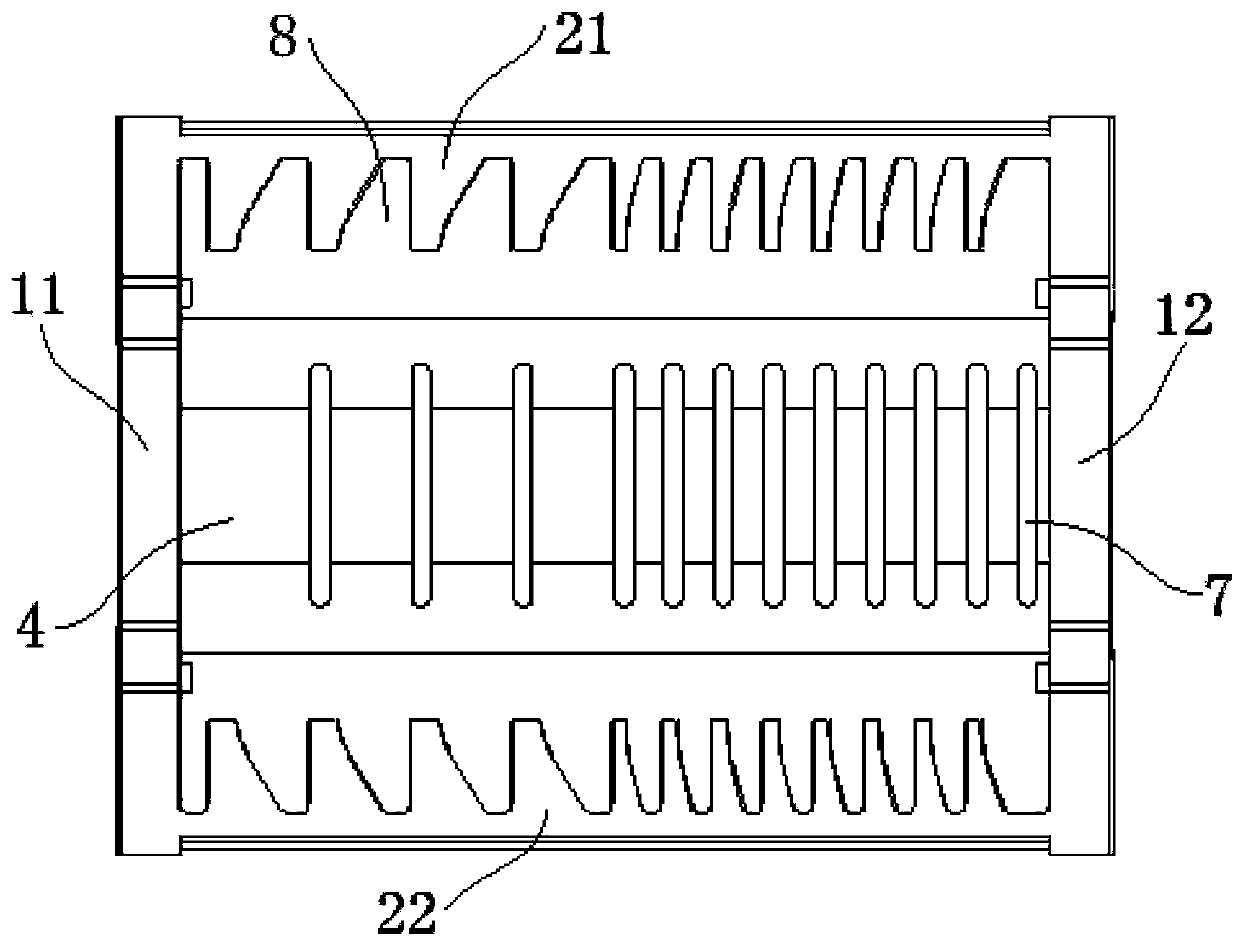

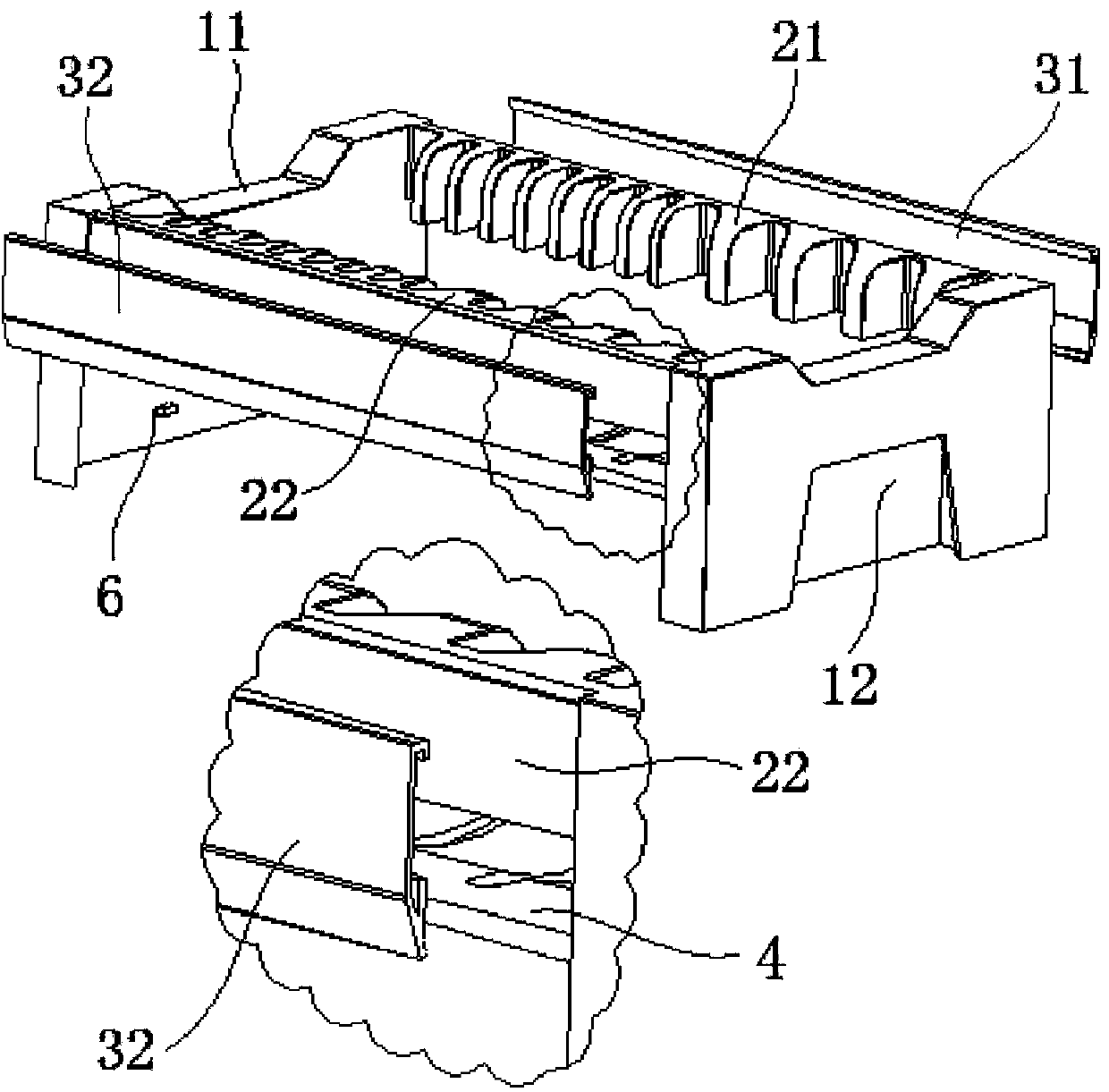

Multi-stage cooling middle liquid-separation air condensator

InactiveCN101025340AReduce thicknessPromote liquid film instability and ruptureSteam/vapor condensersPower engineeringEngineering

Multiple-refrigeration Middle-delivery aerial condenser belongs to thermodynamic equipment technology domain. It composes of multi stages, and every stage is connected by the channels; every stage has two flow stages in which the steam floats to opposite direction; the air input is connected with the first channel , and the first channel is connected with the second channel by a row of parallel distribution heat exchange tube of the first stage; the second channel is connected with the heat exchange tube of next stage; apostrophe ,until get to the last channel; there are fins set out of the heat exchange tube; the shell is set out of the heat exchange tube and fins. The steam is put into the heat exchange tube of the first stage to refrigerate through the steam input and the first channel, and the air-liquid mixture flows into channel, and then the liquid and the air are separated; the steam gets into the heat exchange tube of next stage. This invention is suitable for large power engineering refrigeration, and it has efficient condensation capacity and large coefficient of heat transmission; the heat transfer area of the equipment is made use of sufficiently and efficiently; the fabric is flexible and smart, the applicability of the space is high.

Owner:TSINGHUA UNIV

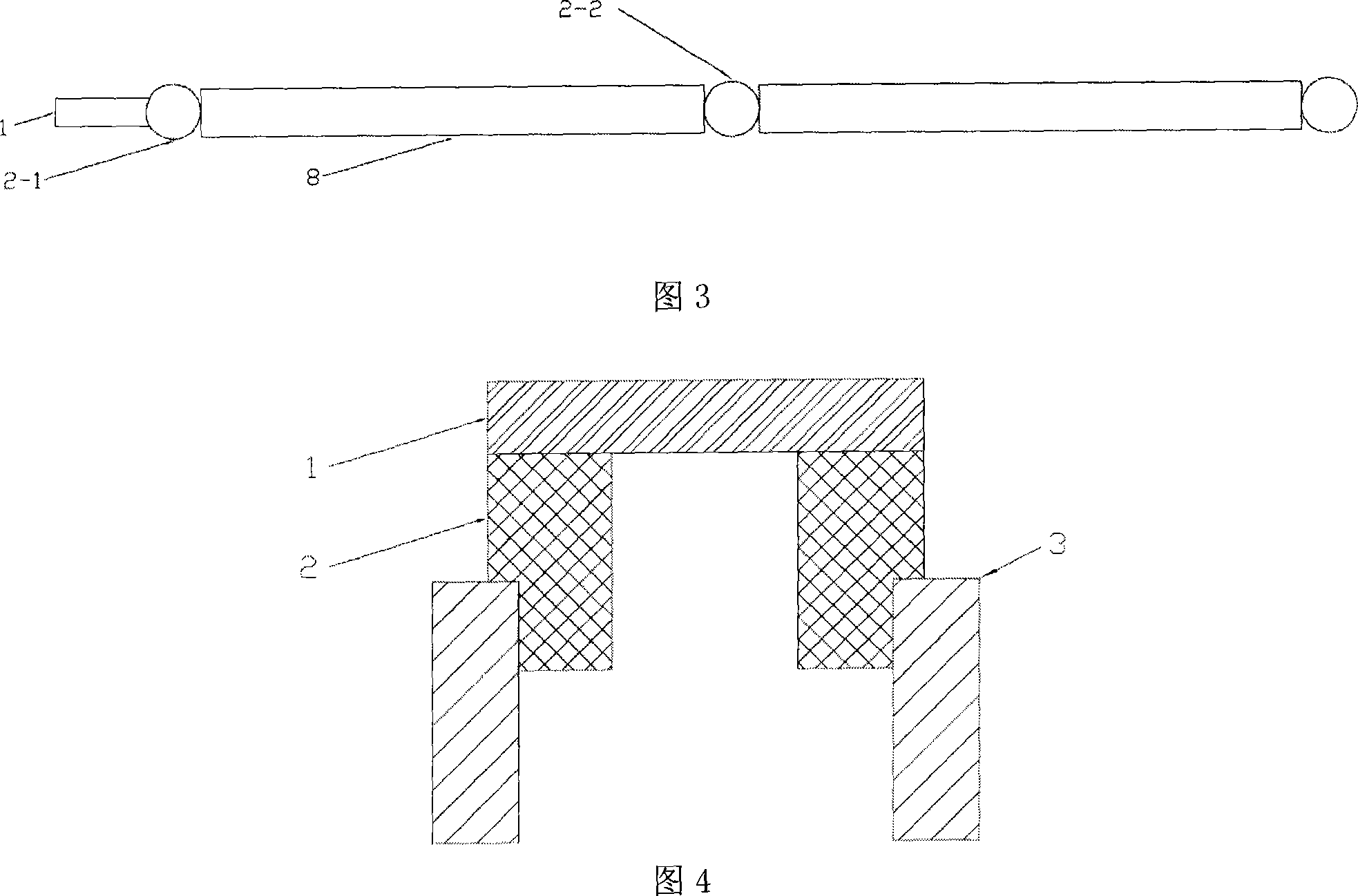

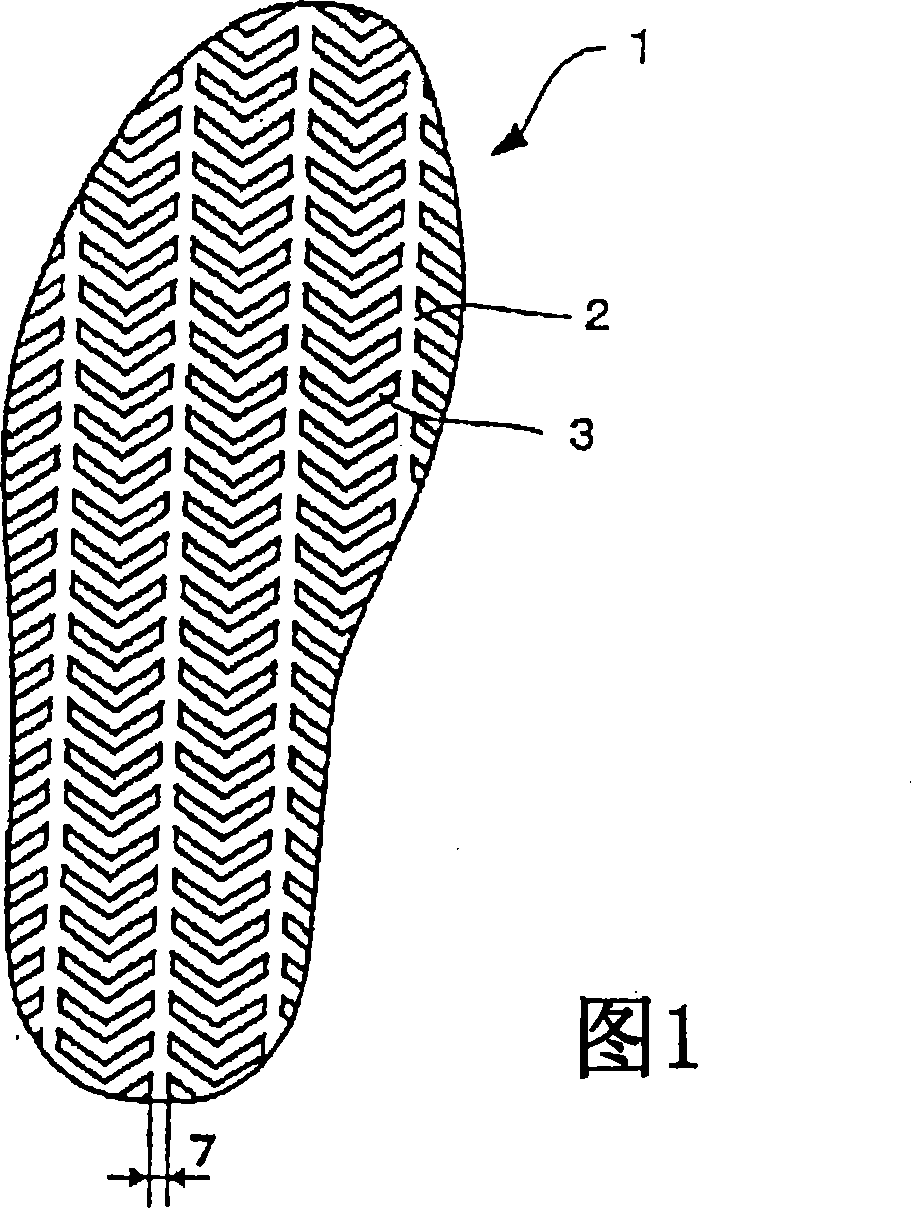

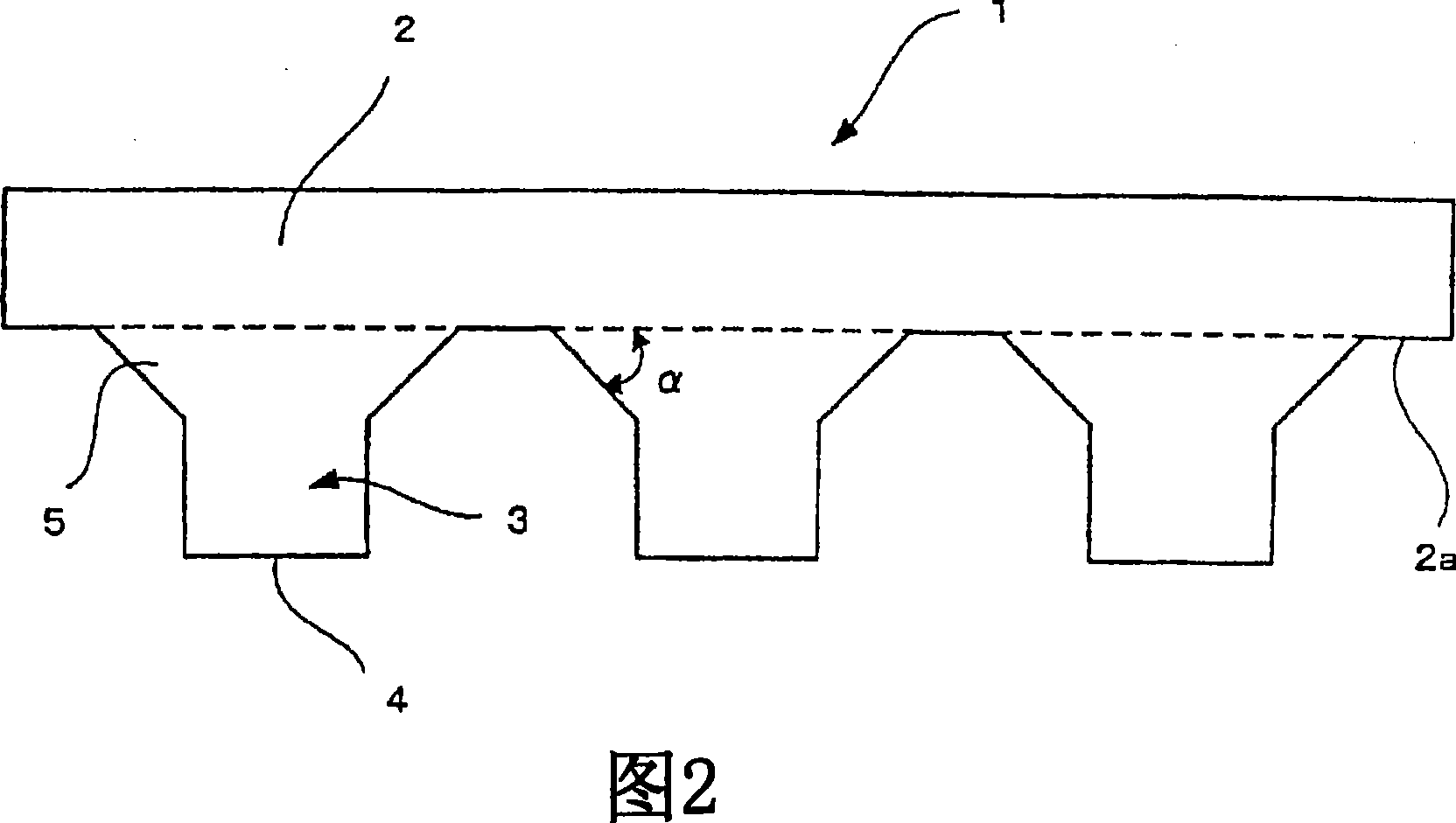

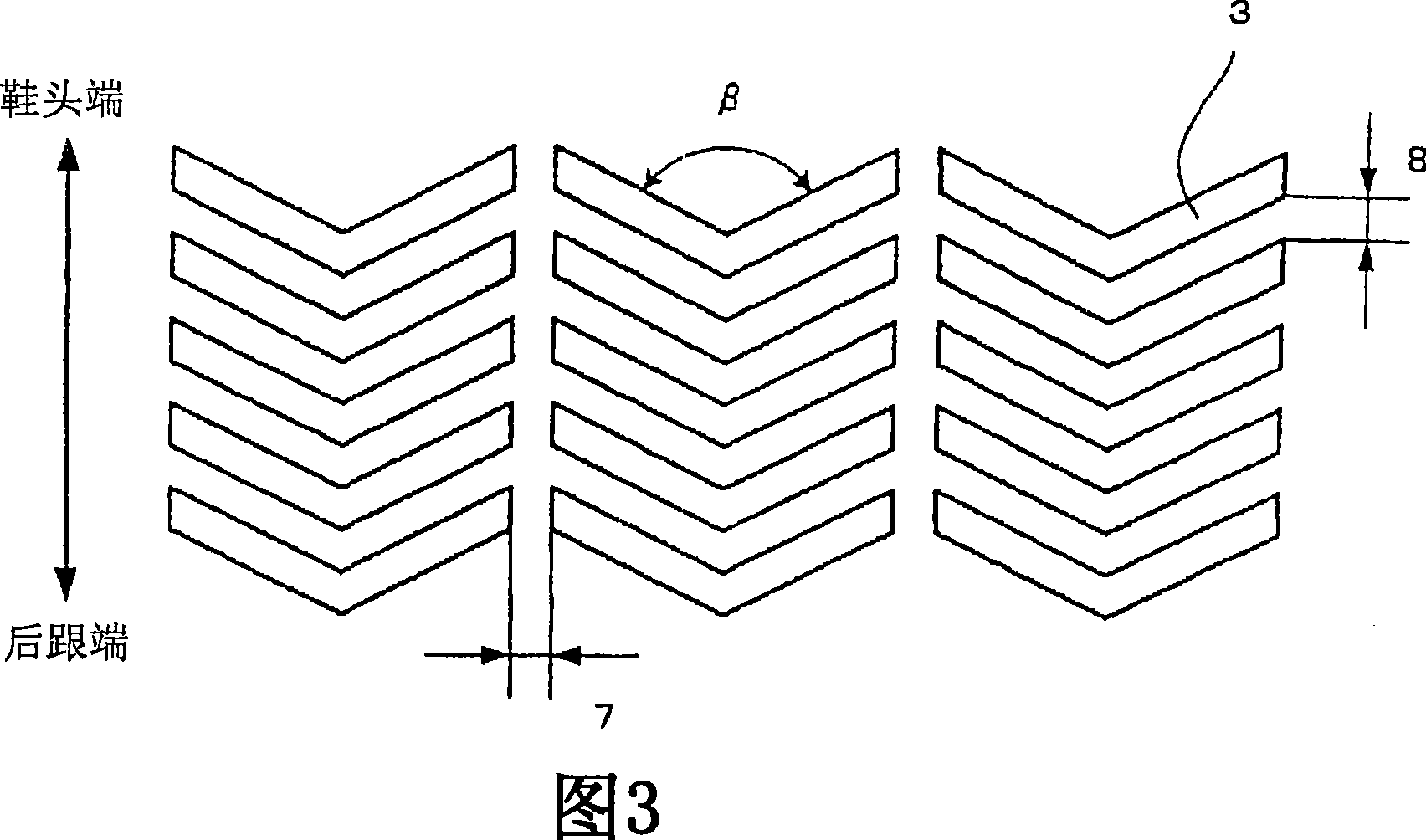

Slip-resistant shoe sole

The slip resistant shoe sole 1 of the invention comprises a plurality of ground contact projections 3 formed on the ground contact side of the sole base 2 with a predetermined gap between adjacent ground contact projections 3 in the longitudinal direction of the base 2, the ground contact projections 3 having a V-shaped horizontal cross section, having inclined reinforcements 5 provided at the roots of the ground contact projections 3 on the base 2, and being formed using an elastomeric polymer with a JIS-A hardness of 45 to 80 as measured at 20 DEG C.

