Patents

Literature

59results about How to "Shorten bleaching time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process of grass cloth

InactiveCN102747436ALow residual glue rateImprove dye uptakeBleaching apparatusVegetable materialYarnBacillus alcalophilus

The invention discloses a manufacturing process of grass cloth. The process comprises the steps of pre-stage preparation, degumming, warp yarn preparing, weaving, bleaching, dehydrating, dyeing, finishing, and packaging. According to the invention, ramie is subjected to the degumming process by using bacillus alcalophilus, such that ramie residual gum content can be effectively reduced, product safety is improved, and cloth dye uptake can be improved. With modification upon the bleaching process, cloth color stability is ensured, and bleaching duration can be reduced, such that working efficiency can be improved. The grass cloth manufacturing process provided by the invention is advantaged in low environmental pollution, high dye uptake, high color fastness, and short dyeing duration. With the process, economic benefit can be improved. The process is suitable for industrialized productions.

Owner:TAICANG MINGLIU GARMENT

Pearl bleaching process

The invention discloses a pearl bleaching technology, which comprises the following steps that: in the sufficient sunshine, pearls after being polished are put into prepared bleaching liquid and soaked at the temperature ranging from 14 to 17 DEG C for 48 to 50 hours for bleaching treatment, and then rinsed and dried; the step is repeated for at least one time; classification: unqualified pearls are screened out and the bleaching treatment for unqualified pearls continues to be repeated for at least one time. In the invention, the format of the bleaching liquid, consisting of a hydrogen peroxide bleaching agent, a composite interface agent, a composite catalyst and a methanol solvent, is adopted for bleaching at the low temperature of 14 to 17 DEG C so as to realize the good bleaching effect under low concentrations of the hydrogen peroxide bleaching agent within a short time, thus effectively reducing the damage to the skin of the pearl and improving the glossiness of the pearl. By adopting the method of the invention, the pearls bleached have better gloss, smooth surface, higher whiteness and good stability.

