Hanging podded moving weighing releasing method

A drop-in method and pod-type technology, applied in the field of waste drop-in devices, can solve the problems that the garbage room cannot be solved, the labor intensity of the staff is high, and the cost is high, so as to reduce the labor operation cost, the cleaning and transportation cost, and the sanitation labor. Operation, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

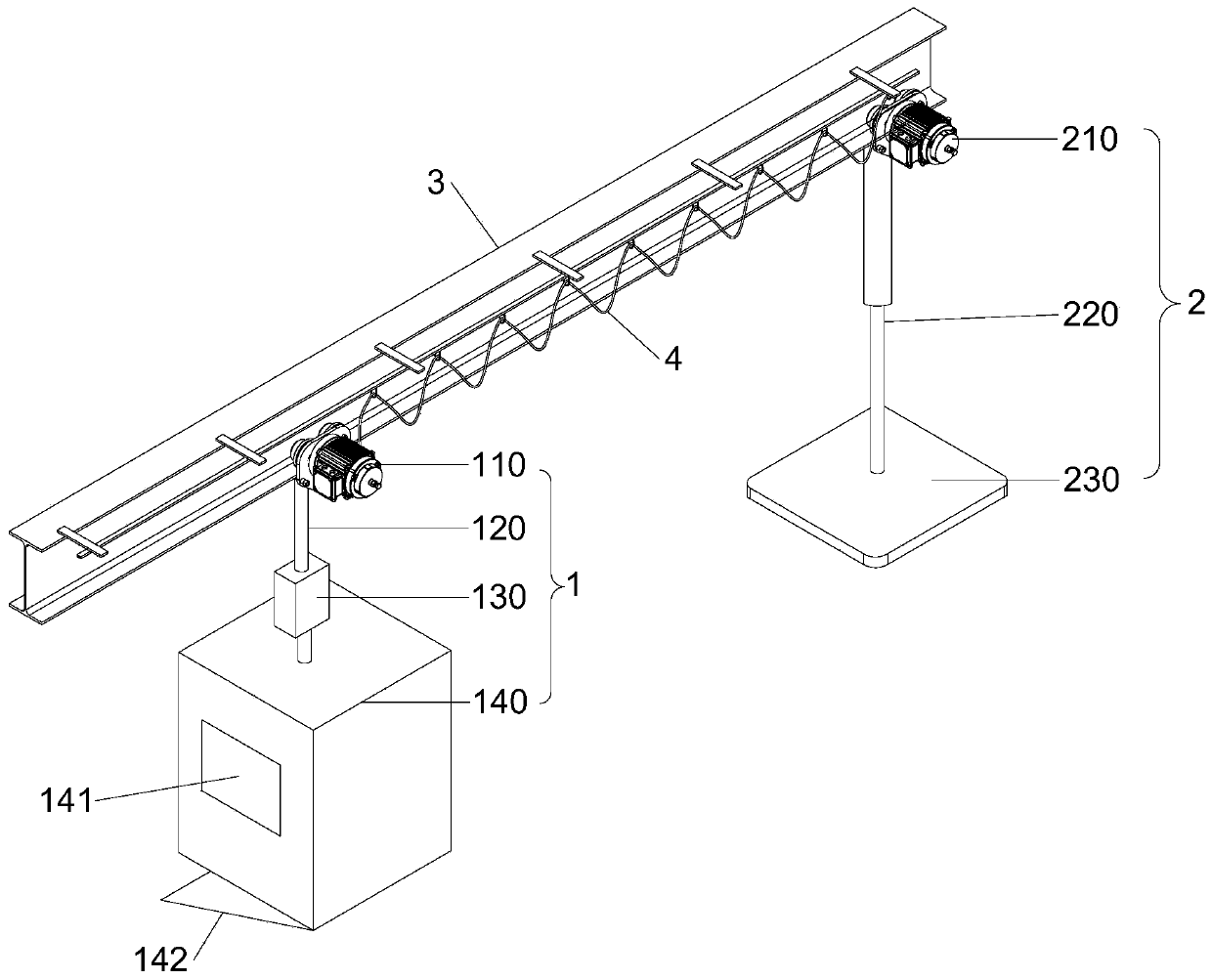

Embodiment 1

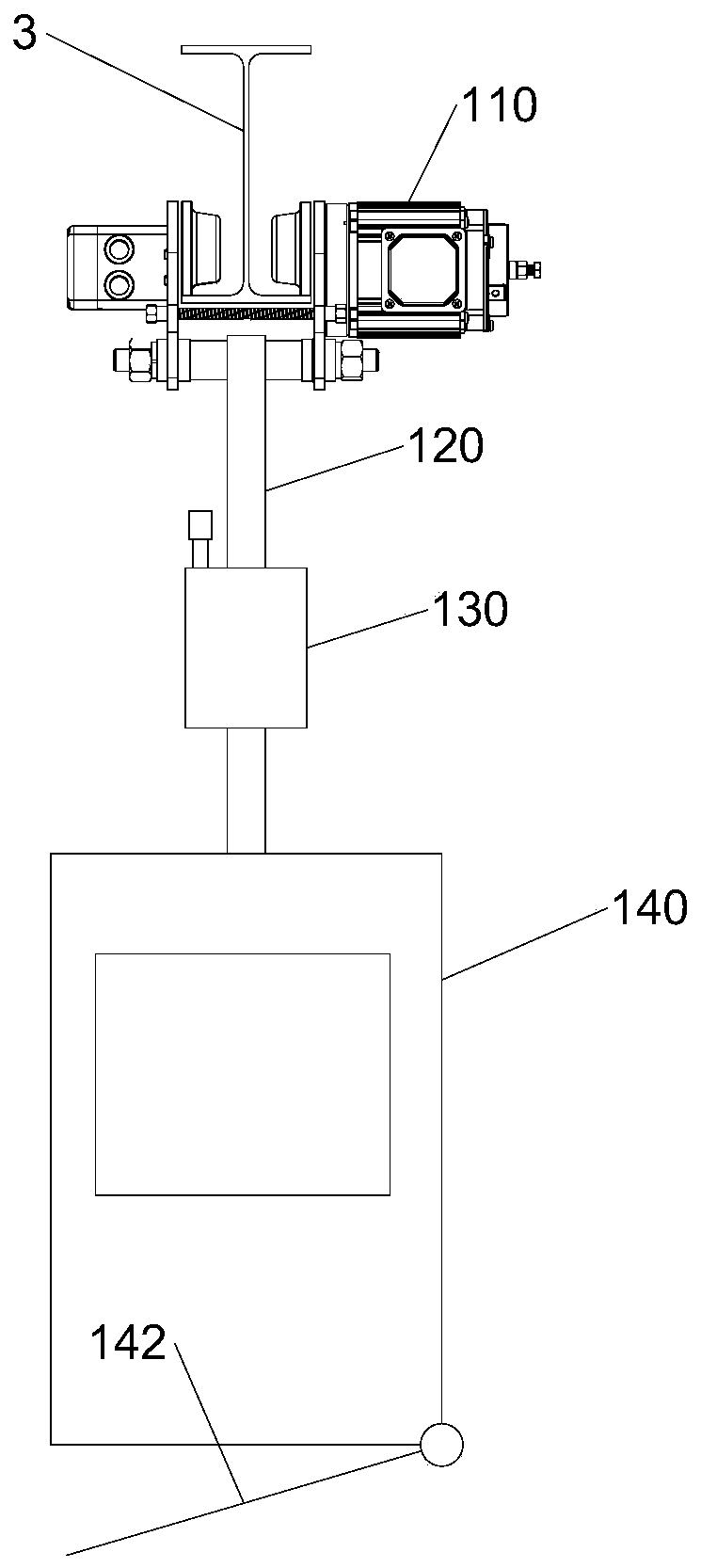

[0042]The suspended pod type mobile weighing and dispensing device of the present invention includes a guide rail 3 installed on the upper end of the garbage room, the two ends of the guide rail 3 are respectively hoisted with a mobile dispensing device 1 and a mobile compression device 2, and the bottom of the guide rail 3 is provided with multiple A garbage bin, mobile throwing device 1 comprises the first mobile sports car 110, boom 120, load cell 130 and pod body 140; The lower end of the boom 120 is connected to the pod body 140 through the load cell 130; the mobile compression device 2 includes a second mobile sports car 210, an electric compression rod body 220 and a compression disc 230, the second mobile sports car 210 and the guide rail 3 Connection, the upper end of the electric compression rod body 220 is connected to the second mobile sports car 210, and the lower end of the electric compression rod body 220 is connected to the compression disc 230.

[0043] After...

Embodiment 2

[0045] The use method of the suspension pod type mobile weighing and throwing garbage device of the present invention comprises the following steps:

[0046] S1 When the load cell 130 senses that garbage is dropped into the pod body 140, the first mobile sports car 110 on the upper end of the boom 120 is driven to move along the guide rail 3; Control the number of rotations of the motor or use a position sensor to limit the first mobile sports car 110 to automatically reach the set point along the track, and use electromagnetic brakes, springs or friction plates to brake;

[0047] S2 then sends a signal to the receiving device of the pod body 140 to open the drop-in door 142 at the lower end of the pod body 140, and the garbage in the pod body 140 is automatically dumped into the trash can at the corresponding position below the guide rail 3; The lower end of the pod body 140 is dropped into the door 142, and the pod body 140 is driven by the first mobile sports car 110 to ret...