Owner:NISSHIN RUBBER

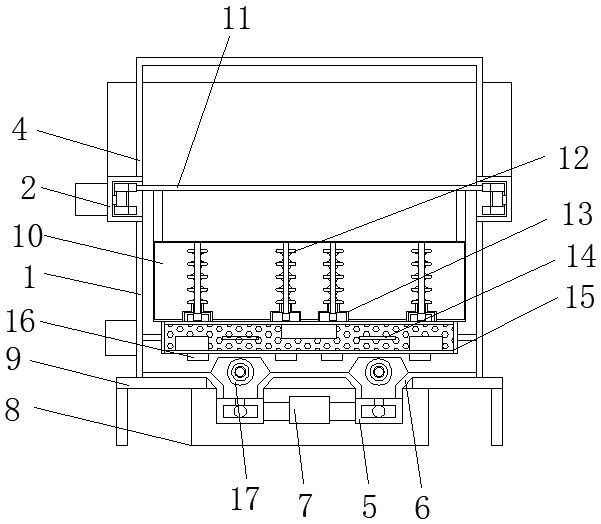

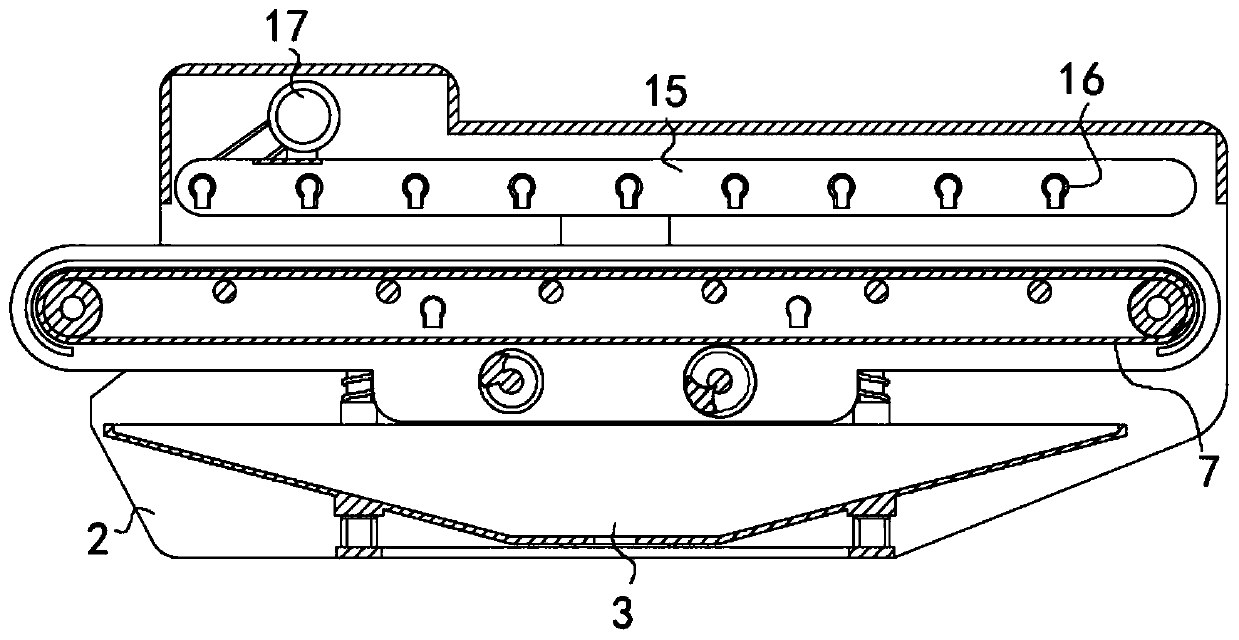

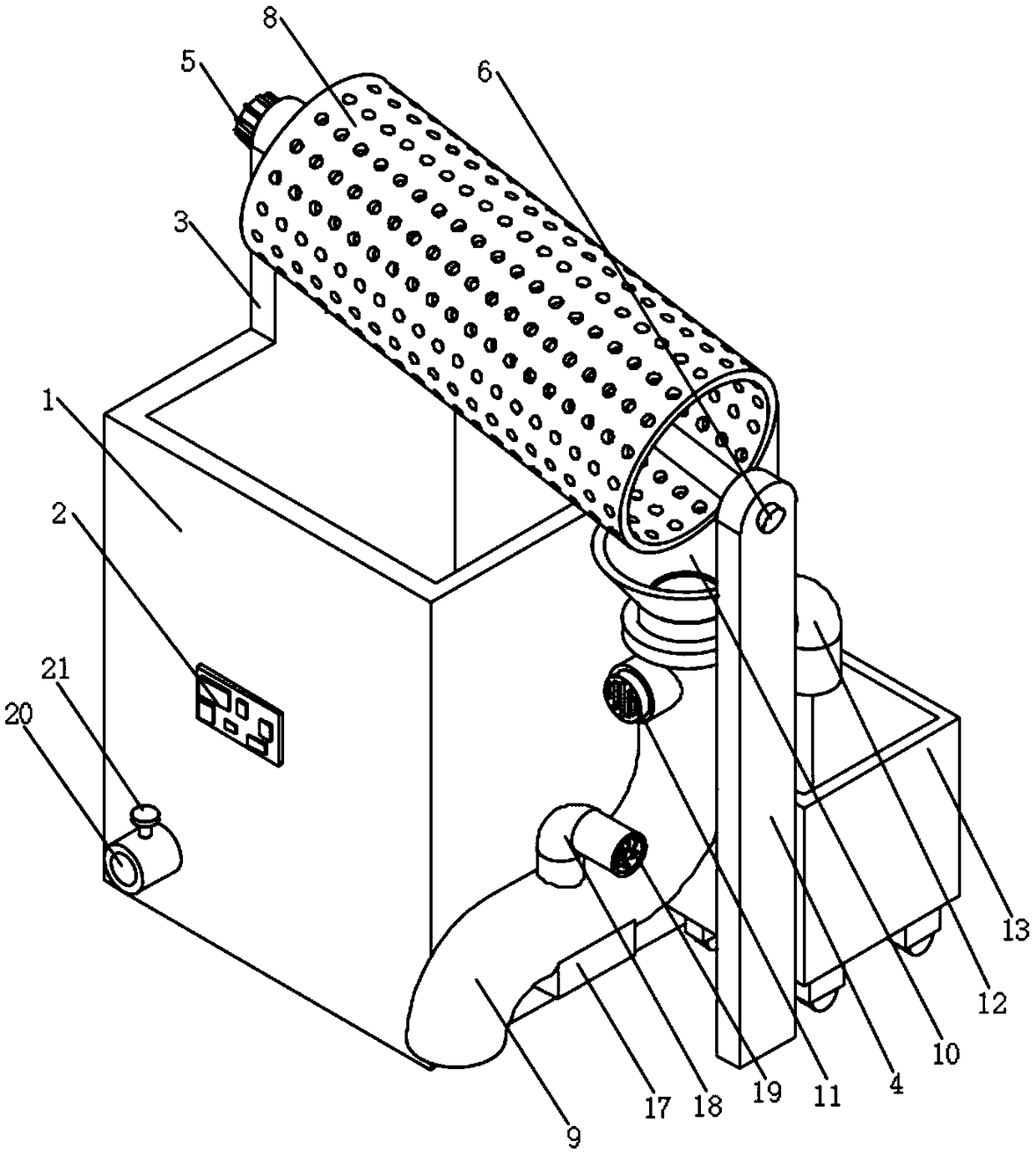

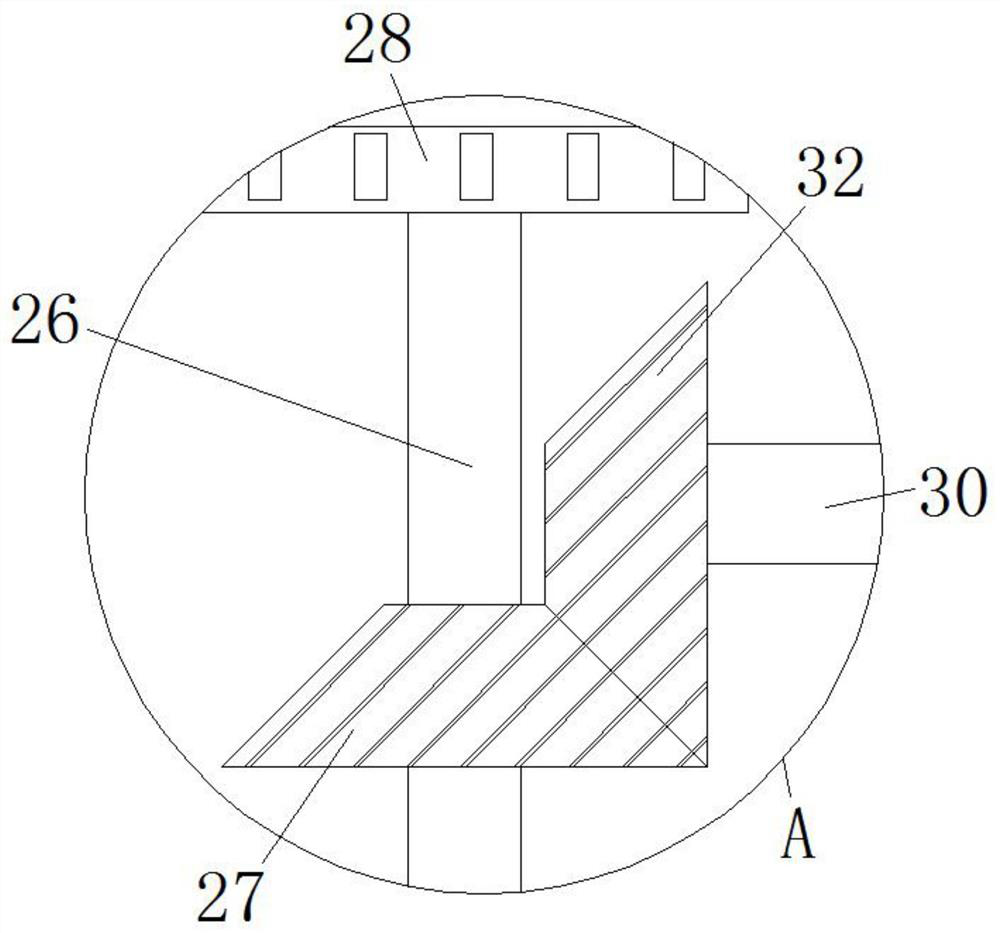

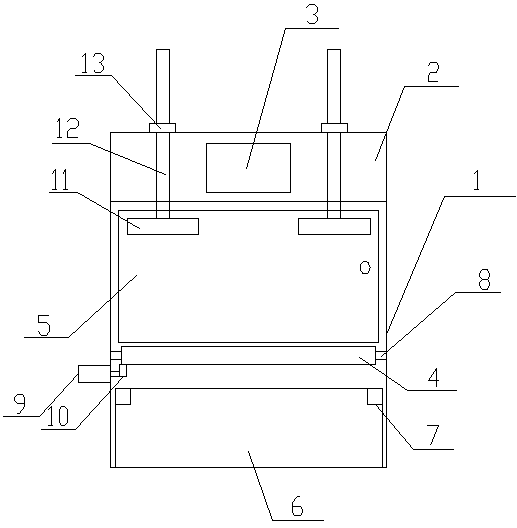

Linen fiber bleaching device for textile production

InactiveCN111826839AImprove bleaching efficiencyReduce lossTextile treatment machine arrangementsTextile treatment carriersFlax fibrePulp and paper industry

The invention discloses a linen fiber bleaching device for textile production and relates to the technical field of textile production. In order to solve the problem that the bleaching time is difficult to control and linen fibers are easy to damage when the linen fibers are soaked in a solution to be stirred, the linen fiber bleaching device specifically comprises a shell, a plurality of supporting frames are fixedly installed at the bottom of the shell, driving mechanisms are fixedly installed on the two sides of the top of the shell, a capping mechanism is fixedly installed between the topends of the two driving mechanisms, and bleaching sections extending downwards are arranged in the middle sections of the driving mechanisms. According to the linen fiber bleaching device for textileproduction, a bleaching solution is in contact with a heating mechanism when being sprayed out; the linen fibers are heated and cooked; the linen fiber bleaching efficiency is improved; the linen fibers are drained; a bleaching solution is recycled; the loss of the solution is reduced; the situation that the working environment is affected due to solution dripping is avoided; raw materials can becontinuously bleached due to the fact that the raw materials enter from one end and exit from the other end, and the linen fiber bleaching processing efficiency is improved.

Owner:宣城红妆美人床上用品有限公司

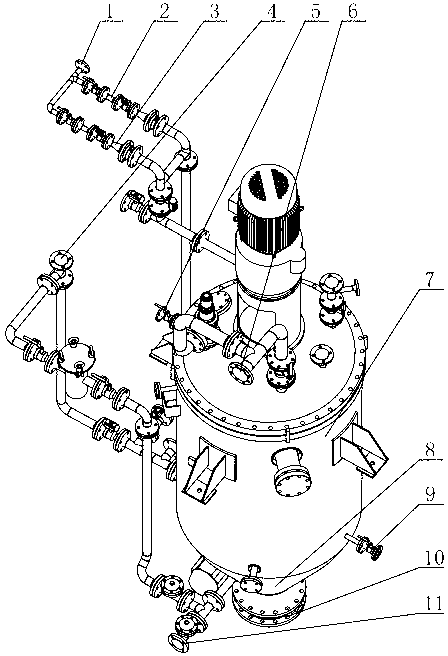

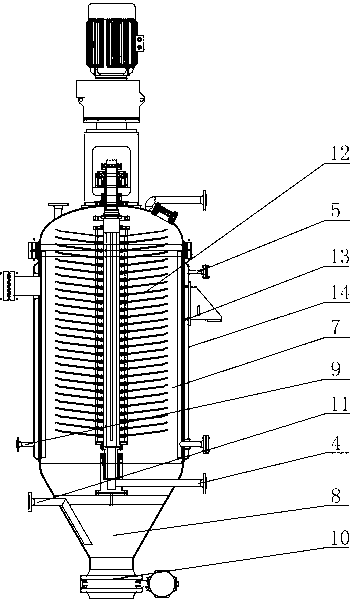

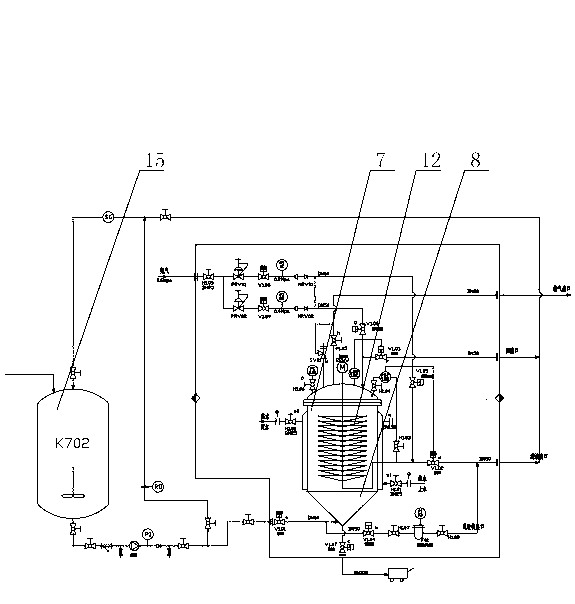

Rotating disk filter

The invention relates to a rotating disk filter. The rotating disk filter comprises a filter barrel, wherein the bottom of the filter barrel is of the shape of an inverted cone, the lower part of the inverted-cone-shaped bottom is provided with a deslagging port, the inverted-cone-shaped bottom is connected with a material inlet by a pipeline, the filter barrel comprises an inner barrel and an outer barrel, a heat source cavity is formed between the outer wall surface of the inner barrel and the inner wall surface of the outer barrel, for the heat source cavity, a heat source inlet is formed in one side of the outer barrel, and a heat source outlet is formed in the other side of the heat source chamber; and the filter barrel is provided with a material outlet by the pipeline, the top of the filter barrel is provided with a filter cover, the upper part of the filter cover is provided with an air outlet, and the top of the filter cover is also provided with a back blowing device by the pipeline. The rotating disk filter has the advantages of reasonable structure and convenience in operation. The bottom of the filter barrel adopts an inverted-cone-shaped structure, and the rotating disk filter can efficiently solve the problems that filter cake piles and remains during the deslagging so as to cause the incomplete deslagging.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

