Single-motor pneumatic oscillating arm of jig dyeing machine

A single-motor, dye-jigger technology, applied in the field of dye-jiggers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

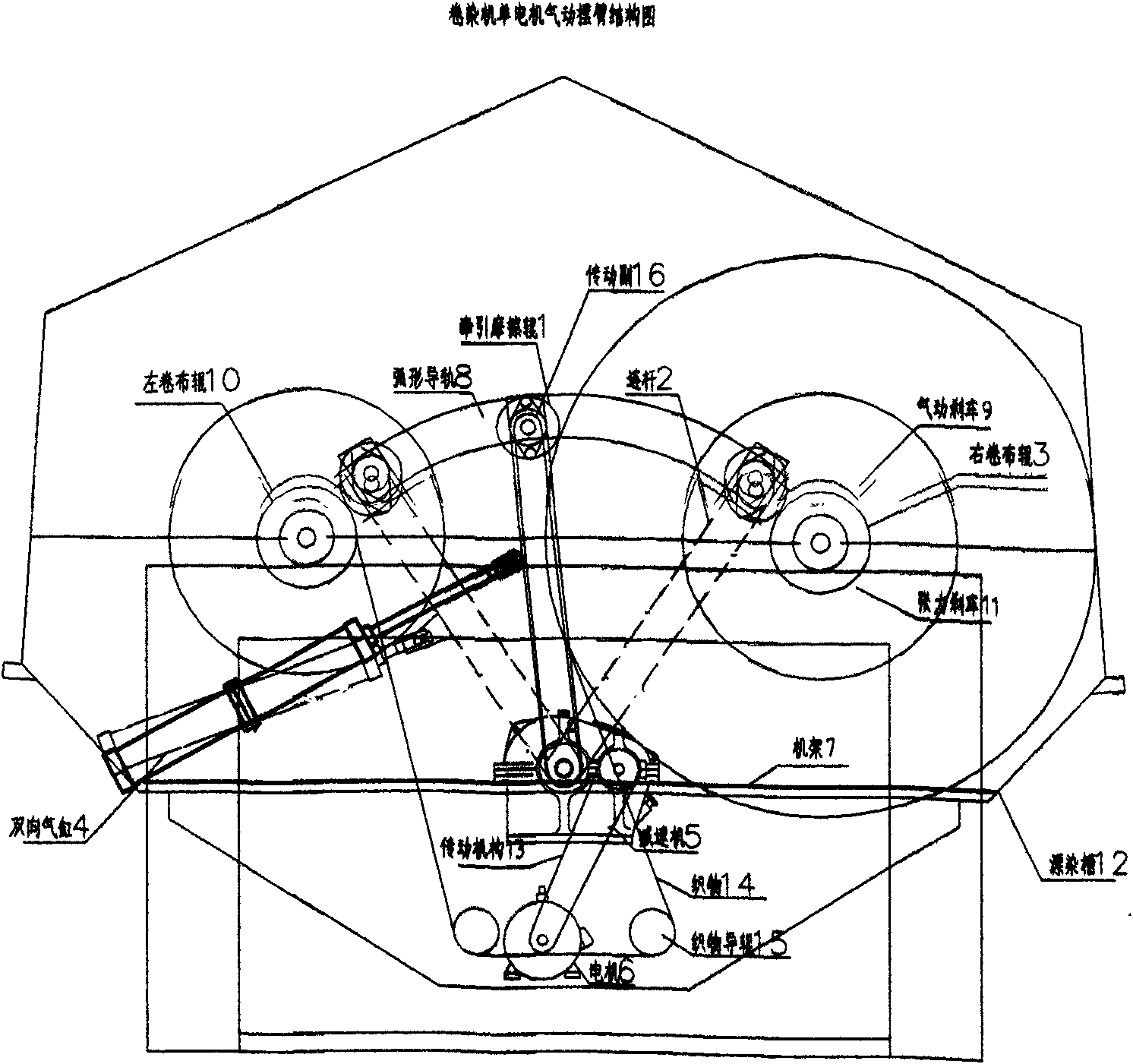

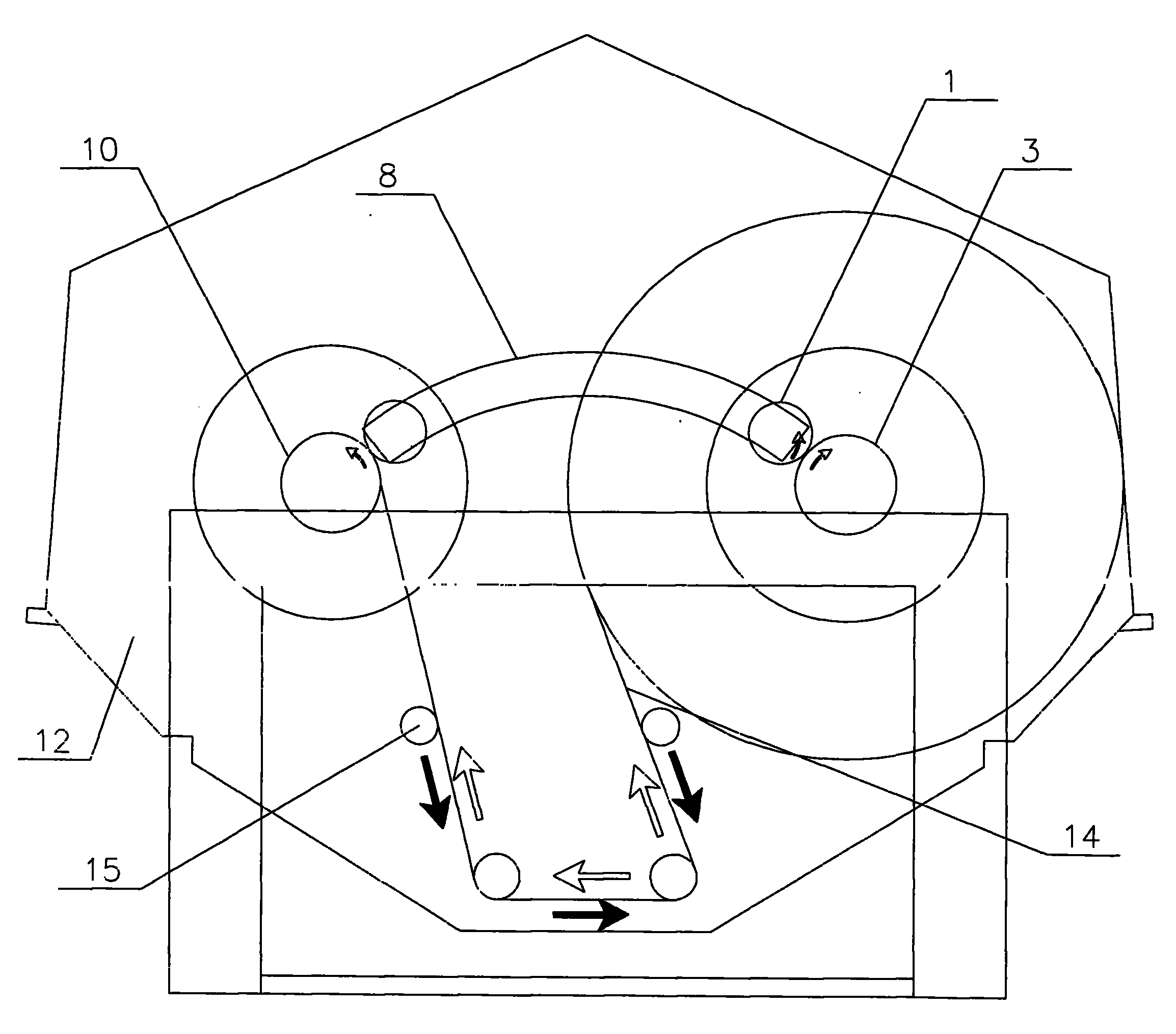

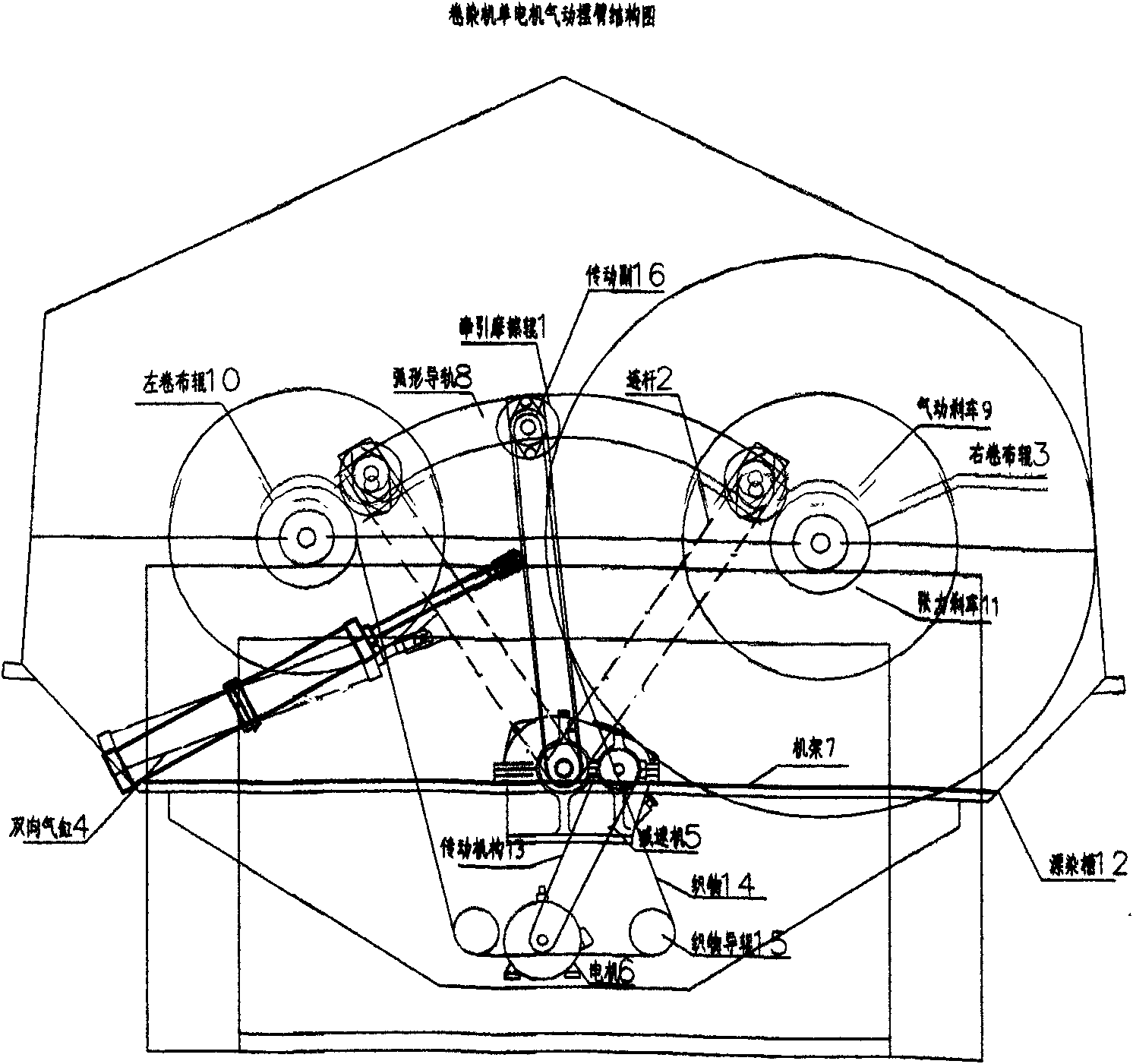

[0007] The present invention as figure 1 Shown, by frame 7, bleaching and dyeing tank 12, left fabric rolling roller 10, transmission mechanism 13, right fabric rolling roller 3, pneumatic brake 9, tension brake 11, fabric guide roller 15, arc guide rail 8, connecting rod 2, Composed of two-way cylinder 4, friction roller 1, reducer 5, motor 6 and so on. The motor 6 is connected to the speed reducer 5 by the transmission mechanism 13 and decelerates; as figure 1 , Shown in 5, there are assembly holes at connecting rod 2 two ends, and the assembly holes of two-way cylinder 4 guide rods are arranged between the assembly holes at connecting rod 2 two ends. One end assembly hole of the connecting rod 2 is assembled on the shaft end of the friction roller 1 , and the other end assembly hole of the connecting rod 2 is assembled on the output shaft of the reducer 5 . The transmission pair 16 transmits power between the reducer 5 and the friction roller 1 . The guide rod end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com