Draining method for beef processing

A beef draining technology, applied in food drying, food science, etc., can solve the problems that affect the work of cooked beef, cannot fully drain the moisture of beef food, and slow drying speed, etc., to achieve good draining effect, easy operation, and air-drying thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The draining method of beef processing comprises the steps:

[0024] A. Place the beef at the bottom of the drain tank, and pass high-pressure air into the heating box through the air intake pipe. When the high-pressure air passes through the turbine of the heating box, it is heated into hot air, and then the hot air is guided through two jet pipes respectively. Flow to the upper and lower parts of the drain tank, and deliver hot air from the upper and lower sides of the beef;

[0025] B. When the airflow passes through the turbine in the heating box, the airflow pushes the turbine, and the turbine starts to rotate, so that the pressing rod moves down, and the beef is squeezed through the pressure head;

[0026] C. When the draining work stops, the air flow to the intake pipe is stopped, and the pressure rod is reset by the spring connected to the top of the draining tank;

[0027] Wherein, a closed conductive coil is wound on the outside of the turbine, and an alterna...

Embodiment 2

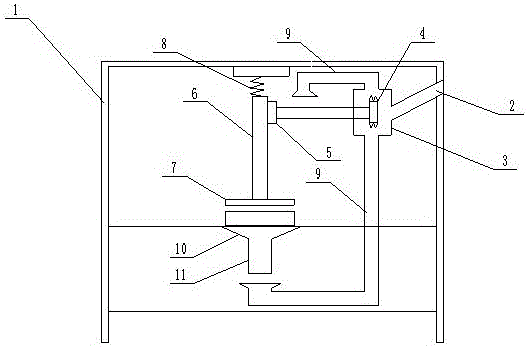

[0035] The used equipment of beef processing method in embodiment 1 is basically as figure 1 Shown:

[0036] The draining device for beef processing comprises a draining box 1, the side wall of the draining box 1 is provided with an air inlet pipe 2, the air inlet pipe 2 is connected with a heating box 3, a turbine 4 is installed inside the heating box 3, and a turbine 4 is installed outside the turbine A closed conductive coil (not shown) is wound, and an alternating current is passed through the closed conductive coil, so that the closed conductive coil generates an alternating magnetic field, and an eddy current effect is generated inside the entire turbine 4, so that the turbine 4 generates heat, and when the airflow passes through the turbine 4 When it is heated, it is heated into a hot air flow; the turbine 4 is coaxially provided with a gear 5, and the gear 5 is engaged with a pressure rod 6, and the lower end of the pressure rod 6 is provided with a pressure head 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com