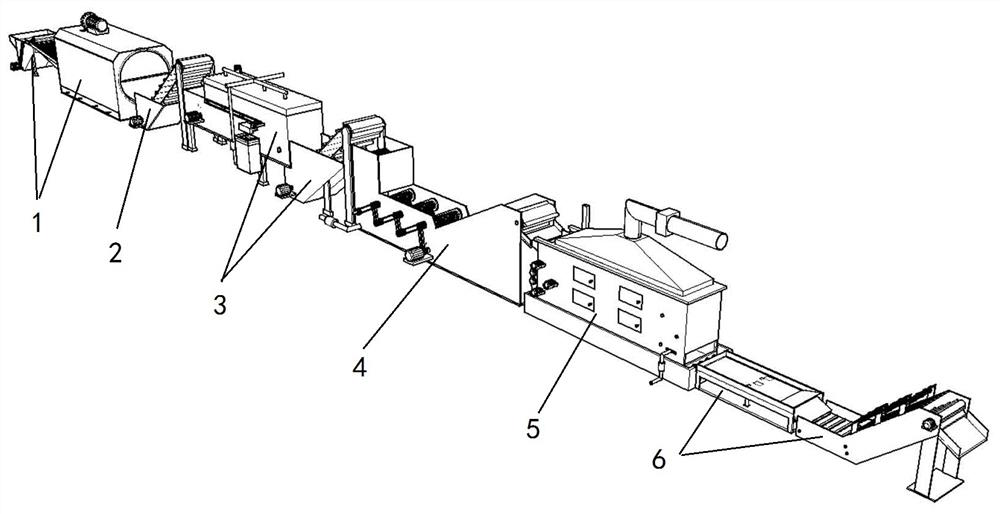

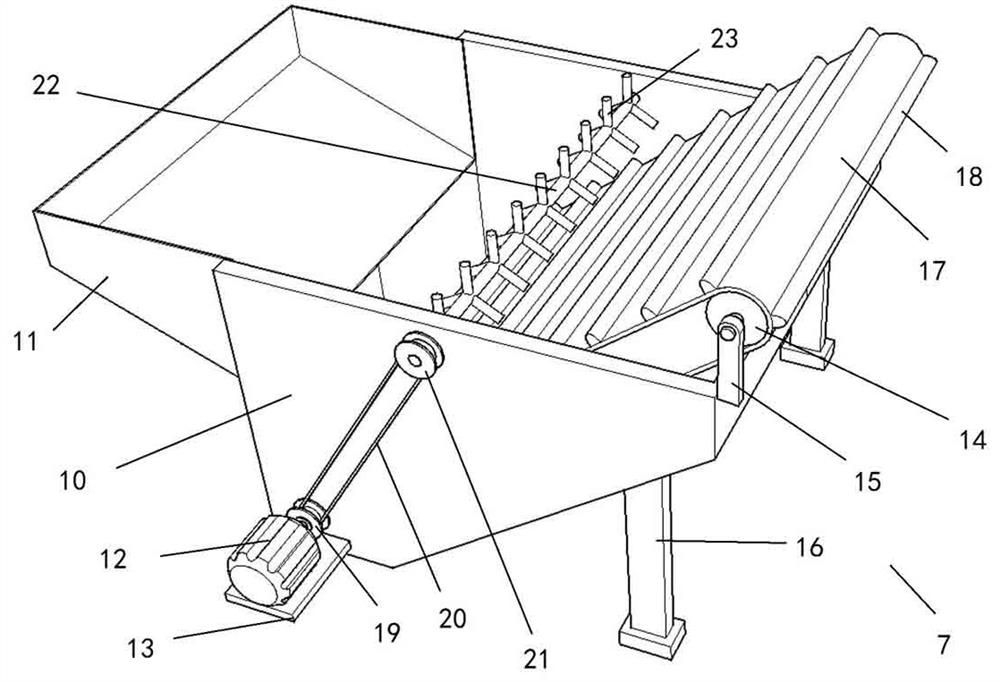

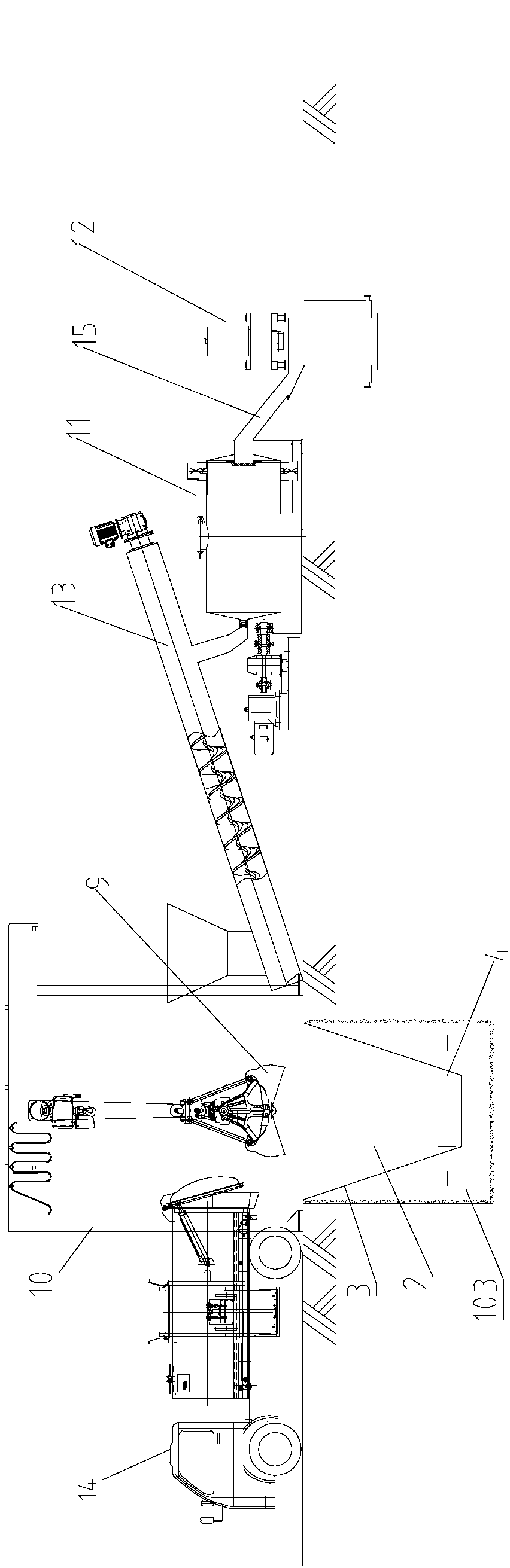

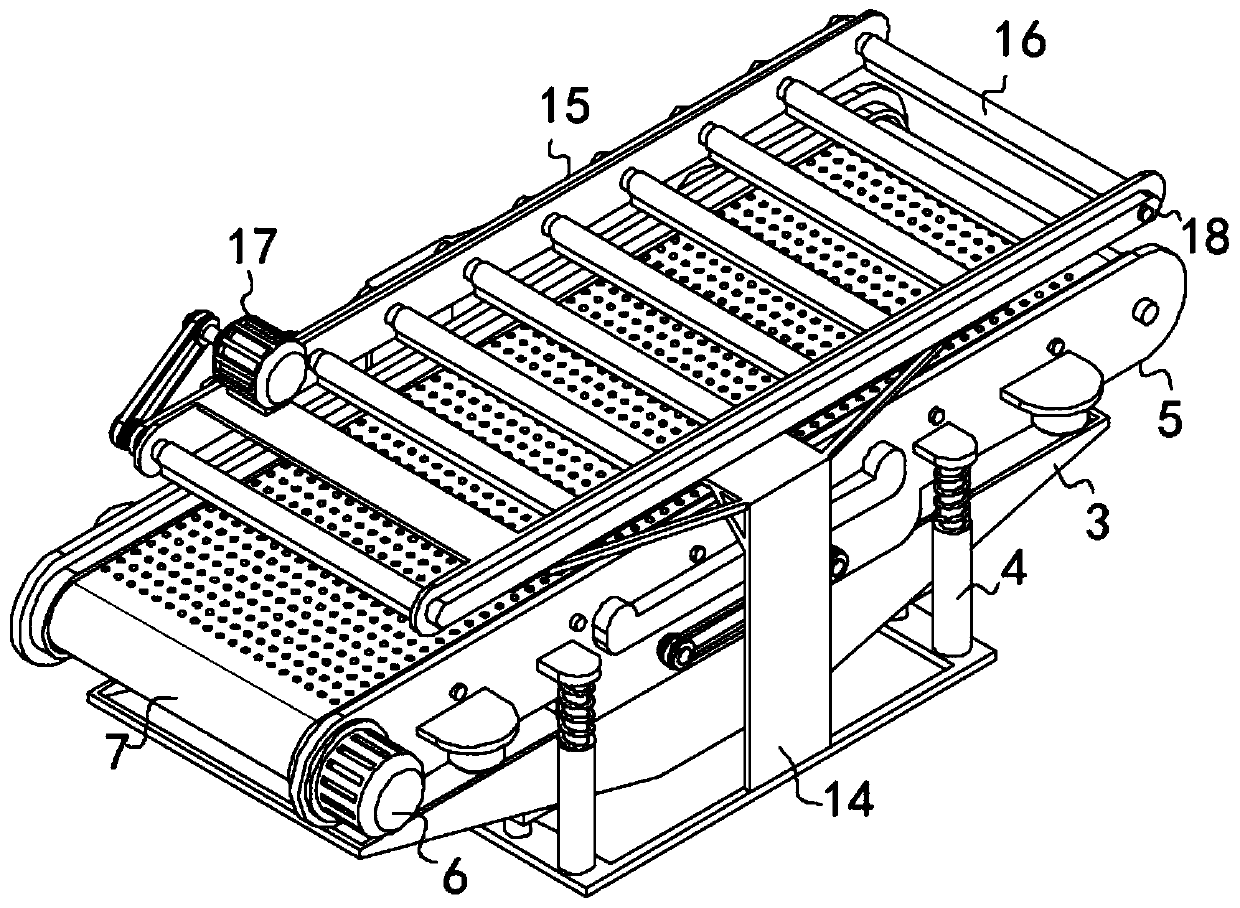

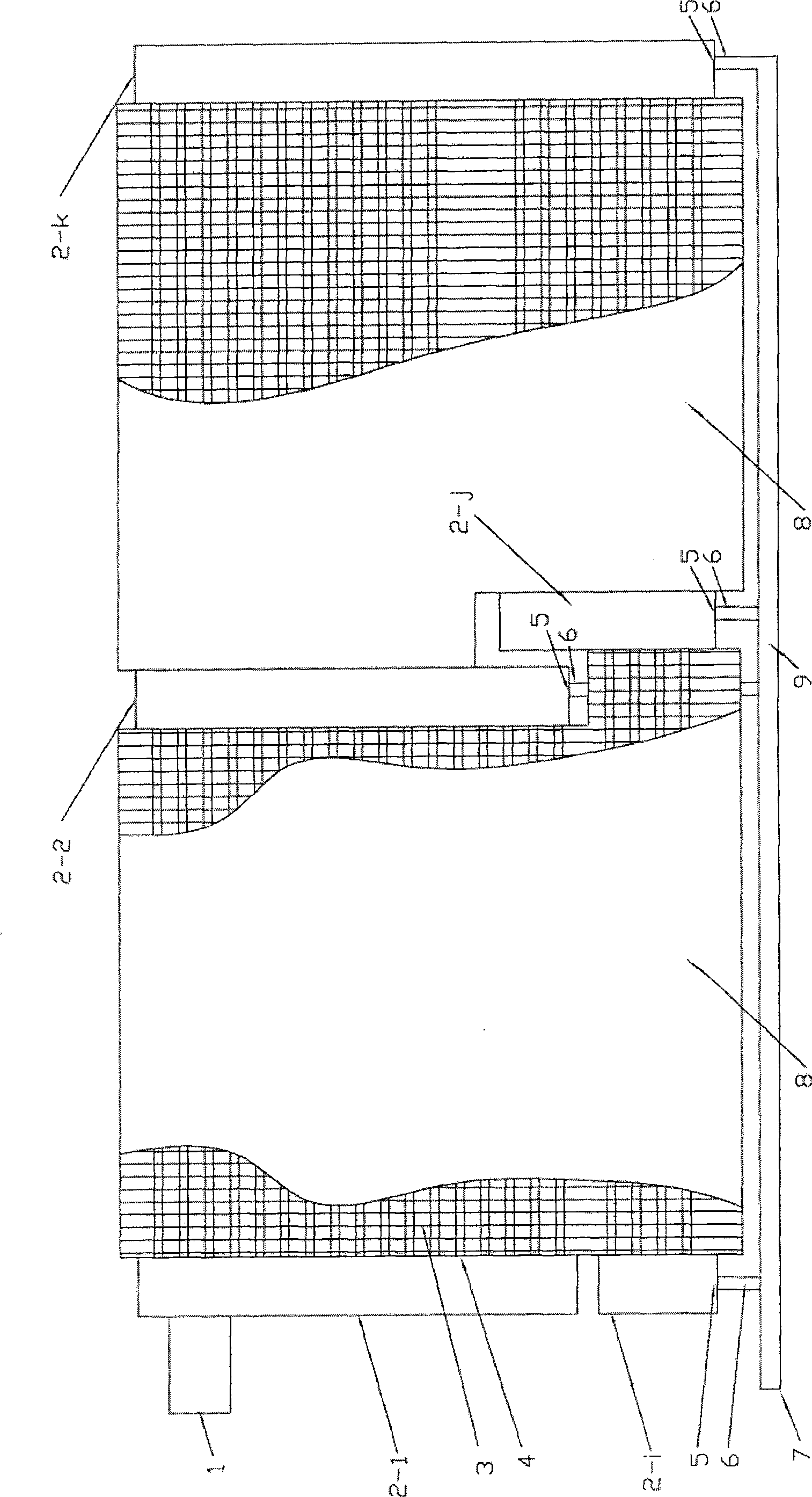

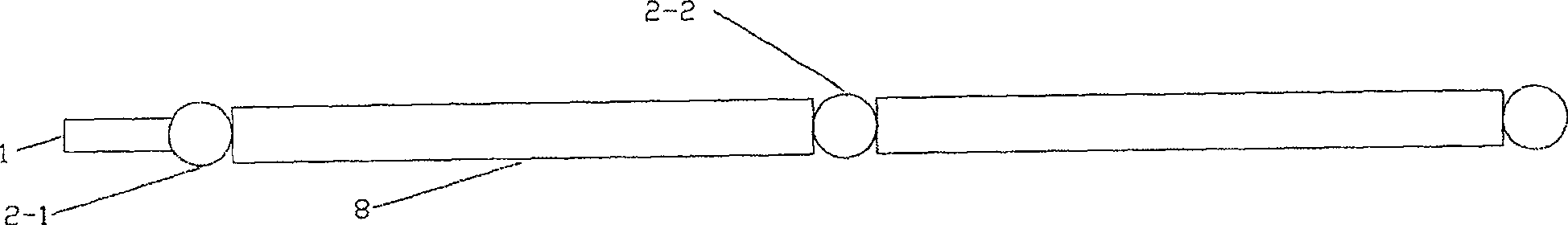

Full-automatic traditional Chinese medicinal material preliminary processing production line and use method thereof

InactiveCN111774303AAvoid accumulationAvoid blockingSievingGas current separationProcess engineeringManufacturing line

Provided are a full-automatic traditional Chinese medicinal material preliminary processing production line and a use method thereof. The full-automatic traditional Chinese medicinal material preliminary processing production line comprises a screening device, a washing device and a soaking device. The discharging end of the screening device is matched with the feeding end of a first conveying device, and the discharging end of the first conveying device is matched with the feeding end of the washing device. The discharging end of the washing device is matched with the feeding end of a secondconveying device, and the discharging end of the second conveying device is matched with the feeding end of the soaking device. The discharging end of the soaking device is matched with the feeding end of a third conveying device. By means of the structure, the whole production line is high in automation degree, device arrangement is reasonable and compact, and processing and operating are stable;and the full-automatic traditional Chinese medicinal material preliminary processing production line is suitable for processing mass traditional Chinese medicinal materials, and the economic benefitsof enterprises are improved.

Owner:五峰知杏堂药业有限公司

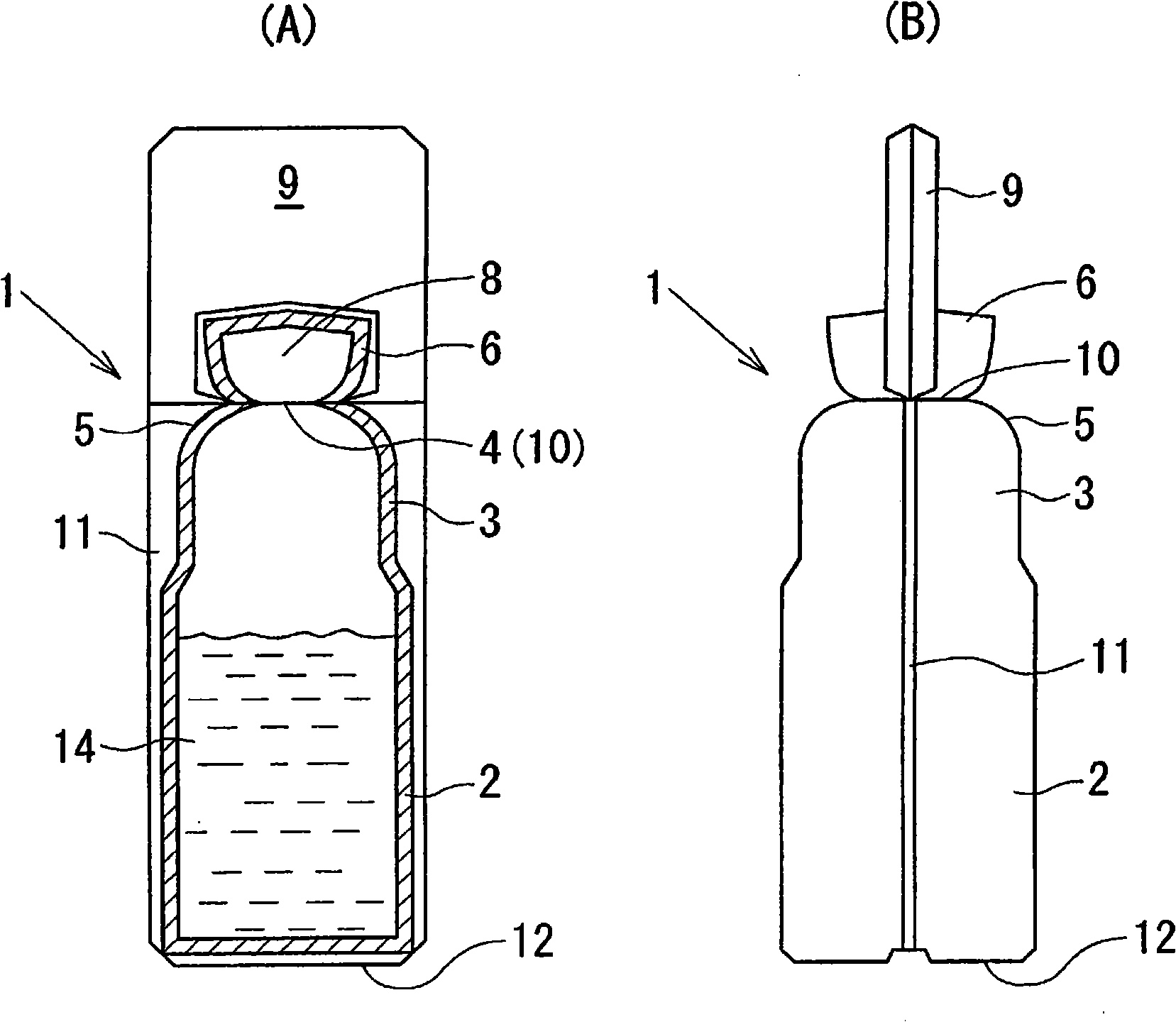

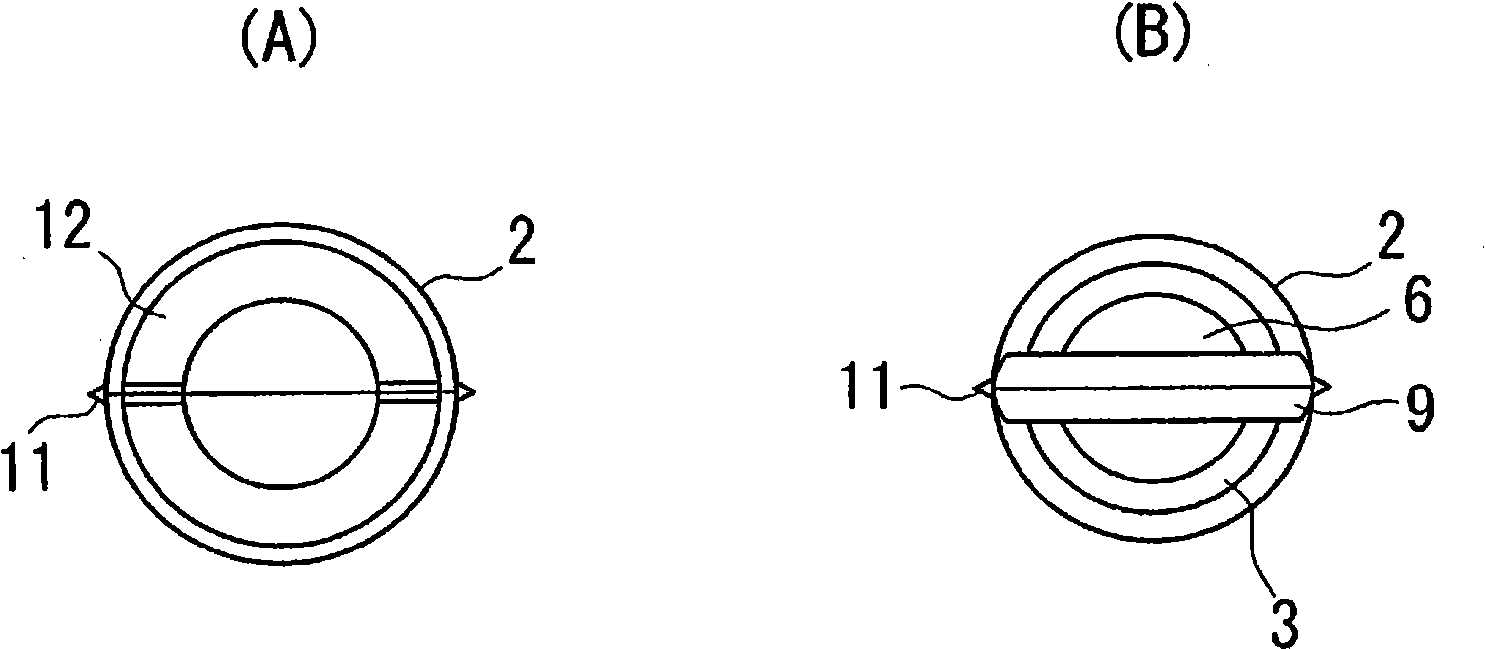

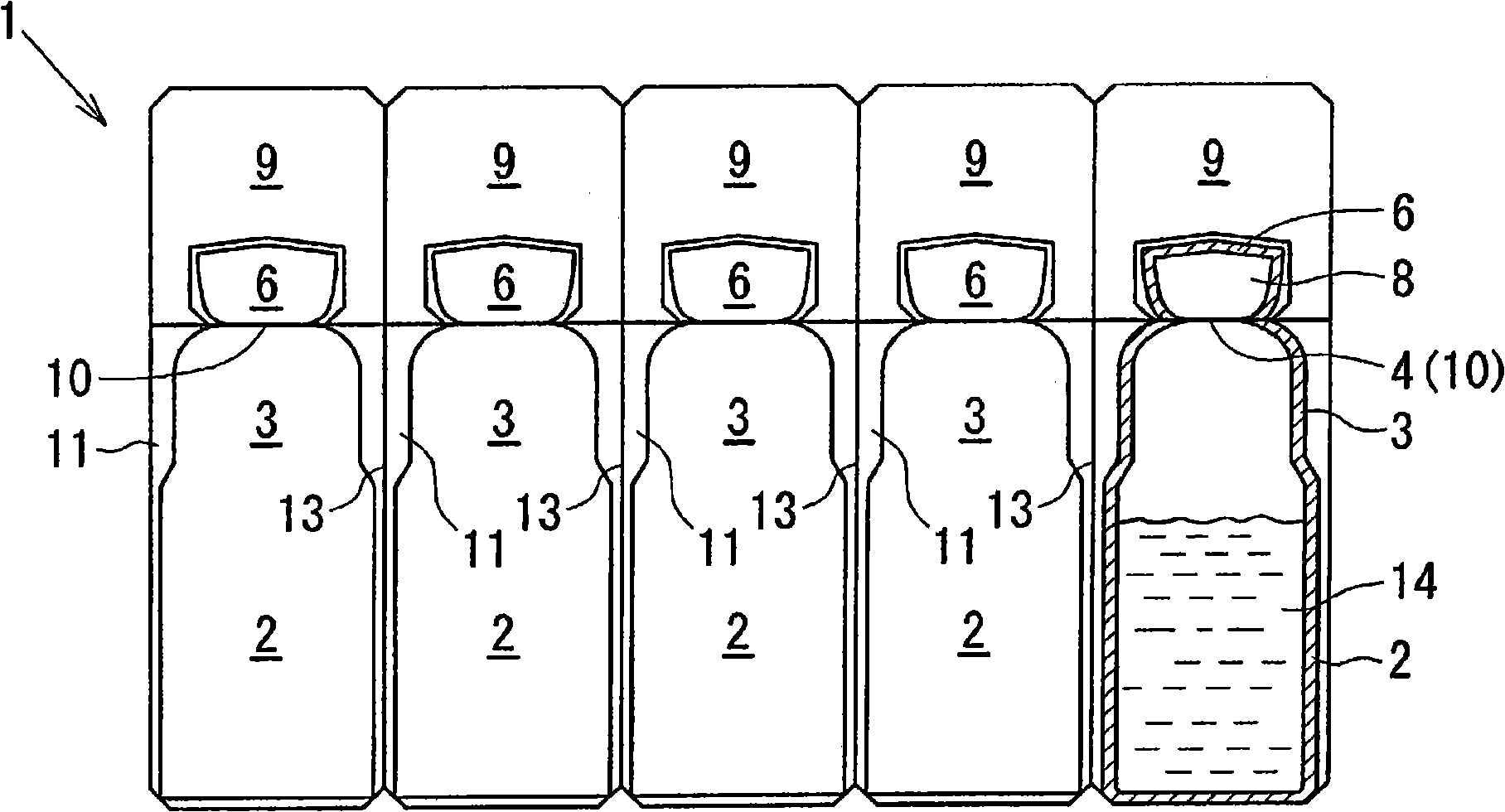

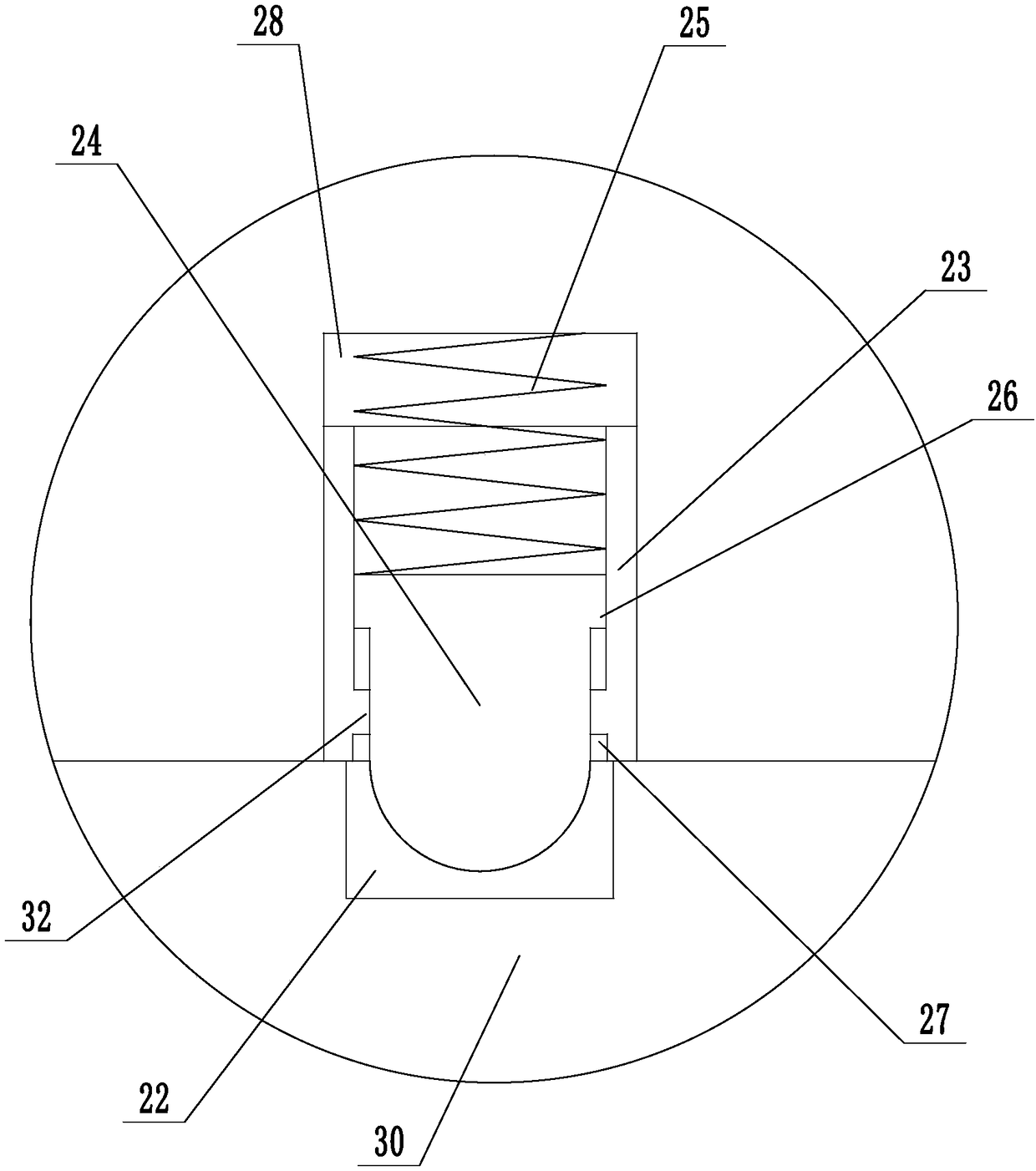

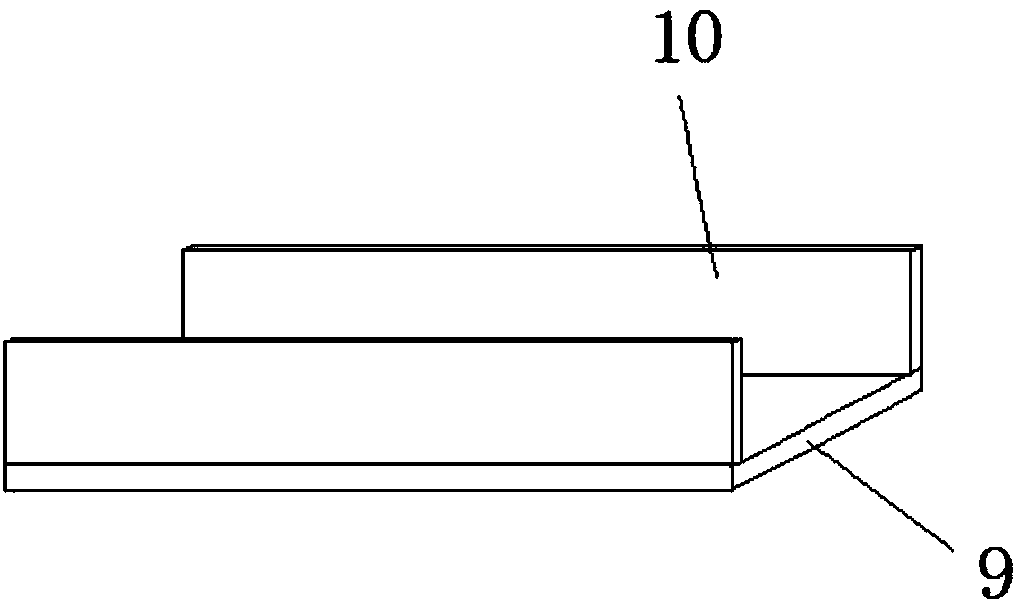

Plastic ampule

ActiveCN102014845AEasy to removeImprove draining effectBottlesPharmaceutical containersAmpouleEngineering

Provided is a plastic ampule being handled suitably at the time of unsealing wherein remaining content liquid can be removed easily by performing a removal operation for dropping the remaining content liquid into a body portion by shaking the plastic ampule before use even when the content liquid remains in the hollow portion of a head portion. The plastic ampule comprises a body portion, a head portion (6) provided continuously to the mouth portion (3) of the body portion through a cut-off portion (10), and a knob portion (9) provided continuously to the head portion (6), the ampule being unsealed by twisting the knob portion (9) with fingers to cut the head portion (6) off the mouth portion (3), wherein the hollow portion (8) in the head portion (6) is formed in the shape of a bowl. Since the hollow portion (8) is formed in the shape of a bowl, content liquid remaining in the hollow portion (8) can be discharged easily, the plastic ampule can be unsealed easily, and the content liquid remaining in the hollow portion (8) is not scattered easily at the time of unsealing.