Owner:浙江梵沛珍珠股份有限公司

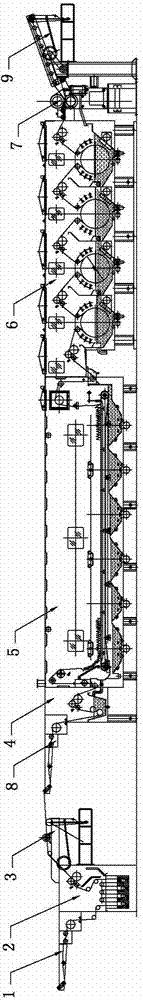

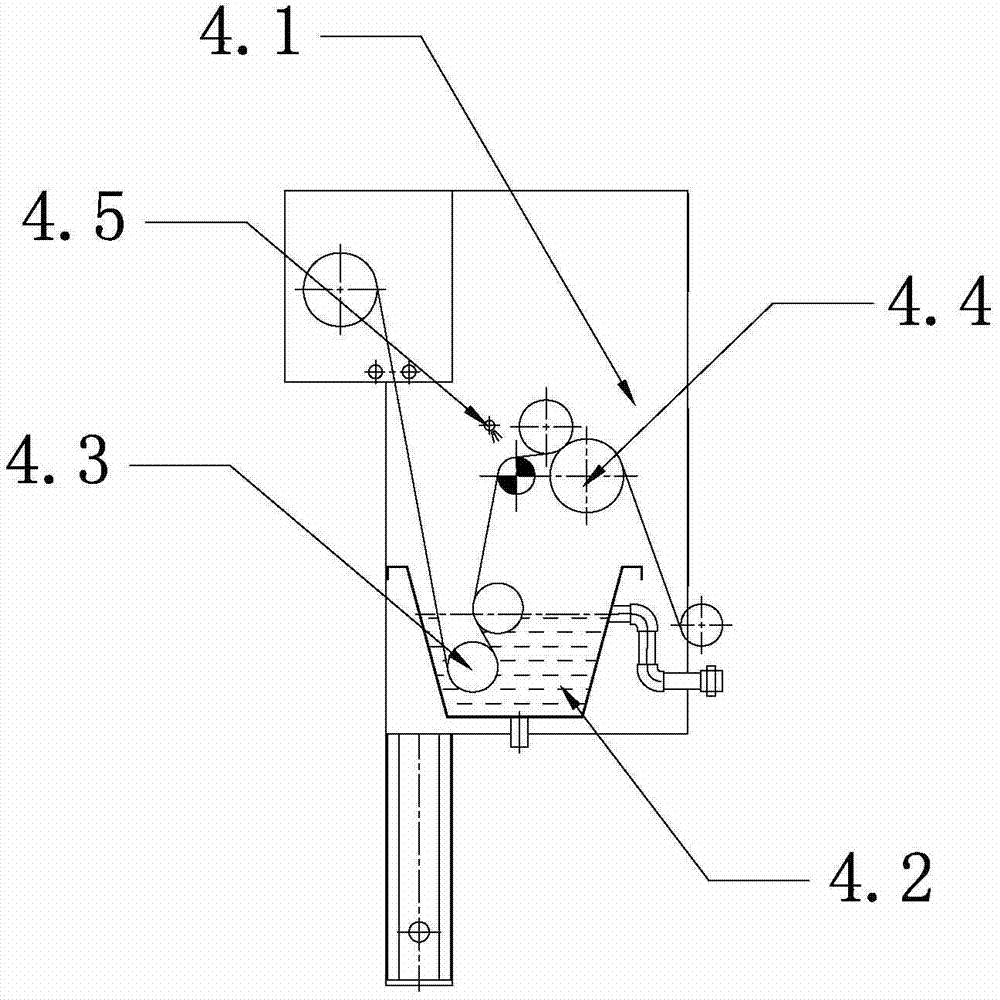

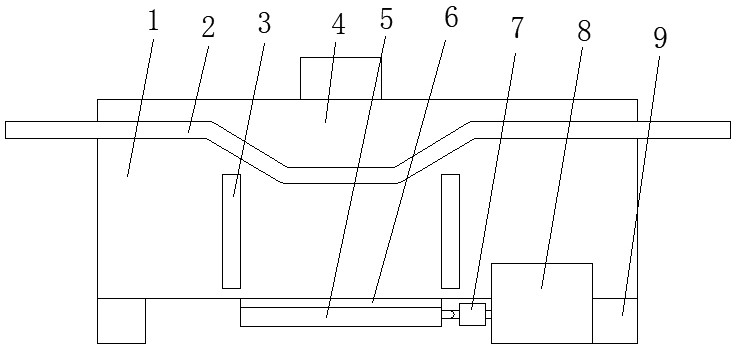

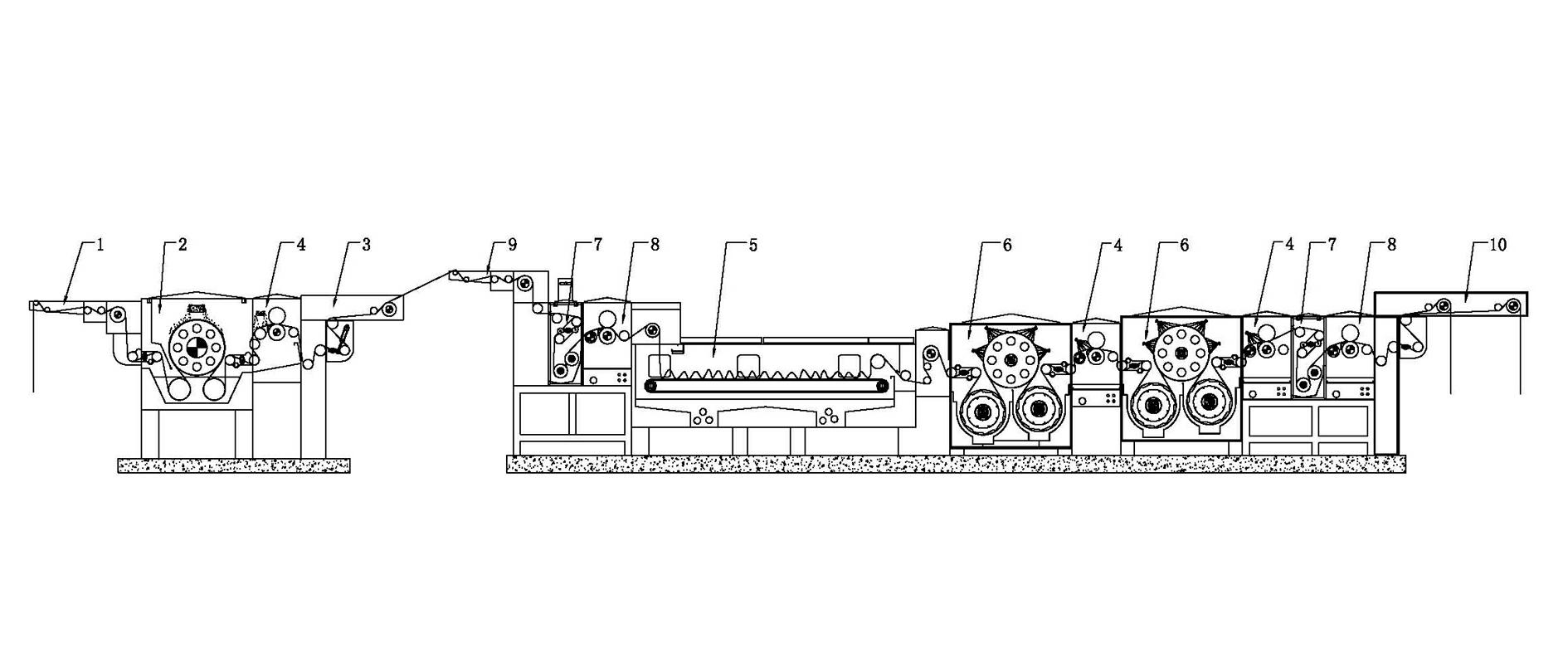

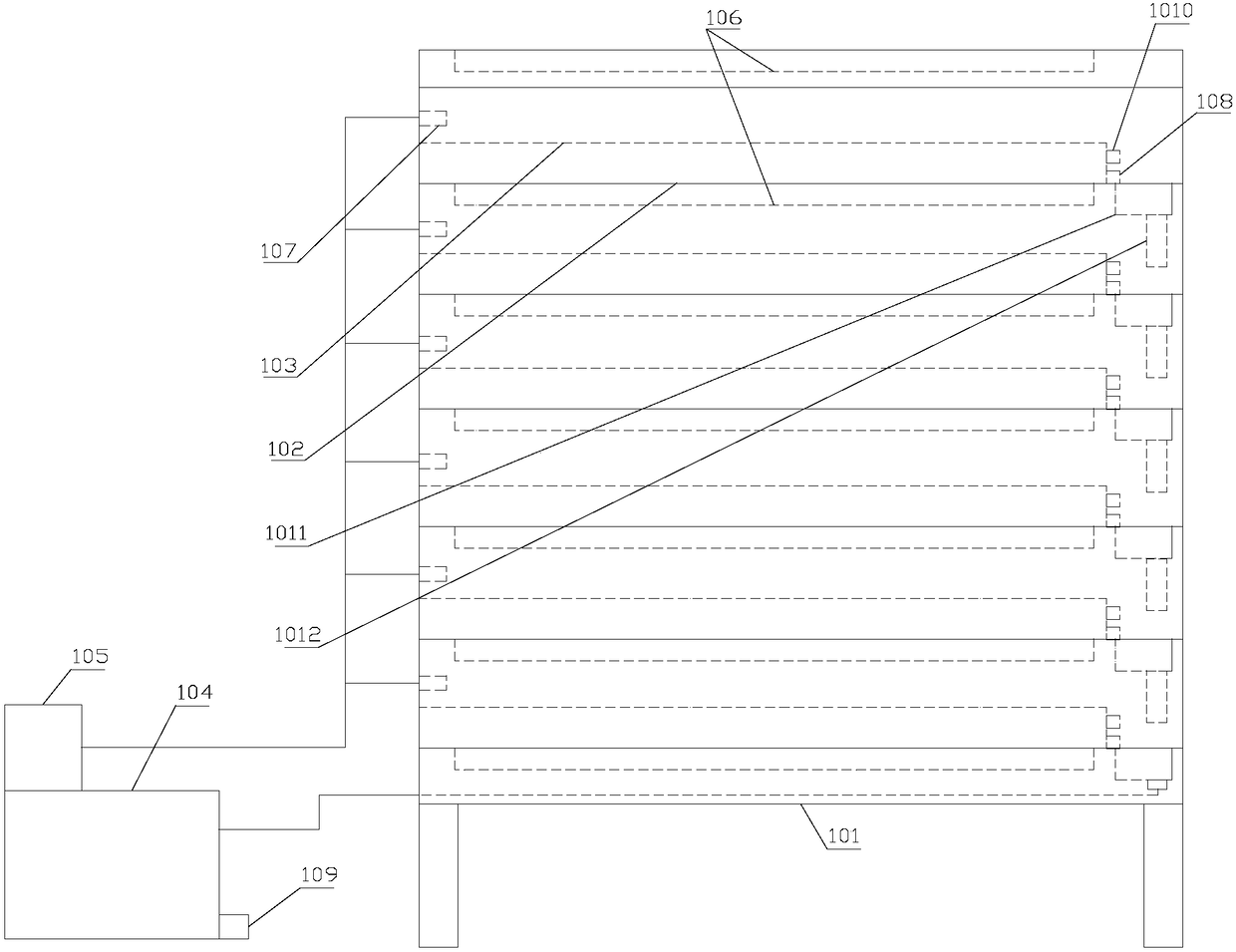

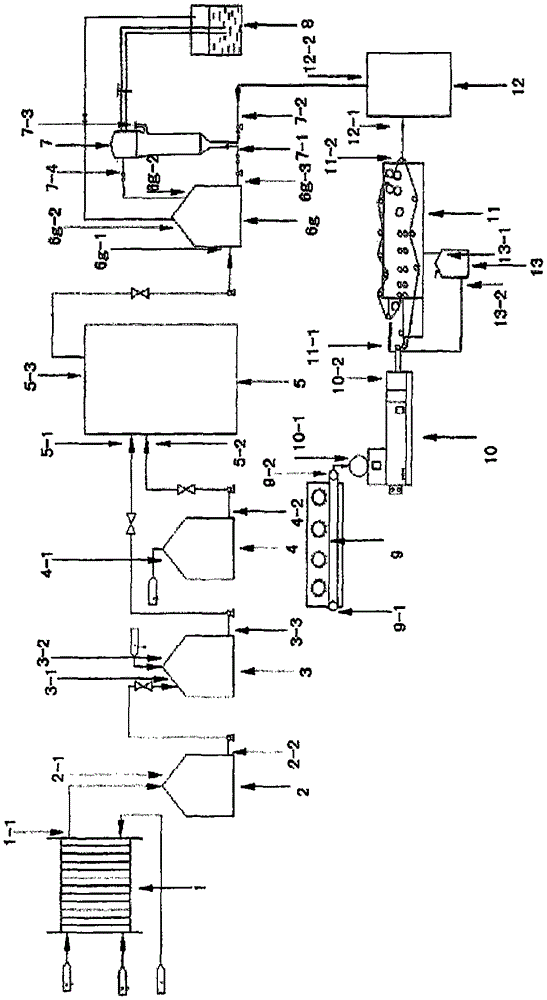

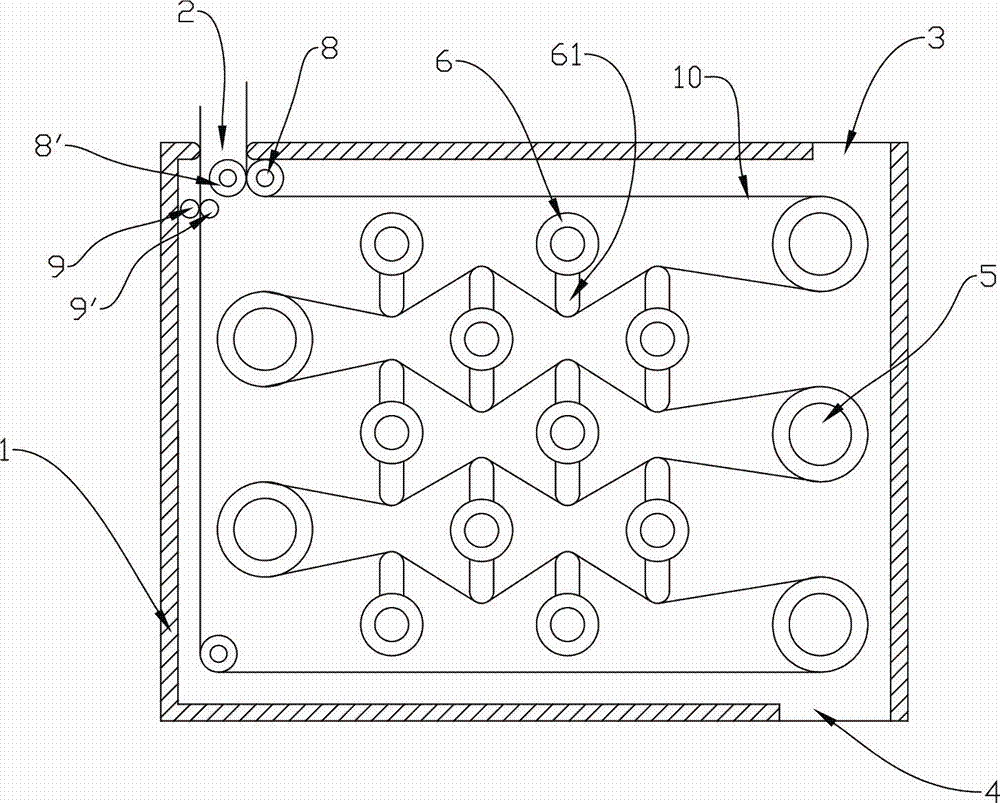

Open-width cotton-knitted cloth refining and bleaching combination machine

ActiveCN103789951AReduce energy consumptionShorten bleaching timeTextile storage in superimposed formSucessive textile treatmentsPulp and paper industryEnergy consumption

The invention relates to an open-width cotton-knitted cloth refining and bleaching combination machine. The open-width cotton-knitted cloth refining and bleaching combination machine is characterized by comprising a cold heap processing cloth feeding frame, a cold heap processor, a cold heap processing cloth discharging frame, a dipping mill, a steamer, a four-wheeled drum washing machine, a mangle device, a post-processing cloth feeding frame and a post-processing cloth discharging frame. The cold heap processing cloth feeding frame is arranged in front of the cold heap processor. The cold heap processing cloth discharging frame is connected behind the cold heap processor. The post-processing cloth feeding frame is connected behind the cold heap processing cloth discharging frame. The dipping mill, the steamer, the four-wheeled drum washing machine, the mangle device and the post-processing cloth discharging frame are sequentially connected behind the post-processing cloth feeding frame. The open-width cotton-knitted cloth refining and bleaching combination machine has the advantages of being capable of lowering energy consumption, shortening bleaching time and improving bleaching efficiency.

Owner:JIANGYIN FUDA DYEING & FINISHING UNITED MACHINERYCO

Method for bleaching cashmere loose fiber

Owner:NINGXIA RONGCHANG CASHMERE IND GROUP

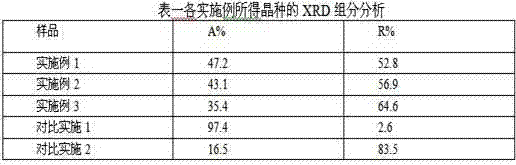

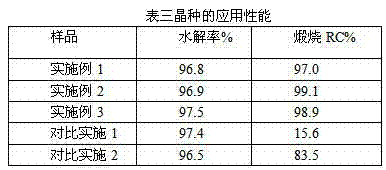

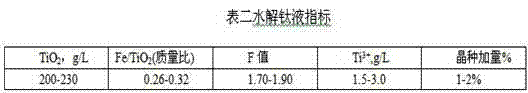

Method for preparing high-activity double-effect seed crystals from metatitanic acid

The invention discloses a method for preparing high-activity double-effect seed crystals from an intermediate product, namely metatitanic acid, of titanium dioxide. The method comprises the following steps of: with metatitanic acid as a raw material, preparing clear titanium sulfate liquid, cooling the clear titanium sulfate liquid, adding a diluent of the clear titanium sulfate liquid to alkaline liquor, controlling pH value to 7.5-9.0, filtering and washing the obtained product, carrying out secondary washing on the washed product, carrying out acid dissolving on hydrofluoric acid and hydrochloric acid for short time under the lower temperature to obtain the high-activity double-effect seed crystals with hydrolyzed seed crystal performance and calcined seed crystal performance. According to the invention, the required titanium source is from the intermediate product produced from the titanium dioxide powder, therefore the method has low cost and production stability; in seed crystals, non-rutile promoted seed crystals and rutile promoted seed crystals are appropriate in proportion and have dual effects of hydrolyzed seed crystals and calcimined seed crystals; when the method is used for titanium dioxide production, calcined seed crystals are unnecessary to be additionally produced, the working procedure of adding the calcined seed crystals in the bleaching process is reduced, the bleaching time is shortened, and the rinsing efficiency is improved at the same time. The seed crystals prepared by using the method disclosed by the invention have high activity, excellent performance and capability of meeting hydrolyzing and calcining requirements just by adding 2 % of seed crystals.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

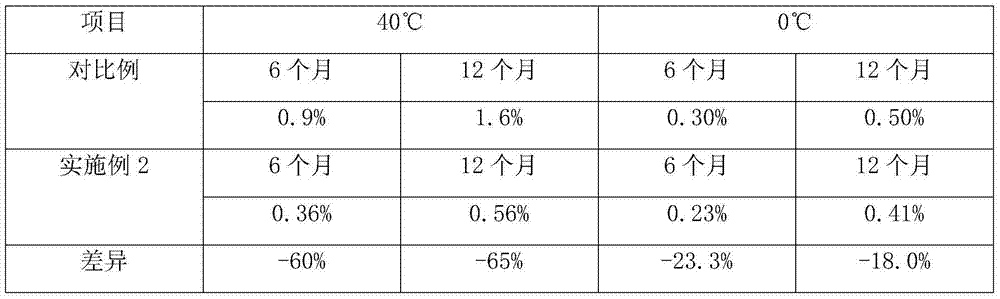

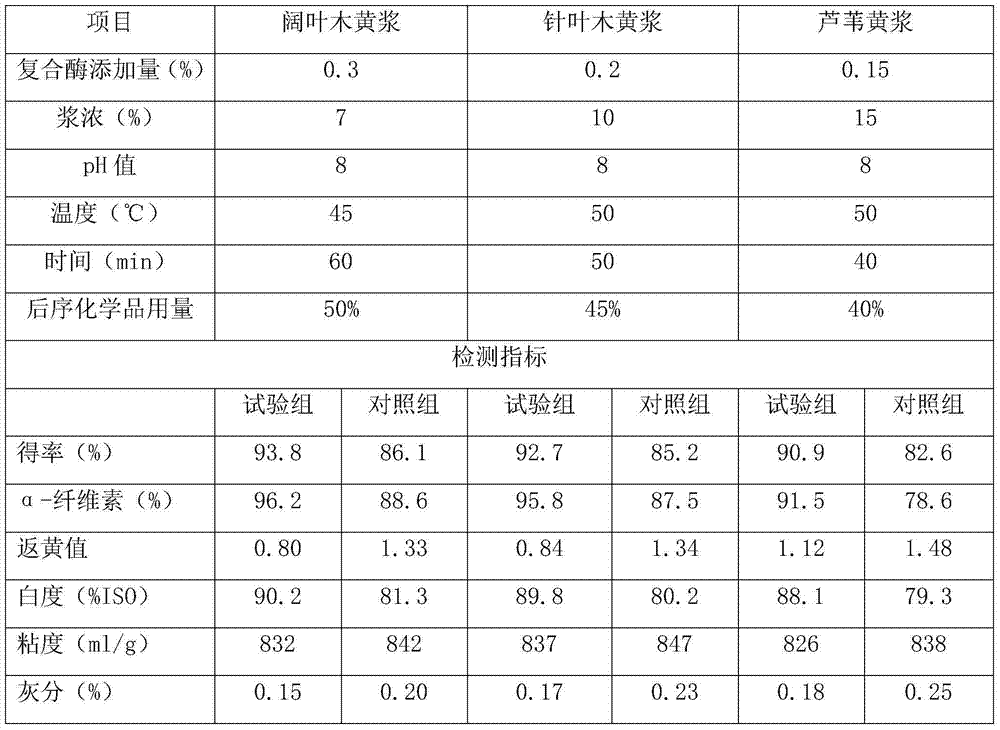

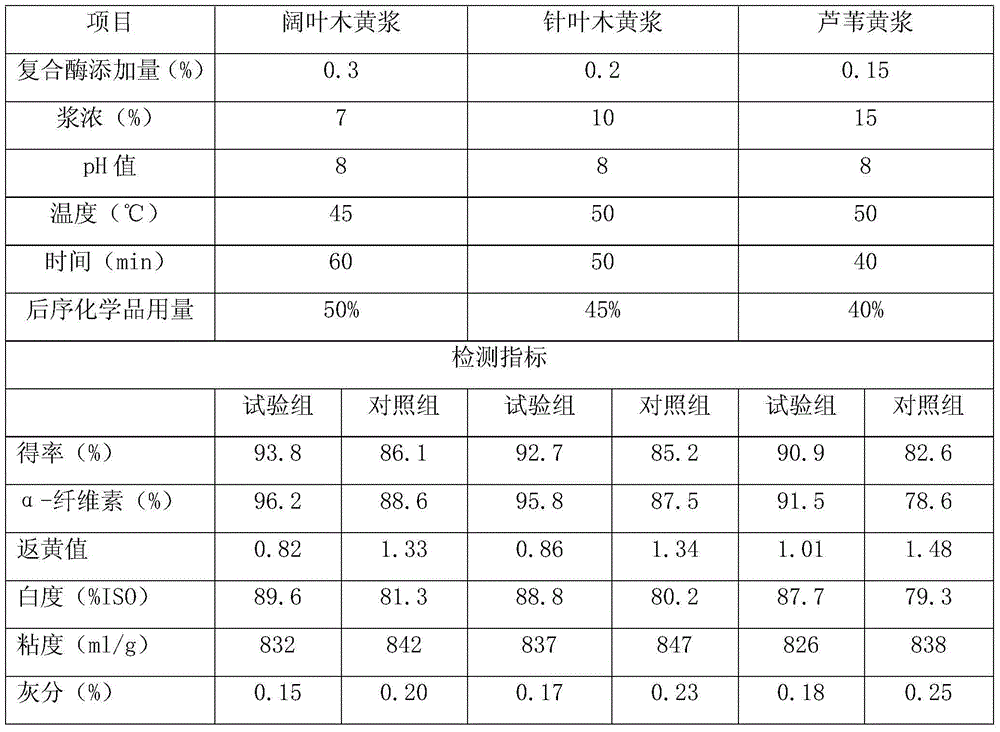

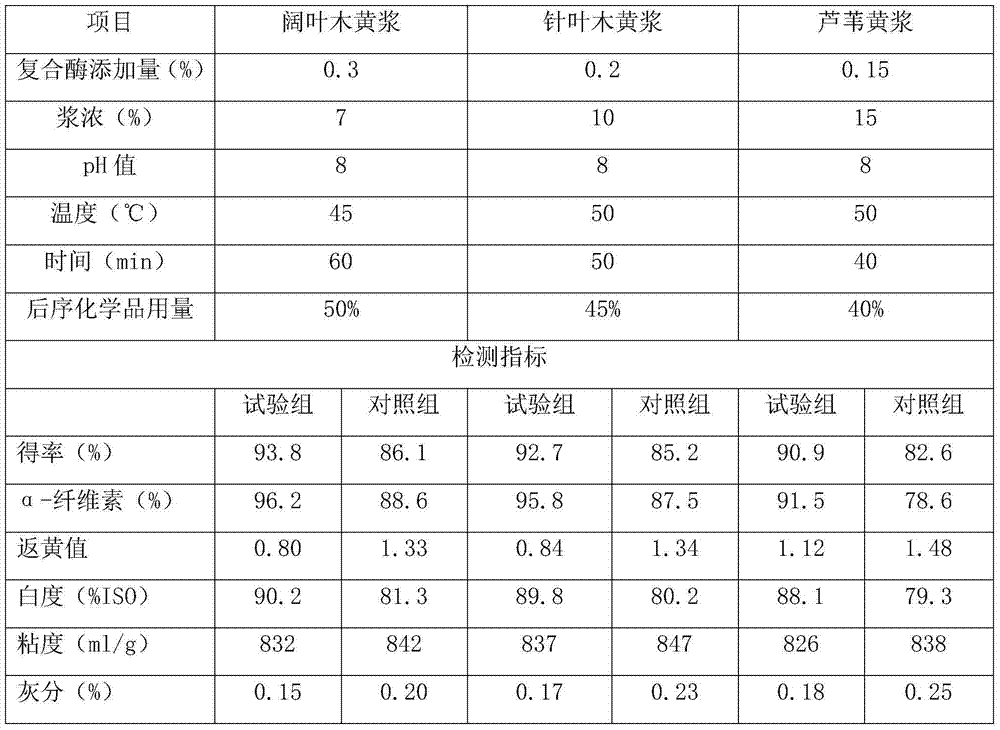

Bleaching compound enzyme for papermaking and preparation method of bleaching compound enzyme

