A downhole throttling process parameter calculation method for a gas well with a high liquid-gas ratio

A technology of process parameters and calculation methods, applied in the directions of calculation, electrical digital data processing, design optimization/simulation, etc., can solve the problems that the calculation results of the throttling process parameters do not conform to the calculation results, and the liquid production volume is not considered, so as to meet the requirements of continuous liquid discharge. Stabilize production requirements, improve drainage effect, and prevent hydrate formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

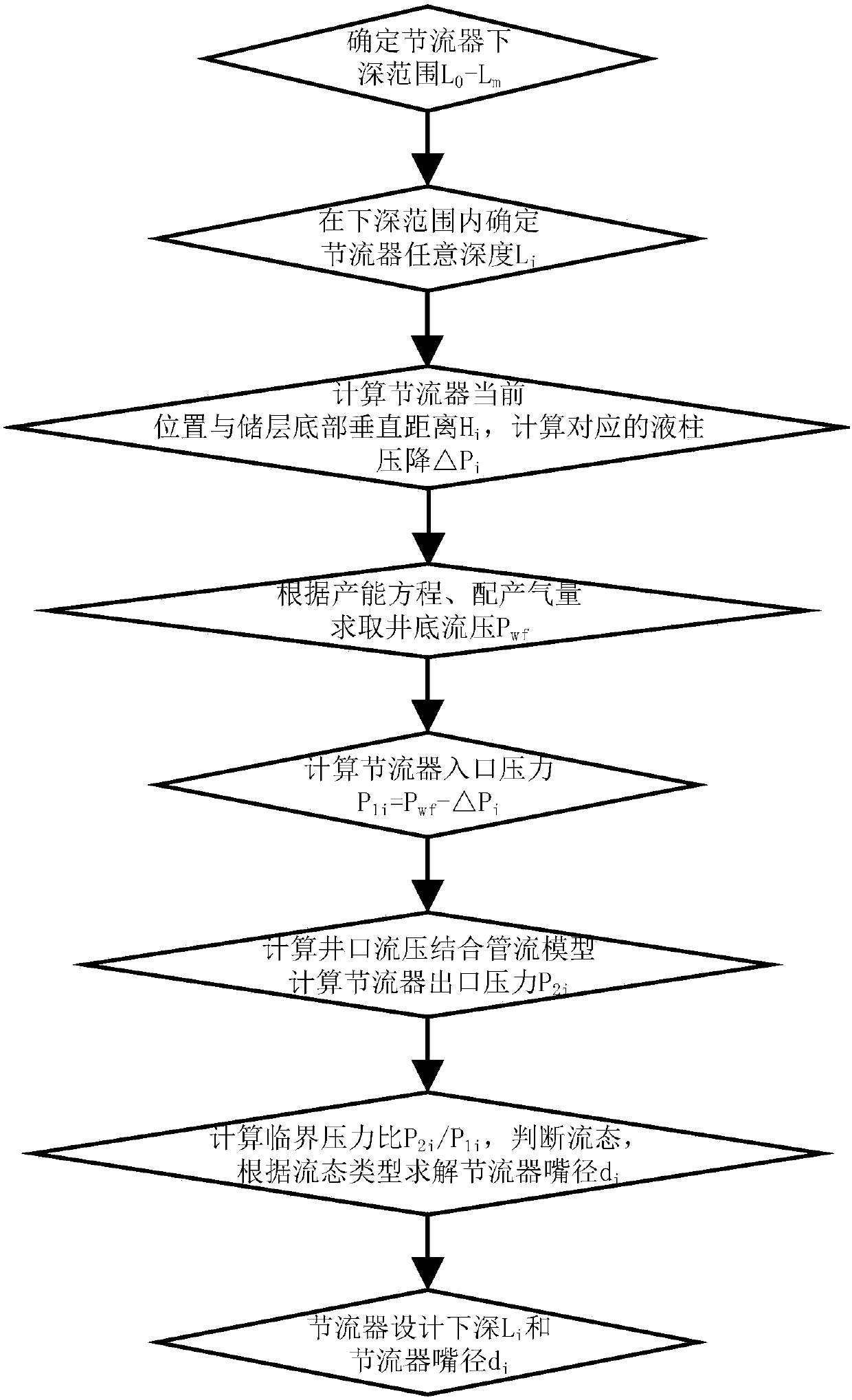

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

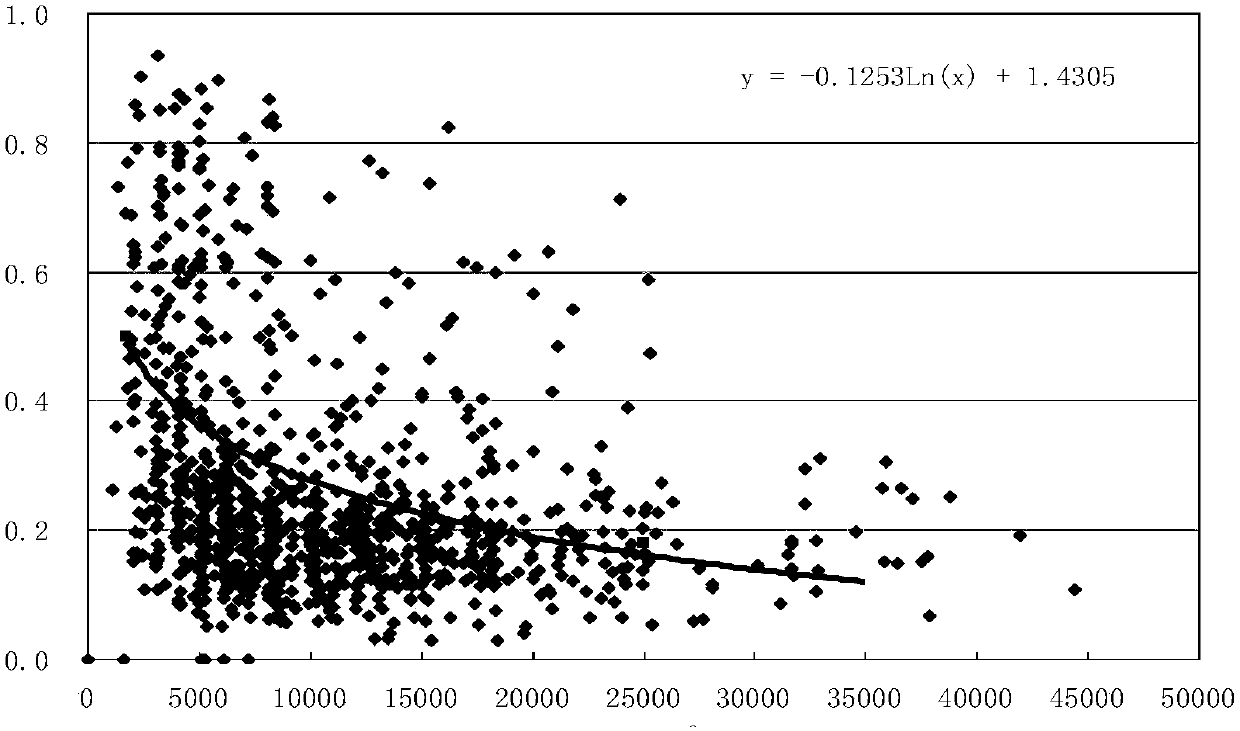

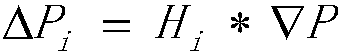

[0027] The invention provides a simple and convenient design method for downhole throttling process parameters suitable for two-phase flow. It is obtained through technical calculation; while the present invention considers the influence of liquid column pressure drop when calculating the choke mouth diameter, and corrects the influence of liquid production on choke pressure difference and wellbore liquid carrying, and the calculation of choke mouth diameter is more accurate. Reasonable and more realistic, it not only effectively prevents the formation of hydrates, but also effectively improves the liquid drainage effect, meets the requirements for continuous liquid drainage and stable production of high liquid-gas ratio gas wells, and effectively guides on-site production.

[0028] In order to achieve the above, the present invention provides a method for ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com