Owner:NIPPON ZOKI PHARM CO LTD

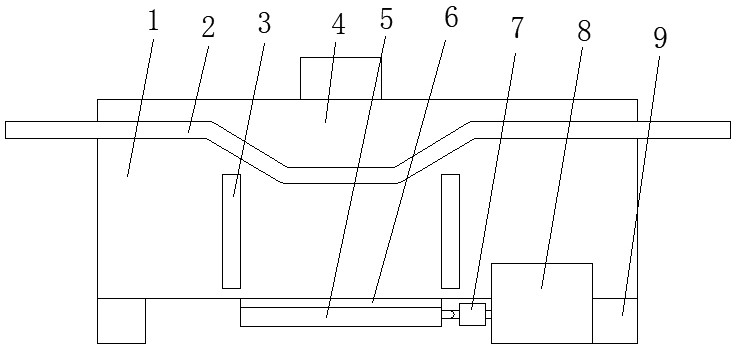

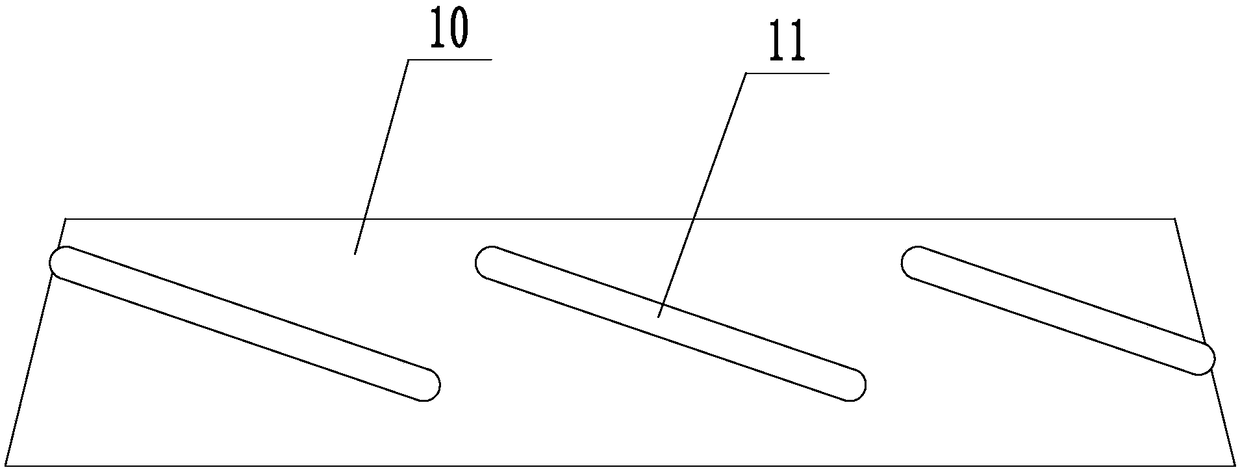

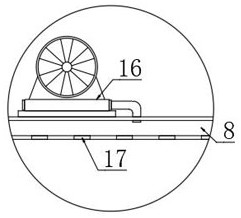

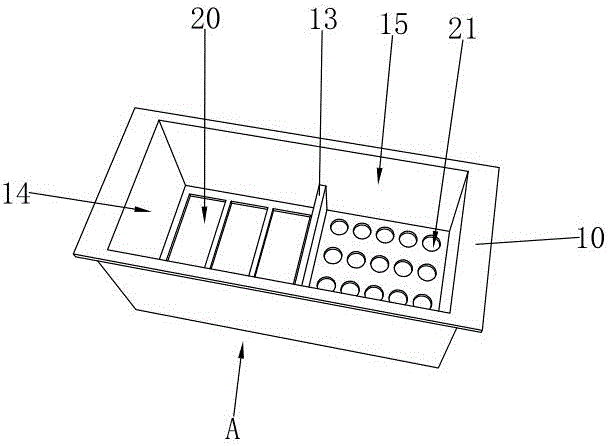

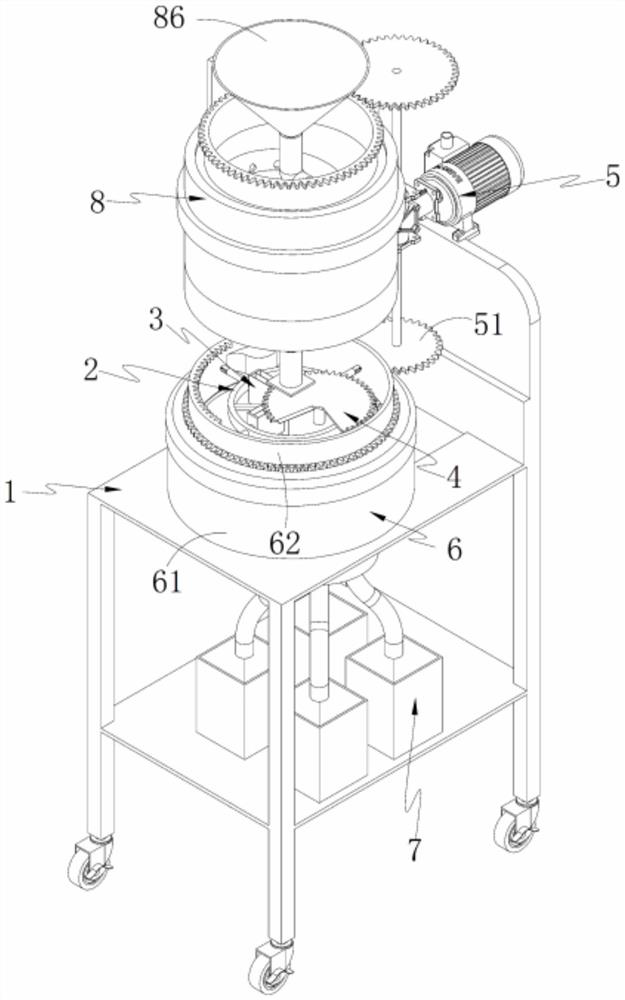

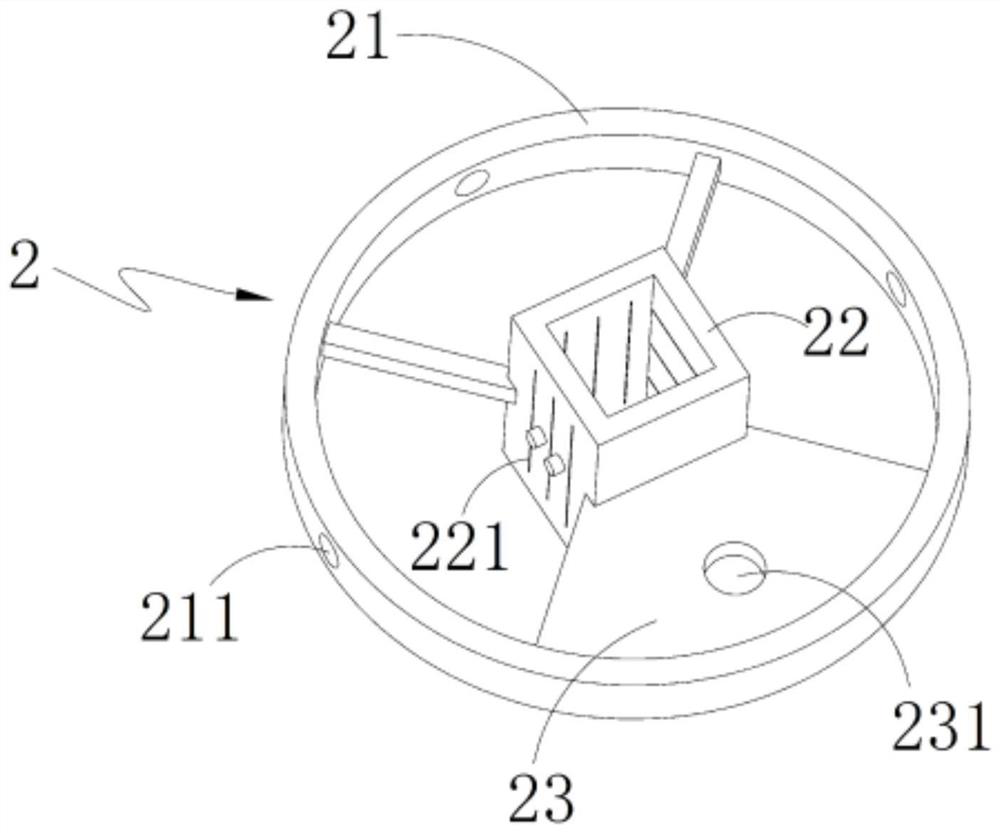

Rotatable volumetric flask rack and application method

ActiveCN108507320ADrain fasterImprove draining effectDrying chambers/containersDrying solid materialsVolumetric flaskEngineering

The invention discloses a rotatable volumetric flask rack and aims to overcome the defect that a volumetric flask which is reversely arranged is inconvenient to drain, low in draining speed and poor in draining effect. The rotatable volumetric flask rack comprises a chassis and a rotating mechanism mounted on the chassis, wherein the rotating mechanism comprises an upper tray, a lower tray and a rotary sleeve; a support column is arranged on the chassis, the rotary sleeve is rotatably mounted on the support column in a sleeving manner, a rotary vibrating mechanism is mounted between the rotarysleeve and the support column, the upper and lower trays are fixedly mounted on the rotary sleeve, a plurality of upper insertion holes are uniformly formed in the upper tray, a plurality of lower insertion holes are formed in the lower tray and the upper insertion holes in a one-to-one correspondence manner, volumetric flasks which are obliquely and reversely placed are inserted between the upper insertion holes and the lower insertion holes, a rotary disc is rotatably mounted on the rotary sleeve, the outer wall of the rotary disc is arranged obliquely and the outer wall of the volumetric flask is attached to the outer wall of the rotary disc, a plurality of outward protruding friction bars are uniformly arranged on the outer wall of the rotary disc, and the friction bars are obliquelyarranged from top to bottom along the anti-clockwise direction.

Owner:舟山出入境检验检疫局综合技术服务中心

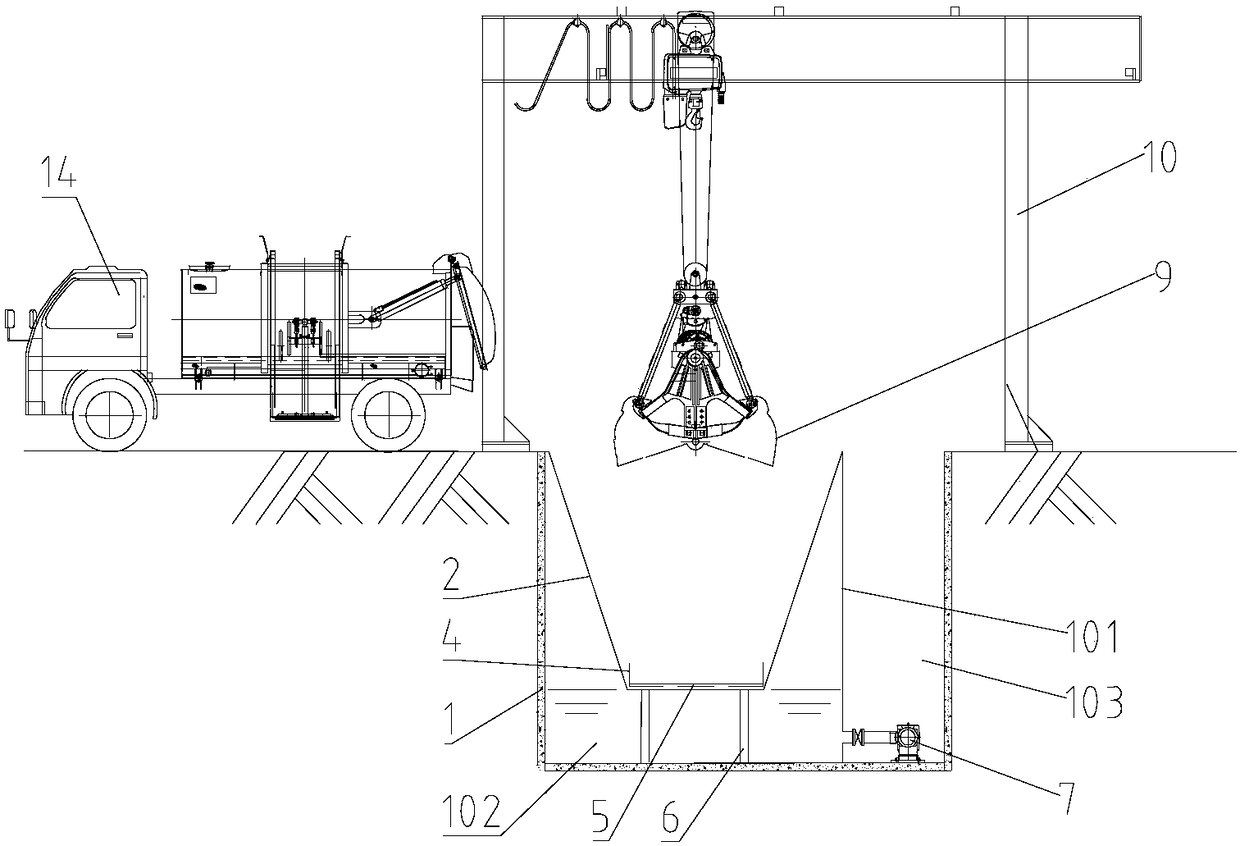

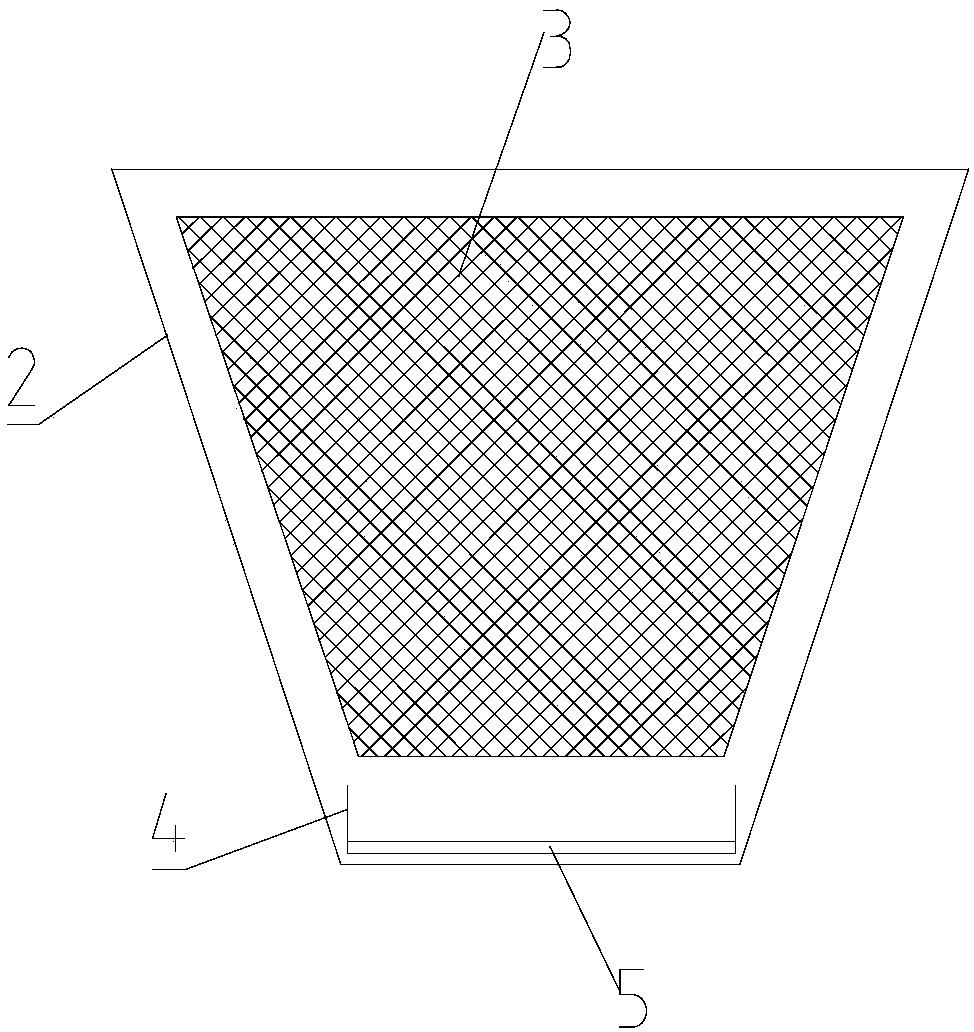

Kitchen waste pretreatment system and process

PendingCN108296261AImprove draining effectEasy to separateTransportation and packagingSolid waste disposalFiltrationImpurity

The invention provides a kitchen waste pretreatment system and process. The kitchen waste pretreatment system comprises a drainage and heavy impurity removing device, a crushing and slurrying device and an extrusion impurity-removing device which are sequentially arranged and communicate with each other. The drainage and heavy impurity removing device comprises a filtration sump which is located underground and provided with an opening; and an open receiving hopper is fixedly arranged in the filtration tank, and the four walls of the receiving hopper are draining filter screens. The bottom ofthe receiving hopper is provided with a metal collecting box, and the bottom of the metal collecting box is provided with a magnet device. The crushing and slurrying device comprises a plurality of grinding balls, and the extrusion impurity-removing device comprises a filter screen. According to the kitchen waste pretreatment system, organic materials can be prevented from drained in the slurryingprocess of kitchen waste, and impurities can be effectively separated from the kitchen waste; and a crushing and slurrying machine cannot be damaged by plastic or metal materials, and the stable andefficient operation of the treatment system is guaranteed.

Owner:宜升(天津)环境技术有限公司

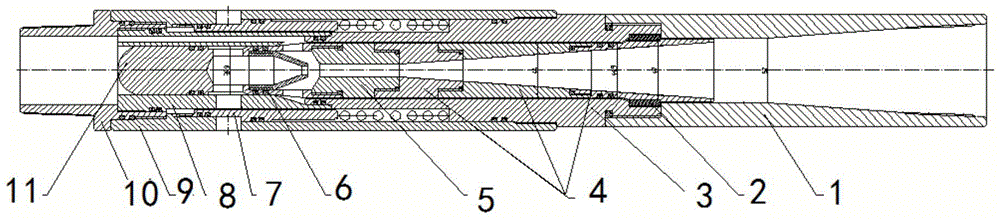

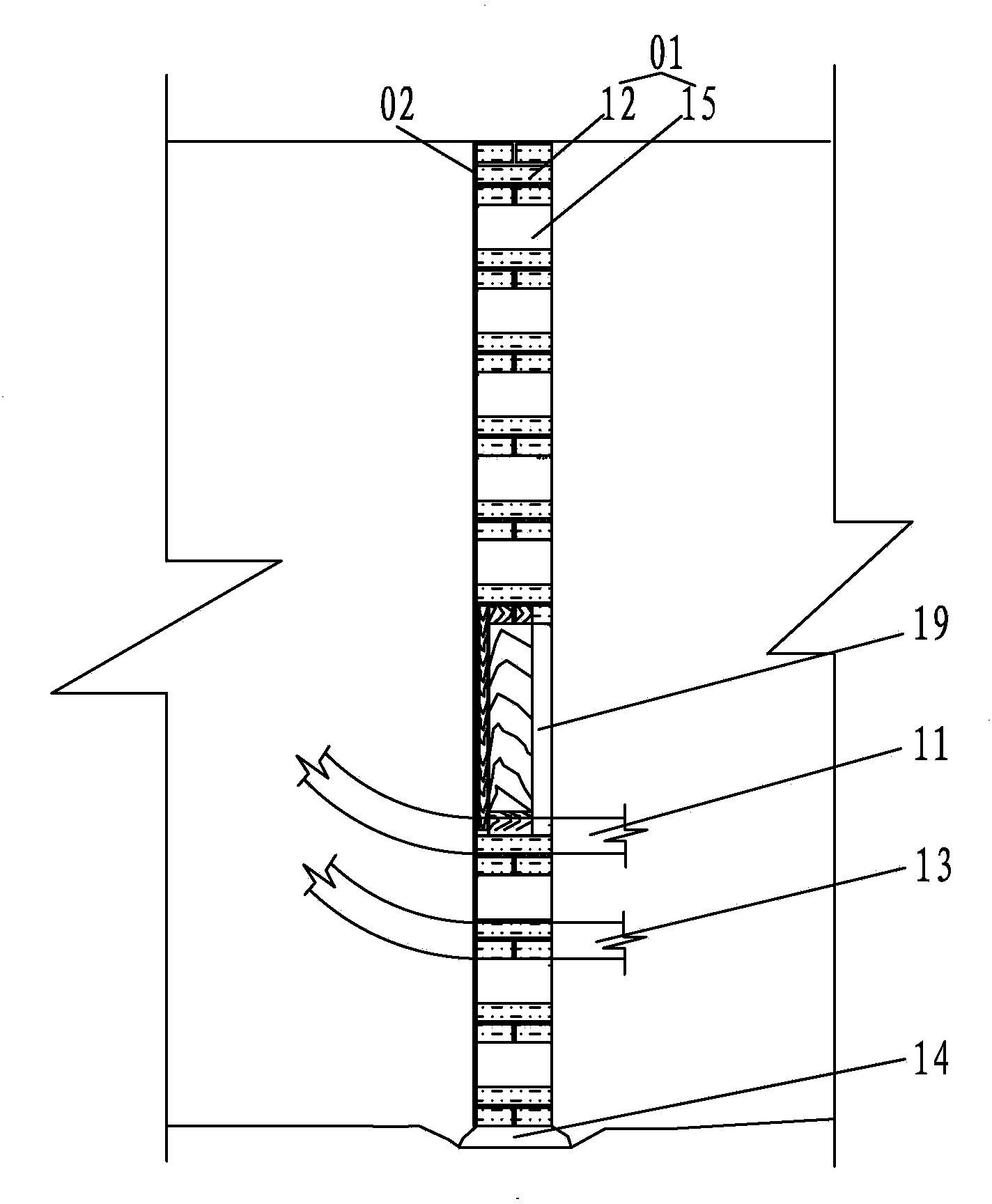

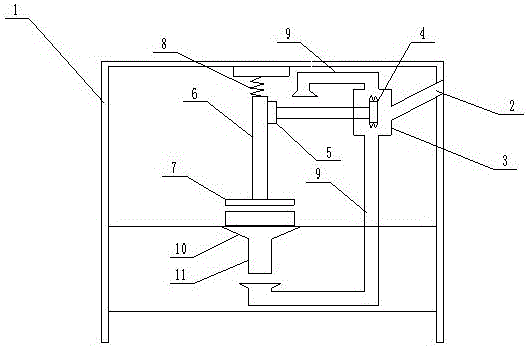

Split negative-pressure backflow machine and technological method

InactiveCN104632175AImprove extrusion efficiencySolve the problem of easy to block the throatCleaning apparatusFluid removalUpper jointOil water

The invention discloses a split negative-pressure backflow machine and a technological method, and belongs to the technical field of acidification backflow and negative-pressure plug removal of oil-water wells. An upper joint is connected with a middle joint; the middle joint is connected with an outer cylinder and a shunt joint; an inner cavity of the middle joint is connected with diffusion pipes and a throat pipe; an inner cavity of the shunt joint is connected with a nozzle and a guide cone; the outer periphery of the shunt joint is connected with a backwashing valve and a lower joint; and a locking ring is connected between the middle joint and the diffusion pipes. The split negative-pressure backflow machine and the technological method have the advantages of split structure, enlargement of internal acid squeezing channel and improvement of acid squeezing efficiency. The device solves the problems of overhigh acid squeezing pressure and easy blockage of the throat pipe by a temporary blocking agent.