The invention discloses a bleaching compound enzyme for papermaking and a preparation method of the bleaching compound enzyme. The bleaching compound enzyme for papermaking, which has the advantages of complete enzyme system, good bleaching effect, easiness in preservation and good storage stability, is prepared by taking high temperature-resistant alkaline xylanase as main raw material, scientifically compounding a thermophilic bacillus culture, laccase and a medium thereof, dextranase, EDTA (ethylenediaminetetraacetic acid), a protecting agent, an activator, mannose, lipase, tannase, pectase, a whiteness stabilizer, a nonionic surfactant, an antioxidant and the like, completely retaining paper pulp cellulose and simultaneously dissolving out and degrading lignin to the greatest extent. The bleaching compound enzyme disclosed by the invention can significantly improve yield and quality of paper pulp against broad-leaf wood, coniferous wood and reed yellow slurry, and the whiteness is improved by 10.94%, 11.97% and 11.10% respectively; the yellow index is reduced by 39.84%, 37.31% and 24.32% respectively; the amount of conventional chemical products can be saved by 50-60%; and the purposes of reducing cost and protecting an environment are finally achieved.

Owner:黄冈晨鸣浆纸有限公司

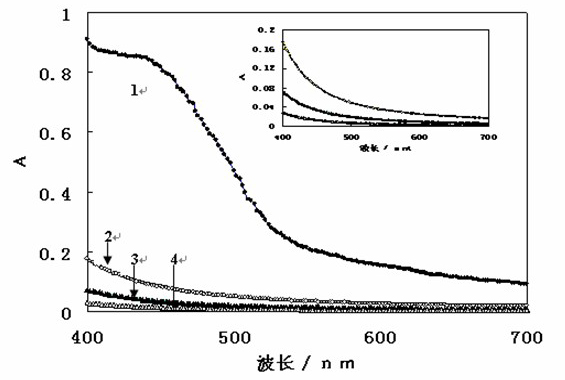

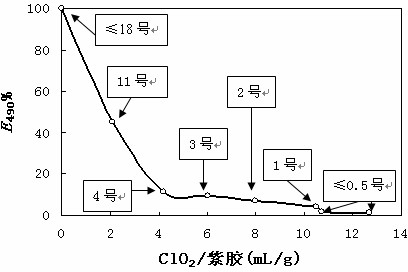

Method for beaching shellac using chlorine dioxide and alcohol solvent, and application thereof

InactiveCN102408832AImprove stabilityImprove bleaching efficiencyCosmetic preparationsToilet preparationsSolventEthanol

The invention discloses a method for beaching shellac using chlorine dioxide and an alcohol solvent. The method comprises the following steps of: dissolving shellac using the alcohol solvent into solution, adding chlorine dioxide to the solution under the condition of constant temperature and stirring the solution for bleaching for certain time, thereby obtaining bleached shellac solution; adding dilute sulphuric acid to the bleached shellac solution so that the bleached shellac is separated out, and then repeatedly washing the bleached shellac until the pH of washing water is neutral; and drying the shellac at the room temperature, thus obtaining the bleached shellac, wherein the absorbance of the ethanol solution in the position of 490 nm can be reduced to 1.6% of the raw material shellac, while the color index thereof can be reduced to be less than 0.5#; and other technical indexes are capable of meeting the requirements of the refined bleached shellac level I. The method is characterized in that: bleaching conditions are mild; a non-alkaline condition is adopted; the bleaching temperature is low; the dosage of an acidic precipitator is low; the color index of the obtained bleached shellac is low; and accurate control and regulation can be performed by adjusting the dosage of the chlorine dioxide, etc; therefore, the application of the bleached shellac in special fields can be extended.

