Installation construction method for extra-large glass of sloping roof

An installation method and technology of inclined roof, applied in the direction of roof, roof engineering tools, construction, etc., can solve the problem of slope, hoisting equipment cannot be hoisted in place at one time, affecting the progress and safety of construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

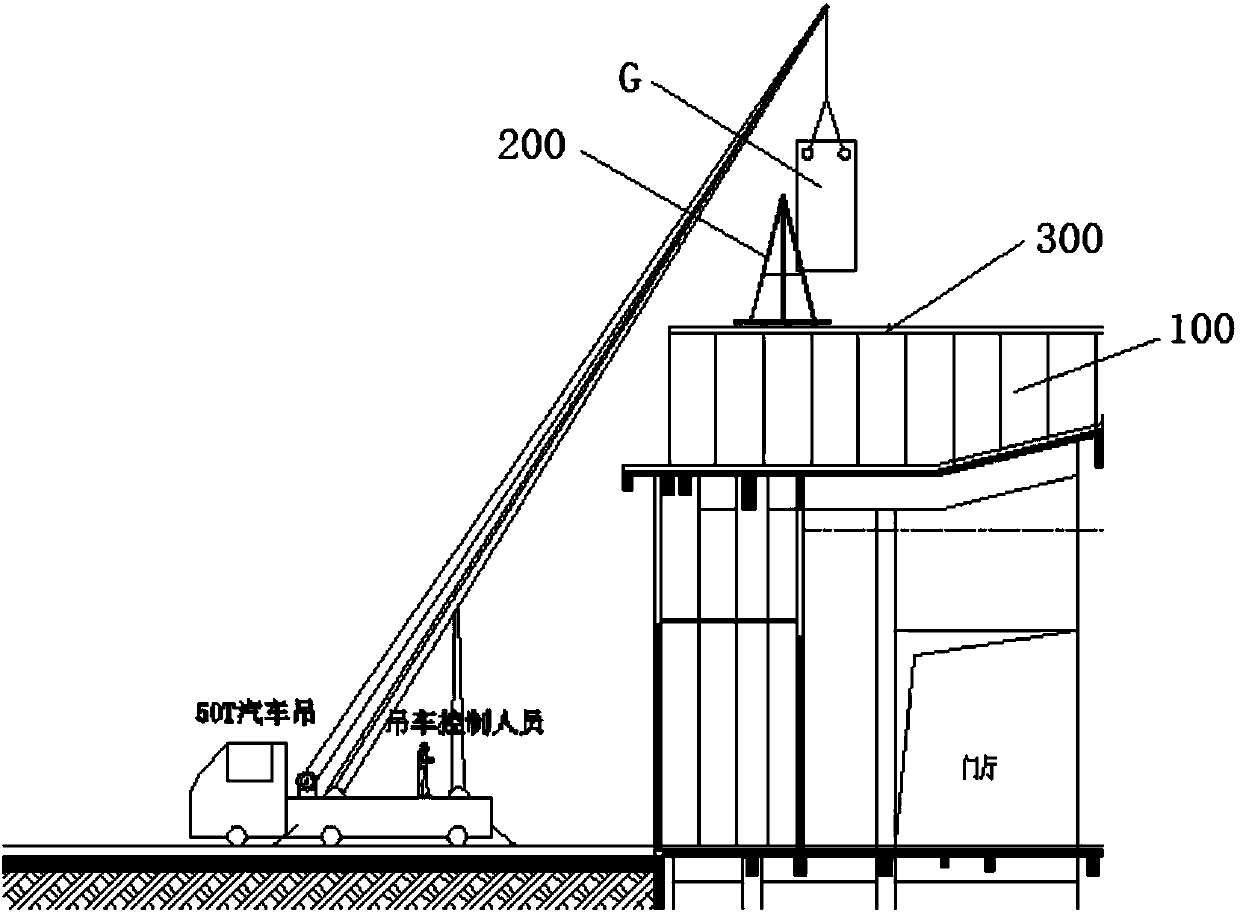

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

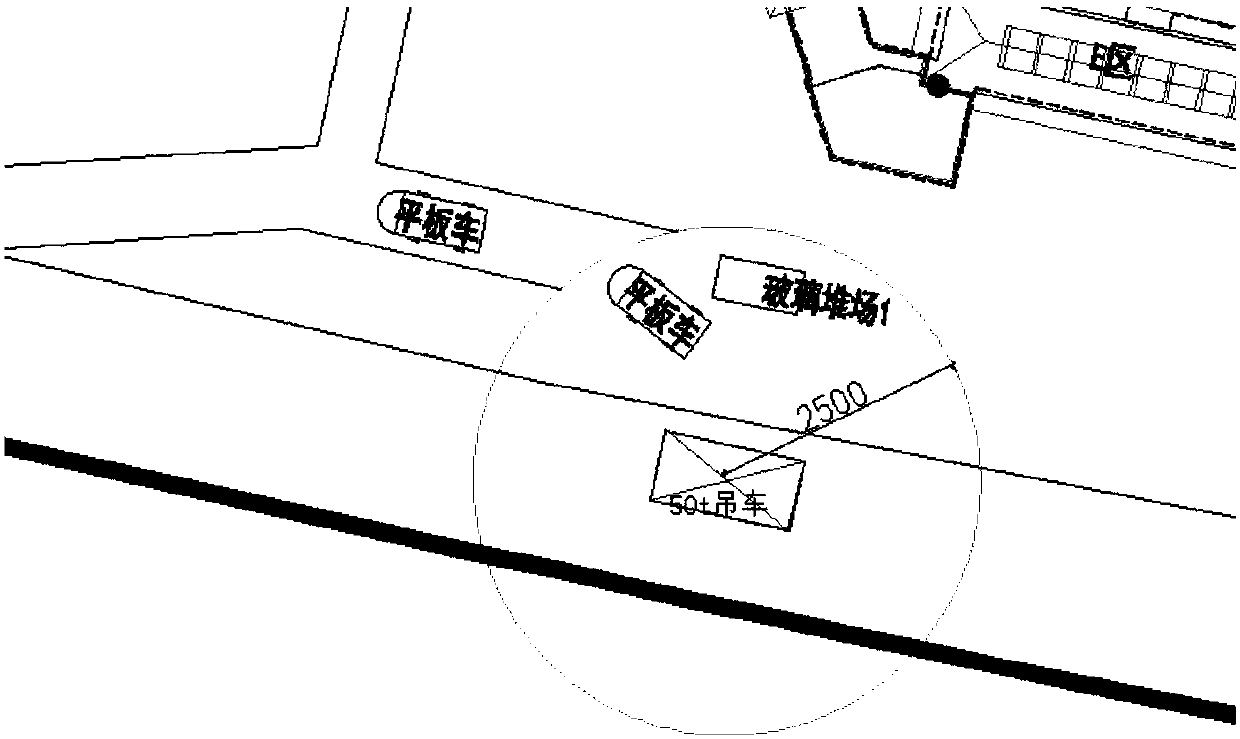

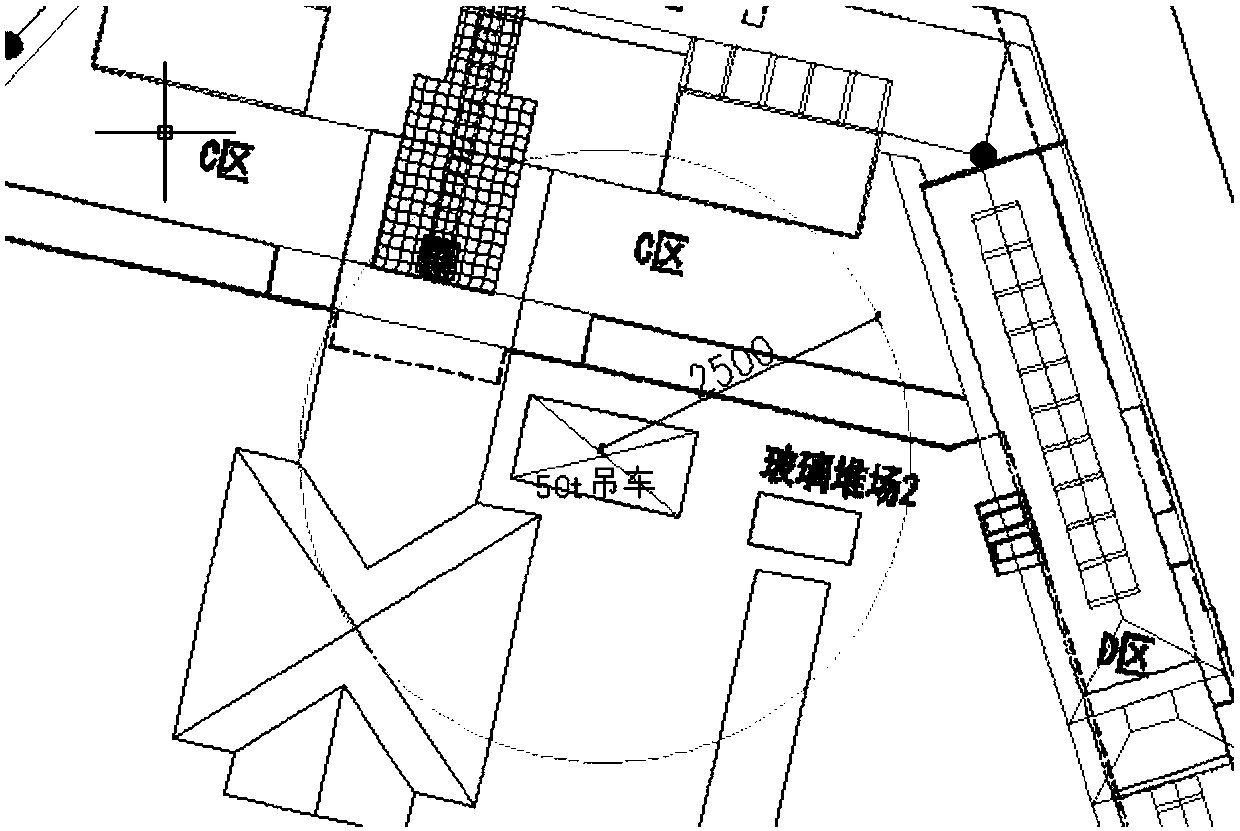

[0032] The super-large glass installation method on inclined roofs is used in hotels, shopping malls and other buildings with complex shapes.

[0033] In this embodiment, the glass curtain wall on the inclined roof has a grid width of 2.4 meters and a height of 4.5 meters, which belongs to super large and super heavy glass construction. This embodiment is located on the 5th, 6th, 7th, and 8th floors of the glass curtain wall at the sloping roof elevation of 16.89 meters. The outside of the glass curtain wall is a large arch shape, and the top is a structural floor, which belongs to the construction technology of "concave space" hoisting.

[0034] The super-large glass curtain wall covers an area of 300 square meters, which is a vertical and horizontal hidden frame curtain wall. The main keel is a 120x80x10 steel frame, the horizontal keel is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com