Embodiment 3

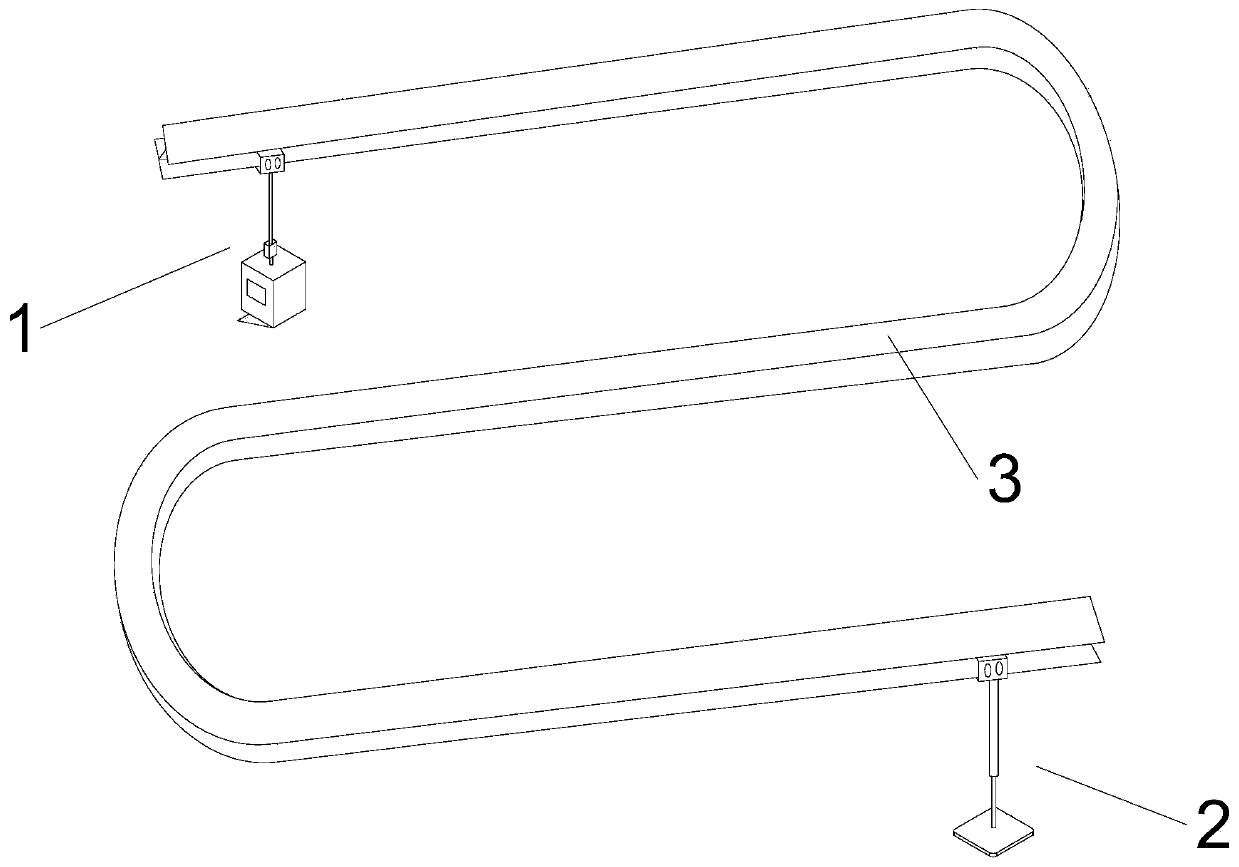

[0052] This embodiment is further optimized on the basis of Embodiment 1 as follows: the guide rail 3 is a linear I-steel track, and the garbage cans are arranged side by side under the linear I-steel track. The guide rail 3 is an S-shaped I-steel track, and the garbage can is arranged linearly below the S-shaped I-steel track.

[0053] Its working principle and process are: set two initial positions respectively at the first and last ends of the same guide rail 3, install the mobile delivery device 1 at the initial position of the head end, and install the mobile compression device 2 at the initial position of the tail end. Sorting and numbering are carried out along the track according to the set distance, and N position points are set. The track position points correspond to the trash cans in the fixed area along the line below, and the corresponding sorting numbers are set, and N trash cans are set. And in accordance with the priority sequence set in advance by the program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com