Split negative-pressure backflow machine and technological method

A technology of negative pressure flowback and process method, which is applied in the field of negative pressure plugging removal and acidification flowback of oil and water wells. Squeeze the acid channel and reduce the effect of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

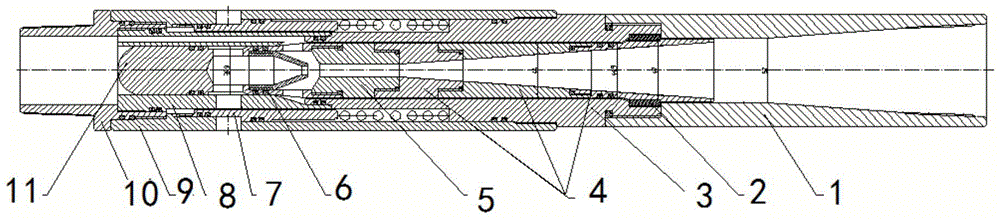

[0021] Embodiment 1: The purpose of the present invention is to apply the principle of the negative pressure flowback device to make a split type negative pressure flowback device that can be delivered to the throat. This split structure increases the flow channel of the liquid and solves the problem that the acid squeeze pressure is too high and the temporary plugging agent is easy to block the throat; by using it in conjunction with the sliding sleeve, it can realize stratified negative pressure flowback acidification.

[0022] Such as figure 1 As shown, a split-type negative pressure flowback device is composed of an upper joint 1, a lock ring 2, an intermediate joint 3, a diffuser pipe 4, a throat pipe 5, a nozzle 6, a backwash valve 7, a shunt joint 8, and an outer cylinder 9 , lower joint 10, guide cone 11, and other parts are combined, the upper joint 1 is connected to the middle joint 3, the middle joint 3 is connected to the outer cylinder 9, the shunt joint 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com