Owner:PETROCHINA CO LTD

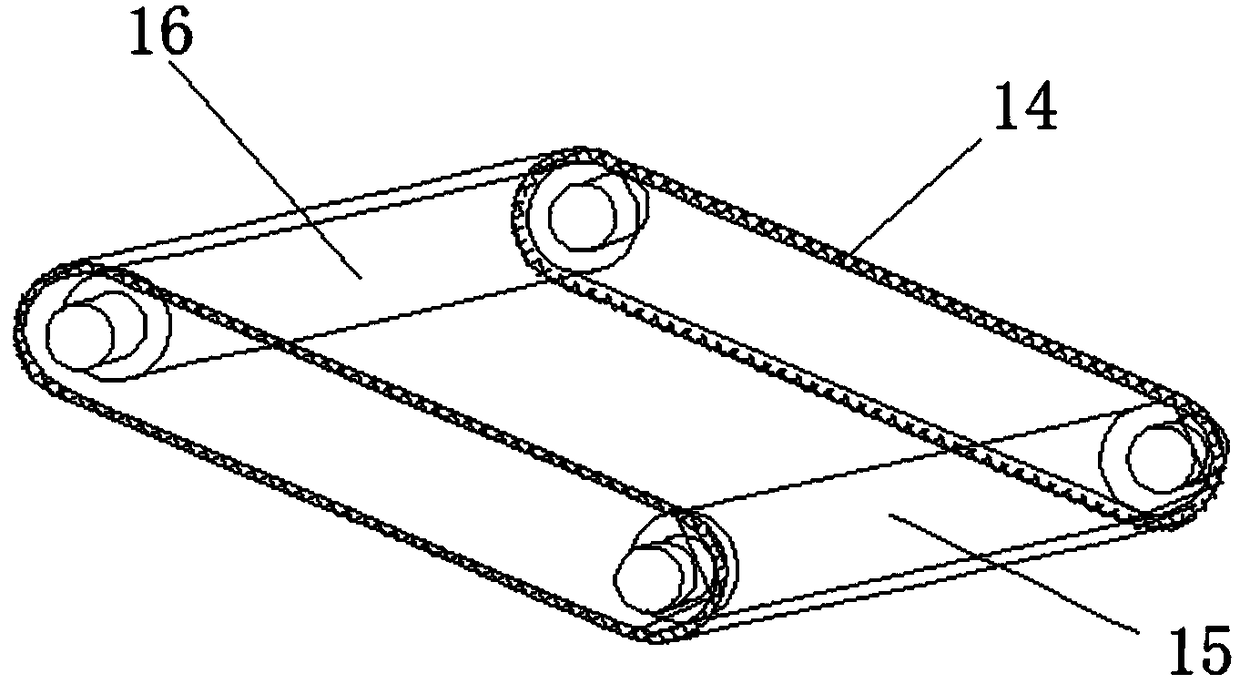

Feeding device for food processing

InactiveCN111392361AImprove cooling effectAdequate exerciseDomestic cooling apparatusDrying solid materials without heatElectric machineryCooling effect

The invention discloses a feeding device for food processing, and relates to the technical field of food processing. The feeding device comprises a base. A dustproof shell is fixedly connected to thesurface of the base. The top surface of the base is fixedly connected with a waste water receiving tank through a connecting frame. Two groups of damping buffering pieces which are symmetrically arranged are fixedly connected to the top surface of the base. The top surface of the base is connected with a conveying frame body through a damping buffer piece. An annular driving piece is fixedly mounted between the inner surfaces of the conveying frame body. An annular draining belt is connected to the peripheral side face of the annular driving piece. A group of vibration motors are fixedly connected to the two side faces of the conveying frame body. According to the feeding device for food processing, through the design of the annular draining belt, the vibration motors and a cooling spray pipe, cooling, conveying and draining work of food materials can be completed integrally, meanwhile, the static cooling of a traditional cooling device is changed into dynamic cooling during cooling, and through dynamic cooling, the cooling range can be enlarged, and the cooling effect can be improved.

Owner:合肥德纳达信息科技有限公司

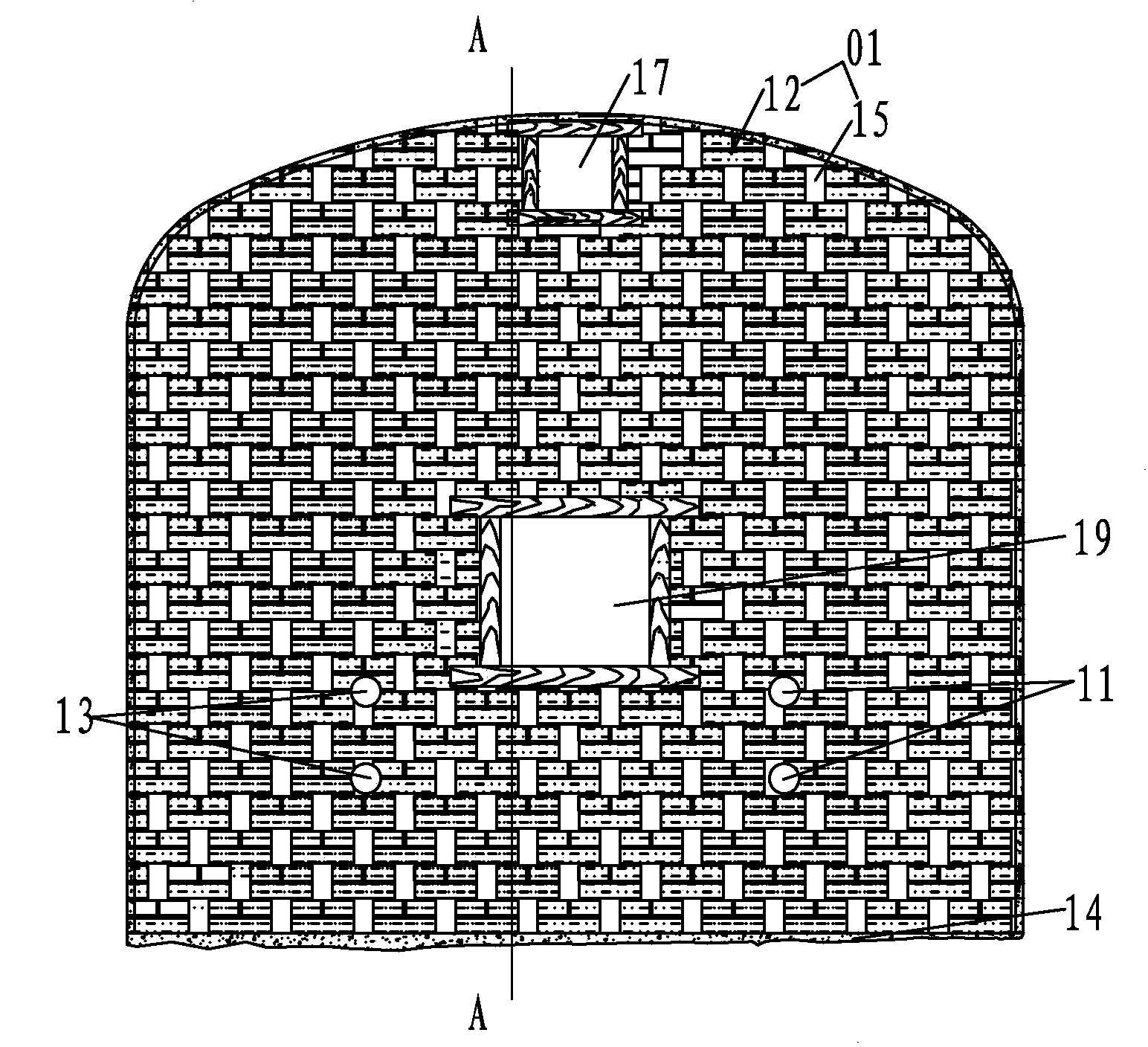

Water drainage wall adopting brick structure and used in cut-and-fill stoping method

A water drainage wall adopting a brick structure and used in a cut-and-fill stoping method comprises a wall body and geotechnical cloth arranged on the inner side of the wall body, wherein filling pipes and filling air-returning and water-returning pipes are arranged on the wall body; the wall body is built by bricks; intervals are reserved between the bricks and form water drainage holes; an observing hole is formed in the position close to the top of the wall body; and a man hole is formed in the middle of the wall body. The water drainage wall adopting the brick structure and used in the cut-and-fill stoping method is good in water drainage effect, not easy to block and low in cost, and has the firm wall body.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

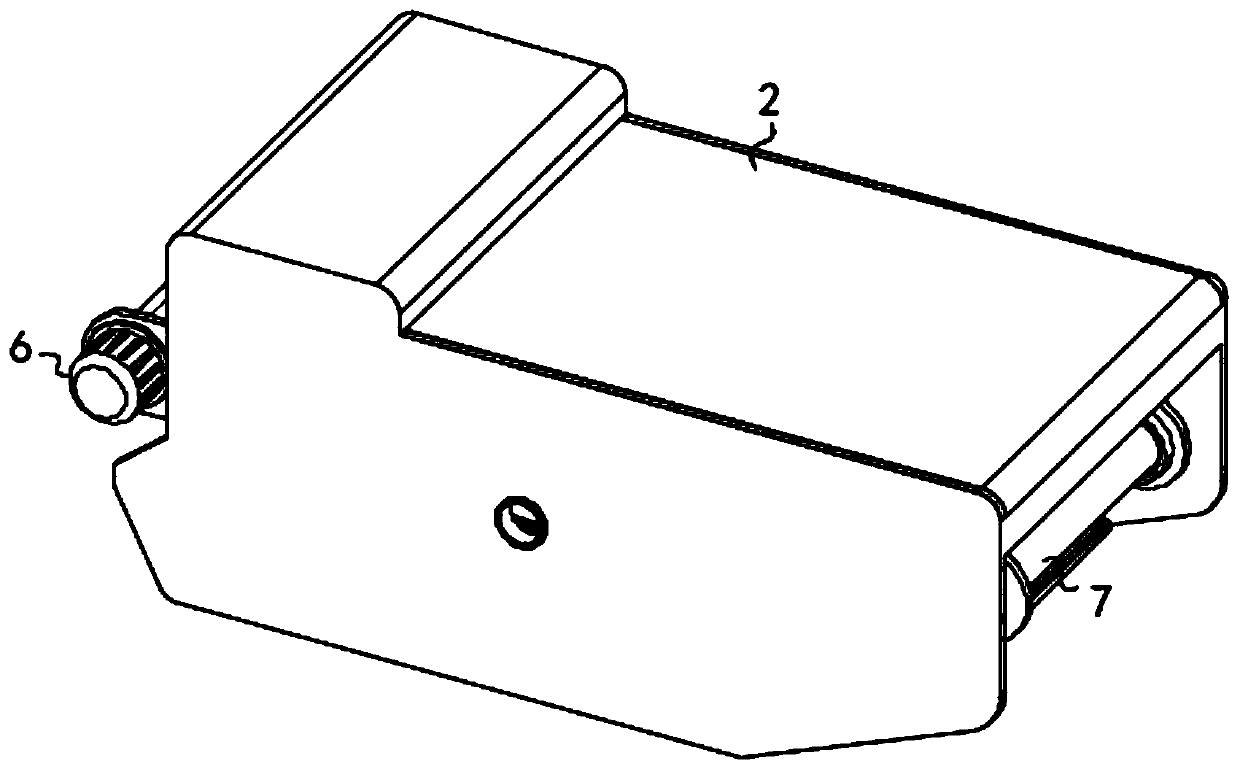

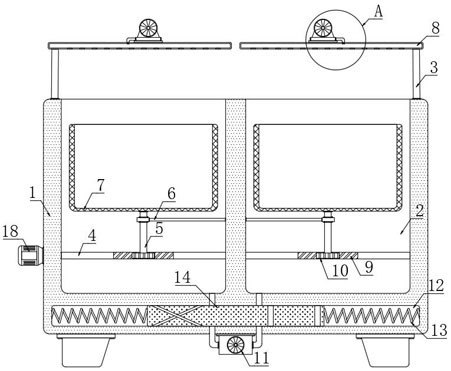

Device for soaking parts in anti-rust oil

ActiveCN113369081AAvoid dripping situationsAvoid the hassle of post-cleaningPretreated surfacesCoatingsStructural engineeringMechanical engineering

The invention discloses a device for soaking parts in anti-rust oil. The device comprises a shell, two treatment grooves are symmetrically formed in the upper end of the shell, a net frame is arranged in each treatment groove, a mounting frame is mounted on the inner wall of each treatment groove, the lower end of each net frame is fixedly connected with a vertical rod, the lower end of each vertical rod is rotationally connected with the corresponding mounting frame, the lower end of each vertical rod penetrates through the corresponding mounting frame and is fixedly connected with a worm wheel, and a rotating rod is rotationally connected between the inner walls of the two sides of each treatment groove. According to the device, through the arrangement of the two net frames, oil draining and oil soaking can be achieved synchronously, the net frames do not need to be moved many times, the situation that oil attached to the net frames drips all around is avoided while the oil soaking step is optimized, the overall oil soaking and oil draining efficiency is further improved through the arrangement of fans, and therefore the effect of improving the overall machining efficiency is achieved.

Owner:南通豪派金属制品有限公司

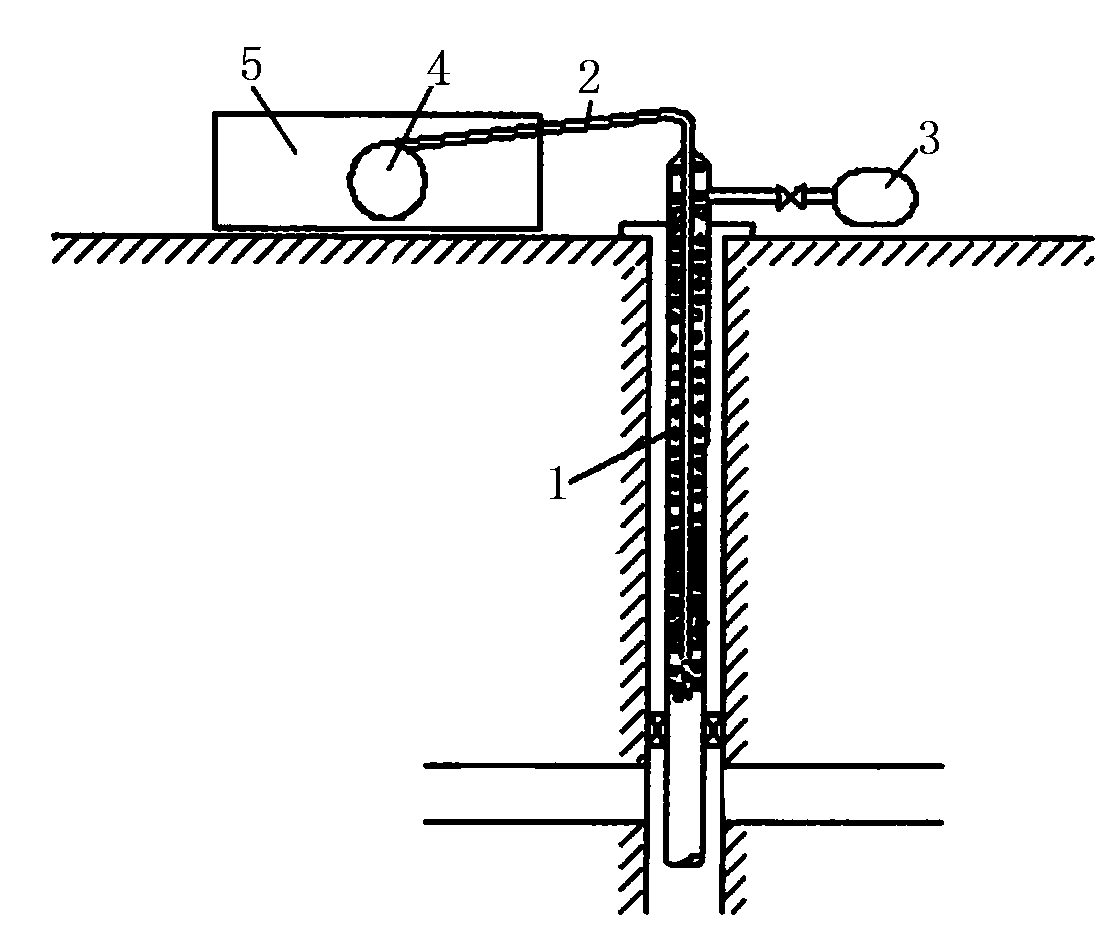

Liquid drainage system

InactiveCN103527152ASimple connection structureImprove draining effectFluid removalNitrogenCoiled tubing

The invention relates to an oil well oil pumping system, in particular to a liquid drainage system which comprises production tubing and coiled tubing. The production tubing wraps the coiled tubing, the top portion of the production tubing is connected with a valve and an oil reservoir in sequence, a liquid drainage pipe is arranged on the oil reservoir, a nitrogen recycling device is arranged in the oil reservoir, and the top portion of the coiled tubing is connected with an injection pump and a nitrogen tank. The liquid drainage system is simple in connection structure, good in liquid drainage effect and strong in practicability.

