Rust removing and paint spraying device for inner wall of pipeline

A technology for pipes and paint spraying equipment, applied in the directions of spraying device, liquid spraying device, grinding drive device, etc., can solve the problems of large amount of paint, large elastic potential energy, uneven painting on the inner wall of the pipeline, etc., and achieve the effect of even painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

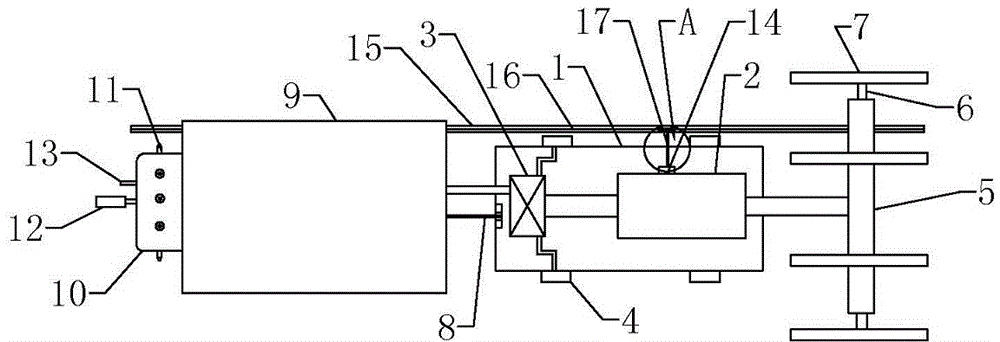

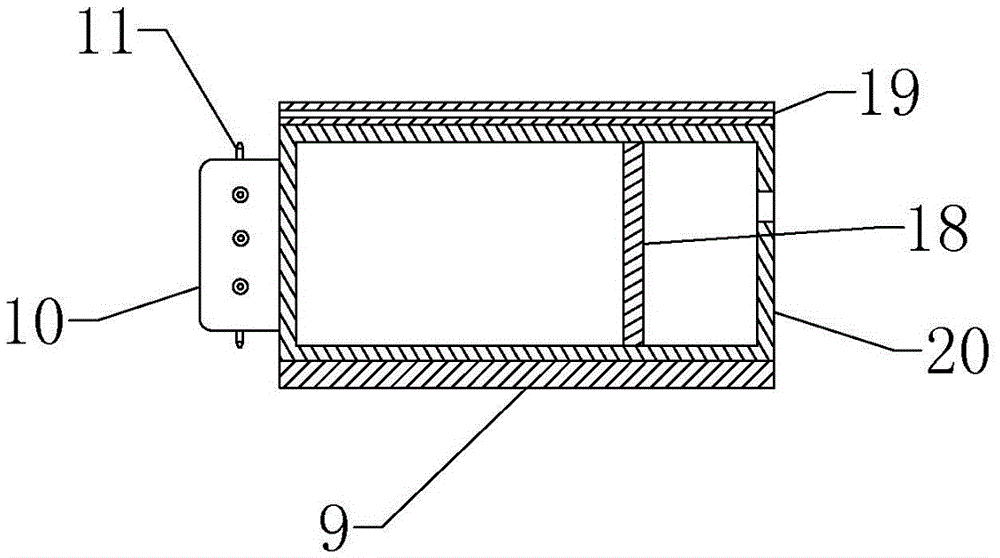

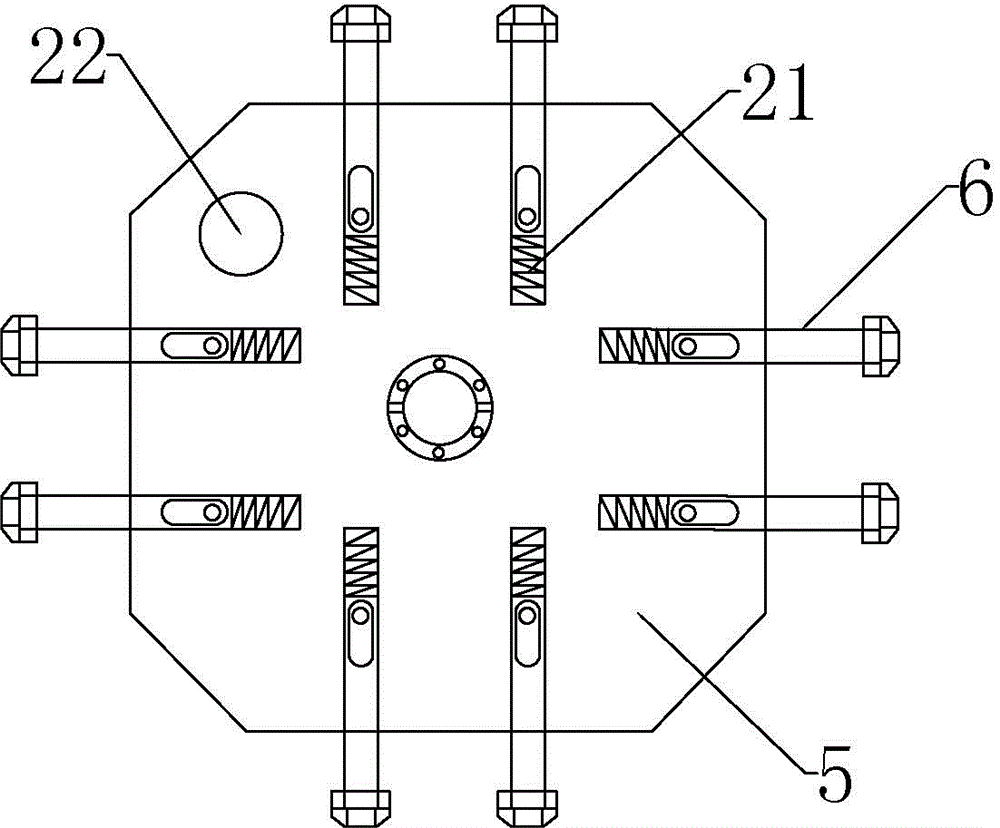

[0019] The reference signs in the drawings of the description include: base plate 1, double-axis motor 2, impeller shell 3, air bag wheel 4, fixed panel 5, tensioning shaft 6, derusting cutter head 7, hook 8, rust absorbing felt ring 9, Nozzle end cover 10, nozzle 11, heating plate 12, air pipe 13, junction box 14, power line 15, chute 16, pantograph 17, piston 18, channel hole 19, cylinder 20, tension spring 21, opening Hole 22.

[0020] Example basic reference Figure 1~Figure 4 Shown: the rust removal and painting device for the inner wall of the pipeline, including a biaxial motor 2, a junction box 14 for controlling the start and stop of the biaxial motor 2 is installed on the biaxial motor 2, there is a wiring port in the junction box 14, and the biaxial motor 2 is installed on On the base plate 1, the airbag wheel 4 is installed on the bottom of the base plate 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com