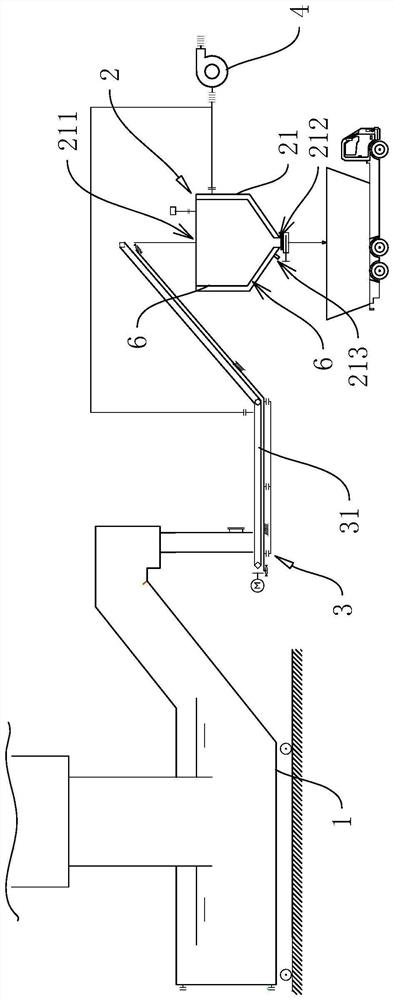

Efficient treatment system for hazardous waste incineration ash

A technology for incineration of ash and slag and treatment system, applied in incinerators, combustion types, combustion methods, etc., can solve problems such as troublesome and large labor consumption, and achieve the effect of reducing the number of transfers and accelerating draining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

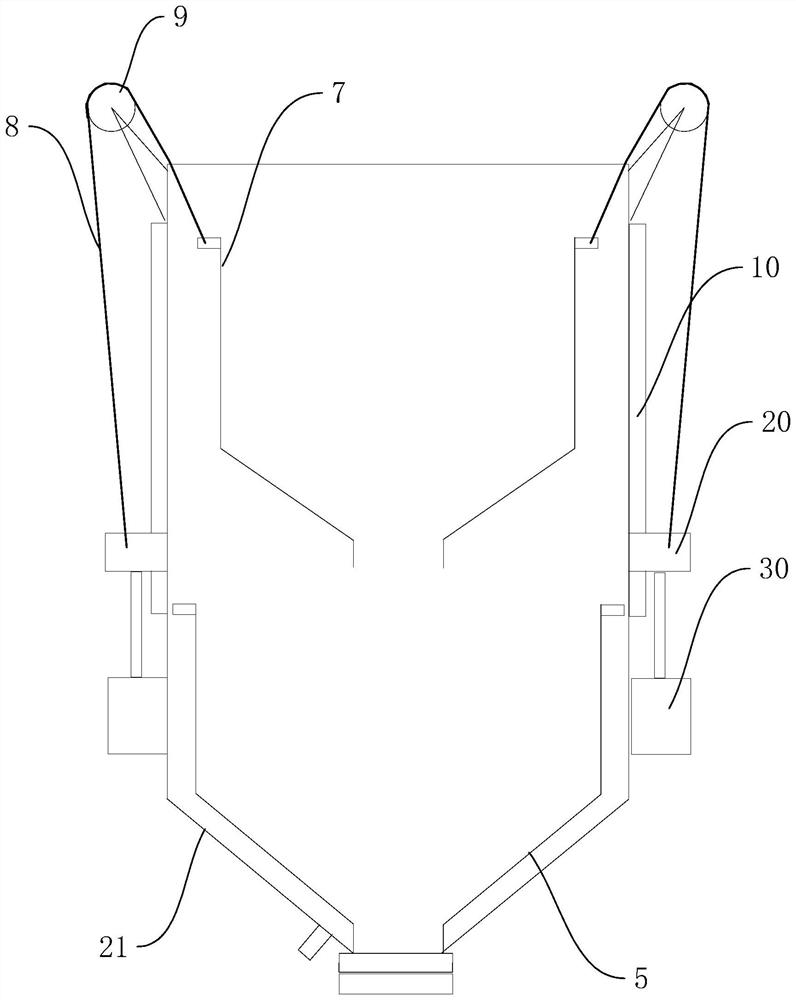

[0038] refer to figure 2 , the difference between the embodiment of the present application and the first embodiment is: the second filter screen 7 is arranged up and down in the drain bin 21, the filter hole diameter of the second filter screen 7 is smaller than the filter hole diameter of the first filter screen 5, and the second filter screen 7 is The filter screen 7 is located on the inner side of the first filter screen 5, and the shape of the first filter screen 5 is the same as that of the second filter screen 7. When the second filter screen 7 descends, the lower end of the second filter screen 7 and the first filter screen 5 contact to prevent ash from entering between the first filter screen 5 and the second filter screen 7 . The water filtering bin is provided with a driving member 8 for driving the second filter screen 7 to rise and fall, the driving member 8 is set as a driving rope, and four driving ropes are provided, and a plurality of fixed pulleys 9 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com