Owner:KUNMING UNIV OF SCI & TECH

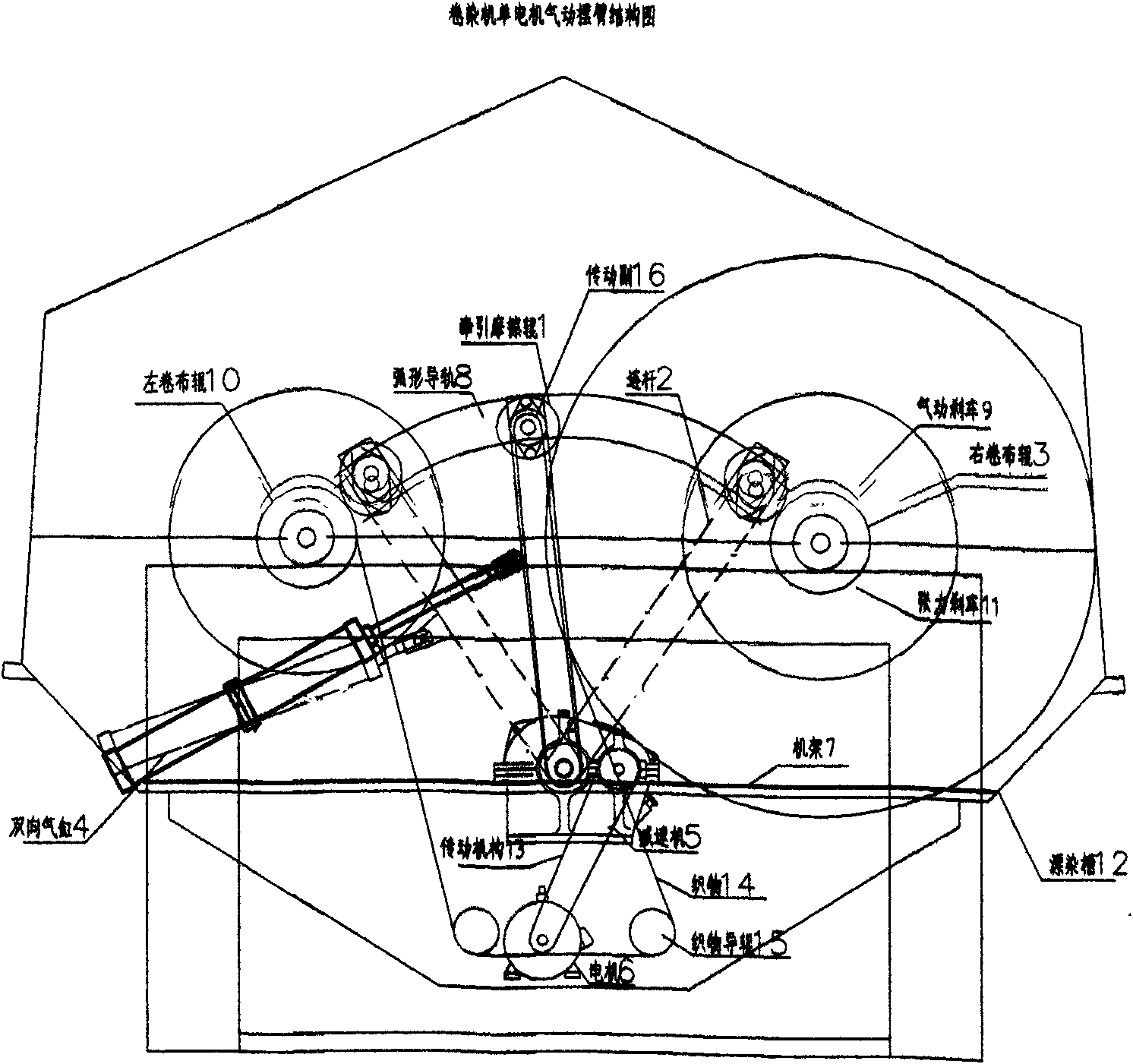

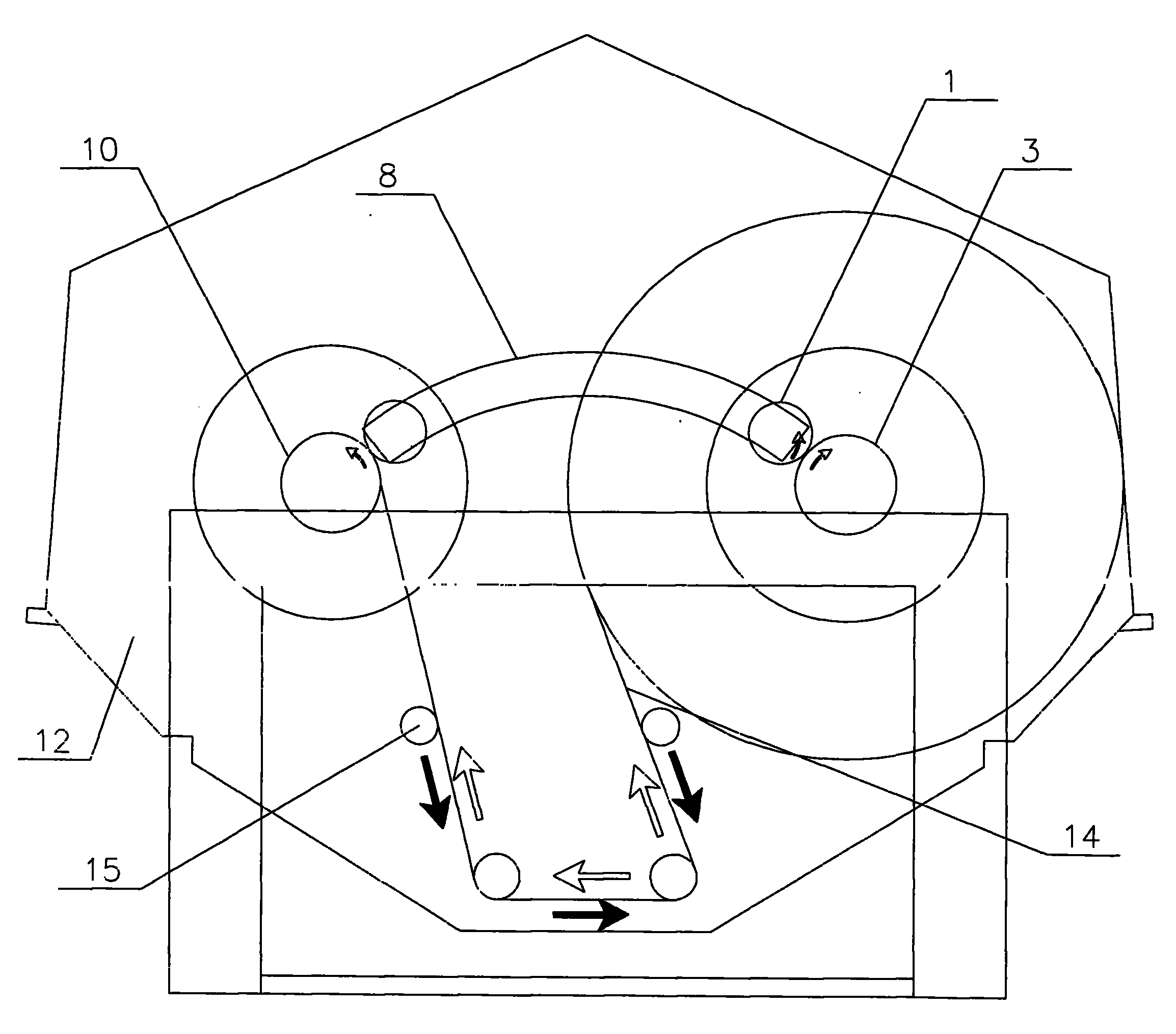

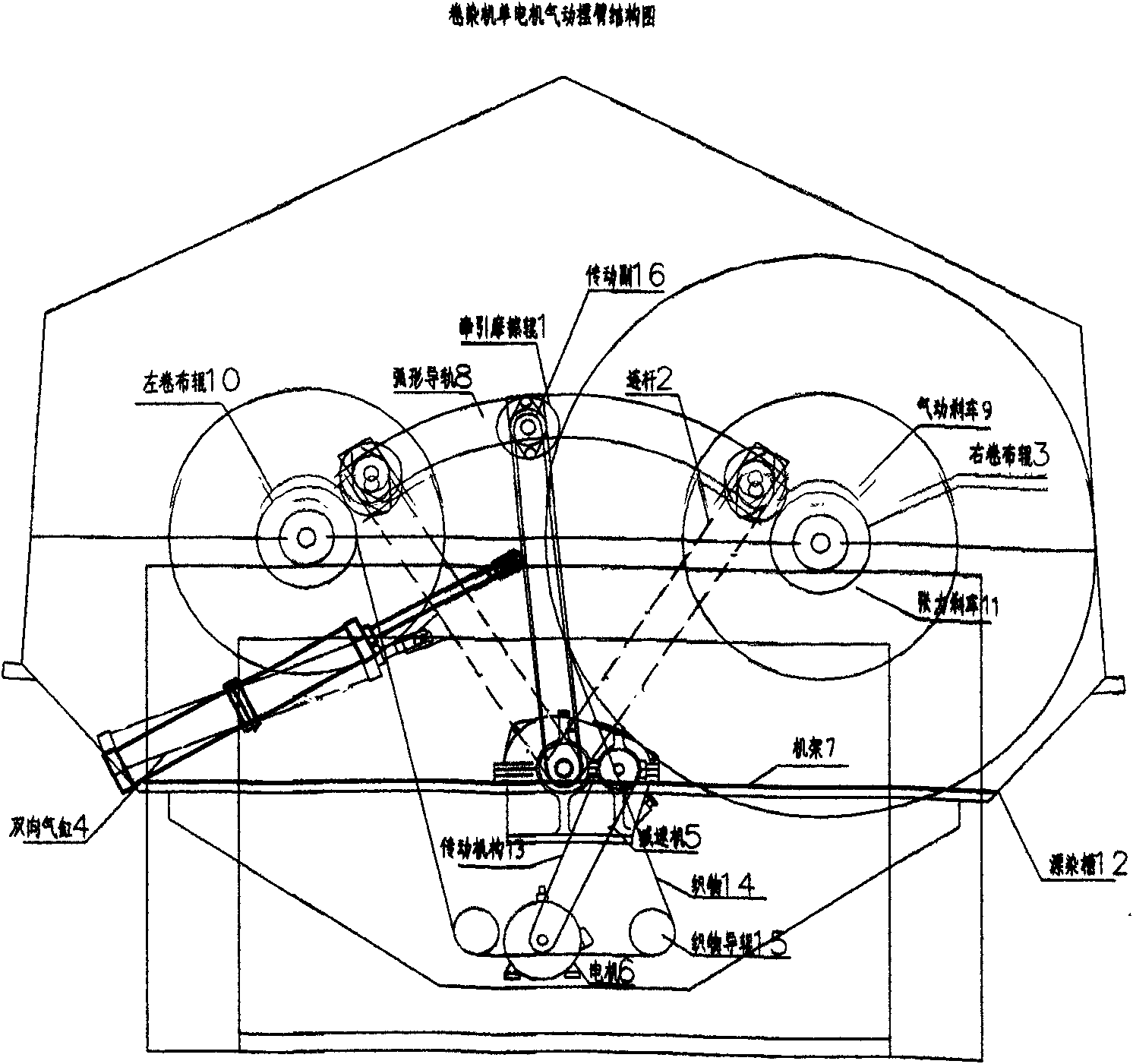

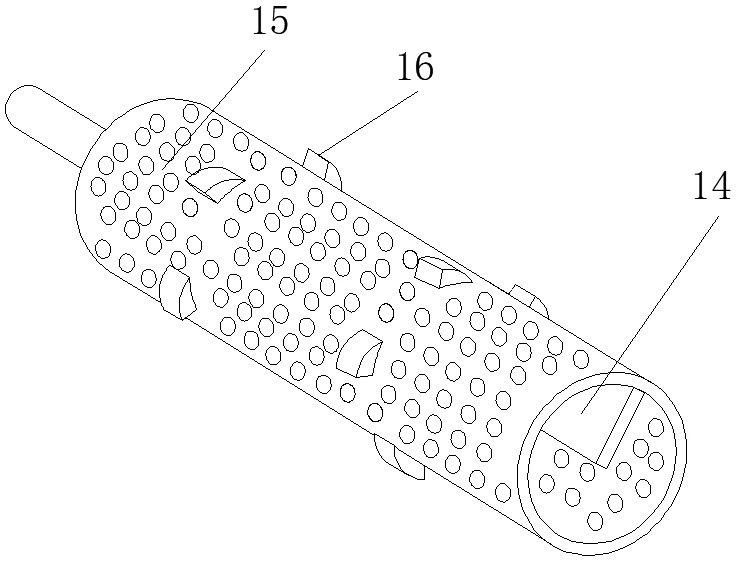

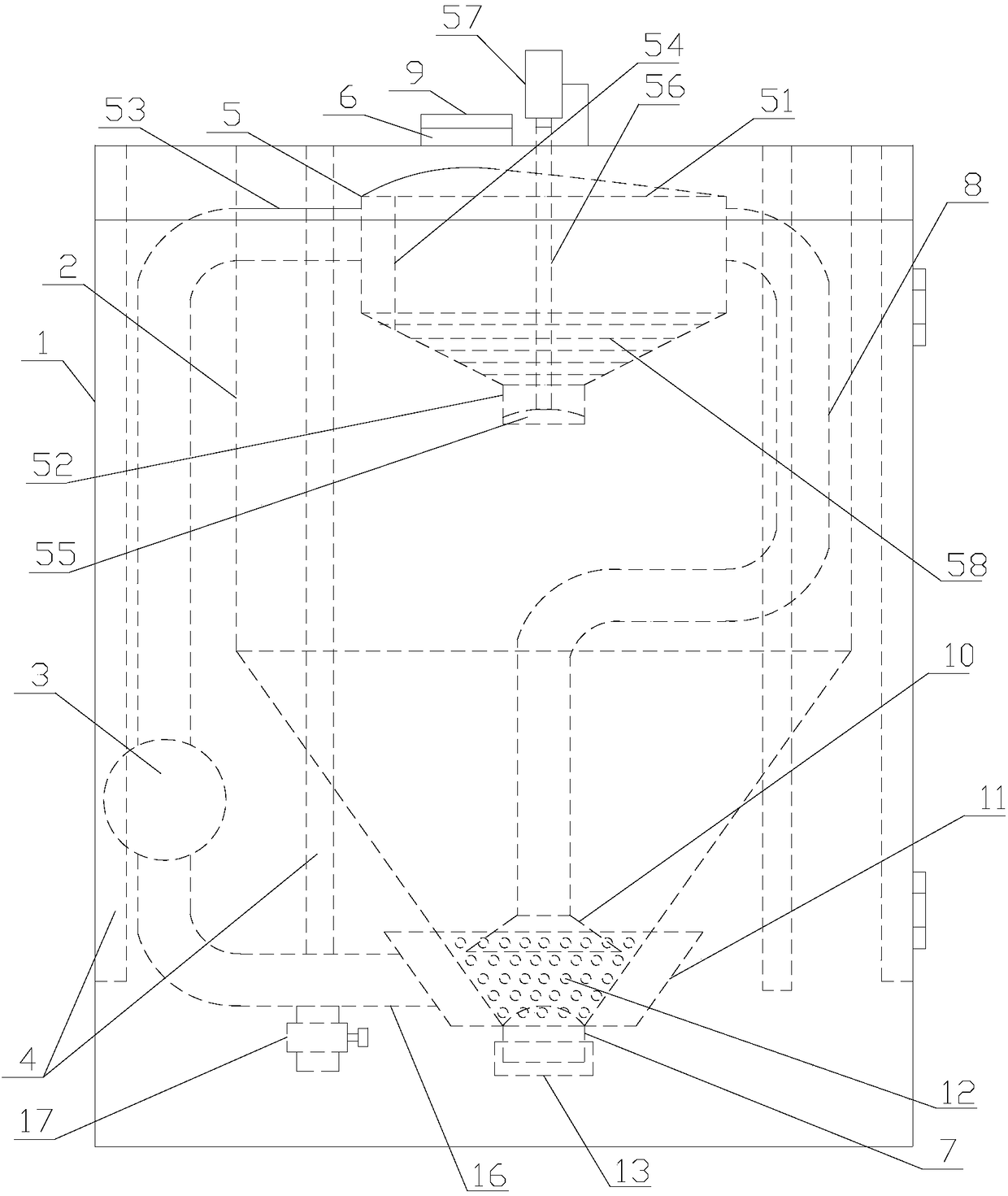

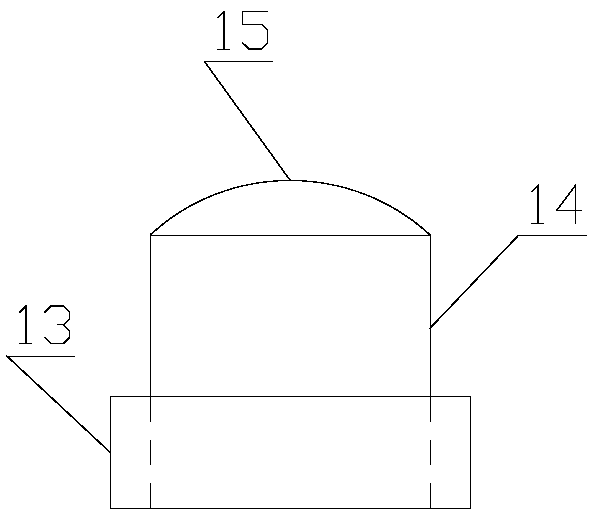

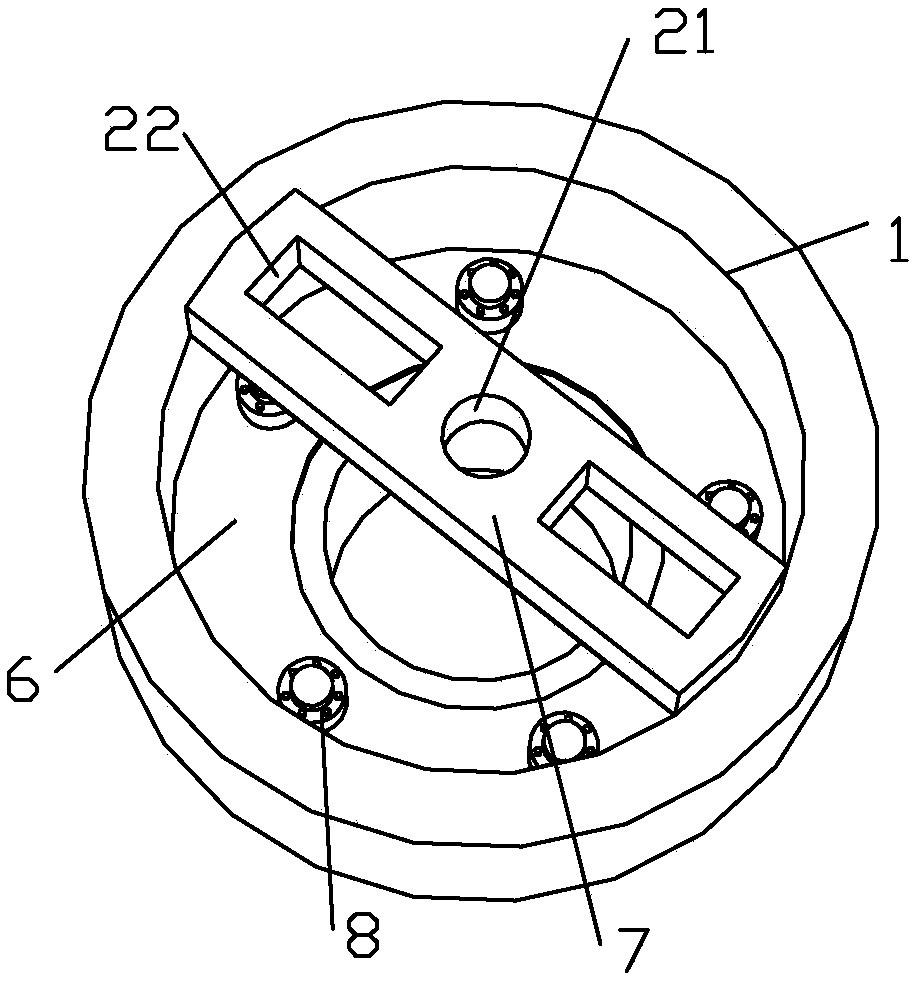

Single-motor pneumatic oscillating arm of jig dyeing machine

InactiveCN101988239AConstant speedImprove dyeing effectLiquid/gas/vapor open-width material treatmentLiquid/gas/vapor removal by squeezing rollersReducerPulp and paper industry

The invention discloses a single-motor pneumatic oscillating arm of a jig dyeing machine. The invention relates to the jig dyeing machine in the technical field of printing and dyeing machines. The existing jig dyeing machine uses double motors for reversing fabric, and the running speed of the fabric is non-constant. The single-motor pneumatic oscillating arm adopts the single motor for dragging, and the reversing function of the fabric 14 in a bleaching and dyeing pond 12 is completed by a transmission mechanism consisting of an arc-shaped guide rail 8, a connecting rod 2, a two-way cylinder 4 and a friction roller 1. Assembly holes are arranged at two ends of the connecting rod 2, a guide rod mounting hole for the cylinder 4 is arranged between the two assembly holes for connecting the cylinder 4, and the fulcrum of the cylinder 4 is fixed on a frame 7. The two ends of the connecting rod 2 are assembled at the shaft end of the friction roller 1 and an output shaft of a speed reducer 5. The arc-shaped guide rail 8 is mounted on the side wall, the connecting rod 2 can oscillate through expansion and contraction of the cylinder 4, and the friction roller 1 can slide along the arc-shaped guide rail 8 and be in close contact with cloth rollers 3 and 10 for compressing the fabric 14. A tension brake 11 can prevent relaxation of the fabric 14. The running speed of the fabric 14 can realize constant speed by linear speed of the friction roller 1, and the press dehydration role can reduce the number of times of bleaching and dyeing, thereby saving steam, water, electrical energy and auxiliaries.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

