Plastic ampule

A technology for ampoules and plastics, which is applied in the field of filling plastic ampoules with liquid medicine, and can solve problems such as difficulty in removing the inner solution and easy scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

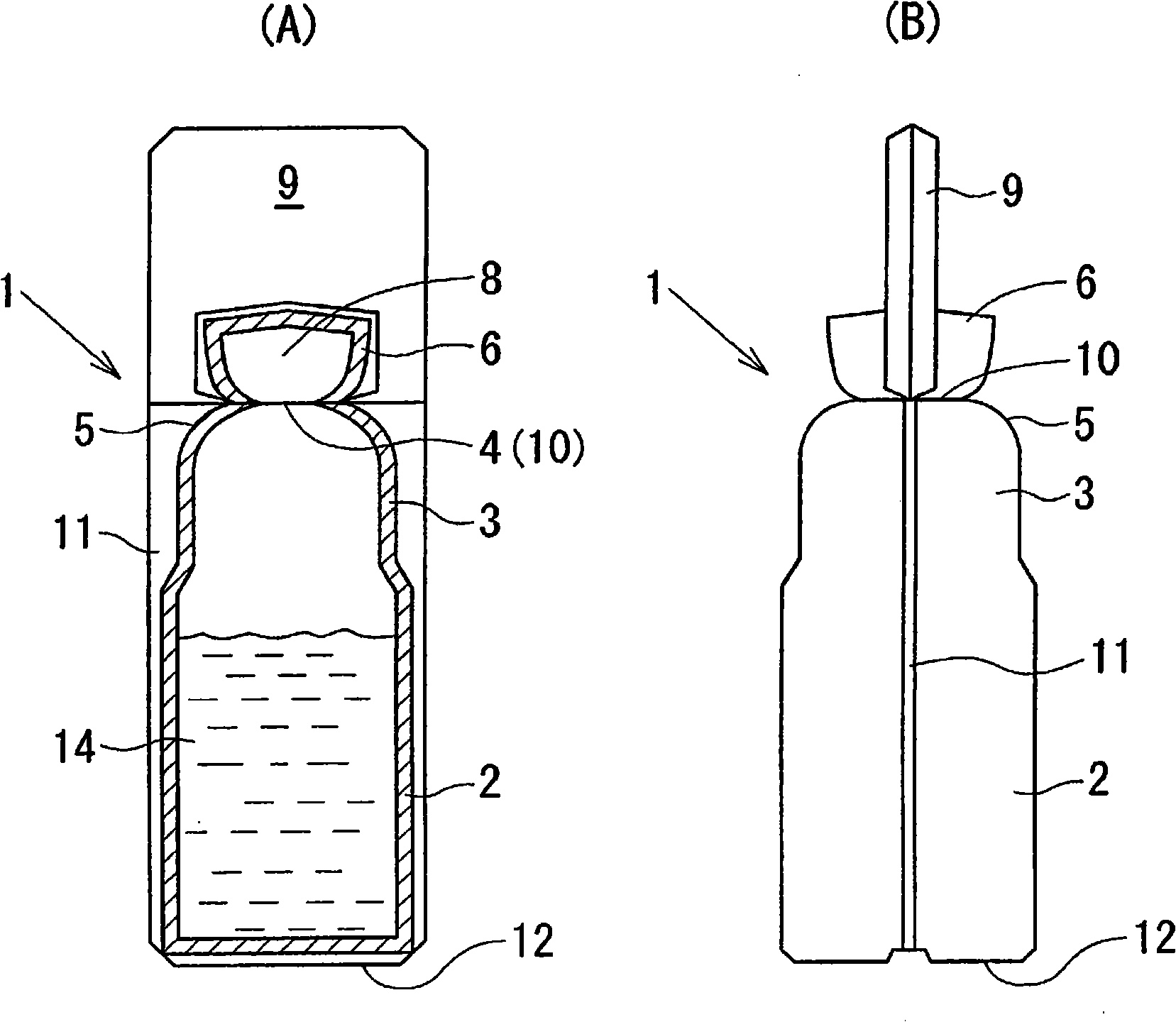

[0129] exist figure 1 In the plastic ampoule 1 shown in (capacity 5mL, inner solution volume 3mL), the size of the hollow part 8 of the head 6 is set as follows (refer to Figure 4 (A)).

[0130] The maximum dimension of the horizontal direction of the hollow part 8 (the dimension of the largest diameter part of the horizontal direction of the hollow part 8) W': 10mm, the maximum dimension of the up-down direction of the hollow part 8 (between the lower end of the hollow part 8 and the top of the upper inner surface The height of the central part in the vertical direction) H': 7mm, the minimum dimension of the hollow part 8 in the vertical direction (the height of the inner surface 7 of the hollow part 8) H: 6mm, and the inner diameter W of the opening 4: 5.5mm.

[0131] Here, the height of the inner surface 7 of the hollow portion 8 is defined as the lower end portion of the hollow portion 8 (corresponding to the opening portion 4 and the opening portion 10) and the upper e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter size | aaaaa | aaaaa |

| Inner diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com