Linen fiber bleaching device for textile production

A flax fiber and installation groove technology, applied in the field of textile production, can solve problems such as affecting the quality of bleaching processing, shortening the bleaching time of flax fibers, and damage to flax fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

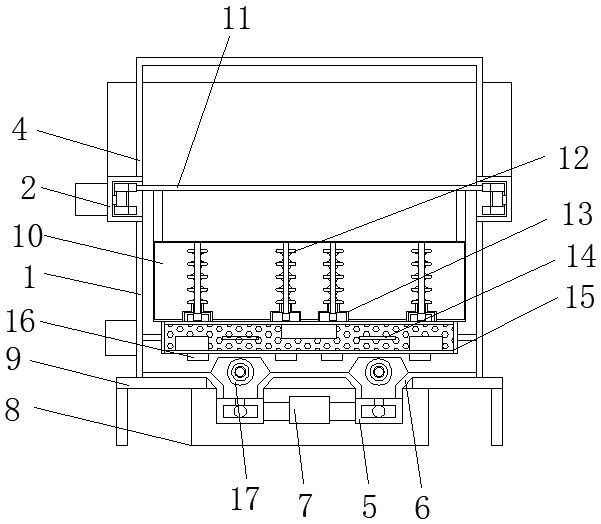

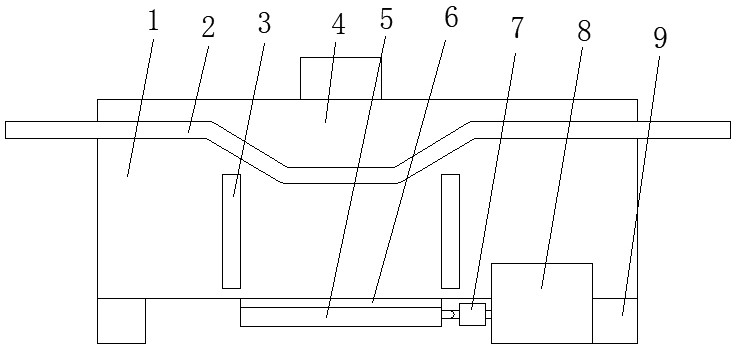

[0027] refer to Figure 1-4 , a flax fiber bleaching device for textile production, comprising a housing 1, a plurality of support frames 9 are fixedly installed on the bottom of the housing 1, and driving mechanisms 2 are fixedly installed on both sides of the top of the housing 1, and two driving mechanisms 2. A capping mechanism 4 is fixedly installed between the top ends of the drive mechanism 2. The middle section of the drive mechanism 2 is provided with a bleaching section extending downward. Both ends of the drive mechanism 2 extend to the outside of the housing 1. The bottom of the housing 1 is provided There are two installation grooves 6, and the bottom ends of the two installation grooves 6 are fixedly installed with a rectangular tube 5, the top of the rectangular tube 5 is provided with a plurality of through holes, and the bottom side of the housing 1 is fixedly installed with a filter 8, And between the filter 8 and the two rectangular tubes 5, a delivery pump ...

Embodiment 2

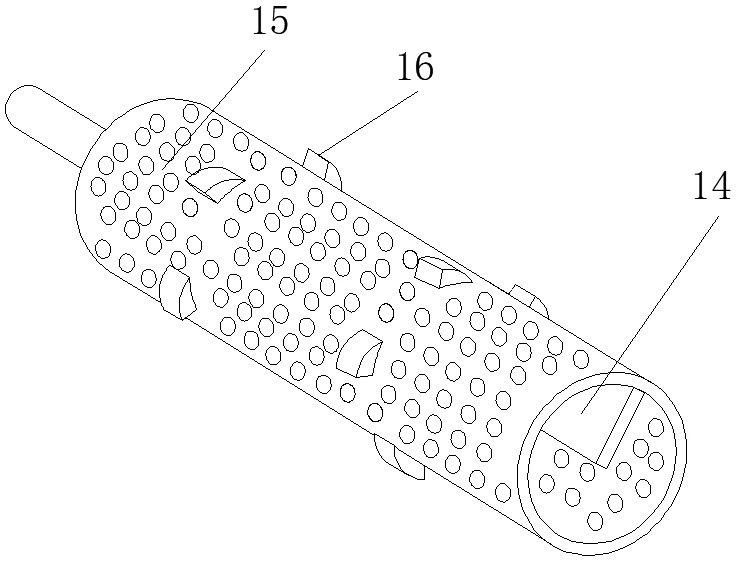

[0036] refer to Figure 1-5 , a flax fiber bleaching device for textile production. Compared with Embodiment 1 in this embodiment, the elastic rod mechanism 12 includes a rod body 121 made of flexible material, and the outer top end of the rod body 121 is provided with a plurality of ring-shaped convex structures 122 , and the bottom end of the rod body 121 is provided with a spherical sliding portion 123 .

[0037] When this embodiment is in use, the sliding portion 123 of the spherical structure is arranged to reduce the friction with the arc-shaped raised block 16, so as to avoid affecting the rolling of the net cylinder 15. At the same time, the setting of the annular raised structure 122, Reinforce around the rod body 121 to prevent the rod body 121 from being bent to the side due to force and cause shedding, and during the deformation process of the rod body 121 up and down, the arc-shaped convex block 16 increases the contact area with the flax fiber, and at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com