Rotatable volumetric flask rack and application method

A volumetric bottle and bottle rack technology, which is applied to chemical instruments and methods, drying chambers/containers, and dry solid materials, etc., can solve the problems of slow draining speed, inconvenient operation, and poor draining effect, and achieve fast draining speed and easy operation. Convenience and the effect of improving the draining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

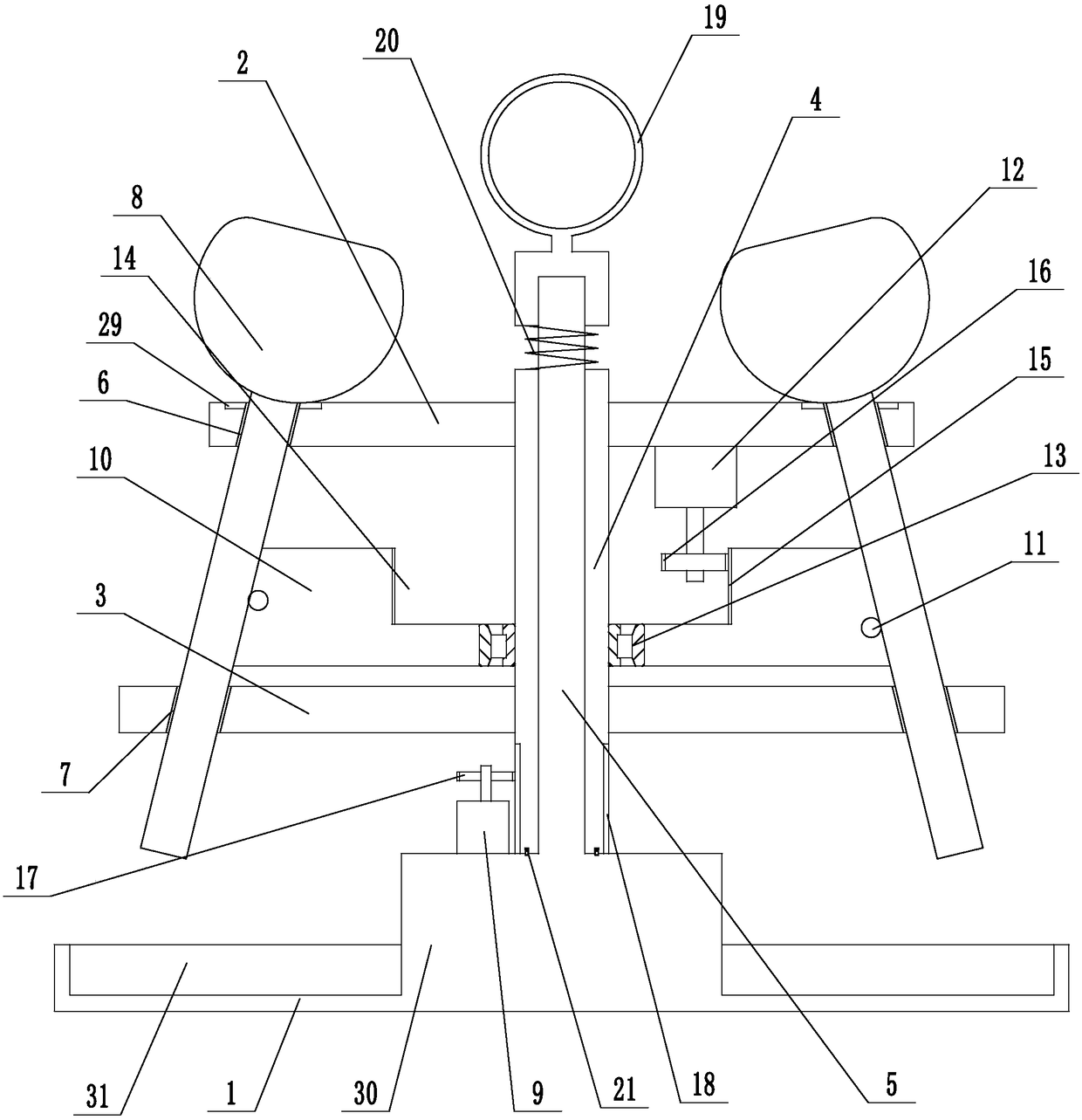

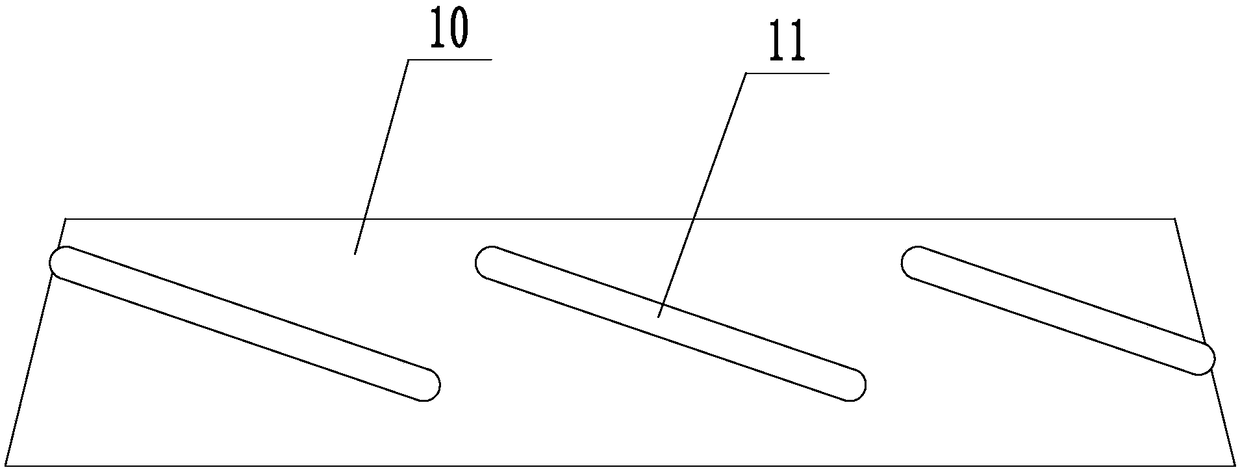

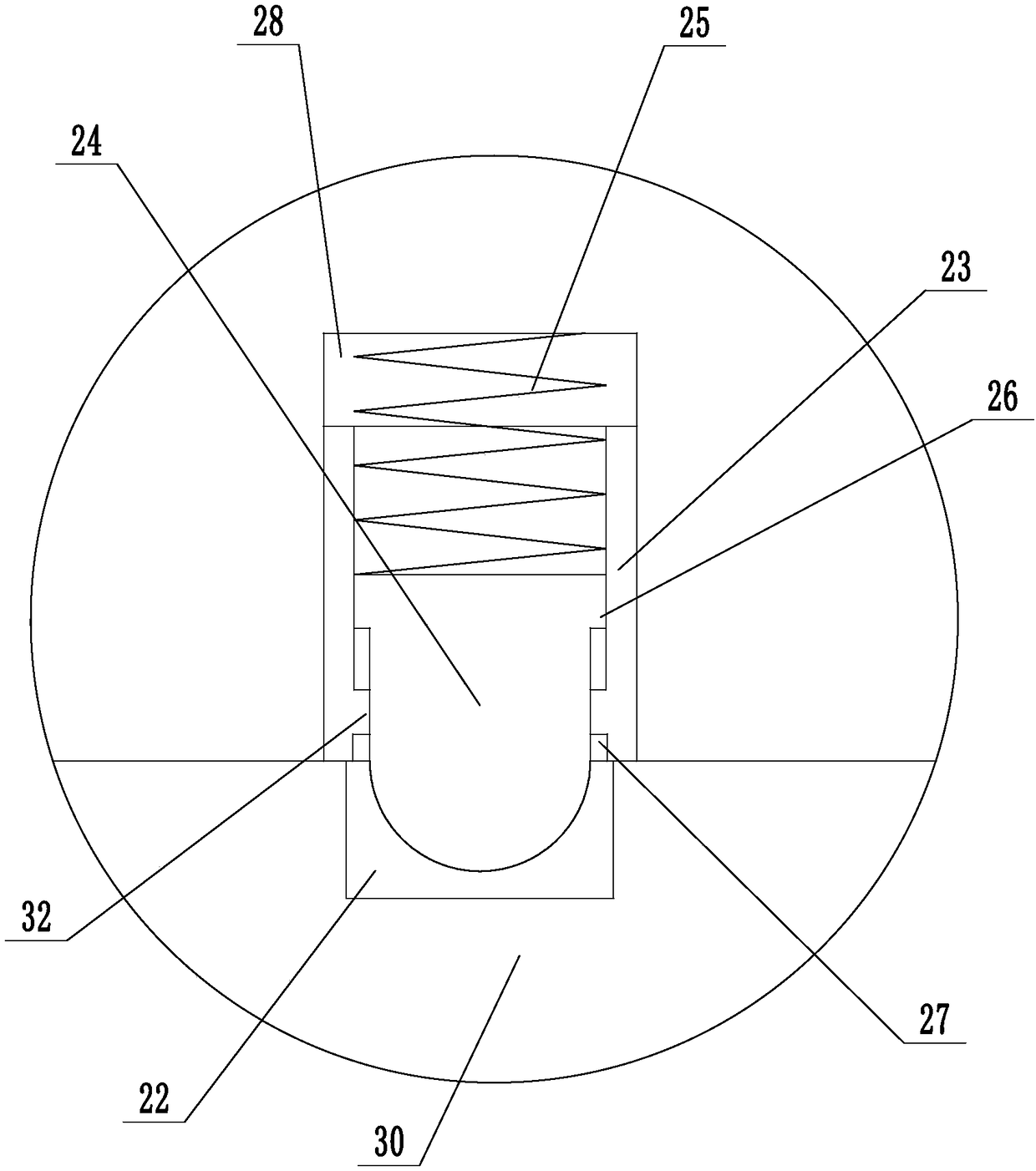

[0022] Embodiment: a kind of rotatable volumetric flask rack (see attached Figures 1 to 3), including the chassis 1, the rotating mechanism installed on the chassis, the rotating mechanism includes the upper tray 2, the lower tray 3, the rotating sleeve 4, the chassis is provided with a pillar 5, the rotating sleeve can be rotatably set on the pillar, and the connection between the rotating sleeve and the pillar A rotating vibration mechanism is installed between them. Both the upper tray and the lower tray are fixedly installed on the rotating sleeve. Six upper jacks 6 are evenly arranged on the upper tray, and several lower jacks are arranged on the lower tray and the upper jacks one by one. 7. A protective pad 29 is installed on the opening edge of the upper end of the upper jack, and a volumetric bottle 8 placed obliquely and inverted is inserted between the upper jack and the lower jack. Both the upper jack and the lower jack are set inclined outward from top to bottom, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com