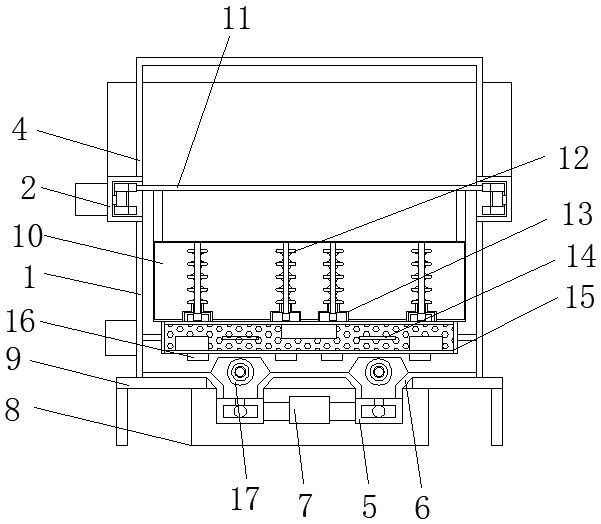

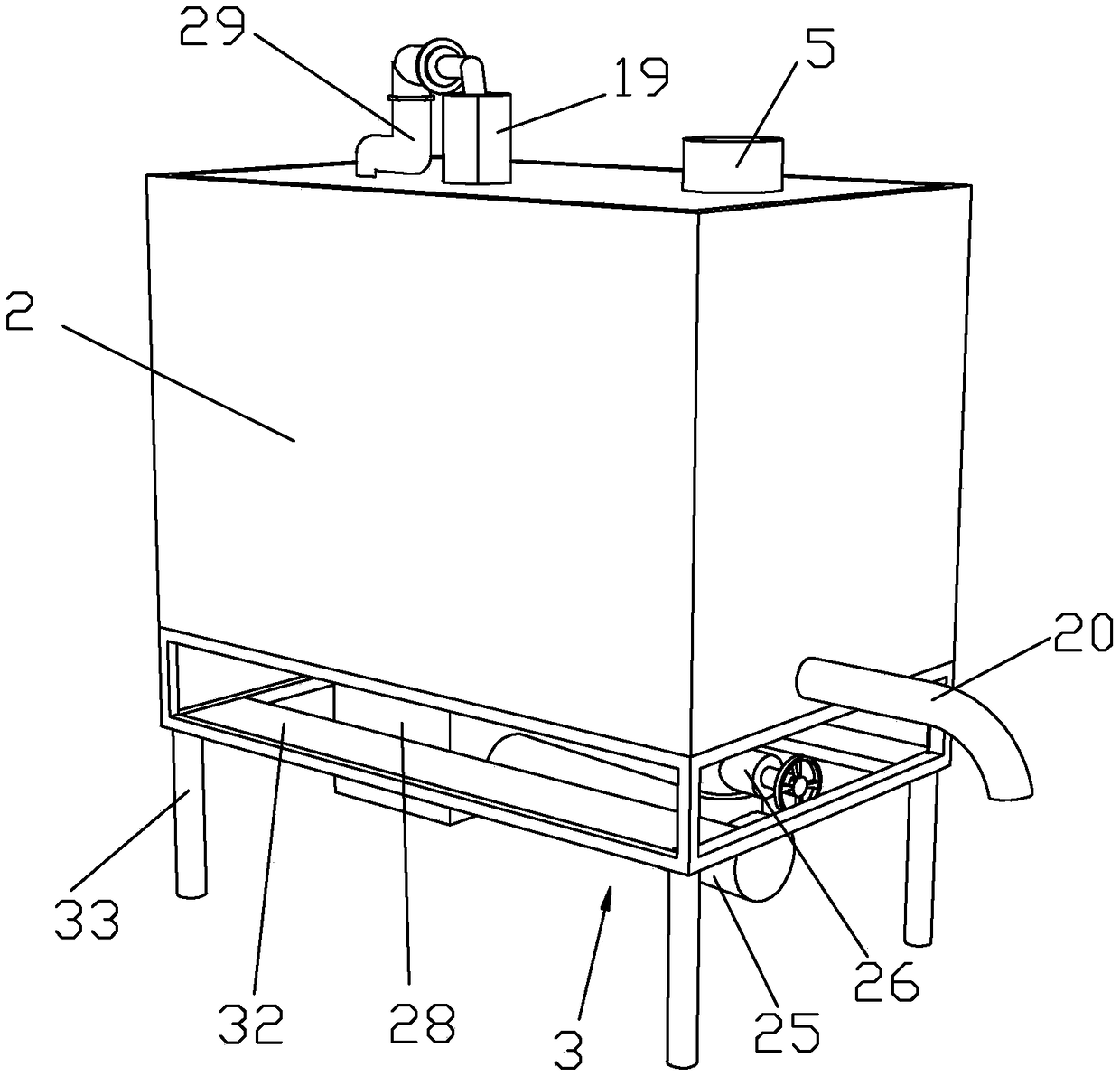

Linen fiber bleaching device for textile production

InactiveCN111826839AImprove bleaching efficiencyReduce lossTextile treatment machine arrangementsTextile treatment carriersFlax fibrePulp and paper industry

The invention discloses a linen fiber bleaching device for textile production and relates to the technical field of textile production. In order to solve the problem that the bleaching time is difficult to control and linen fibers are easy to damage when the linen fibers are soaked in a solution to be stirred, the linen fiber bleaching device specifically comprises a shell, a plurality of supporting frames are fixedly installed at the bottom of the shell, driving mechanisms are fixedly installed on the two sides of the top of the shell, a capping mechanism is fixedly installed between the topends of the two driving mechanisms, and bleaching sections extending downwards are arranged in the middle sections of the driving mechanisms. According to the linen fiber bleaching device for textileproduction, a bleaching solution is in contact with a heating mechanism when being sprayed out; the linen fibers are heated and cooked; the linen fiber bleaching efficiency is improved; the linen fibers are drained; a bleaching solution is recycled; the loss of the solution is reduced; the situation that the working environment is affected due to solution dripping is avoided; raw materials can becontinuously bleached due to the fact that the raw materials enter from one end and exit from the other end, and the linen fiber bleaching processing efficiency is improved.

Owner:宣城红妆美人床上用品有限公司

Bleaching water for preventing elastic jeans from loss of elasticity by washing and application of bleaching water

InactiveCN104532539ABright shadePure shadeDry-cleaning apparatus for textilesBleaching apparatusAcetic acidCellulose

The invention relates to bleaching water for preventing elastic jeans from loss of elasticity by washing and application of the bleaching water. The bleaching water is prepared from the following components in parts by weight: 30-40 parts of a polysulfanilamide derivative, 1-5 parts of a monoamine and polyamine mixture, 0.1-1 part of EDTA tetrasodium salt and 5-15 parts of a polyamino acid derivative. The application specifically comprises the following steps: (1) desizing the bleaching water; (2) enzymatic washing the bleaching water by cellulose; and (3) chlorine bleaching the bleaching water. Compared with the prior art, the bleaching water provided by the invention has the obvious advantages of preventing spandex from loss of elasticity and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

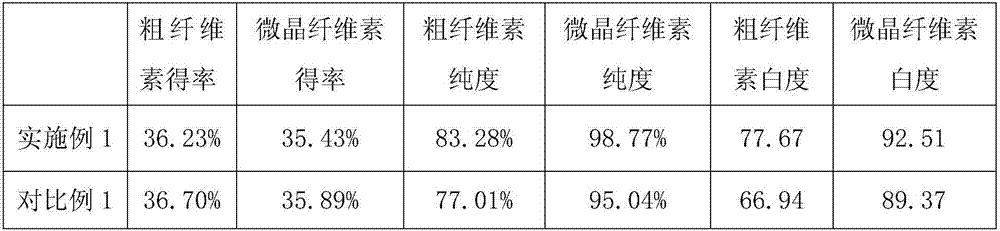

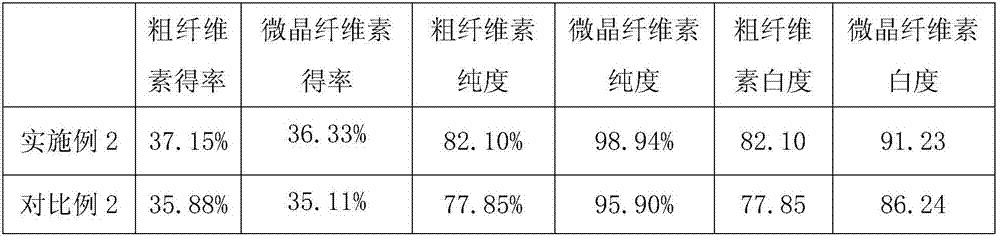

Method for preparing microcrystalline cellulose from Chinese herb residue

The invention discloses a method for preparing microcrystalline cellulose from Chinese herb residue, comprising the following steps: a, mixing Chinese herb residue and distilled water, slightly boiling, and centrifuging to obtain filter residue; b, alkali treatment: adding the filter residue into a sodium hydroxide solution, carrying out water-bath treatment, centrifuging, washing precipitate to neutral level, and collecting filter residue; c, acid treatment: adding distilled water to the filter residue, adjusting pH to 1-2, carrying out water-bath treatment, centrifuging to obtain filter residue, washing to neutral level, and drying; d, extraction of Chinese herb residue crude cellulose: adding the filter residue into bleaching liquid, carrying out water-bath treatment, carrying out suction filtration, washing to neutral level, and drying to constant weight to prepare the microcrystalline cellulose. The preparation method of the invention is beneficial to raise utilization rate of waste Chinese herb residue resources and provides a safe, cheap and convenient raw material resource for the production of microcrystalline cellulose.

Owner:兰州名德药业有限公司

Paper pulp bleaching compound enzyme and preparation method thereof

The invention discloses a paper pulp bleaching compound enzyme and a preparation method thereof. Through scientific compounding of high temperature-resistant alkaline xylanase as a main raw material and bacillus thermophilus culture, laccase and its medium, glucanase, EDTA, a protective agent, an activator, seminase, lipase, tannase, pectase, a whiteness stabilizing agent, a nonionic surfactant and an anti-oxidant, the paper pulp bleaching compound enzyme is prepared. The paper pulp bleaching compound enzyme completely retains paper pulp cellulose, maximally dissolves and degrades lignin, has the advantages of complete enzyme system, good bleaching effects, storage easiness and good storage stability, can substantially improve a yield and quality of paper pulp of broad leaf wood, needlebush and reed yellow waste slurry, respectively improves whiteness by 8.18%, 8.13% and 8.23%, respectively reduces a yellow index by 38.35%, 35.82% and 31.76%, saves a conventional chemical article use mount by 50-60%, reduces a cost and protects the environment.

