Pretreatment technology before digital printing of high-count cotton fabric

A technology of digital printing and high-count cotton, which is applied in the treatment of textile materials, the biochemical treatment of enzymes/microorganisms, and the treatment of liquid/gas/steam textile materials. and other problems to achieve the effect of improving bulkiness, improving bleaching efficiency, increasing cleanliness and whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

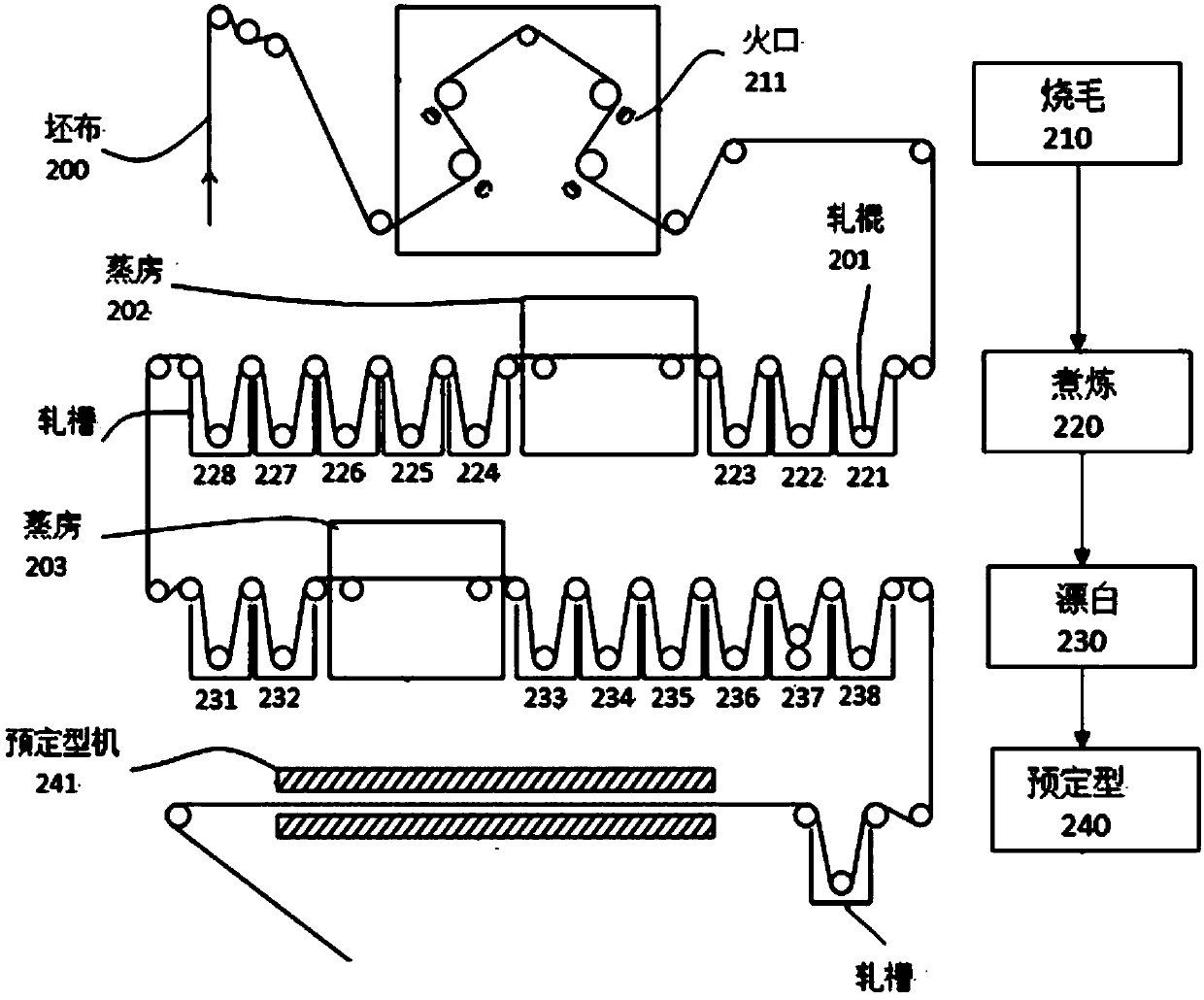

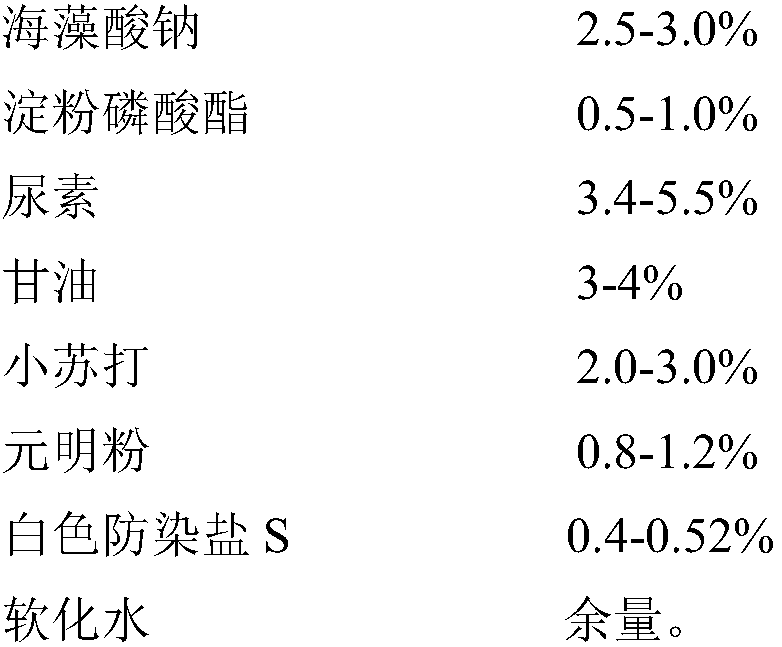

[0041] A pretreatment process for digital printing of high-count cotton fabrics, comprising the following steps: singeing → ultrasonic boiling → mercerizing → padding slurry → digital printing, specifically as follows:

[0042] 1) Singeing (210): Two positive and two negative singeings are used, and the speed is 60m / min;

[0043] 2) Ultrasonic cooking and bleaching:

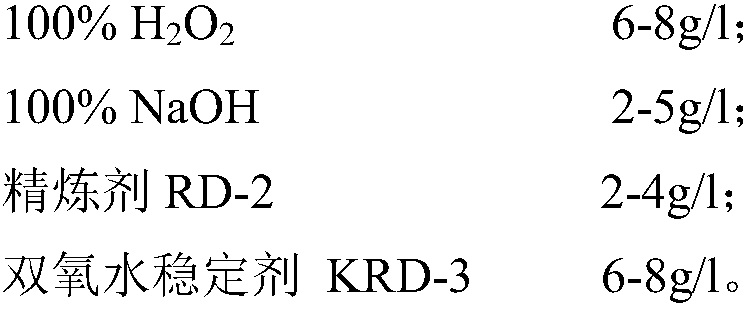

[0044] ①Scouring (220): The fabric after singeing is fed into the long car for boiling and bleaching at a speed of 45m / min. The temperature of [202] is controlled at 100°C, and the temperature of the rolling groove in the back section of the cooking and steaming box [202] is controlled at 80-90°C; Need to go through the rolling grooves 221, 222, 223 in the front section of the steaming box successively, the fabrics after the steaming box go through the washing rolling grooves 224, 225, 226, 227, 228 successively, after the rolling grooves in the front section of the boiling box [202] The excess rate of fabric r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com