Method for manufacturing high-strength screws with fine threads for wind-driven generator foundations

A technology of wind power generator and manufacturing method, which is applied in the field of manufacturing high-strength screw with fine thread, which can solve the problems of large calorific value, unstable forming, and difficult to dissipate, so as to reduce resistance, improve extrusion efficiency and extrusion stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] One embodiment of the manufacturing method of the high-strength screw of the present invention will be described in detail below.

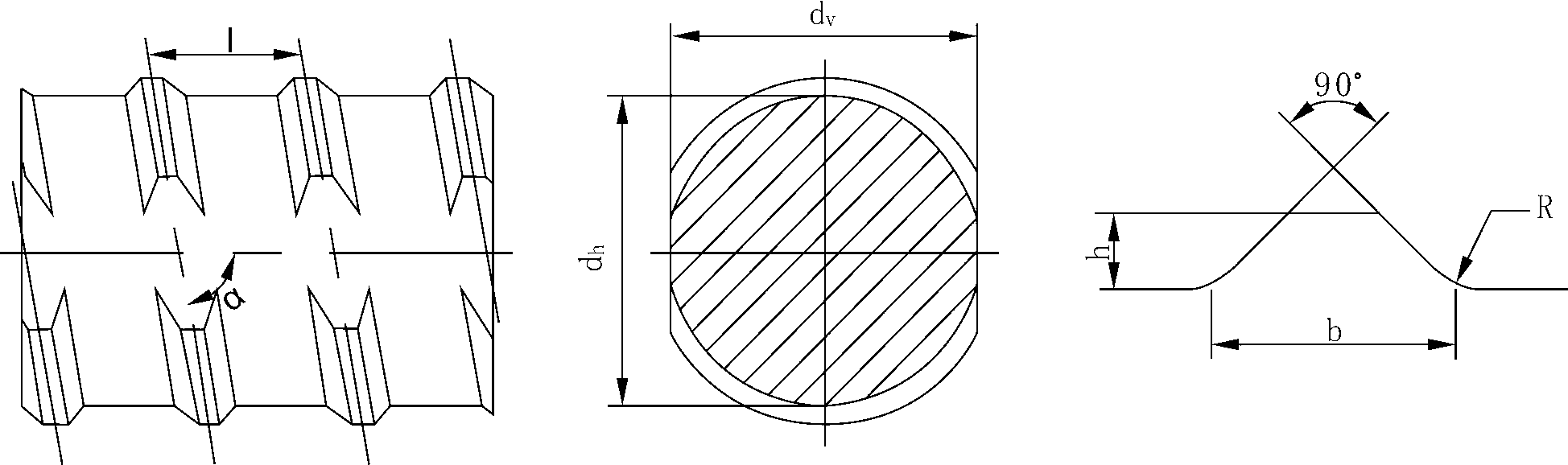

[0036] attached figure 1 middle: d h —diameter of base circle, d v —base circle diameter, h—thread height, b—thread bottom width, l—thread pitch, R—thread root arc, α—lead angle;

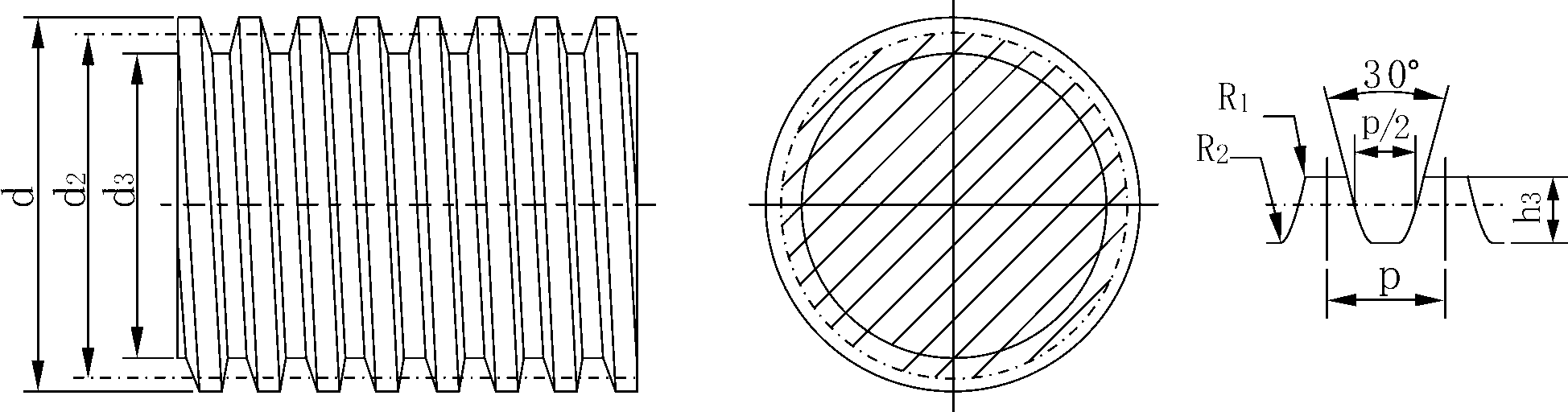

[0037] attached figure 2 Middle: d—diameter of outer circle, d 2 —pitch diameter, d 3 —Minor diameter, R1—outer diameter fillet radius, R2—thread root angle radius, P—thread pitch, h3—thread height;

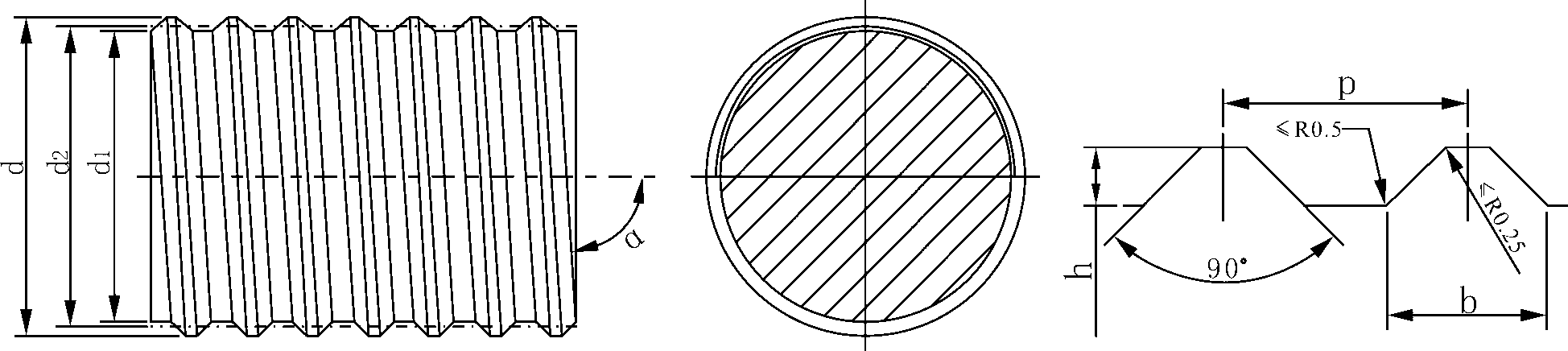

[0038] attached image 3 Middle: outer diameter d, middle diameter d 2 , base circle diameter d 1 , Lead angle α, thread height h=2mm, pitch P=8.45mm, outer diameter fillet radius R≤0.25mm, thread root angle radius R≤0.5mm, thread bottom width b=5.5mm.

[0039] see image 3 , the thread of the fine-threaded high-strength screw for the foundation of the wind power generator in the embodiment of the present invention is a fine-pitched trapezoidal thread, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com