Owner:湖南新鸿鹰生物工程有限公司

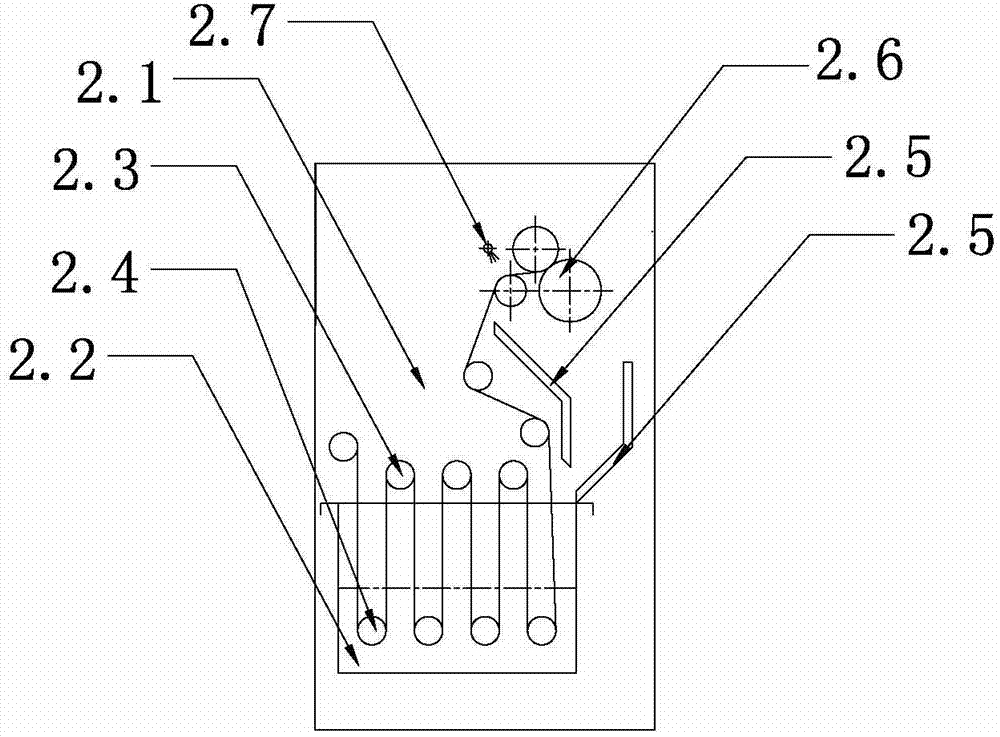

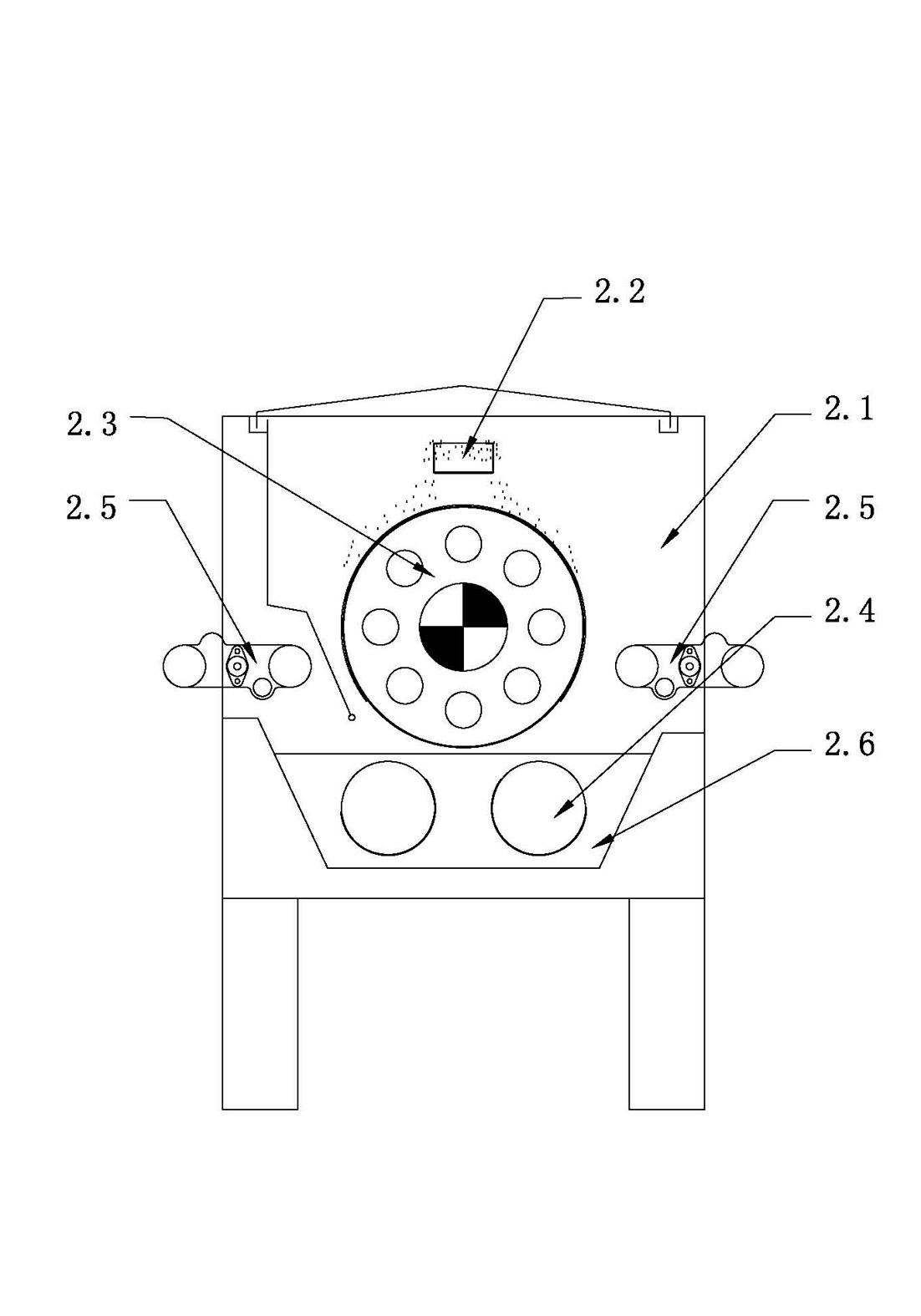

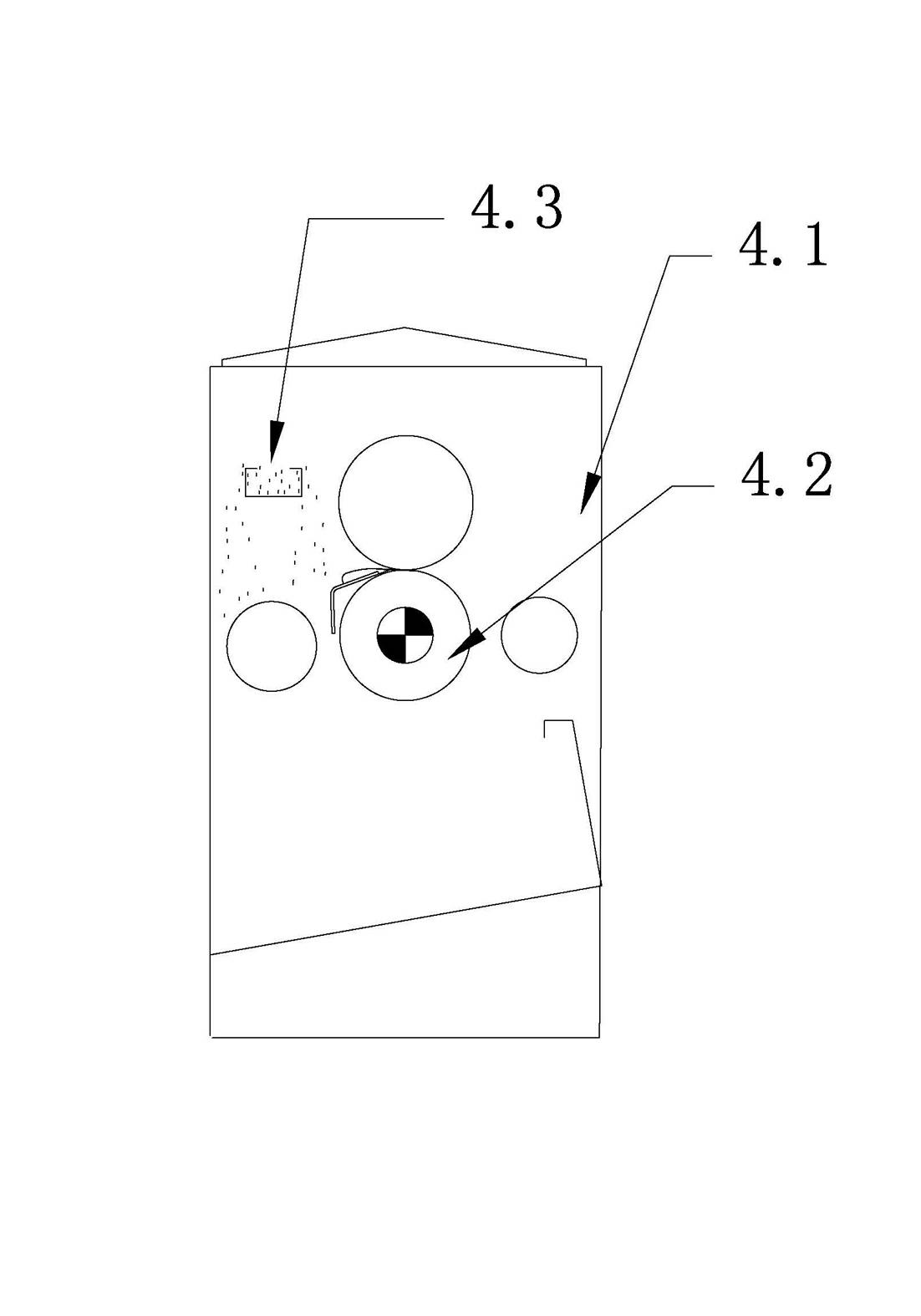

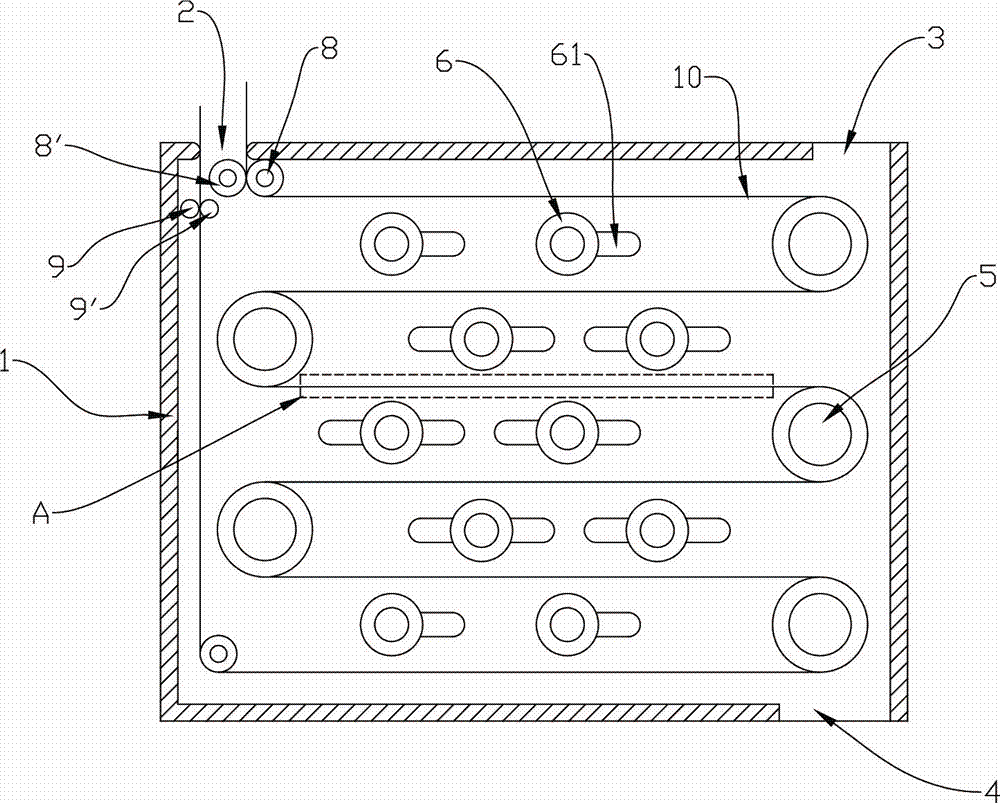

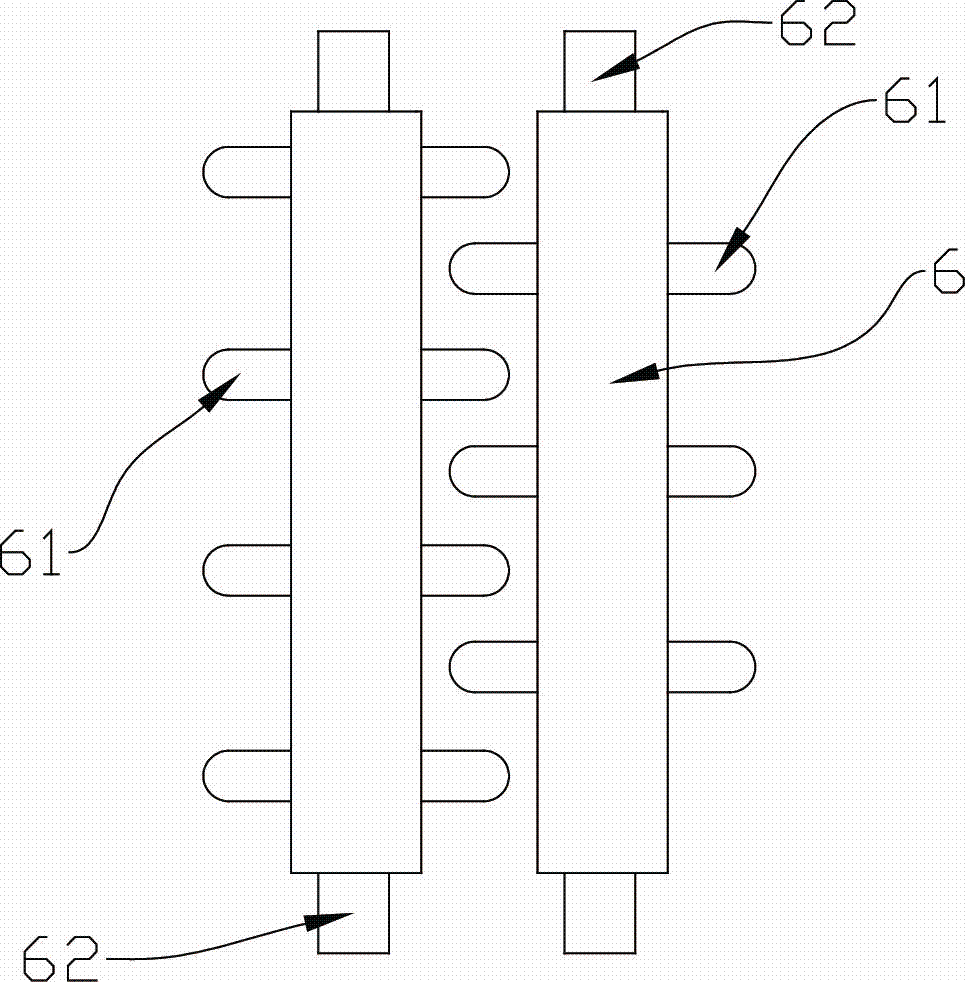

Knit cold-batching bleaching processor

ActiveCN102634947AReduce energy consumptionShorten bleaching timeSucessive textile treatmentsTextile treatment machine arrangementsEnergy consumptionRolling mill

The invention relates to a knit cold-batching bleaching processor. The processor comprises a cold-batching processing cloth inlet frame, a cold-batching processor, a cold-batching processing cloth outlet frame, spray rolling mills, a steamer, oscillating rinsing machines, immersing machines, padder devices, a post-processing cloth inlet frame and a post-processing cloth outlet frame; the cold-batching processing cloth inlet frame is arranged in front of the cold-batching processor; one spray rolling mill and the cold-batching processing cloth outlet frame are linked behind the cold-batching processor in sequence; the post-processing cloth inlet frame is connected behind the cold-batching processing cloth outlet frame; one immersing machine, one padder device and the steamer are linked behind the post-processing cloth inlet frame in sequence; two oscillating rinsing machines, one spray rolling mill, one immersing machine, one padder device and the post-processing cloth outlet frame are linked behind the steamer in sequence; and one spray rolling mill is installed between the two oscillating rinsing machines. According to the knit cold-batching bleaching processor, the processor has the advantages of capabilities of reducing energy consumption, shortening bleaching time and improving bleaching efficiency by means of continuously bleaching and rising cloth before being dyed.

