Waste ring-pull can squashing equipment and working method thereof

A technology for discarded cans and equipment, which is applied in the direction of manufacturing tools and presses, etc. It can solve the problems of high manufacturing cost, large volume of cans, and low efficiency, and achieve the effects of low production cost, reduced manpower, and improved extrusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

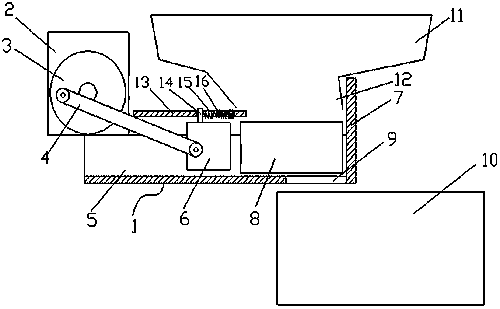

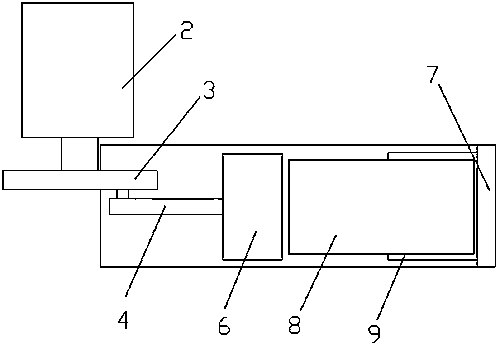

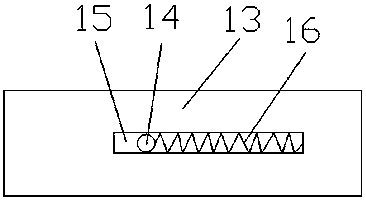

[0016] The discarded cans squeezing equipment of the present invention comprises a machine base 1 and a vertical turntable 3 mounted on the machine base 1 and driven by a motor 2, the distal part of the vertical turntable 3 is hinged to the first end of the push rod 4 , the base 1 is also provided with a guide rail channel 5 and an indenter 6 arranged in the guide rail channel, the rear part of the indenter 6 is hinged with the second end of the push rod 4, and the end of the guide rail channel There is a vertical plate 7, and the workpiece (pop cans, etc.) 8 to be extruded is filled in the guide rail channel between the pressure head 6 and the vertical plate 7. The bottom of the guide rail channel has an open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com