Machining method for Y-shaped groove part of hydraulic support structural part

A hydraulic support and parts processing technology, applied in metal processing equipment, manufacturing tools, plasma welding equipment, etc., can solve the problems of long processing process, low efficiency, and low groove accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

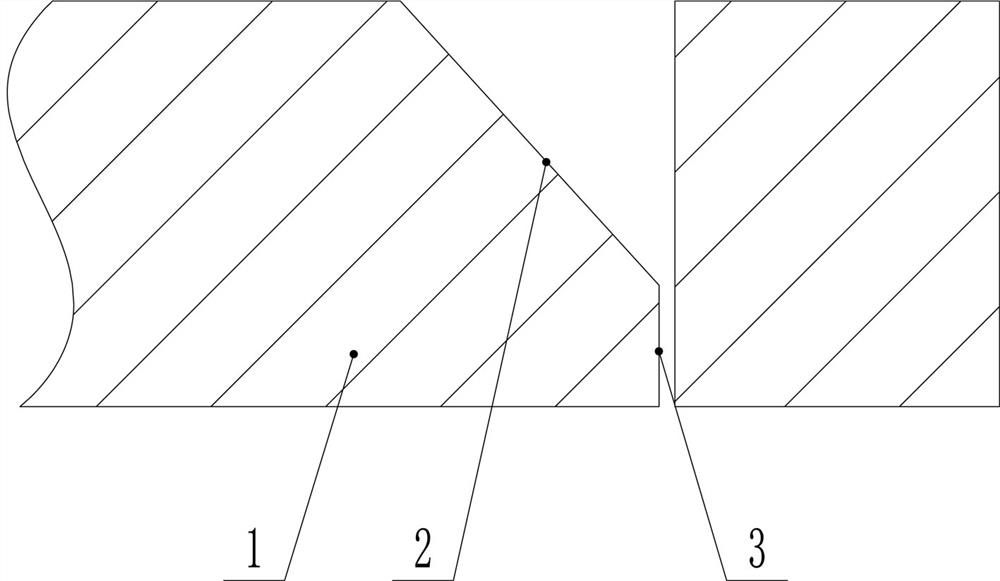

[0027] Such as Figure 2-5 As shown, a method for processing a Y-shaped groove part of a hydraulic support structure, when the thickness of the blunt side 3 is required to be greater than 2mm, includes the following steps:

[0028] (1) Place the steel plate to be cut flat on the workbench of the rotary plasma cutting machine;

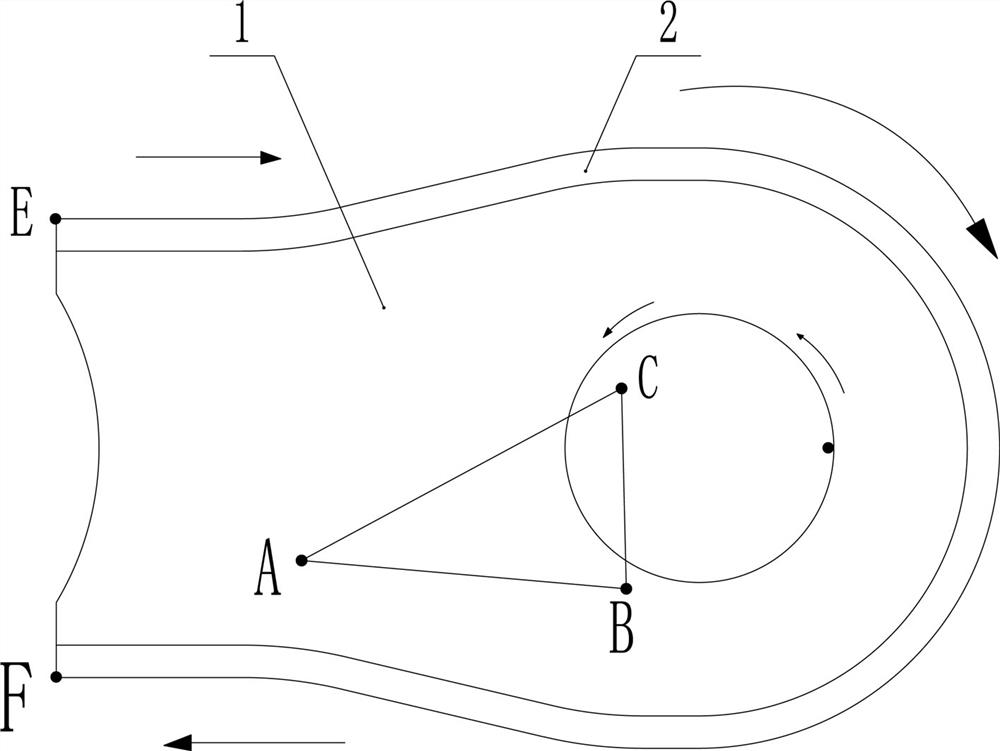

[0029] (2) Collect the spatial coordinates of three points on the top surface of the steel plate that are not on the same straight line; specifically, the tip of the torch 4 can be used to touch the three spatial points A, B, and C on the surface of the steel plate, and through contact sensing method to obtain the three-point space coordinates;

[0030] (3) Calculate the angle β between the steel plate and the horizontal plane according to the spatial coordinates of the three points;

[0031] (4) Adjust the angle of the torch 4 of the rotary plasma cutting machine so that the angle between it and the horizontal plane is β+90° (that is, it is perpendic...

Embodiment 2

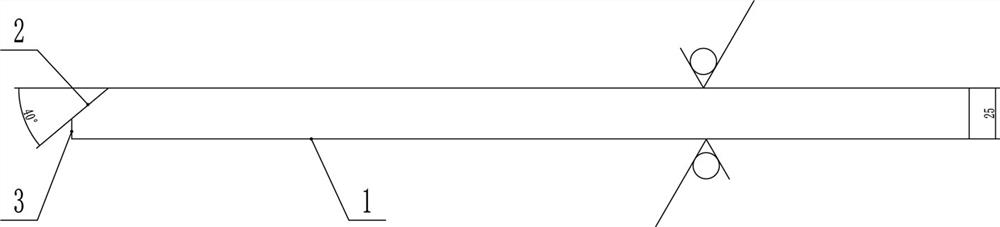

[0036] Such as Figure 6-9 As shown, a method for processing Y-shaped groove parts of a hydraulic support structure, when the thickness of the blunt side 3 is required to be 2mm, includes the following steps:

[0037] (1) Fix the steel plate to be cut on the worktable of the rotary plasma cutting machine;

[0038] (2) Collect the spatial coordinates of three points on the top surface of the steel plate that are not on the same straight line;

[0039] (3) Calculate the angle β between the steel plate and the horizontal plane according to the spatial coordinates of the three points;

[0040] (4) Set the angle of the target Y-shaped groove 2 as α, and use undercut cutting, that is, the opening side of the Y-shaped groove 2 faces away from the cutting torch 4, and adjust the angle between the cutting torch 4 and the horizontal plane to 90°-α- β, cut from one end of the cutting Y-shaped bevel edge of the target part 1 to the other end. During the cutting process, use the function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com