Owner:SHAANXI HI TECH ENERGY DEV

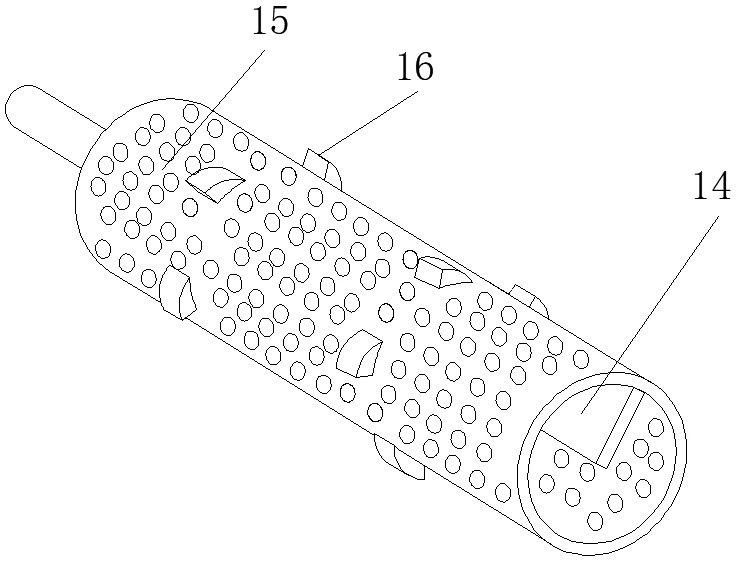

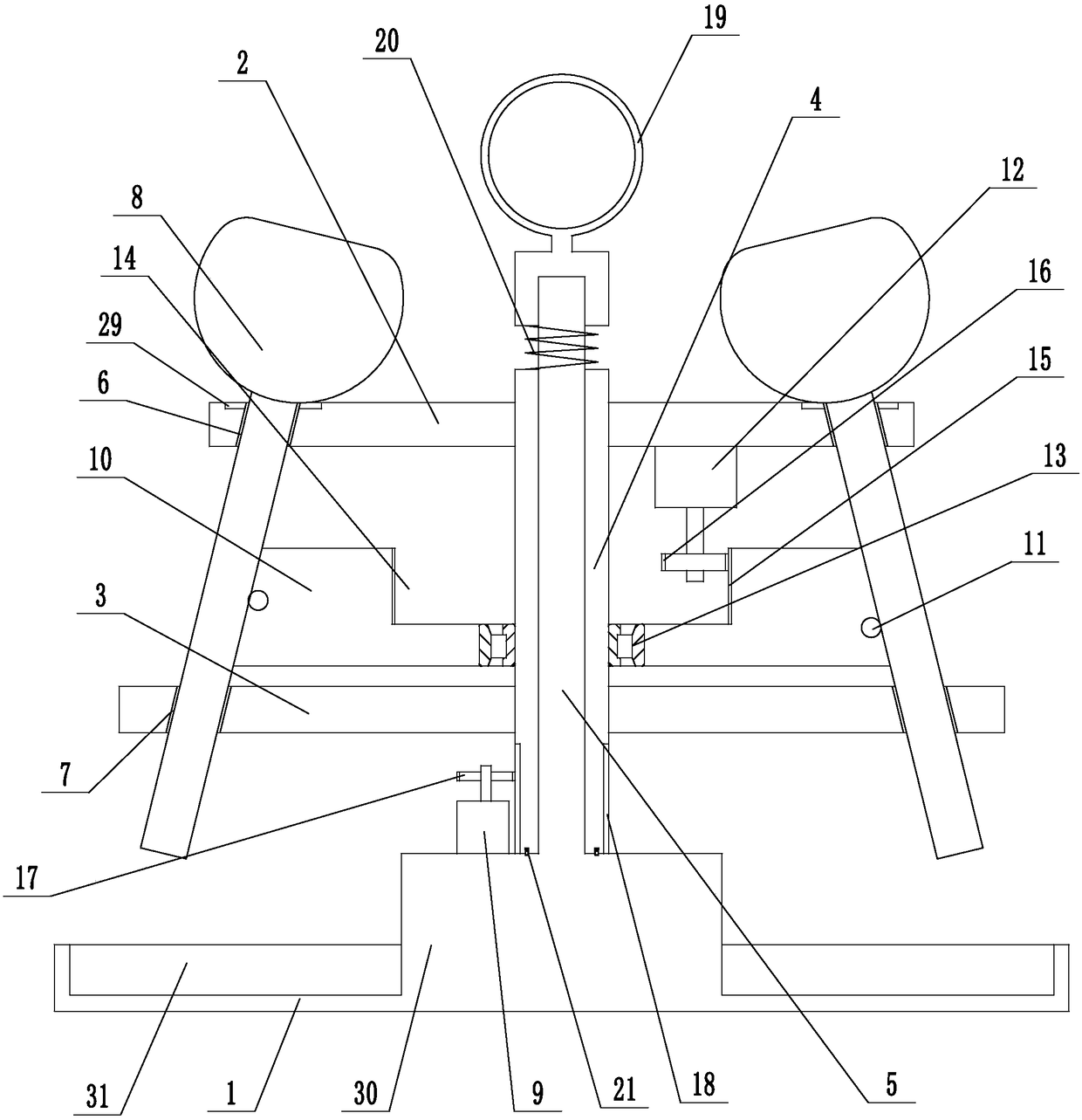

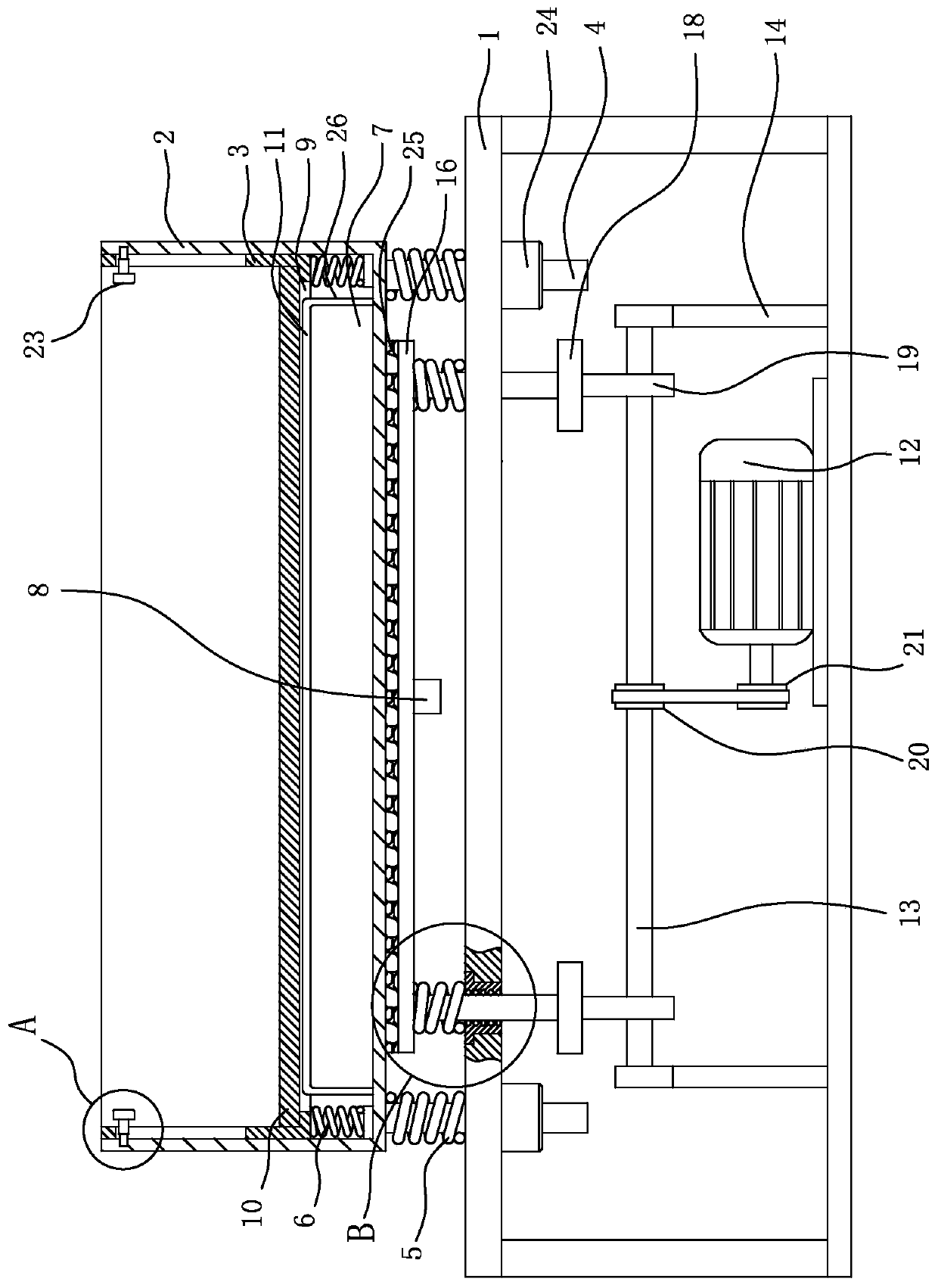

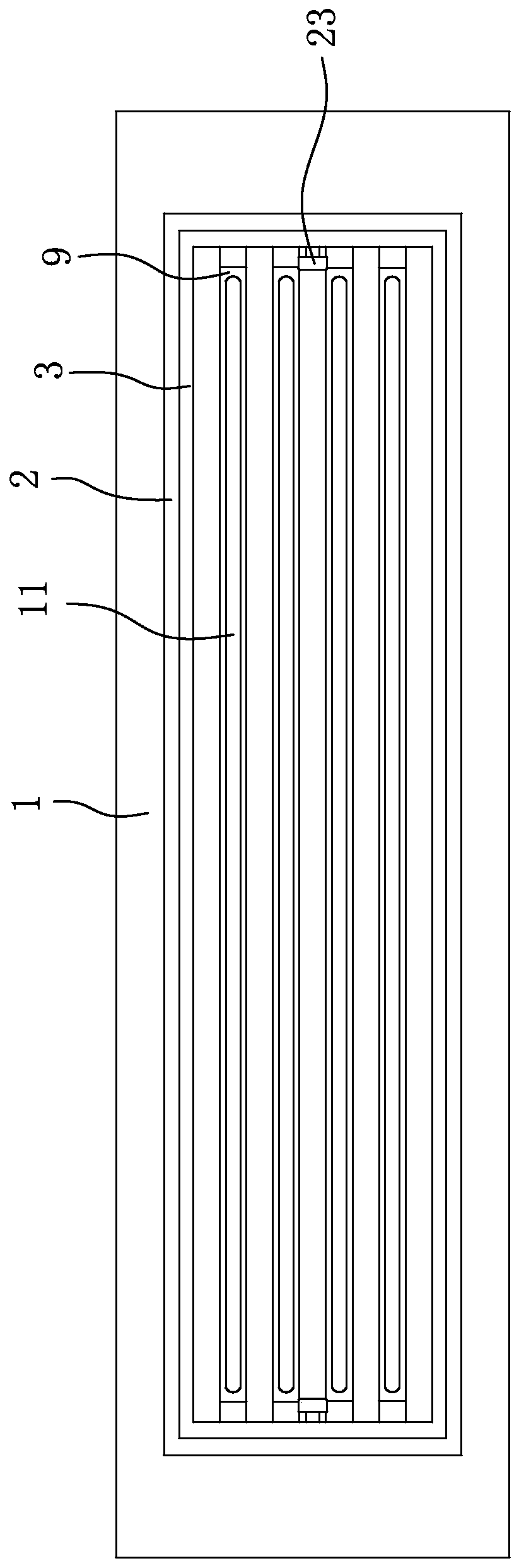

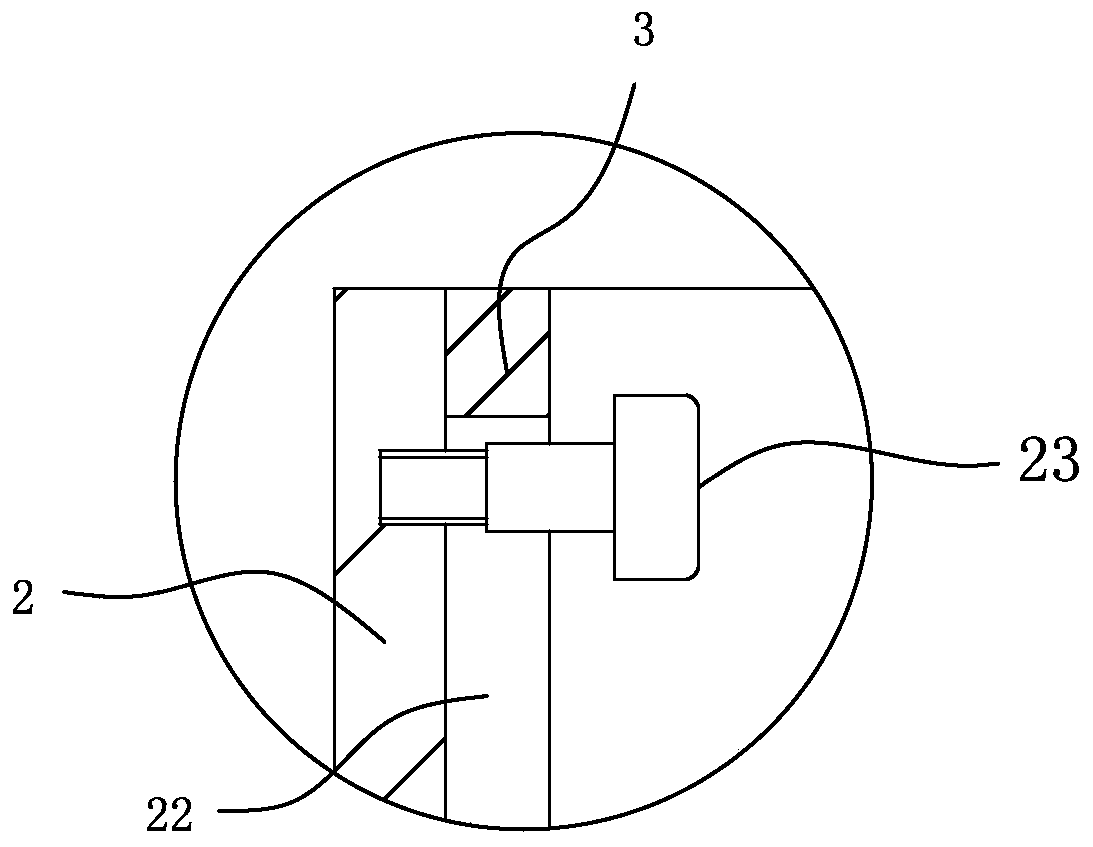

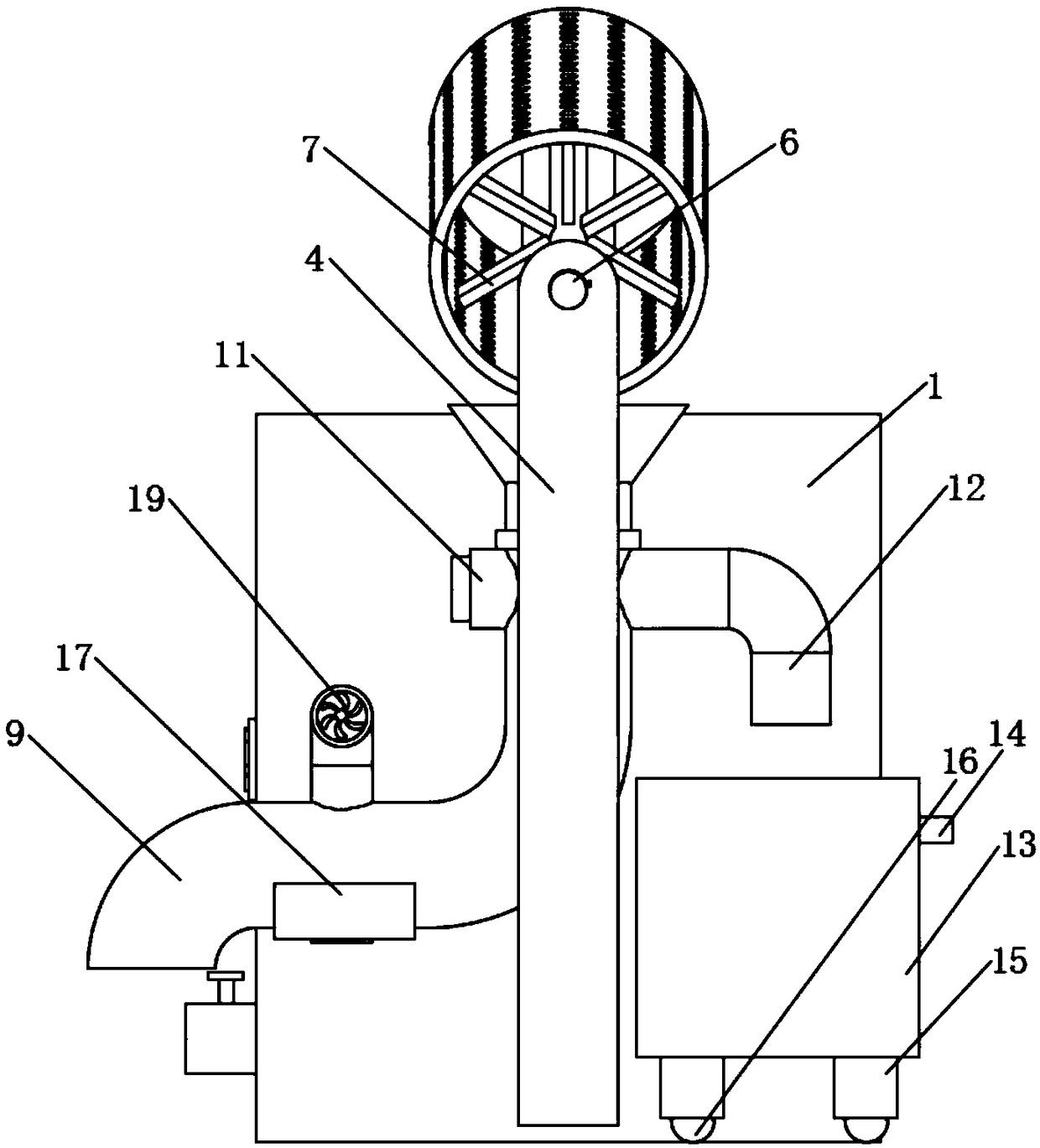

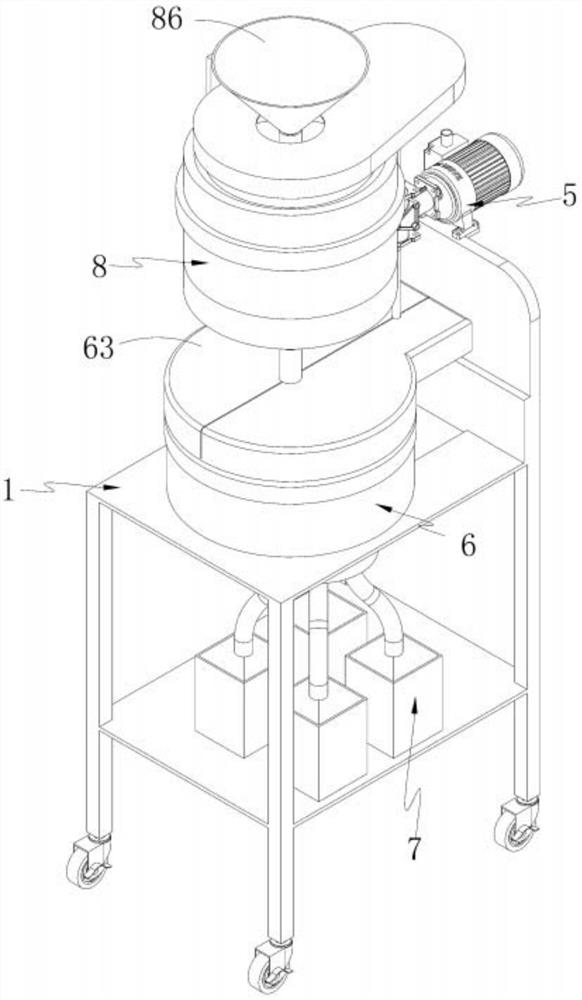

Draining device for processing of aquatic products

ActiveCN110953842AHigh speedImprove draining effectDrying solid materials without heatDrying chambers/containersReciprocating motionAquatic product

The invention discloses a draining device for processing of aquatic products. The draining device comprises a rack, an outer tank body, an inner tank body and a double-cam jacking mechanism, the outertank body is located above the rack and connected with the double-cam jacking mechanism, the double-cam jacking mechanism can drive the outer tank body to move in an up-down reciprocating mode, guiderods penetrating through the rack and being in sliding fit with the rack are arranged at the bottom of the outer tank body, and load-bearing compressed springs are arranged on the parts, between therack and the outer tank body, of the guide rods in a sleeving mode; and buffer springs are arranged at the tank bottom of the outer tank body, the inner tank body is located in the outer tank body andplaced on the buffer springs, a water collecting chamber is formed in a space between the inner tank body and the outer tank body, the bottom of the water collecting chamber is connected with a drainage tube, a plurality of draining long holes are formed in the tank bottom of the inner tank body at intervals, an overhead convex ridge is arranged at the positions, on the two sides of each draininglong hole, of the tank bottom of the inner tank body, and blocking rods fixed to the tank bottom of the outer tank body are arranged in the draining long holes and are in clearance fit with the draining holes. The draining device is novel in structure, convenient to use, stable in operation, good in draining effect and high in draining efficiency.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Draining device for beef processing

The invention relates to the technical field of food processing and discloses a draining device for beef processing. The draining device comprises a draining box, wherein an air-in pipeline is arranged on the side wall of the draining box and connected with a heating box; a turbine is mounted in the heating box; a gear is coaxially arranged on the turbine; the gear is meshed with a press rod; a press head is arranged at the lower end of the press rod; the upper end of the press rod is connected with the top of the draining box through a spring; the heating box is connected with air injection pipes; two air injection pipes convey air flow from the upper part of the draining box and below respectively; a coil is wound on the exterior of the turbine; and alternating current is introduced into the coil. The invention is aimed at providing a draining device for beef processing, which can sufficiently drain residual water in beef and realizes a good draining effect.

Owner:重庆市长寿区舒福食品有限公司

Inserting dish rack

InactiveCN103735192AEasy to fixImprove practicalityKitchenware cleanersKitchen equipmentEngineeringStructural engineering

Owner:COOKTIME KITCHENWARE

Ecological dry breeding method for laying ducks

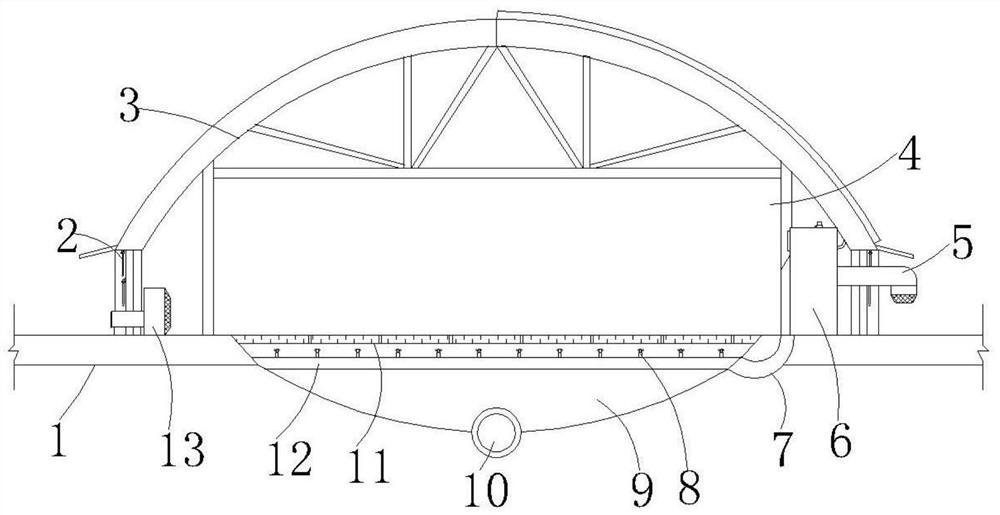

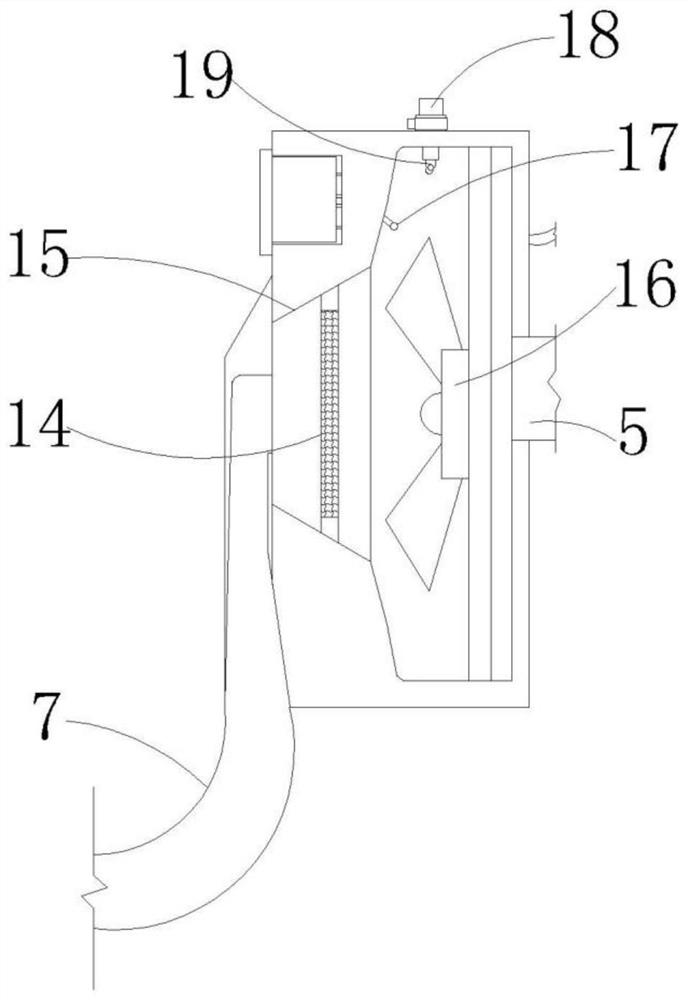

PendingCN113841657AImprove comfortPrecise control of stocking densityAnimal housingBird housingsLaying duckEngineering

The invention discloses an ecological dry breeding method for laying ducks. The method comprises the steps of duck shed construction, shed roof design, side wall design, partition in the shed, breeding facility and equipment arrangement and breeding management key points, the breeding facility and equipment arrangement comprises the steps that an air interchanger, a feeding device, a lighting device and a sun-shading device in the duck shed are arranged, and a sewage treatment system is arranged at a low position near the duck shed, so that rain and sewage separation and up-to-standard discharge are realized. The roof of the duck shed is of a roller shutter type, lighting and rain shielding are facilitated, and the dryness of duck bodies and padding can be effectively improved by means of the draining buffer area; an air control box and an air exhaust box are oppositely arranged, ventilation is enhanced, the duck bodies and padding can be rapidly dried, the internal temperature is controlled, and the laying ducks are prevented from being cold. Facilities in the shed are reasonably arranged according to the structure of the duck shed, the comfort of the duck shed is improved, a good ecological site suitable for healthy breeding of the laying ducks is built, environmental pollution is reduced, agricultural and pastoral recycling is achieved, and economic, ecological and social benefits of laying duck breeding enterprises are integrally improved.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY MEDICINE ANHUI ACAD OF AGRI SCI

Metal liner cleaning and draining device

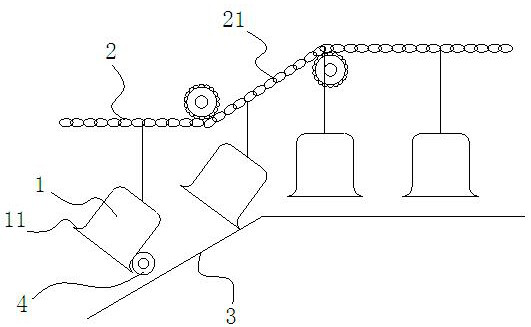

InactiveCN112524897ARemove quickly and completelyAvoid it happening againDrying machines with progressive movementsDrying solid materialsMechanical engineeringMaterials science

The invention provides a metal liner cleaning and draining device which can improve the draining efficiency and the draining effect of a metal liner and improve the production efficiency and the product quality. The metal liner cleaning and draining device comprises a conveying chain belt used for conveying metal liners, wherein the metal liners are hung below the conveying chain belt, a drainingarea is arranged below the conveying chain belt, and an inclined plate is arranged in the draining area. According to the metal liner cleaning and draining device, moisture adhering to the surfaces ofthe metal liners, especially moisture accumulated at flanging of openings of the metal liners, can be removed more quickly and thoroughly, water stains are prevented from being generated on the surfaces of the metal liners, and the product quality is improved.

