Algae-water separation port

A technology of algal water separation and cyanobacteria, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of insufficient environmental stacking capacity, long time, storage difficulties, etc., to inhibit the reproduction of spoilage bacteria, improve water drainage, and promote beneficial microorganisms. effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

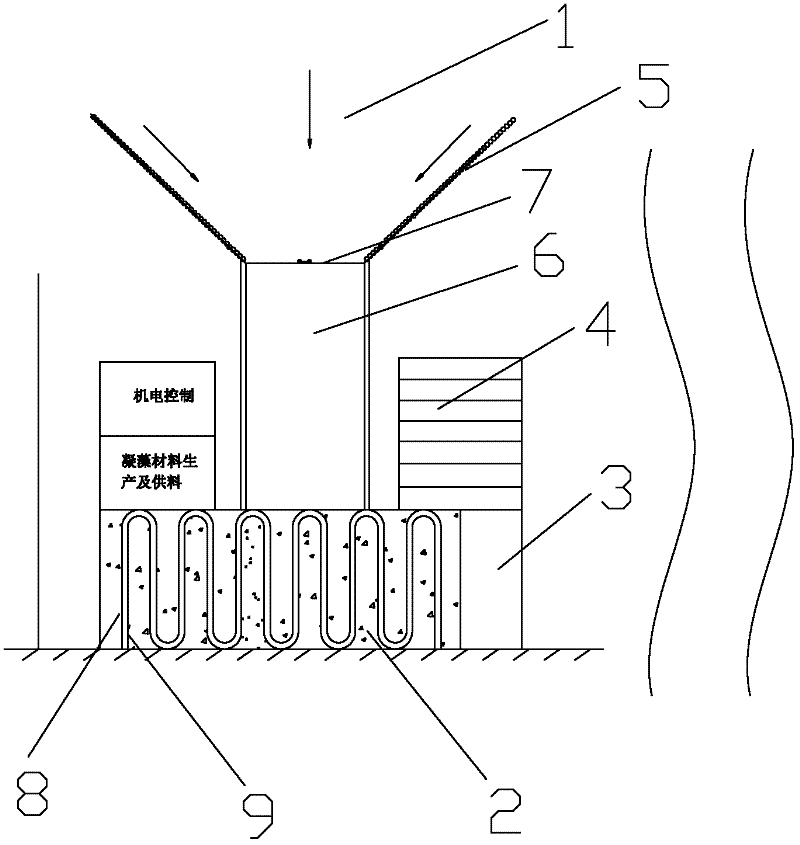

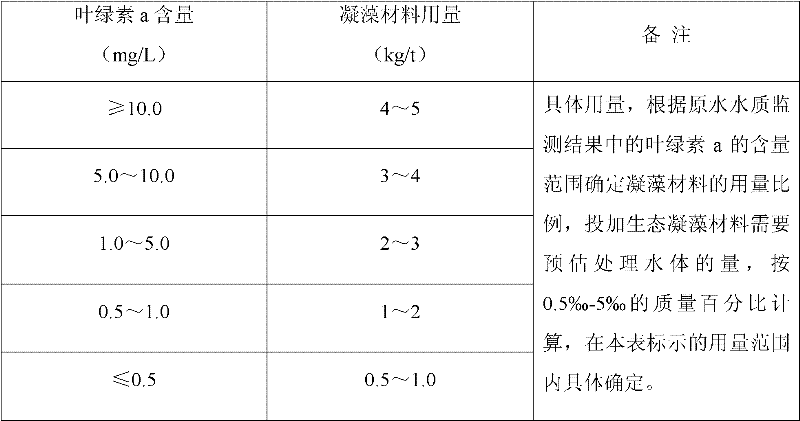

[0035] In this embodiment, the algal water separation port is sequentially provided with a cyanobacteria induction area 1, an algae water separation area 2, an algae mud concentration area 3 and a transformation storage area 4; the cyanobacteria induction area 1 is provided with two guide rails 5 with horn-shaped opening It communicates with the collection channel 6, and the guide column 5 communicates with the collection channel 6 through the gate 7; the algae-water separation area 2 is provided with a feed pipe 8 and an aeration pipe 9 for algae condensation material.

[0036] The conversion storage area 4 is provided with multiple storage pools.

[0037] The guide bar 5 is a flexible suspension fence or a flexible fabric membrane inflation column.

[0038] The cyanobacteria induction zone 1, the algae water separation zone 2, the algae mud concentration zone 3 and the conversion storage zone 4 of the present invention can be set independently of each other, and a manual ope...

Embodiment 2

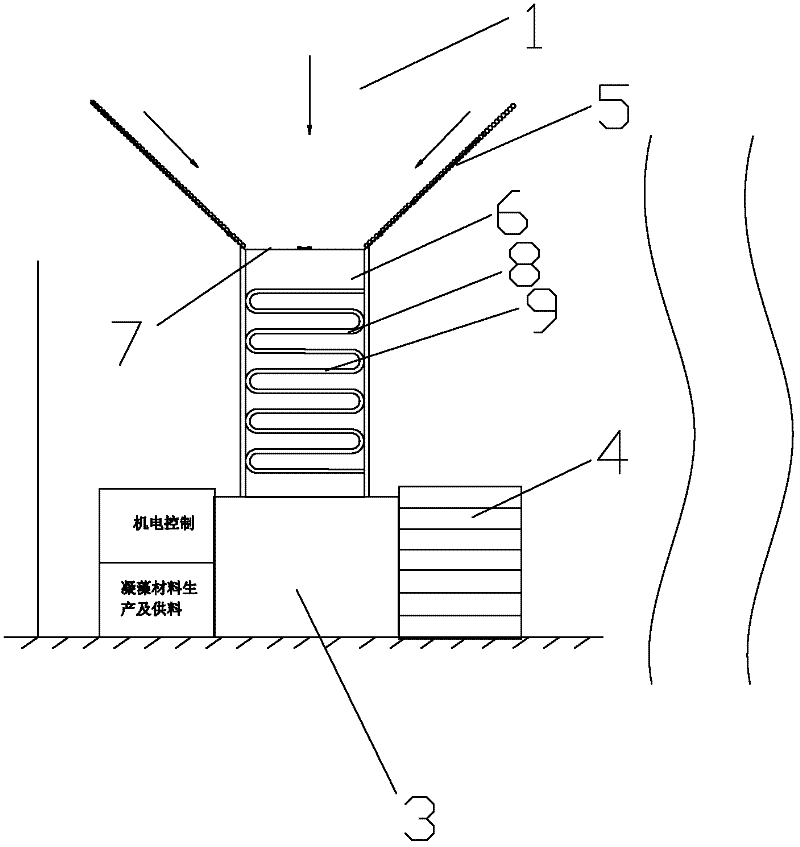

[0042] In this embodiment, the algae-water separation port is sequentially provided with a cyanobacteria induction area 1, an algae mud concentration area 3, and a transformation storage area 4; , the guide column 5 communicates with the collection channel 6 through the gate 7; the collection channel 6 is provided with a feed pipe 8 and an aeration pipe 9 for algae condensation material.

[0043] The conversion storage area 4 is provided with multiple storage pools.

[0044] The guide bar 5 is a flexible suspension fence or a flexible fabric membrane inflation column.

[0045] The processing flow of this program is as follows:

[0046] Open the gate 7, and the cyanobacteria gather in the collection channel 6 from the area surrounded by the guide rail 5 with the help of wind force. After reaching a certain level, the gate 7 is closed, and the algae water can be initially concentrated and drained through the collection channel 6, thereby reducing the subsequent ecological algae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com