Owner:JIANGYIN FUDA DYEING & FINISHING UNITED MACHINERYCO

Pearl bleaching process

InactiveCN100566622CSustained uniform releaseOvercome or weaken surface tensionJewellerySolventMethanol

The invention discloses a pearl bleaching technology, which comprises the following steps that: in the sufficient sunshine, pearls after being polished are put into prepared bleaching liquid and soaked at the temperature ranging from 14 to 17 DEG C for 48 to 50 hours for bleaching treatment, and then rinsed and dried; the step is repeated for at least one time; classification: unqualified pearls are screened out and the bleaching treatment for unqualified pearls continues to be repeated for at least one time. In the invention, the format of the bleaching liquid, consisting of a hydrogen peroxide bleaching agent, a composite interface agent, a composite catalyst and a methanol solvent, is adopted for bleaching at the low temperature of 14 to 17 DEG C so as to realize the good bleaching effect under low concentrations of the hydrogen peroxide bleaching agent within a short time, thus effectively reducing the damage to the skin of the pearl and improving the glossiness of the pearl. By adopting the method of the invention, the pearls bleached have better gloss, smooth surface, higher whiteness and good stability.

Owner:浙江梵沛珍珠股份有限公司

Fast-speed lakh bleaching and antichlorating method

InactiveCN1778853ADoes not change or affect colorShorten bleaching timeNatural resin purificationShellacBleach

A fast bleaching and antichloration method with shellac is carried out by mixing shellac with soda and water, heating to 75í½95íÒC, dissolving into shellac alkaline solution with concentration<25%, filtering, keeping temperature between 75í½95íÒC, agitating for shellac alkaline solution by 50-90r / min speed, adding into chlorine-contained bleaching agent with chlorine content 15í½22wt%, agitating for 30-40mins to obtain bleaching glue, raising temperature to 85í½95íÒC, and agitating 3í½8mins by 50-90r / min speed to obtain dechloridized glue. Its advantages include long storage period, better product quality and shorter bleaching time.

Owner:李琳

Nucleated pearl processing technology

InactiveCN108420153AAvoid damageDoes not affect permeabilityJewellerySodium bicarbonatePolyethylene glycol

The invention discloses a nucleated pearl processing technology. The technology comprises steps as follows: a), pearls are soaked in a pretreatment liquid for 25-35 h at the temperature of 10-15 DEG C, the pretreatment liquid is prepared from sodium bicarbonate and distilled water through mixing, 10-15 g of sodium bicarbonate is added to 1000 ml of distilled water, and then washing and natural drying are performed; b), the pearls obtained in the step a) are poured into a brightening device containing a treatment liquid and soaked for 3-5 d at the temperature of 10-20 DEG C, then washing and natural drying are performed, and the treating liquid is prepared from components in parts by mass as follows: 10-20 parts of polyethylene glycol, 10-20 parts of glycerin, 4-6 parts of methylene blue and 900-1000 parts of deionized water; and the like. Compared with the prior art, the technology has the advantages that the brightening effect can be good, transparency of the pearls is not affected, bleaching effect is good, pearl damage is reduced, efficiency is improved, and color and luster is uniform.

Owner:浙江梵沛珍珠股份有限公司

Bleached compound enzyme and preparation method thereof

The invention discloses a bleached compound enzyme and a preparation method thereof. The preparation method comprises the following steps: by taking high-temperature-resistant alkaline xylanase as a main raw material, scientifically compounding a bacillus thermophilus culture, laccase and media thereof, dextranase, EDTA, a protective agent, an activating agent, mannose, lipase, tannase, pectinase, a whiteness stabilizer, a nonionic surfactant and an antioxidant, dissolving the lignin to the greatest degree when the pulp cellulose is completely remained, degrading the lignin, thereby obtaining the bleached compound enzyme with the advantages of complete enzyme system, good bleaching effect, simplicity in preservation and good storage stability. According to the broadleaf wood, needlebush and reed yellow pulp, the pulp yield and quality can be obviously improved, and the whiteness is respectively improved by 10.94 percent, 11.97 percent and 11.10 percent; the yellowing value is respectively reduced by 39.84 percent, 37.31 percent and 24.32 percent; the amount of conventional chemicals can be saved by 50-60 percent; and finally, the aims of reducing the cost and protecting the environment are achieved.

Owner:广州隆利生物科技有限公司

Bleaching treatment method of wheat-straw used for weaving

InactiveCN106217551AReduce usageSimple methodRadiation/waves wood treatmentWood treatment detailsCelluloseBleach

The invention discloses a bleaching treatment method of wheat-straw used for weaving. The bleaching treatment method of the wheat-straw used for weaving is simple and practicable, the working efficiency can be improved by 14.6%, the cost is low, the batch treatment can be realized, the effect is lasting through three-step bleaching and the cost can be saved by 11.7%. After the wheat-straw is soaked in fermentation liquor, the produced small molecule substances are capable of decomposing darker pigments and preliminarily softening the cellulose, so that the bleaching effect can be reinforced; after the wheat-straw is ultrasonic soaked in an acidic alcoholic solution, the antibiotic, disinfectant, anti-mildew and anti-moth effects can be realized and the rapid and uniform bleaching can be realized by leaching part of pigments; after the wheat-straw is bleached by ultrasonic, the permeation can be rapid and the bleaching can be uniform from outside to inside, so that the bleaching time can be obviously shortened. The usage amount of bleaching agents is less and the bleaching treatment can be conducted after the bleaching agents are diluted by water, so that the safety and the efficiency are good, the cost is low and the effect is lasting.

Owner:阜南县创发工艺品有限公司

Method for blanching straw plaited articles

InactiveCN107756574AAvoid color reversalReduce dosageWood treatment detailsReed/straw treatmentBreaking strengthAfter treatment

The invention relates to the technical field of straw plaiting processing and treatment, in particular to a method for blanching straw plaited articles. The method comprises the following steps: inoculating lactobacillus acidophilus to activating liquid, performing activating cultivation to obtain activated liquid, soaking the straw plaiting material into the activated liquid to perform treatment,adding 3 to 3.8 percent by weight of hydrogen peroxide into the treatment liquid, mixing uniformly, performing treatment again, completely washing the straw plaiting material after treatment, and drying. According to the method, the use amount of the hydrogen peroxide is reduced, the effect of protecting the straw plaiting raw material is achieved, the breaking strength of the blanched raw material is enhanced, the blanching effect is good, the blanching time is obviously shortened, and drying is conducted after blanching.

Owner:阜南佳利工艺品股份有限公司

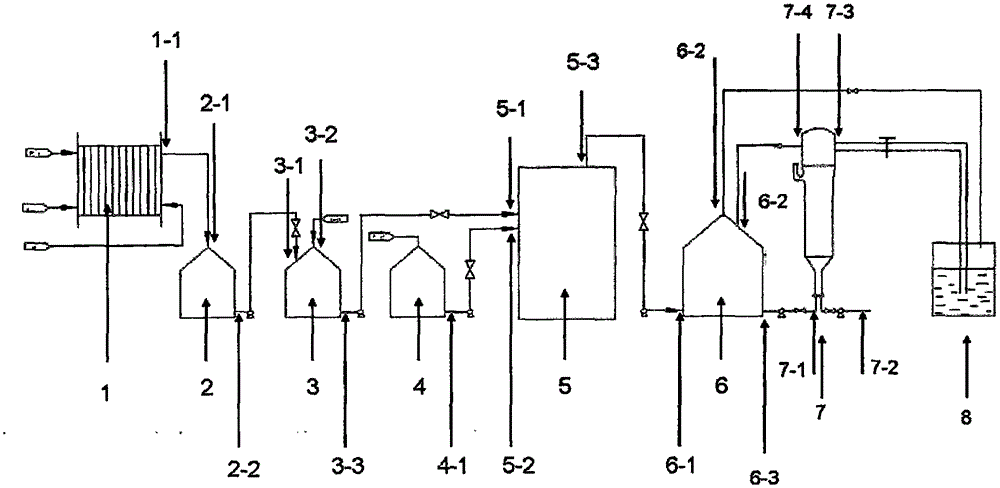

A device and a method for bleaching waste textiles with gas phase chlorine dioxide

ActiveCN105525463AHigh purityReduce damageTextile treatment machine arrangementsBleaching apparatusChlorine dioxideGas phase

The invention provides a device and a method for bleaching waste textiles with gas phase chlorine dioxide. The device for bleaching waste textiles with gas phase chlorine dioxide comprises a chlorine dioxide generating system and a gas phase bleaching system. The method for bleaching waste textiles with gas phase chlorine dioxide comprises a chlorine dioxide generating step and a gas phase bleaching step. Hydroxyl radical active oxygen with strong oxidizing property is used for preparing chlorine dioxide, and the reaction condition is moderate, the energy consumption is low and the prepared chlorine dioxide is high in purity; when waste textiles are bleached by using gas phase chlorine dioxide, the high purity chlorine dioxide can reduce bleaching time, increase the whiteness of bleaching, prevent yellowing of products, and guarantee high whiteness stability and low degree of damage to textiles; the device and the method can bring favorable environmental and economical benefits.

Owner:BEIJING PENGSHENG TIANXIAN TECH CO LTD

Apparatus and method for bleaching floccules by using gaseous chlorine dioxide

InactiveCN105568659AHigh purityReduce damageBleaching apparatusChlorine dioxideFiberChlorine dioxide

An apparatus and method for bleaching floccules by using gaseous chlorine dioxide is provided; the apparatus comprises a chlorine dioxide generating system and a gas bleaching system; the method comprises chlorine dioxide generation and gas bleaching steps. The apparatus and method use the hydroxyl radical active oxygen of high oxidability to prepare gaseous chlorine dioxide, reaction conditions are mild, energy consumption is low, the prepared chlorine dioxide is high in purity; the gaseous chlorine dioxide is used in bleaching, and the high-purity chlorine dioxide can shorten the bleaching time and improve bleaching whiteness, so that a product is yellowing resistant, high in whiteness stability and low in fiber damage degree, meets the requirements of national policies and has good environmental and economic benefits.

Owner:BEIJING PENGSHENG TIANXIAN TECH CO LTD

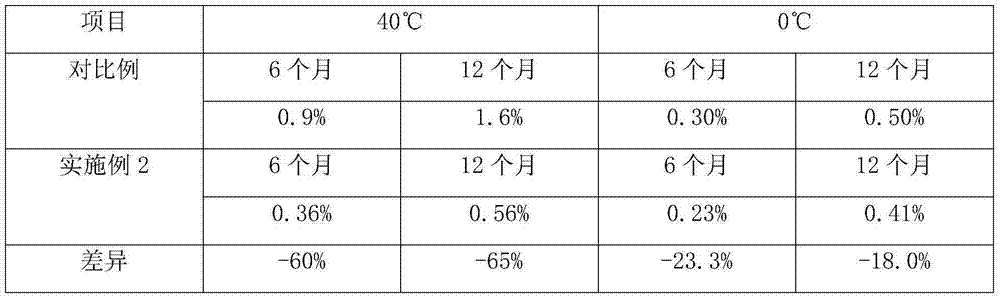

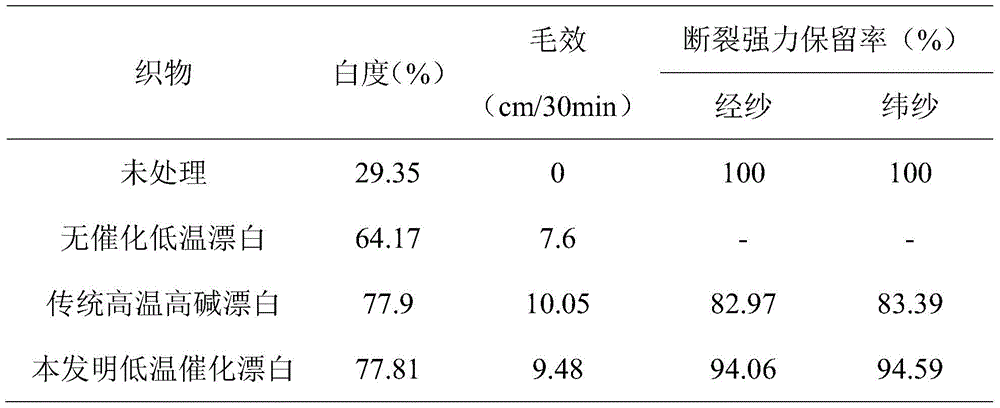

A kind of hydrogen peroxide bleaching catalyst and preparation method thereof

ActiveCN104611906BEffective bleachingAchieve low-temperature low-alkali bleachingBleaching apparatusFiberResource saving

The invention discloses a hydrogen peroxide bleaching catalyst. The hydrogen peroxide bleaching catalyst is formed by mixing a glutin solution and a copper sulfate solution, and the mass ratio of a glutin solute to a copper sulfate solute in a mixed liquid is (15-70):1. The invention further discloses a preparation method of the catalyst. The hydrogen peroxide bleaching catalyst is an aid formed by complexing of glutin and bivalent copper ions, when the catalyst is applied to a hydrogen peroxide bleaching process for fabrics such as cotton and the like, hydrogen peroxide can be effective catalyzed for bleaching, damage to the fabrics can be reduced, the bleaching temperature can be decreased, the bleaching time can be shortened, the consumption of an alkali in bleaching can be reduced, and low-temperature low-alkali hydrogen peroxide bleaching of the fabrics can be realized, so that problems of energy consumption, fiber damage and pollution caused by traditional high-temperature high-alkali hydrogen peroxide bleaching are solved. Besides, raw materials of the aid come from waste protein, waste resources are effectively utilized, environment-friendly and clean production is realized, and the concept of establishing the resource-saving and environment-friendly society is conformed.