Owner:GUANGDONG HUATIAN ELECTRICAL APPLIANCE

Solid-liquid separating device for small-scale industrial wastewater treatment convenient for using

InactiveCN108579174AEasy to useEasy to collectMoving filtering element filtersPulp and paper industryWaste material

The invention discloses a solid-liquid separating device for small-scale industrial wastewater treatment convenient for using. The solid-liquid separating device comprises a support frame and a material taking door. The upper end of the interior of the support frame is fixedly provided with a machine body. The material taking door is mutually connected with a groove through a first rotation shaft.A cross rod is mutually connected with a material receiving plate through a second rotation shaft. The surface of the upper end of the machine body is provided with a material inlet. The surfaces ofthe inner sides of a first scraper and a second scraper are provided with filter components, and the right sides of the interiors of the filter components are provided with a rolling shaft. A shaft rod horizontally passes through the wall surface of the front end of the machine body. The solid-liquid separating device for small-scale industrial wastewater treatment convenient for using is capableof limiting a solid waste material to be collected through waterproof cloth, effectively avoiding scattering and leaking situations in a material taking process, conveniently collecting by a worker, effectively limiting a solid in wastewater through the scrapers, and preventing the solid from entering the lower end of the interior of the machine body, and has the better separating and draining effects, so the solid and liquid in the device are more completely separated in a certain degree.

Owner:ANHUI CAREMIC CONSULTING CO LTD

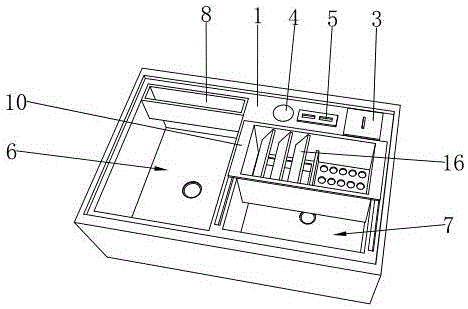

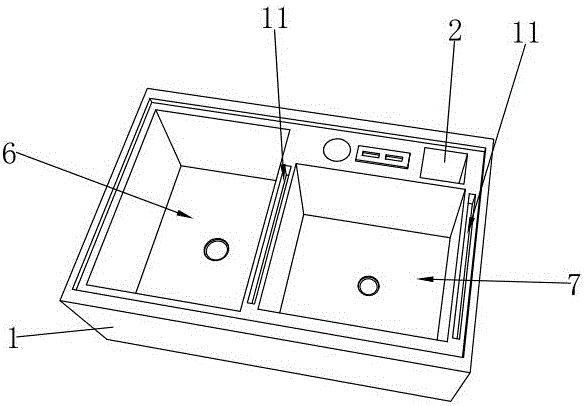

Domestic kitchen trough

The invention discloses a domestic kitchen trough which comprises a trough body. A flushing zone and a draining zone are respectively arranged in the trough body, a draining zone is arranged in the draining zone, a partition plate is arranged in the draining box and separates the draining box into a first draining space and a second draining space, draining plates are uniformly distributed in the first draining space and are obliquely arranged, a supporting base plate is arranged at the bottom of the draining box and comprises a first base plate and a second base plate, the first base plate and the second base plate form an integral structure, the first base plate is located in the first draining space, rectangular through grooves are uniformly distributed in the first baseplate, the second base plate is located in the second draining space, and draining holes are uniformly distributed in the second base plate. The domestic kitchen trough is simple in structure, flexible to connect, high in space utilization rate, capable of achieving classified draining of foods and tableware, good in draining effect and high in practicability.

Owner:QUANNAN COUNTY CAIMEIDA TECH DEV CO LTD

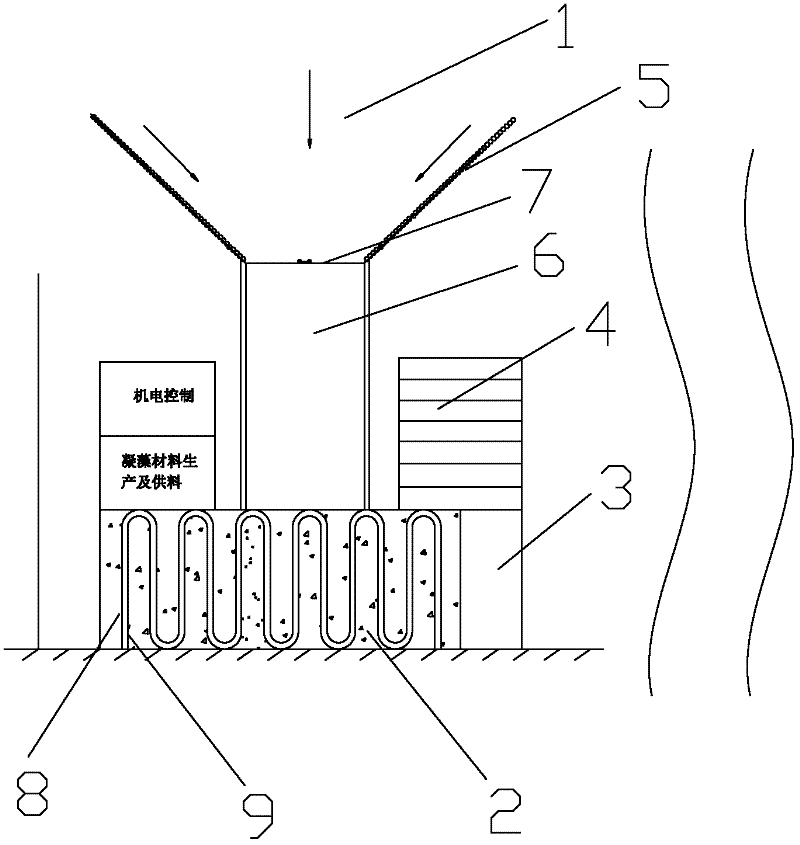

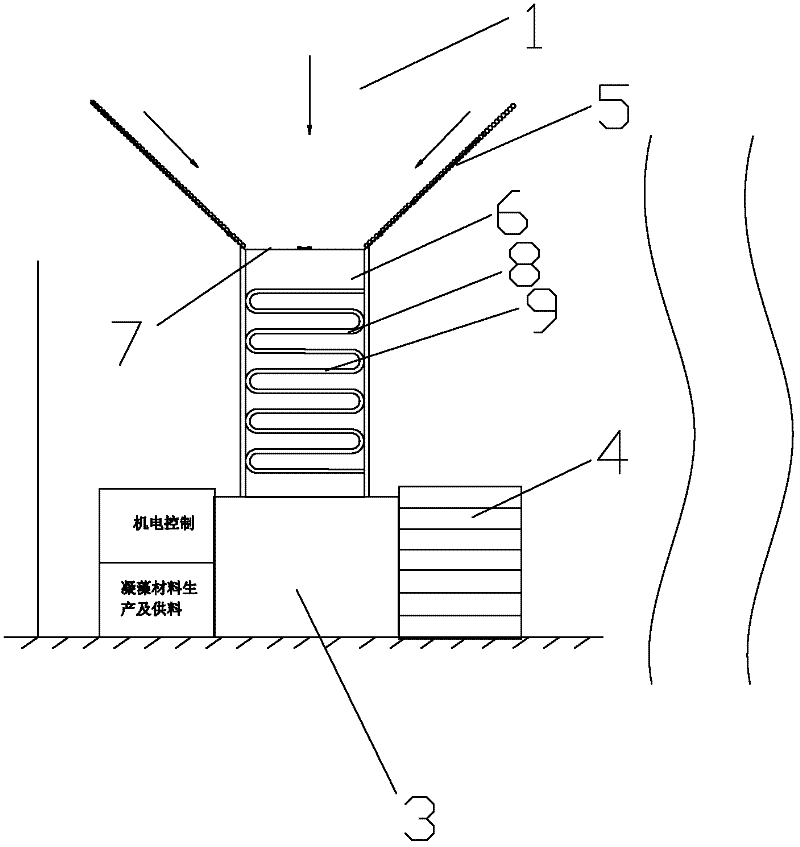

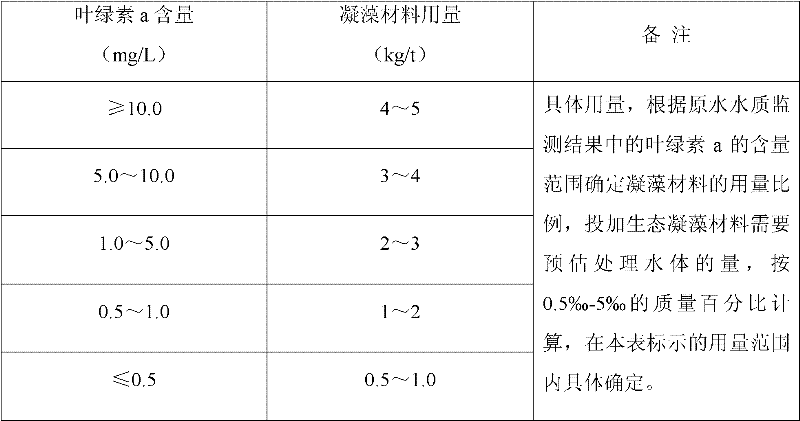

Algae-water separation port

InactiveCN102502930AActivate growthInhibition of reproductionWater/sewage treatment by flocculation/precipitationBlue green algaeOrganic fertilizer

The invention discloses an algae-water separation port. The algae-water separation port is successively provided with a blue-green algae inducing region (1), an algae-water separation region (2), an algae mud concentration region (3) and a transformation storage region (4), wherein two leading fences which are provided with horn-shaped openings are arranged in the blue-green algae inducing region (1) and communicated with a collecting channel (6) through gates (7); a setting algae material feeding pipe (8) and an aeration pipe (9) are arranged in the algae-water separation region (2). In the algae-water separation port, local surrounding control, local separation, local transformation and local utilization are carried out; and the algae-water separation port is rapid in algae-water separation, rapid in transformation, low in cost and high in efficiency, storage is convenient and simple, and a conversion product can be used as an organic fertilizer to be directly applied to cultivation, plant and the like so as to complete digesting circulation.

Owner:合肥市东方美捷分子材料技术有限公司

Drainage and material conveying device in soybean soaking system

InactiveCN109230656AQuality improvementAvoid wastingConveyorsLoading/unloadingSoybean productCoupling

The invention discloses a drainage and material conveying device in a soybean soaking system. The drainage and material conveying device comprises a water receiving tank and a second column, a controlswitch is arranged on the outer side surface of the water receiving tank, an input end of the control switch is electrically connected with an output end of an external power source, a first column is arranged on the upper surface of the water receiving tank, and the second column is arranged on the side face of the water receiving tank; a motor is arranged on the side surface of the first column, an input end of the motor is electrically connected with an output end of the control switch, an output shaft of the motor penetrates through the side surface of the first column and is connected toone end of a rotating shaft through a coupler, and the other end of the rotating shaft is rotatably connected in a through hole formed in the side surface of the second column. According to the drainage and material conveying device in the soybean soaking system, the drainage effect is improved, and water can be drained quickly; meanwhile, bean skin and other impurities can be blown out from a material screening pipe through a material screening fan in a material conveying process, the bean skin and other impurities are prevented from being mixed with soybeans, and the quality of soybean products is improved.

Owner:阜阳市雪伟食品有限公司

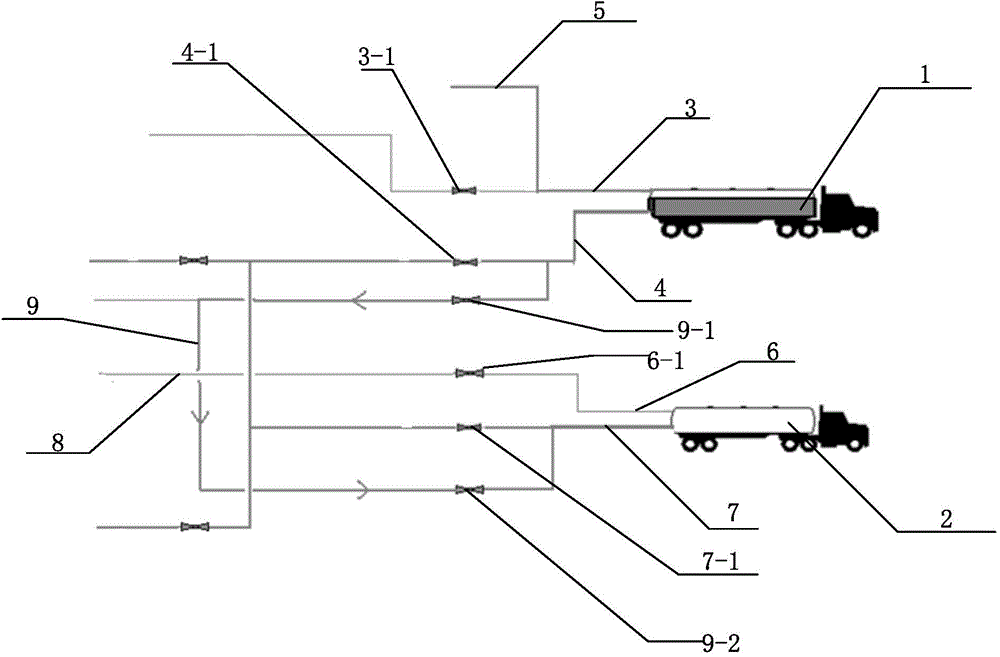

Overload processing method for LNG tank car

InactiveCN104948908ASo as not to damageMethod securityPressure vesselsContainer discharging from pressure vesselsGas phaseEngineering

The invention relates to an overload processing method for an LNG tank car. The overload processing method comprises the following steps: (1) connecting an empty tank car of an unloaded car with a pry, opening a first valve on a gas-phase arm of the unloaded car to decrease the pressure of the empty tank car of the unloaded car to be consistent with pressure of a BOG header, maintaining the first valve at an opening state, and closing a second valve on a liquid-phase arm of the unloaded car; (2) connecting an overloaded car with the pry, sequentially connecting a gas-phase arm and a liquid-phase arm of the overloaded car to the overloaded car, closing a third valve on the gas-phase arm of the overloaded car and a fourth valve on the liquid-phase arm of the overloaded car; (3) communicating one end of a cold-insulation circulating pipeline with the liquid-phase arm of the overloaded car, communicating the other end of the cold-insulation circulating pipeline with the liquid-phase arm of the unloaded car, opening a fifth valve and a sixth valve on the cold-insulation circulating pipeline, and starting a processing process; and (4) finishing the processing when the liquid level of the overloaded car is lower than the highest liquid level. The overload processing method is safe, reliable and efficient, damage of pipelines and equipment is avoided, and the loading operation of other tank cars is not influenced.

Owner:中海福建天然气有限责任公司

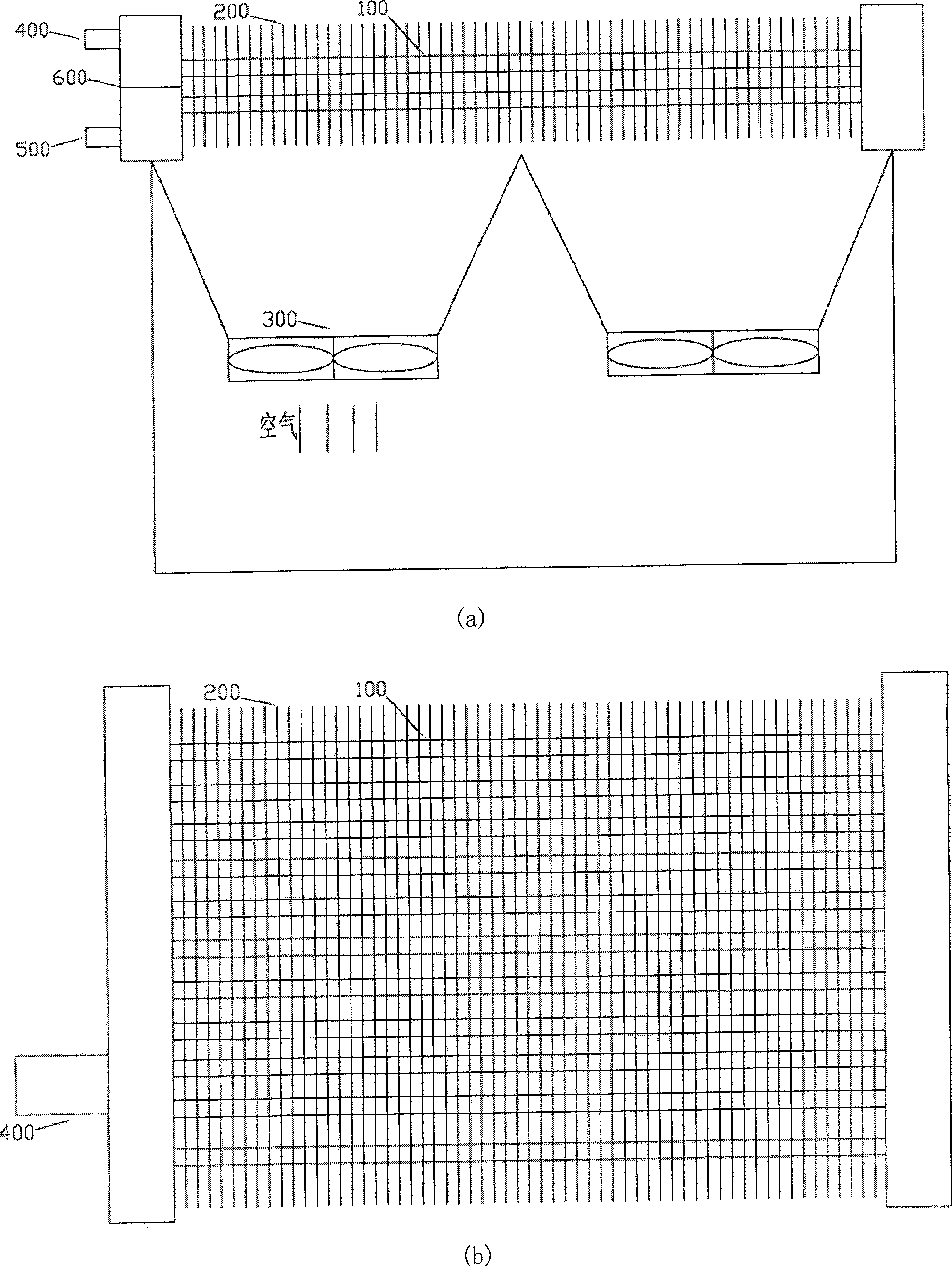

Multi-stage cooling middle liquid-separation air condenser

InactiveCN100491871CReduce thicknessIncrease profitEvaporators/condensersSteam/vapor condensersHeat transmissionEngineering

Multiple-refrigeration Middle-delivery aerial condenser belongs to thermodynamic equipment technology domain. It composes of multi stages, and every stage is connected by the channels; every stage has two flow stages in which the steam floats to opposite direction; the air input is connected with the first channel , and the first channel is connected with the second channel by a row of parallel distribution heat exchange tube of the first stage; the second channel is connected with the heat exchange tube of next stage; apostrophe ,until get to the last channel; there are fins set out of the heat exchange tube; the shell is set out of the heat exchange tube and fins. The steam is put into the heat exchange tube of the first stage to refrigerate through the steam input and the first channel, and the air-liquid mixture flows into channel, and then the liquid and the air are separated; the steam gets into the heat exchange tube of next stage. This invention is suitable for large power engineering refrigeration, and it has efficient condensation capacity and large coefficient of heat transmission; the heat transfer area of the equipment is made use of sufficiently and efficiently; the fabric is flexible and smart, the applicability of the space is high.

Owner:TSINGHUA UNIV

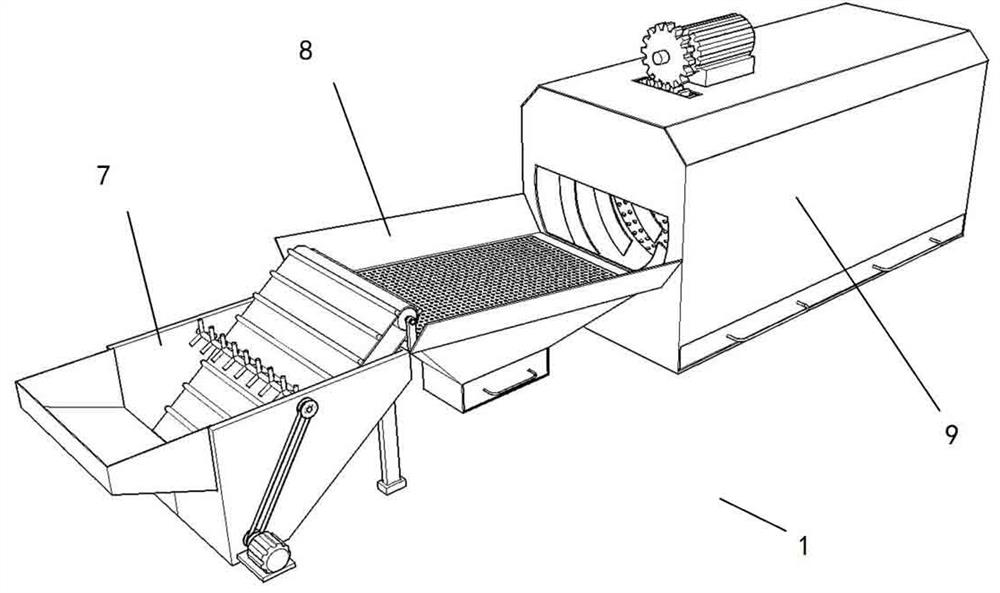

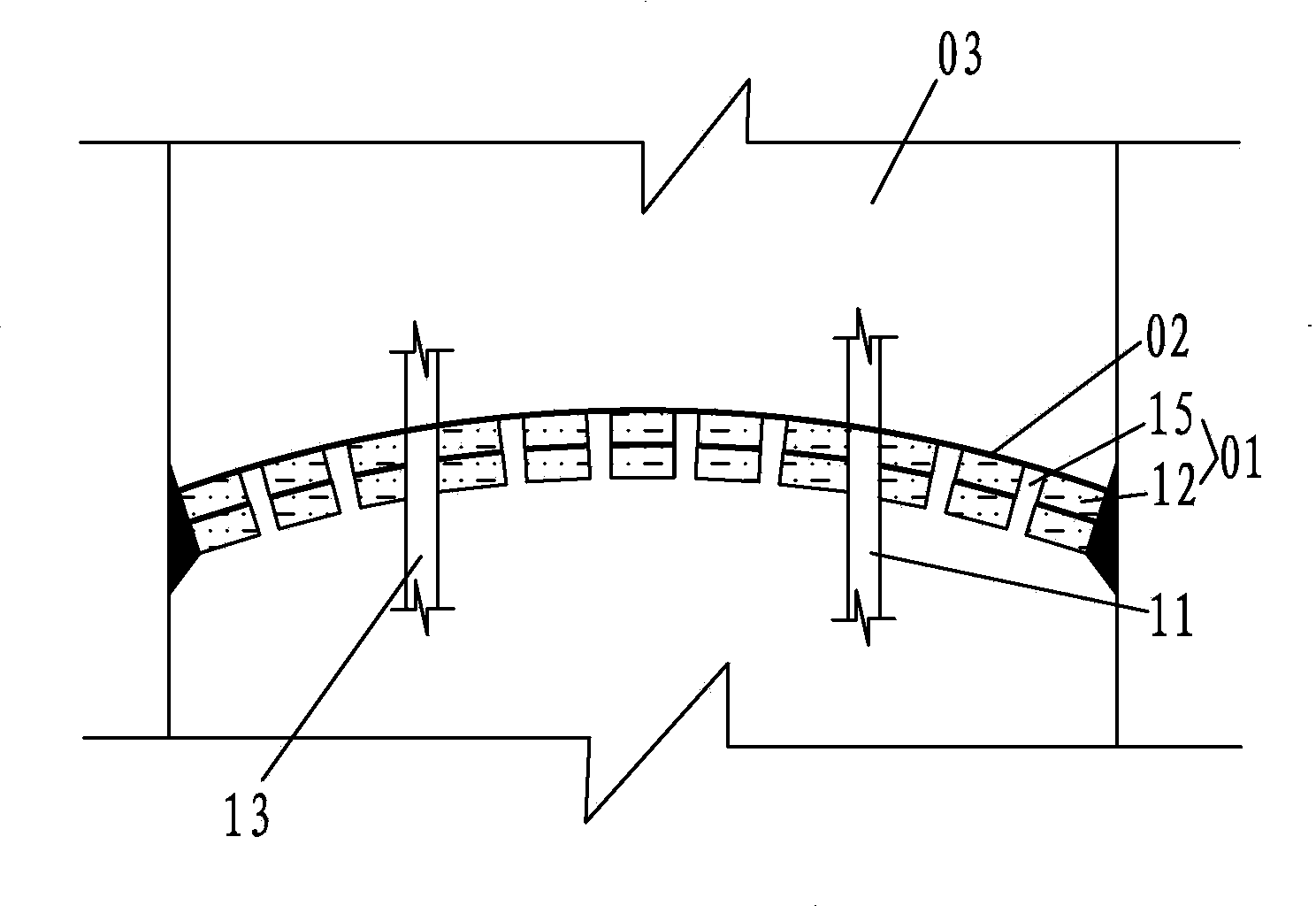

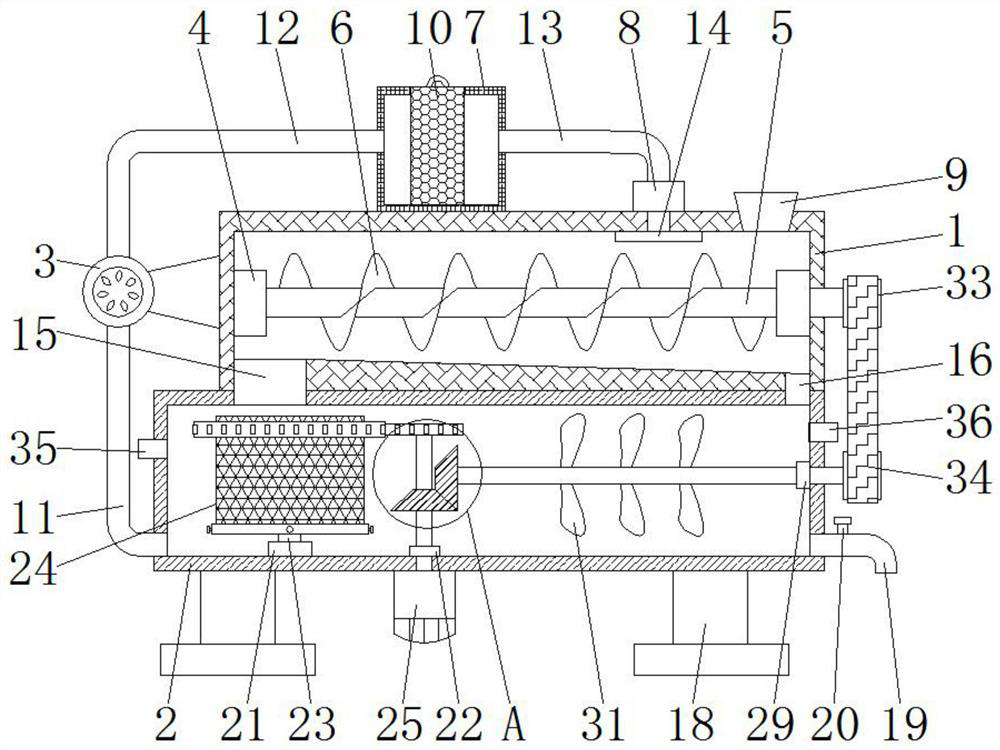

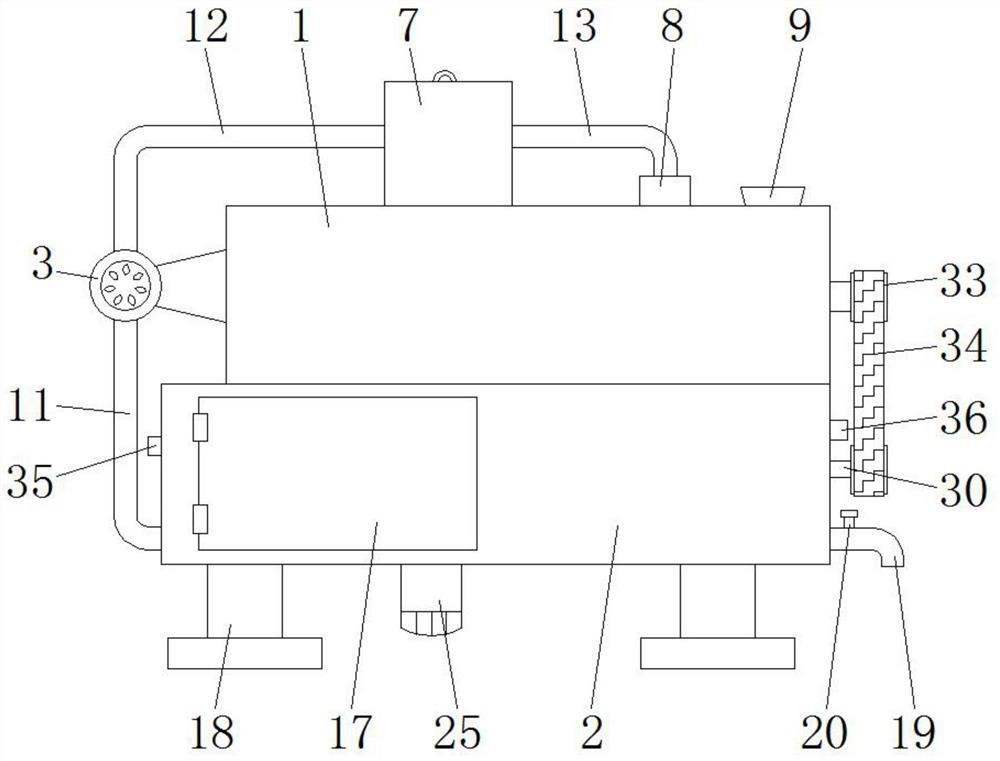

Integrated equipment for dendrobium cleaning and draining

PendingCN113319043AEasy to cleanCompact structureDrying solid materials without heatDrying gas arrangementsEnvironmental engineeringMechanical engineering

The invention discloses integrated equipment for dendrobium cleaning and draining. The integrated equipment for dendrobium cleaning and draining comprises a cleaning box and a draining box located at the bottom of the cleaning box, wherein the left side of the cleaning box is connected with a water pump through a rack, first bearing seats are fixedly installed on the inner walls of the left side and the right side of the cleaning box, and a first rotating rod is rotationally connected between the two first bearing seats; a spiral conveying blade is arranged on the outer surface of the first rotating rod, a filtering box, a pressure pump and a charging hopper are sequentially arranged at the top of the cleaning box from left to right, a filtering block is arranged in the filtering box, the bottom and the top of a water pump communicate with a water inlet pipe and a water outlet pipe separately, and the end, away from the water pump, of the water inlet pipe communicates with the bottom of the left side of the draining box; and the end, away from the water pump, of the water outlet pipe communicates with the left side of the filtering box, the right end of the filtering box communicates with a water guide pipe, and the end, away from the filtering box, of the water guide pipe communicates with the pressure pump, then extends into the right side of the cleaning box and communicates with a spray head. The integrated equipment for dendrobium cleaning and draining is compact in mechanism, capable of carrying out cleaning and draining treatment on dendrobium at the same time, and good in energy-saving effect.

Owner:安徽逸品山庄现代农业发展有限公司

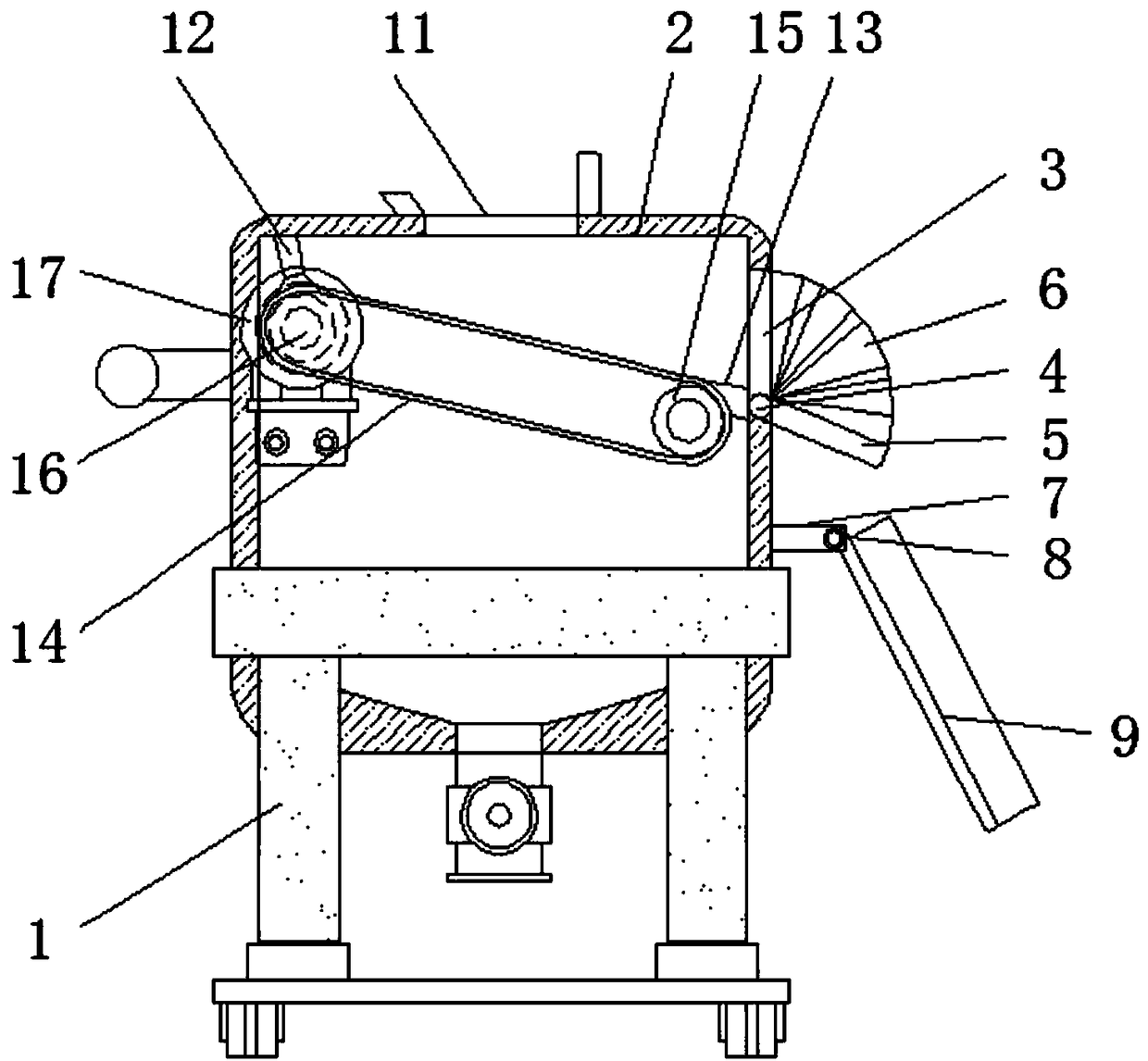

Crushed peanut processing equipment capable of reducing residual oil

ActiveCN112718142ASynchronous cuttingReduce residual oilRotary centrifugesGrain treatmentsAgricultural engineeringProcess engineering

The invention provides crushed peanut processing equipment capable of reducing residual oil. The equipment comprises a rack, a knife rest unit, a cutter, a feeding control unit, a driving unit, a material cutting control unit, a material receiving unit and an oil draining unit, and is characterized in that a spiral oil draining pipe of which a spiral direction is opposite to a rotating direction of a conical rotating disc is arranged on the oil draining unit, so that oil draining and sorting of fried peanuts are achieved, and the peanuts subjected to oil draining sequentially enter a knife rest; the feeding control unit, the knife rest unit, the cutter and the material cutting control unit cooperate with one another, so that the peanuts are cut according to a required particle size, and the problem that the particle uniformity of crushed peanuts is poor due to the fact that the crushed peanuts are produced in a crushing mode is solved; and the crushed peanuts with different particle sizes are classified and collected by means of the material receiving unit, the crushed peanuts with the different particle sizes are independently packaged and sold, the requirements of different customers are met, and a yield of the crushed peanuts is increased.

Owner:阜阳佰恩得新材料技术有限公司

Kitchen garbage can for community garbage classification

InactiveCN110937276AAvoid influenceImprove draining effectRefuse receptaclesProcess engineeringSewage

The invention provides a kitchen garbage can for community garbage classification. The garbage can comprises a garbage can body and a garbage can cover; the garbage can cover is arranged at the upperend of the garbage can body; a garbage throwing door is arranged on the can cover; a draining net is arranged in the garbage can body; a solid garbage taking-out door is arranged in the front surfaceof the garbage can body, and is opened, so that solid garbage blocked by the draining net is taken out; a sewage collecting box is arranged below the draining net, and sewage is collected through thesewage collecting box; a peculiar smell recycling box is arranged on the side wall of the sewage collecting box, an adsorbing material is arranged in the peculiar smell recycling box, and the two endsof the draining net are connected to the box wall of the garbage can body through soft rods. Peculiar smell is collected through the peculiar smell recycling box, the situation that the surrounding environment is affected by peculiar smell volatilization is avoided, a stirring motor drives a stirring rod to stir a draining net, draining is assisted, and the draining effect is improved.

Owner:戴林涛

Draining method for beef processing

The application of the invention relates to the technical field of food processing, and discloses a draining method for beef processing. The draining method for beef processing comprises the following steps that: A, beef is placed at the bottom of a draining box, high-pressure air flow is introduced into a heating box through an air inlet pipeline, the air flow is heated to be hot air flow when passing through a turbine of the heating box, then the hot air flow is respectively diverged above and below the draining box through two air-blowing pipes, and the hot air flow is conveyed to the upper side and the lower side of the beef; B, when the air flow passes through the turbine in the heating box, the air flow drives the turbine, and then the turbine starts to rotate, so that a pressure bar moves downwards, and the beef is squeezed through a pressure head; and C, when draining work is stopped, the operation of introducing the air flow into the air inlet pipeline is stopped, and the pressure bar is reset through a spring connected with the top of the draining box. A closed conductive coil is curled around the outer part of the turbine, a gear is engaged with the pressure bar, and the gear is coaxially connected with the turbine. By adopting the method disclosed by the invention, the purpose of fully draining beef foods can be achieved.

Owner:重庆市长寿区舒福食品有限公司

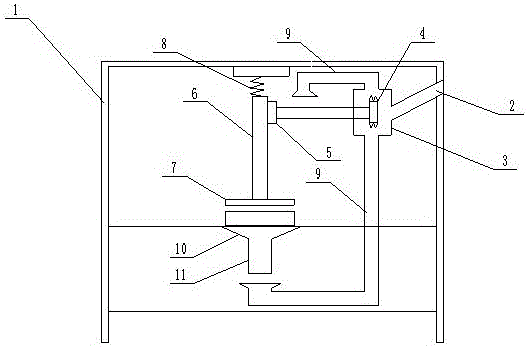

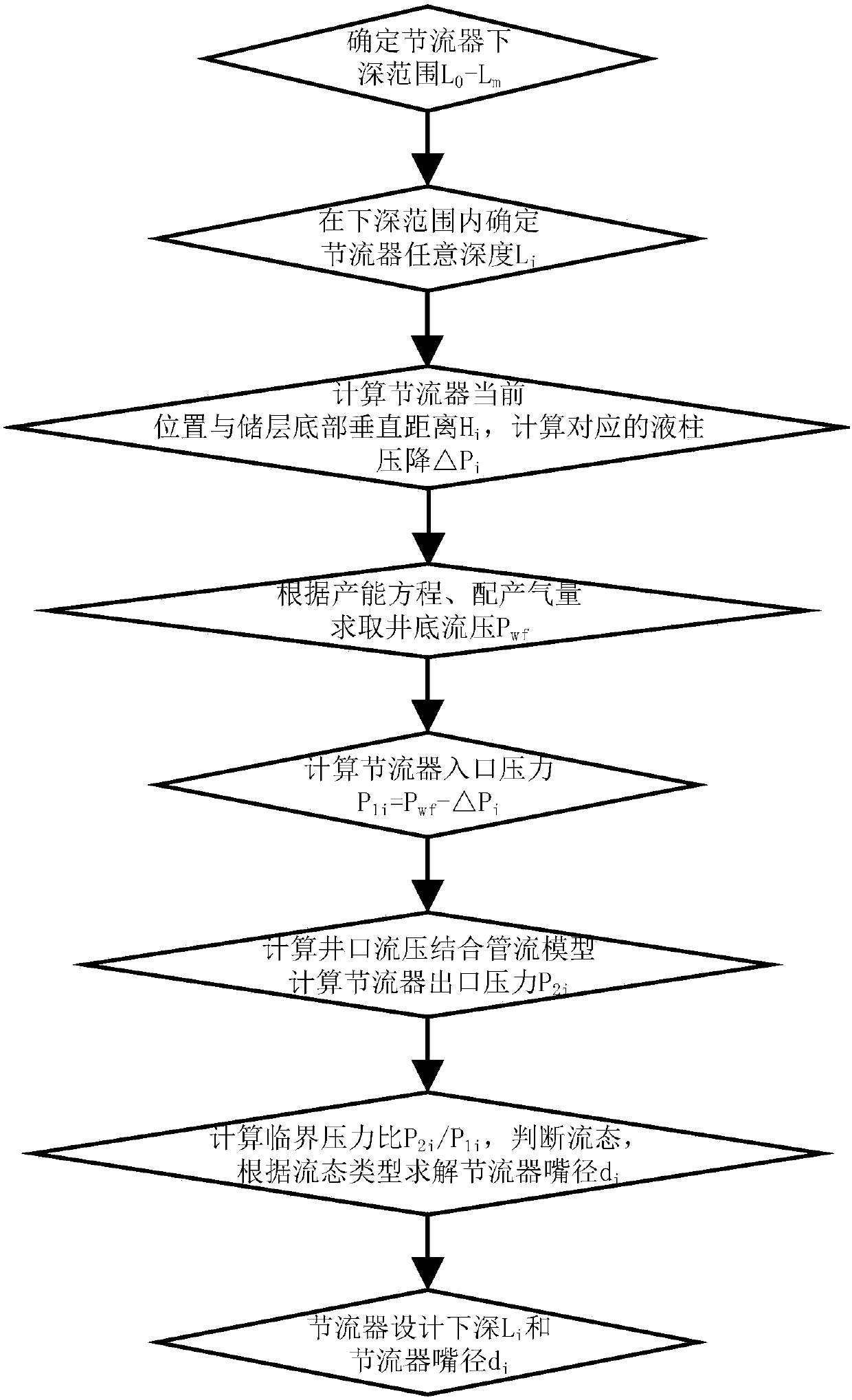

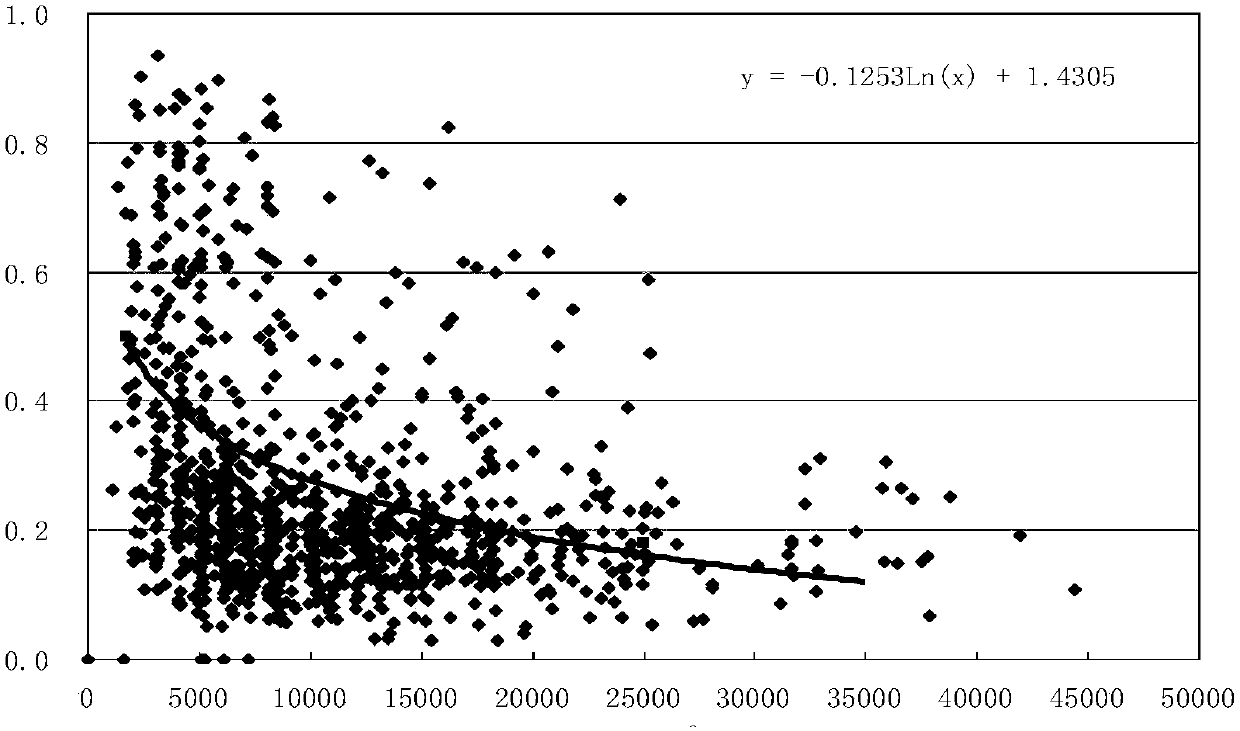

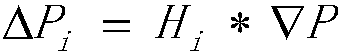

A downhole throttling process parameter calculation method for a gas well with a high liquid-gas ratio

ActiveCN109598007AOptimize mouth sizeCorrected the defect that the influence of liquid production volume on throttle pressure difference was not consideredGeometric CADDesign optimisation/simulationProcess engineeringPressure difference

The invention relates to the technical field of downhole throttling, in particular to a downhole throttling technological parameter calculation method for a high-liquid-gas-ratio gas well. According to the method, the defect that a single-phase fluid underground throttling model does not consider the influence of the liquid production amount on the throttling pressure difference is overcome; The factor of liquid column pressure drop is introduced in the process of optimizing the nozzle diameter of the throttler, generation of hydrates is effectively prevented and controlled, the liquid drainage effect is improved, the requirement for continuous liquid drainage and stable production of a gas well with the high liquid-gas ratio is met, field production is effectively guided, the calculationprocess is simple and convenient, and field operation is easy.

Owner:PETROLEUM ENG TECH RES INST CHINA PETROLEUM & CHEM CORP NORTH CHINA OIL & GAS CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com