Owner:QIANJINAG YIHE CHEM PROD

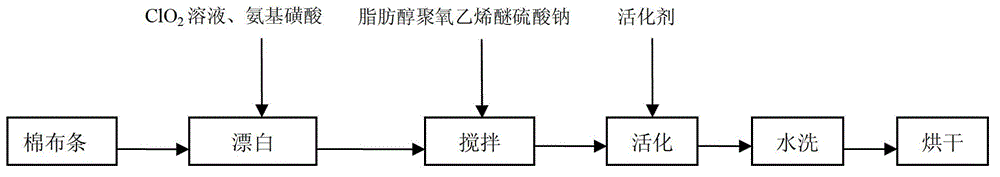

Method for bleaching cotton fabric by chlorine dioxide

InactiveCN103334291AHigh whitenessImprove bleaching effectBleaching apparatusSocial benefitsChlorine dioxide

The invention discloses a method for bleaching a cotton fabric by chlorine dioxide. The method comprises the following operating steps: 1, mixing a chlorine dioxide solution with a sulfamic acid solution according to a volume ratio of 50:1, and uniformly stirring; 2, adding cotton cloth strips to a mixed solution obtained in step 1 for fully immersing the cotton cloth strips, adding fatty alcohol polyoxyethylene ether sodium sulfate, and bleaching at 35-45DEG C through stirring for 2min by a stirrer each 30min when the pH value of the bleaching system is 3-4; 3, adding a 2mol / L activator to a solution obtained 120-150min after the bleaching treatment, and uniformly stirring; and 4, allowing a solution obtained in step 3 to stand for 30min, taking out cloth samples, washing with water, and drying in an oven at 120DEG C for 3-4h. The method has the advantages of bleaching efficiency and technological controllability increase, bleaching time shortening, wastewater treatment cost saving, environmental pollution reduction, and obvious economic and social benefits.

Owner:GUANGXI UNIV

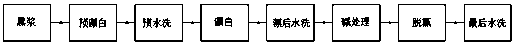

Refined Cotton Bleaching Process

The invention discloses a bleaching process for refined cotton. The bleaching process includes the steps of a, pre-bleaching, to be more specific, discharging 25-30t of black slurry formed after cooking into a bleaching tank, injecting 20-25t of wastewater after bleaching into the bleaching tank, adding a hydrochloric acid solution, regulating pH to 4-6, injecting 5-10t of activating agent sodium hypochlorite solution into the bleaching tank, controlling effective chlorine to be at 0.5-1.0g / L, starting a stirrer for stirring for 20-30 minutes, and discharging 25-35t of water to the a sewage tank;; b, pre-washing; c, bleaching, d, washing after the bleaching; e, performing alkaline treatment; f, removing the chlorine; g, performing final washing. The bleaching process has the advantages that the activating agent is used in the pre-bleaching to reutilize the bleached wastewater, a bleaching effect is brought into play again, the discharge of bleaching wastewater is reduced, sewage treatment cost is lowered, and energy conservation and environment protection are achieved.

Owner:HUBEI JINHANJIANG REFINED COTTON

Spandex fabric bleaching method

ActiveCN104499265AReduce manufacturing costImprove bleaching efficiencyBleaching apparatusWhitening AgentsRoom temperature

A spandex fabric bleaching method comprises the following steps: A. putting spandex fabric into a bleaching machine, adding water, heating to 58 to 62 DEG C, and keeping for 9 minutes to 11 minutes; B. changing water to reduce the water temperature to room temperature; C. at room temperature, adding a whitening agent and scouring enzyme for soaking for 22 minutes to 27 minutes; D. heating to 78 DEG C to 82 DEG C, then adding hydrogen peroxide, soaking for 9 minutes to 12 minutes; E. heating to 96 DEG C to 98 DEG C, after heating to 96 DEG C to 98 DEG C, keeping for 40 minutes-45 minutes, and at the same time, intermittently stretching and expanding the fabric; and F. cooling to 68 to 70 DEG C, circularly washing with water. The spandex fabric bleaching method has the following advantages: (1) by the stretching and expanding operation, the spandex fabric is fully contacted with a bleaching liquid in a short period of time, the bleaching efficiency is improved, material damage caused by long time soaking of the spandex fabric in the bleaching liquid is avoided; and (2) the spandex fabric bleaching method can shorten bleaching process time, reduce the energy consumption, and reduce the production cost of enterprises.

Owner:ZHEJIANG HANGZHOUWAN TEXTILE GOODS

Bleaching method of bagasse pulp

The invention discloses a bagasse pulp bleaching method, including the steps: preprocessing unbleached pulp by H2SO4 to reduce the content of transition metal ions; adding in a proper amount of H2O2, Mg2+ and DTPA; adding in NaOH and Na2SiO3; adding in O2 for bleaching. The invention can make the Soda-AQ processed bagasse pulp reach 79.26% ISO whiteness by single-stage bleaching, the experiment verifies that the whiteness reaches 79.92% ISO whiteness, reaching the level of C-E-H tri-stage bleaching.

Owner:SOUTH CHINA UNIV OF TECH

Fast identification method for plant dyed cotton fabric and chemical dyed cotton fabric through bleaching

ActiveCN109900687AShorten identification timeSimple and fast operationMaterial analysis by observing effect on chemical indicatorDistilled waterColor changes

The invention discloses a fast identification method for plant dyed cotton fabric and chemical dyed cotton fabric through bleaching. The method comprises steps that the chlorite, the activator and thepenetrant are respectively added to the distilled water so that concentrations are 10-15% of the chlorite, 4-6% of the activator and 2-3% of the penetrant respectively to obtain the solution, mineralacid is then added to the solution, the pH is adjusted to 1-3, and a special reagent is prepared; the special reagent is measured and obtained, a pair of tweezers are utilized to completely immerse the fabric in the special reagent for 3-5 seconds, and then the fabric is quickly removed and placed on a white identification plate; the color change of the fabric on the white identification plate isobserved within 1-10 s after the fabric is taken out, if the fabric fades or turns white, the fabric is the plant dyed fabric; if the fabric has no color change, the fabric is the chemical dyed fabric. The method is advantaged in that operation is simple and convenient, identification is simple and easy, the consumption time is short, the result is accurate, universality is realized, and the identification time of the plant dyed fabric is shorter than 10s.

Owner:QINGDAO UNIV

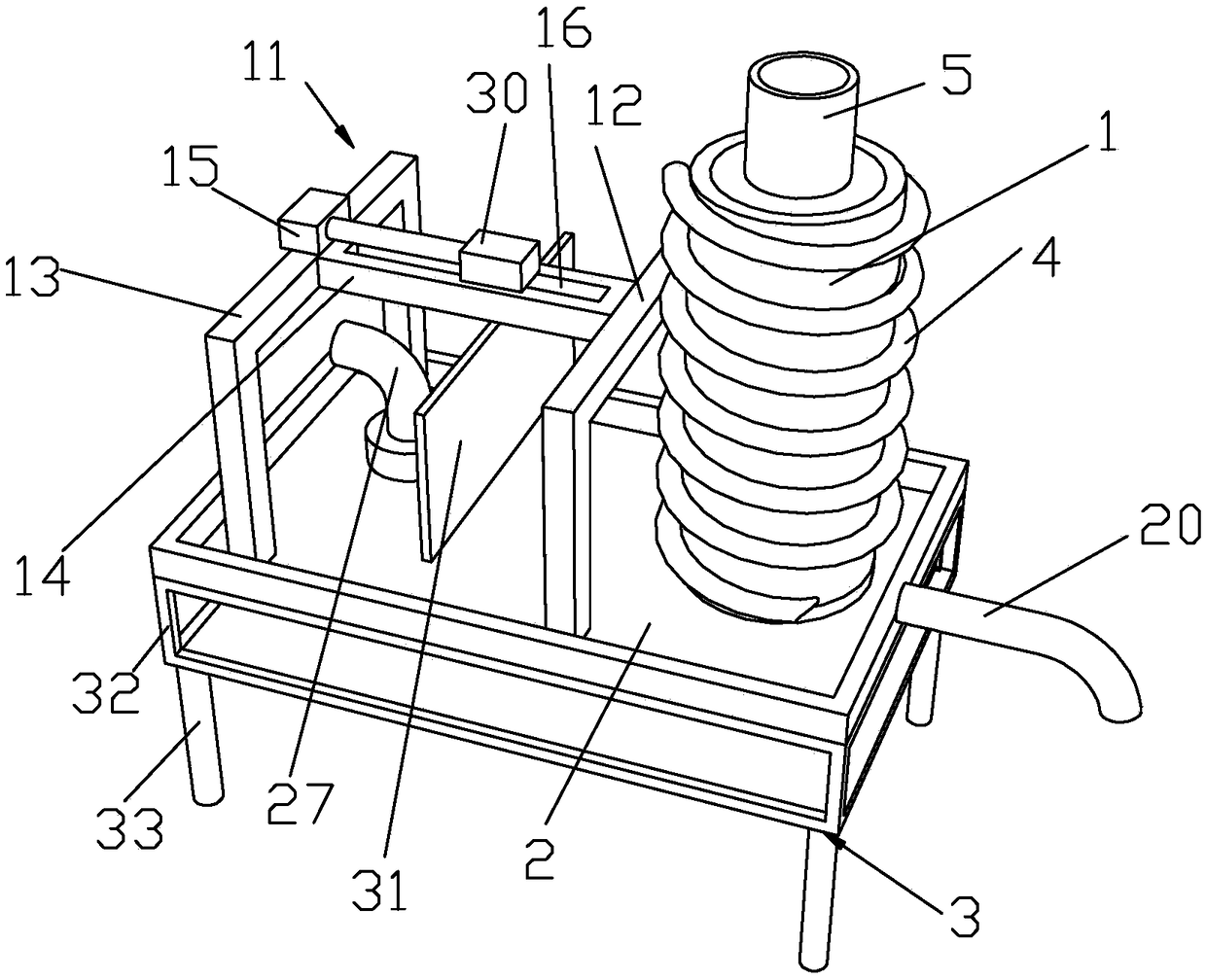

Pulp bleaching device for packaging paper

ActiveCN109183486AGuaranteed vertical installationGuaranteed circulationPulp bleachingBleachPulp and paper industry

The invention discloses a pulp bleaching device for packaging paper. The device comprises a reaction kettle and a reaction tank. The reaction kettle is installed in the reaction tank; the reaction tank is installed on a base; the reaction kettle is a cylindrical structure, and the outer side of the reaction kettle is surrounded by a heating pipe; a mounting ring plate and a mounting strip plate are arranged in the reaction kettle; the mounting ring plate is provided with a high-pressure nozzle hole; a pushing device is arranged in the reaction tank; and the upper inner side wall of the reaction tank is provided with an air inlet hole, which is communicated with a steam generator through an intake pipe. The device has a high-efficiency bleaching effect. By the device, paper pulp can be fully contacted with a bleaching agent; the bleaching time can be saved and the bleaching process can be simplified; the damage to the fiber structure of paper pulp by multiple operation steps is reduced,and the original quality of paper pulp can be guaranteed; the bleaching efficiency can be improved; equipment investment and floor space are reduced; and the production cost is reduced.

Owner:嵊州市东浦天地彩印包装有限公司

Fast identification method for plant dyed yarn and chemical dyed yarn bleaching

ActiveCN109991214AShorten identification timeSimple and fast operationMaterial analysis by observing effect on chemical indicatorTextiles and paperYarnDistilled water

The invention discloses a fast identification method for plant dyed yarn and chemical dyed yarn bleaching. The fast identification method comprises the following steps that chlorite, activators and penetrating agents are added into distilled water respectively, thus the concentration is 6%-10% of the chlorite, 1%-5% of the activators, and 1%-5% of the penetrating agents, a solution is prepared andobtained, then inorganic acids are added to the solution, the pH value is adjusted to 1-3, and a special reagent is prepared; the specific reagent is measured and taken, a tweezers is used for completely immersing yarn in the special reagent 2-3 s, and then the tarn is quickly taken out and place on a white identification plate; yarn color change on the white identification plate is observed within 1-10s after the yarn is taken out, and if the yarn fades or turns white, the yarn is plant dyed yarn; and if the yarn has no color change, the yarn is chemical dyed yarn. The fast identification method has the advantages of having simple and convenient operation, simple and easy identification, short time consumption, accurate result and generality, and identification time of plant dyeing products is less than 10s.

Owner:QINGDAO UNIV

Electrochemical bleaching and setting process for ultrasonic-plasma pretreatment of black horsetail hair

InactiveCN109487531AReduce tanglingImprove preprocessing effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPlasma technologyFatty alcohol

The invention discloses an electrochemical bleaching and setting process for ultrasonic-plasma pretreatment of black horsetail hair. The process includes washing the black horsetail hair with a detergent, adding medium water, and preforming ultrasonic treatment; then adopting a plasma technology to preform pretreatment; dissolving penetrants of fatty alcohol polyoxyethylene ether and sodium silicate in water, adjusting the pH value, adding hydrogen peroxide, heating the solution, fixing the obtained pretreated black horsetail hair on an anode of a graphite electrode, setting electric field power, preforming electrochemical bleaching treatment, washing with water, and drying; soaking the bleached and decolorized horsetail hair in distilled water, controlling the water content, setting the setting temperature, and setting in wet heat; and stretching and thinning the wet heat-set horsetail hair, pre-steaming and then stretching, steaming, washing with water, treating the hair with a setting agent, steaming and setting, washing with water, treating with boiling water, and air drying.

Owner:太和县兴阳鬃尾有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com